STELLA DEL NORD Cantiere delle Marche (CdM)

- Inspiration

STELLA DEL NORD has 6 Photos

Stella Del Nord News

Andrea Bocelli becomes new owner of the ...

Similar yachts.

Karisma | From EUR€ 34,000/wk

- Yachts >

- All Yachts >

- All Motor Yachts Over 100ft/30m >

- STELLA DEL NORD

If you have any questions about the STELLA DEL NORD information page below please contact us .

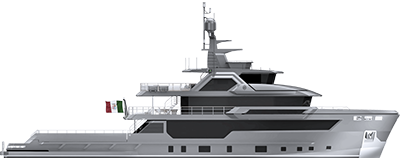

STELLA DEL NORD is a 26.1m (85'8") luxury explorer motor yacht built by the Italian shipyard Cantiere delle Marche (CdM) and launched in 2015. The yacht features exterior design and naval architecture by HydroTec and lovely interiors by PFA Design. She sleeps up to eight guests in four cabins, with a crew of four to provide expert service on every journey.

NOTABLE FEATURES OF STELLA DEL NORD: ~Built to RINA Classification ~Abundance of sunbathing areas on board ~Comfortable modern interiors ~Skylounge library ~Range of 6,700 nautical miles ~Air conditioning ~Wi-Fi

The lower deck swim platform provides a large area for sunbathing next to the water or for spreading out with the water toys. On the main deck aft, there is an alfresco dining table with chairs to seat up to eight guests, all of which are sheltered by the upper deck overhang.

The upper deck offers another sun-exposed alfresco dining area with room along the stern for sun loungers, while the foredeck has a broad sunbed in front of the bridge and the bow section conceals a loveseat where a couple of guests can watch the sunset in privacy.

On the flybridge, the helm controls are placed forward to port with additional seating adjacent. The amidships section is furnished with a bar and seating around a raised table for alfresco meals, and the sun-exposed stern provides a sunbed for resting after a hearty meal.

The lower deck hosts the guest and crew accommodation, leaving the main deck dedicated to the shared guest spaces. The main salon provides a formal dining area forward with an aft lounge consisting of a sofa and armchairs around a coffee table.

STELLA DEL NORD Specifications

| Type/Year: | Cantiere delle Marche (CdM)/2015 |

|---|---|

| Refit: | |

| Beam: | 7.43m (24'5") |

| L.O.A.: | 26.1m (85'8") |

| Crew: | 4 |

| Guests: | 8 |

|---|---|

| Max Speed: | 11.5 knots |

| Cabins: | 4 |

| Engines: | 2 x CAT C12 @ 385hp |

| Cruise Speed: | 10 knots |

| More Yacht Info: | |

|---|---|

| Builder/Designer: | , , |

| Locations: |

The skylounge doubles as a library and three sofas create a cosy reading or conversation space around a coffee table, leaving the starboard side open for access to the stairway or the upper deck aft.

A pair of Caterpillar 287 kW CAT C12 engines create a maximum speed of 11.5 knots with an extensive range of 6,700 nautical miles at 8.5 knots.

Yacht Accommodation

The accommodation sleeps a maximum of 8 guests over 4 en-suite cabins: 1 Master suite, 1 VIP stateroom and 2 twin cabins each with a Pullman berth. The crew of 4 will ensure that all guests receive top quality service throughout the cruise duration.

Amenities and Extras

We do have available further amenity, owner and price information for the 26.1m (85'8") yacht STELLA DEL NORD, so please enquire for more information.

STELLA DEL NORD Disclaimer:

The luxury yacht STELLA DEL NORD displayed on this page is merely informational and she is not necessarily available for yacht charter or for sale, nor is she represented or marketed in anyway by CharterWorld. This web page and the superyacht information contained herein is not contractual. All yacht specifications and informations are displayed in good faith but CharterWorld does not warrant or assume any legal liability or responsibility for the current accuracy, completeness, validity, or usefulness of any superyacht information and/or images displayed. All boat information is subject to change without prior notice and may not be current.

Quick Enquiry

CHRISTINA V | From EUR€ 70,000/wk

'SU' | From US$ 30,000/wk

MOSAIC | From EUR€ 37,500/wk

EXPLORER YACHTS

- PRE-OWNED DIVISION

- M/Y STELLA DEL NORD

STELLA DEL NORD

Darwin class 86' - 2015.

M/Y Stella del Nord is the fourth and most recent Darwin Class 86’ built by Cantiere delle Marche.

She’s the perfect size for Owners that want to start their way into expedition yachting: not too big and not operationally expensive (max crew of four, can be registered under the 200 GT, both engines consume 70 l/h at cruising speed, etc etc) not too small to be uncomfortable during long cruises (it has two salons, 4 guest cabins , a proper lazarette to store supplies, a spacious sundeck, the possibility to carry a 5 mt tender)

Her pedigree of real, sturdy, over engineered explorer vessel is well proved by the cruising record of her sistership M/Y Percheron which has completed three hassle-free Atlantic crossings (the last one no-stop from Bermuda to Gibraltar)

- AVAILABILITY May 2019

- YEAR BUILT 2015

- PRICE € 6.100.000

- VAT STATUS Paid

- REGISTERED LENGHT 23,99 mt / 78,7 ft

- LOA 26,10 mt / 86 ft

- GROSS TONNAGE 206 GT, registered 199 GT

- GUEST CABINS 4

- MAIN ENGINES HOURS 1.380

- DIESEL GENERATORS HOURS 4.700

- LOCATION Marina di Pisa, Tuscany (Italy)

FOR INFO Carlo Aquilanti M +39 340 05 20 435 E [email protected]

Explorer Yacht Darwin Class 86

M/Y Percheron - Navigation with 57 knots of wind

Yacht brochure.

M/Y STELLA DEL NORD - 2015 LAST UPDATE: 28.03.2019

ARRANGEMENT PLAN

We have combined the best designers, captains and skilled workers: experiences and visions of the most have merged into a unique project. Our class of yachts is selected by the sea.

Explore your own course

FOR A BEST EXPERIENCE PLEASE TURN YOUR DEVICE

Same soul, different shapes. Discover all our Explorer Yacht ranges.

DARWIN CLASS

- Trending Topics:

- Salone Nautico

- Elettronica

- Yacht Industry

- Yacht Design

- Barca A Vela

M/Y Stella del Nord, Cantiere delle Marche, la nuova barca di Andrea Bocelli

Andrea Bocelli armatore di Stella del Nord un Darwin Class 86’ M/Y

- Yacht industry

Il Darwin Class 86’ M/Y Stella del Nord è stato venduto ad Andrea Bocelli

Il 24 aprile scorso vi avevamo informati che la vendita di tre Darwin Class, M/Y Stella del Nord (Darwin 86’), M/Y Acala e M/Y Babbo (entrambi Darwin 102’) ci era stata affidata in Esclusiva.

Oggi Vasco Buonpensiere – co-fondatore e Direttore Vendite e Marketing di Cantiere delle Marche – è orgoglioso di annunciare che il primo explorer della lista, M/Y Stella del Nord, è stato venduto ad Andrea Bocelli, il famosissimo cantante e compositore, presentato a CdM dal broker italiano Corte srl di Lavagna.

Questa vendita conferma l’affidabilità, l’efficienza e la professionalità del Pre-owned Sales Department di CdM. Grazie all’esperienza di CdM nel mondo degli explorer, il team del Pre-owned Sales Department sa esattamente come raggiungere i clienti giusti anche grazie a una rete di contatti con i principali broker a livello internazionale. E’ importante sottolineare che CdM si occupa solo della vendita di yacht costruiti dal cantiere stesso. Questa caratteristica fa del Pre-owned Sales Department di CdM il miglior interlocutore possibile per il nuovo armatore a cui vengono fornite dettagliate informazioni e uno storico completo su ciascuno yacht usato in vendita.

Il team appositamente creato guida e supporta il nuovo Armatore in tutta la fase di negoziazione, nelle prove in mare, nella contrattualistica e nelle procedure di consegna dello yacht. Nel caso in cui il nuovo proprietario desideri modificare lo yacht per adattarlo alle sue specifiche esigenze e al suo gusto, CdM, tramite il suo Dipartimento Tecnico è in grado di supportarlo. Il cantiere può anche svolgere i lavori di refitting presso la sua nuova banchina.

M/Y Stella del Nord, quarto Darwin Class 86’ varato da CdM nel 2015, ha standard di costruzione molto alti ed essendo stato trattato estremamente bene dal suo primo armatore, è stato messo in vendita in condizioni ineccepibili.

Il Darwin 86’ è lo yacht perfetto per Andrea Bocelli che, oltre ad essere cantante strepitoso, è anche un esperto armatore che, dopo aver avuto parecchi altri yacht di varie dimensioni, ha deciso di voler avere un vero explorer yacht. L’artista stava cercando uno yacht che consentisse a lui e alla sua famiglia di navigare a lungo e verso destinazioni lontane nel massimo comfort, anche in condizioni meteo severe. Il Darwin 86’ risponde perfettamente a queste sue esigenze: non troppo grande né complicato da governare (un equipaggio di quattro persone, registrato sotto 200GT, estremamente efficiente nei consumi) ma abbastanza spazioso da garantire spazio e comodità ai suoi passeggeri.

Subito dopo aver preso possesso dello yacht, Bocelli ha fatto rotta verso Napoli dove è arrivato in tempo, e perfettamente riposato, per il suo concerto, nonostante la navigazione con mare molto mosso. Come inizio non male!

Informazioni generali sul M/Y Stella del Nord

Ampio e spazioso e con un’altezza interna di 2.10m, Stella del Nord è uno yacht elegante con interni in Olmo, raffinate tappezzerie e parquet in Iroko. Ha due saloni, uno sul ponte principale e uno su quello superiore, quattro comode cabine per gli ospiti sottocoperta, compresa l’armatoriale a centro nave, amplissimi spazi di stivaggio e uno spaziosissimo sun deck. Il terrazzo poppiero del ponte superiore può alloggiare un tender di 5 metri.

Stella del Nord è un explorer di razza, robusto, con una tenuta di mare eccezionale come dimostrato dalla sua gemella, M/Y Percheron, che ha effettuato tre traversate atlantiche senza il ben che minimo problema.

Sotto il profilo tecnico M/Y Stella del Nord, come tutti gli explorer di CdM, presenta standard elevatissimi, con una ridondanza degli equipaggiamenti e una facilità di manutenzione che consentono la massima sicurezza in tutte le condizioni e in tutti i luoghi. Dotato di due motori Caterpillar Cat C12 da 287kW ciascuno, raggiunge la velocità di 11,5 nodi e ha una straordinaria autonomia di 6.700 miglia a 8,5 nodi.

2022 già in regata sul Garda, la vela d'inverno continua a navigare

Related posts.

Cantiere delle Marche: varato il Darwin 86 Alexa

Cantiere delle Marche annuncia la vendita di Deep Blue 115

Cantiere delle Marche trionfa ai World Superyacht Awards

The global authority in superyachting

- NEWSLETTERS

- Yachts Home

- The Superyacht Directory

- Yacht Reports

- Brokerage News

- The largest yachts in the world

- The Register

- Yacht Advice

- Yacht Design

- 12m to 24m yachts

- Monaco Yacht Show

- Builder Directory

- Designer Directory

- Interior Design Directory

- Naval Architect Directory

- Yachts for sale home

- Motor yachts

- Sailing yachts

- Explorer yachts

- Classic yachts

- Sale Broker Directory

- Charter Home

- Yachts for Charter

- Charter Destinations

- Charter Broker Directory

- Destinations Home

- Mediterranean

- South Pacific

- Rest of the World

- Boat Life Home

- Owners' Experiences

- Interiors Suppliers

- Owners' Club

- Captains' Club

- BOAT Showcase

- Boat Presents

- Events Home

- World Superyacht Awards

- Superyacht Design Festival

- Design and Innovation Awards

- Young Designer of the Year Award

- Artistry and Craft Awards

- Explorer Yachts Summit

- Ocean Talks

- The Ocean Awards

- BOAT Connect

- Between the bays

- Golf Invitational

- Boat Pro Home

- Superyacht Insight

- Global Order Book

- Premium Content

- Product Features

- Testimonials

- Pricing Plan

- Tenders & Equipment

CdM motor yacht Stella del Nord sold

The 26 metre Cantiere Delle Marche explorer yacht Stella Del Norde has been sold by the yard’s new brokerage division to the famed Italian opera star Andrea Bocelli.

Built in steel and aluminium to a design by Hydro Tec , she was delivered in 2015 as the eighth hull in the yard’s Darwin series. A contemporary interior by PFA Design in light elm joinery paired with natural fabrics accommodates eight guests in four cabins. These consist of full-beam master and VIP suites and two twins, all with entertainment centres and en-suite bathroom facilities. In addition, there are quarters for five crew.

The open-plan main saloon has large windows allowing ample daylight and there is a U-shaped settee to starboard facing two armchairs to port, all upholstered in high quality leather. Forward is an entertainment centre including a large screen television while further forward is a dining area with seating for eight guests.

The brief from Stella del Nord ’s owners was for a focus on outdoor living, which can be seen on the 40 square metre sun deck with its gas barbecue, bar, dining area, lounge area and a helm station. More al fresco entertaining and dining is offered on the aft deck, with built-in upholstered bench seating and a freestanding table with six chairs. Port and starboard stairs lead down to a wide swim platform. Twin 385hp Caterpillar diesel engines give her a range of 7,000 nautical miles at 8.5 knots.

Stella del Nord was asking €6,100,000.

Sign up to BOAT Briefing email

Latest news, brokerage headlines and yacht exclusives, every weekday

By signing up for BOAT newsletters, you agree to our Terms of Use and our Privacy Policy .

More about this yacht

More stories, most popular, from our partners, sponsored listings.

We have received your message and will get back to you shortly.

We will call you back.

Consultation, answering your questions.

Your email:

or your telephone:

Industry leader in

sales and service of boats, ships since 1959.

Unfortunately, this boat is not available for sale. It will be removed from the website soon.

Yachts with similar parameters:

Find a yacht

Cantiere delle Marche

Stella del nord - cantiere delle marche, specifications.

- All Specifications

- Detailed Information

Basic Information

Builder: Cantiere delle Marche Category: Mega Yacht Model Year: 2016 Year Built: 2016 Country: Italy

LOA: 86' 0" (26.21m) Beam: 10' 7" (3.23m) Max Draft: 13' 0" (3.96m)

Speed, Capacities and Weight

Cruise Speed: 10 Kts. (12 MPH) Cruise Speed RPM: 1500 Kts. Cruise Speed Range: 5599 Max Speed: 12 Kts. (14 MPH) Displacement: 430 Pounds Water Capacity: 898 Gallons Holding Tank: 260 Gallons Fuel Capacity: 10303 Gallons

Accommodations

Total Heads: 5

Hull and Deck Information

Hull Material: Steel Hull Configuration: Displacement w/ Bulbous Bow

Engine Information

Engines: 2 Manufacturer: Caterpillar Model: C-12 (Heavy Duty B Rating) Engine Type: Inboard Fuel Type: Diesel

STELLA DEL NORD is the highest spec Cantiere delle Marche 86 Darwin ever built to date with warranty coverage until May 2017. She was built for the sole purpose to travel and explore the world in comfort all on her own bottom. At 7 knots on her C-12 CATS she is burning a total of 13 gallons a hour. With a range of 7,800 miles. At a true cruise at 10 knots she is burning 18 gallons a hour with a range of 5,599 miles.

She is a original owner yacht privately used and never chartered. However built with the option, saftey and capability under RINA class.

- Recreational craft directive 94/25CE of 16/06/1994

- RSG guidelines design category A

- Rules of the classifcation of yachts RINA class, Malta Cross DOT Mach

- MCA, MGN 280 compliance.

- Dependable C-12 Caterpillars with 2X ZF W325 3.958:1 Transmission - ( Warranty May 2017)

- 2 X KOHLER 55KW (1700HR) + 1 KOHLER 17.5 KW (AROUND 900HR) - Warranty May 2017

- Water Maker 2X Idromar international desalinators with reverse Osmosis model MC3J Duplex. Including UV Ray sterilizer, salt softener and automatic clorinzation. - Total combined daily nominal capactiy 7200 Litre/day.

- 4 Stateroom/ 5 Head layout. Plus 4 crew layout (2 Cabins)

- **PRELIMINARY SPEC & PHOTOS COMING ASAP**

DYSID:3036625

STELLA DEL NORD SPECS- CdM 86 DARWIN

Interior Furnishing - STELLA DEL NORD 86 Cdm DARWIN

The main essence for the interior joinery is technical ALPI wood, painted open pore for the walls and the visible surfaces. The floors are in natural oak average flaming with open pore. The general interior layout and the arrangement of furnishing are reported on the General Arrangement Plan. (see photos in specs)

Push locks are “RAZETO E CASARETO” art. 800400 flush lock, chromed or equivalent of the same value.

The handles will are “FORESTI E SUARDI” art. 475.c.

The light switch panels and plugs will are “BTICINO” LIGHT TECH code TA with silver switches.

Saloon, Lower deck accommodations, corridors and sky lounge

Walls: Plain panels installed horizontally, made of ALPI and painted open pore. Joinery visible surfaces. Made of ALPI and painted open pore. Doors and drawers have push lock closing system.

Counter tops : Are made of ALPI and painted open pore, 25mm thick, with anti rolling frame.

Cupboards and drawers interiors : Are all natural cedar sanded and are not treated. Flooring: Wooden floor with 100mm planks, natural oak, average flaming, of uniform colour, painted open pore, installed longitudinally from bow to stern.

Internal doors : Are made of plain ALPI, painted open pore, 35mm thick, with recessed and anti-vibration lock.

External doors : Are painted of the same color of the superstructure of the yacht.

Ceilings : Are made of removable panels for inspection, in marine plywood, lacquered gloss in a light colour.

Saloon, VIP and master cabin , Have recessed ceilings lacquered matt with perimetral framing lacquered gloss and the curtains recess which are Lacquered finished.

Stairs to lower deck : The steps are completely in ALPI painted open pore, curved handrails with stanchions all in polished chrome steel, covered in carpet and with courtesy lighting.

Sofas : The sofa structure are made of ALPI. The void space underneath the seating are accessible from the top for storage. Strip led courtesy lighting are installed underneath the seat overhang.

Saloon Table : Is semi-oval 220 x 90-110mm with wooden top with a rounded bull nose and a polished stainless steel bases.

Owner’s, VIP and Guests Cabins

(1) Master stateroom Owner’s bed is 1.80 x 2.00mt .

(2) VIP bed: 1.80 (head) – 1.40 (feet) x 2.00mt.

(3/4) Guests’ beds are 0.80 x 1.95mt. Only the double beds are provided with a gas spring lift able slat bases to access storage underneath. The guest’s cabins are equipped with a pullman bed with security lock and balanced and frictioned movement.

Headboard throughout the cabins are leather up to the ceiling for both master and VIP, lower for the guest cabins. The thickness of the padding of the headboards are 10mm.

Bathrooms.

Owner’s cabin

WC: Tecma mod. Silence std. Head: Tecma model. Bathroom top: covered in SILESTONE. Sink: Above top Taps and fittings: Paffoni taps Walls: Are all in ALPI smooth, painted open pore. Joinery visible surfaces: Are made of ALPI and painted open pore. Doors and drawers all have push lock closing system.

Ceilings: Flat removable panels in marine plywood, lacquered in a light glossy color Flooring: Wooden floor with 100mm planks, natural oak, average flaming, painted open pore, installed longitudinally from bow to stern. Skirting board: Solid oak 60mm flush Shower: laminated finish Shower tray: teak Shower door: tempered glass with stainless steel frame (with lock to be used during navigation)

Starboard and Portside guest Cabins Bathrooms

WC: Tecma mod. Silence std. Bidet: Tecma Bathroom top: covered in SILESTONE or similar Sink: Above top Taps: Paffoni taps Walls: in whitewashed oak, painted open pore Joinery visible surfaces: made of ALPI and painted open pore. Doors and drawers all have push lock closing system. Ceilings: Flat removable panels in marine plywood, lacquered in a light glossy colour Flooring: Wooden floor with 100mm planks, natural oak, average flaming, painted open pore, installed longitudinally from bow to stern. Skirting board: Solid oak 60mm flush Shower: laminated finish Shower tray: teak Shower door: tempered glass with stainless steel frame (with lock to be used during navigation)

VIP Cabin Bathroom.

Crew and Captain’s Bathrooms

WC: Tecma mod. Silence std. Top: plywood lacquered or iroko veneered Sink: ceramic type built-in the top Taps: Paffoni Walls: Marine plywood panels laminated in ivory colour with angles and finishings in solid iroko.

Ceilings: opaque ivory lacquered smooth removable panels Flooring: Wooden floor with 100mm planks in iroko, installed longitudinally from bow to stern painted open pore, natural.

Baseboard: Is iroko 60mm Shower: laminated marine plywood Shower tray: in resin with teak tray on top.

Main Deck and Upper day toilets - Tecma model and Silence std.

Sink: Is round and in stainless steel Taps: Paffoni

Walls: smooth in whitewashed oak painted open pore

Ceilings: smooth lacquered in a light glossy colour removable panels Flooring: Wooden floor with 100mm planks, natural oak, average flaming, painted open pore, installed longitudinally from bow to stern.

Skirting board: in solid oak 60mm.

Wheelhouse and Stairs from main to upper deck

Walls: Light coloured teak (or oak) painted open pore? Dashboard: in marine plywood covered with synthetic leather. Visible surfaces of the furniture aft of the wheelhouse: in teak (or oak) painted open pore.? Doors and drawers all have push locks. Countertops: veneered in teak (or oak) painted open pore, rounded bull nose and anti rolling frame. Cupboards and drawers interiors: in natural cedar sanded and not treated.

Flooring: Wooden floor are 100mm planks in teak (or oak), installed longitudinally from bow to stern with white grouting.

Skirting board: Are solid teak (or oak) 16mm high x 6mm thick Ceilings: Flat removable panels in marine plywood, lacquered ivory aft of the wheelhouse. Dark brown in the wheelhouse up to the door, painted with anti reflection paint.

Curtains recess: in marine plywood, lacquered. Access stairs to wheelhouse: steps will be teak (or natural oak) painted open pore with a polyurethane or acrylic base, covered in carpet and with courtesy lighting underneath the steps overhang.

Captain’s Chair: 1 fixed chair

Chart Table: The chart table/bookshelf has a base with a nautical chart drawer and positioned behind the captain’s chair and build of the same main essence of the boat.

Crew Quarters-

Walls: Marine plywood panels laminated in ivory colour with angles and finishings in solid Iroko.

Visible surfaces of the furniture aft of the wheelhouse are marine plywood panels laminated in ivory colour. Doors and drawers all have push locks.

Cupboards and drawers interiors: Are in natural cedar sanded and not treated.

Flooring: Wooden floor with 100mm planks in iroko, installed longitudinally from bow to stern painted open pore, natural. Internal doors: in laminated marine plywood. Curtains recess: lacquered. Mattresses: in polyurethane with non removable lining, fire resistant, anti-acarus

Crew Mess. -

Walls: Flat marine plywood panels, mounted horizontally (approx. 600mm) with solid wood junction 5-6mm wide.

Visible surfaces of the furniture aft of the wheelhouse: Marine plywood panels finished in oak. Doors and drawers will have push locks. Doors and drawers are flush mounted with external framing in solid wood. The veneering of the furniture are at 90° in respect to the one of the walls.

Flooring: Porcelain stoneware or similar product with anti slip treatment for safety.

Internal doors: Sliding, laminated marine plywood, oak finishing on the internal side. Same finishing of the corridor on the external side.

Ceilings: Flat removable panels in marine plywood, lacquered. Curtains recess: Lacquered. Skirting board: Solid wood or lacquered. Sofas: structure made of laminated marine plywood, with rounded corners. The void space underneath the seating, will be accessible from the top for storage.

Galley -

Walls: Flat marine plywood panels, mounted horizontally (approx. 600mm) oak veneer with solid wood junction 5-6mm wide lacquered ivory.

Visible surfaces of the furniture aft of the wheelhouse: Marine plywood panels are finished in Oak. Doors and drawers all have push locks. Doors and drawers are flush mounted with external framing in solid wood, flat with no moldings. The veneering of the furniture will are at 90° in respect to the one of the walls. The Flooring is Porcelain stoneware with anti slip treatment for safety. Internal doors: Are sliding, laminated marine plywood, oak finishing on the internal side. Same finishing of the corridor on the external side.

Ceilings: Flat removable panels in marine plywood, lacquered. Curtains recess which is lacquered. The Skirting board is marine plywood finished with laminated oak.

Household Appliances-

Galley Cook top: n. 1 Miele Marine KM 5975 Microwave oven: N.1 Miele Marine M8261-1 Fridge:N1MieleMarine KFN12923Forno:n.1MieleMarineH5981BPEDST1da90cm

Range hood: 1 Miele Marine DA 3190 Insinkerator: General Electric GFC 701F Dishwasher: 1 Miele Marine G1252 SCI

Dinette Washing machine: 1 Miele Marine W3824 WPS LW Dryer: 1 Miele Marine T 8422C Fridge: 1 built in refrigerator/freezer KFN9753iD (2) built in stand up freezers FN9752I

Ice Maker: Vitrifrigo IMClassic Refil Wine cellar: 1 Miele KWT 4154 UG – 1

Main Deck Cockpit Area Cocktail cabinet : Features a drawer refrigerator with a Vitri Frigo mod DW100RFX.

Internal wheelhouse lounge features the following. Drawer fridge Vitri Frigo model DW100RFX.

Sundeck Fridge: Vitri Frigo model DW100RFX.

Exterior Areas & Main deck

Sofa: Built in the structure with cushion made in close cell material covered by acrylic upholstery.

Table : 10 seat table by (270x90/125) in marine plywood teak veneer, specifically painted for external use. Cylindrical bases are in stainless steel.

Ceilings : Flat removable panels in marine plywood, lacquered.

Upper deck Ceilings: Flat removable panels in marine plywood, lacquered in ivory color.

Table : 12 seat table (300 x 90/120) in marine plywood teak veneered specifically painted for external provided with an extension and stainless steel gas pop up base.

Sun Deck- STELLA DEL NORD

Jacuzzi : On the aft part of the sundeck a Jacuzzi tab model Jacuzzi Nova for 3 people with external diameter of 1.8mt, 400lt capacity, 63cm is the height.

Sun Bed : n. 2 structural sun bed (PTS) with storage space underneath. Cushions with close cell padding, covered by acrylic upholstery. Sun bed portside of the pilot station. Sofa: Is a L shaped sofa (with side table and coffee table) starboard side (behind pilot station).

Teak Decks The main deck, the upper deck, the sun deck, the foredeck and the swimming platform are covered with teak, with staves of 12mm of thickness on a suitable leveling material. The coamings are filled with black rubber

Pilot Station : Structural seating and pilot station in alloy or composite material for three people.

Machinery- STELL DEL NORD

The engine room’s entrance is located on main deck through a passage in the port side of the superstructure. Engine room’s flooring plates are removable for bilge’s inspection. Engine room is arranged to make easier as possible maintenance operation. Every equipment and parts that have to be accessible frequently are accessible.

All rotating devices upon the flooring plates are protected. All those components which during their use reach a temperature higher than 90°located in walking ways will be insulated. Handrails are provided where is necessary.

Flooring plates and Gratings

Textured aluminium plates of 5mm thickness are installed in the engine room and installed considering the surveillance and the maintenance of the engines and the main machineries. They are installed supported from a stainless steel frame, removable where needed.

Engine room’s ventilation

Main engines and auxiliary engines suck air for combustion directly from the inside of engine room. The engine room’s ventilation is actuated from two electrical fan, 2 speed, and reversible with variable speed (frequency driver).

Main Engines Installation- TWIN CATERPILLAR C-12s

The propulsion system is composed from two diesel engines fed by a turbo compressor moved from exhaust gas. Each engine is coupled to a reduction/inverting gear box that transmit the energy through a shaft at one propeller with fixed blades. Engines are provided with:

Instruments’ digital panel in the wheelhouse

Second instruments’ analog panel for engine room

Fuel transfer pump

Water separator filter

Vibration absorbers on the fore basement

Second starting engine installation predisposition

Engine Transmissions

Two reduction/inverting gear box with the following main characteristics are provided:

Electric command valve

Elastic joint between engines and transmissions

Semi-solid vibration absorbers

Intermediate clutch

Manual mechanical brake on shaft for mono-engine navigation

Electric generators

The electric generators are located in the engine room. They are installed on appropriate foundations with vibration absorbers.

Air compressed system

A central air compressed power unit is provided in the garage. It drive air compressed (7bar) to automatisms, ship’s services and horn. The compressor is air-cooled with a dedicated tank of 24l capacity at 7 bar pressure and has an inlet air filter.

Main Engines gas exhaust System

The yacht is provided with n.2 gas exhaust for each engine; one above the water line used as by pass for low pressure gas and the other under the water line for high pressure gas. To reduce heating from gas pipes and silencers, they are insulated and water-cooled in the proximity of the hull’s terminals (made in stainless steel). The thru hull fittings are in big thickness steel and they are connected to the stainless steel part with a flexible joint “Steelflex” type.

Electric Generators Exhaust System

The system is designed to reduce the maximum back pressure and noises. The system is composed from a silencer and from a water separator filter for each generator. The best access to the generators is granted in order to perform all the necessary maintenance operations.

Electrical installation & Generality.

The electrical installation and all devices, switchboards, engines, switches, cables and relative installation, are in accordance with the Rules of I.E.E.E. and Classification Society for electrical and electronics devices installation on ships. The system is provided with all devices for the production, the distribution, the energy consumption and their relative essential protection for a correct functioning.

The cables are placed in appropriate ducts so located to allow, where possible, an easy installation and maintenance. In the accommodation areas, the cables are hidden behind panels and ceilings. In the engine room the cable are not installed under the flooring plates. In the exterior areas or in dangerous spaces, the cables are protected with metallic ducts or sheaths.

All low voltage and RF cables are lay down separately from that at 230/400V. Where this is not possible, the Shipyard uses cable with the same index of insulation. Where cables pass in the ducts, pipes or sheaths, the Shipyard use a spacing factor of 40% and however comply with the Regulation.

Energy generation & Diesel generator Electrical

The two main 3-phases generator (380V, 50Hz) are connected to the main switchboard through an automatic parallel system. Each generator can, however, supply current at one bush bar in case of failure. If necessary, the bush bars can be connected to each other to permit at one generator to feed the entire electrical network.

Furthermore the generators are equipped with automatic parallel earth system. The generators have diesel engine that are self-heating, self-controlled, ventilated and protected from liquid leakages. They are provided with sound shield box with an appropriate thickness of sound absorber material.

For each generator is provided a control and command’ switchboard with a counter and a gauge for oil’s pressure. The start and stop generator’s commands are outside the sound-shield box.

Batteries for Emergency electrical installation

Accumulator batteries can feed all the users that are design to work in emergency condition, for a period as long as indicated in the Rules. Those batteries are located in appropriate boxes in designated places. The black-out of electrical system is managed from a device that automatically feed the emergency users directly from the batteries.

The batteries are charged from two automatic battery chargers able to keep the batteries in charge and re-charge them with the timing indicated in the Regulations. Batteries can be re- charged also from main engines’ alternators through a battery isolator.

Batteries for engines’ starting

The following batteries for 6-times engine cold starting are provided on top of the ones of the emergency electrical installation:

Main engines’ starting MMPP

Portside diesel generator DG1

Starboard side diesel generator DG2

These batteries are charged by:

Main engine starting batteries MMPP: by their own alternators and emergency battery charger through an isolator.

Port side diesel generator DG1: by their own alternator and from starting battery charger through an isolator

Starboard side diesel generator DG2: by their own alternator and from starting battery charger through an isolator.

Shore line

A shore line (3x380/415V, 50 Hz) is provided and connected to an insulation transformer (50kVA). The connection is provided on the transom and is provided with 20m cable length with CEE 380V plug. An automatic switch is provided for system’s protection.

Electrical Distribution

380Vac circuit (3ph)

Works with Gensets or/and shore line. The circuit connects the main switchboard to the distribution sub-panels.

220Vac circuit (mono phase)

Works with gensets and/or shore line 380V (3ph). The circuit feeds all the monophase users, but is limited from the automatic switch of shore line.

24Vdc emergency circuit

It is fed by the emergency batteries and provides 24V to all emergency devices for a minimum period of 4h (navigation and communications devices, emergency lights, etc.).

Distribution in the engine room

Works with gensets or/and the shore line 380V. The fed objects are necessary for the navigation (fuel transfer, windlasses, capstans, etc.) and include air conditioning, fresh water maker, sewage treatment, etc.

C02 fixed fire fighting system from engine room

The engine room is equipped with a fixed fire fighting system, with CO2 and two speeds, composed from a set of tanks connected to a delivery circuit. The system can be moved locally or from remote. The system is provided with:

Discharge delay for 20s, to allow the exit from engine room.

Pressure switch for the engine room extractors stop

Pressure switch for the engine room and wheelhouse’s alarms activation

Portable Fire extinguishers

CO2 or powder portable extinguishers are installed on board in accordance with Regulation and flag authority requirements.

Switchboard & Generality

All the materials and the installations are designed, realized and adequately insulated to work at an room temperature of 45°C (52.5°C in engine room) and built in accordance to Yacht’s Classification Rules. The switchboard and the distribution panels have no frontal under power and are provided with switches and/or fuses, depending to the cases, for the protection of overcharges or short-circuit for every connected users.

Main switchboard

The switchboard’s frame is composed from steel section bars and is covered with painted plates. The bush bars are made with copper and are bolted to appropriate cables. The main switchboard, tested in accordance with the Rules, is located in the engine room, and feeds all the users on board, among which:

N.1 fire pump

N.1 bilge pump

N.1 black water discharge pump

N.1 fresh water pump distribution and toilet grey waters autoclave

N.1 engine room fan

N.1 fuel transfer pump

N.2 hot water boilers

N.1 diesel separator

N.1 steering pump

N.1 air compressor 7 bar

N.1 fresh water maker

N.1 power pack for tender’s crane

N.2 windlasses

N.2 capstans

N.1 power pack for gangway

N.1 battery charger for engines starting

N.2 battery chargers for emergency’s batteries and main engines starting

Air conditioning for crew and guests areas

N.1 switchboard for shore line/genset distribution

N.1 switch to wheelhouse distribution panel

N.1 switch to lower deck distribution panel

N.1 switch to saloon distribution panel

N.1 switchboard for air conditioning

N.1 switch to galley distribution panel

N.1 stabilizer system

Lighting system

All above users are equally distributed on two sections of main switchboard to permit that every genset feeds one section. The section is remote controlled.

The main switchboard clamps are located in the top and are easy accessible for clamps closing and maintenance. In the switchboard is easy to identify every single cable, clamps and internal connection by the means of numeration. Every clamp connects one incoming cable and one out coming.

The main switchboard is fed also from shore line through an insulation transformer adequate for the service of all users that can be operating in harbor: toilets, heating/air conditioning, galley, refrigerators, laundry, entertainment, radio. For the generators are used selective switches for short-circuit (on gensets) and magneto thermic switches for overcharge protection.

The switchboard is able to work with vibration; the magneto thermic relays are able to work with a temperature of 52.5°C Label and tags are applied on the devices and connector to identify the users. In the top part of each section are provided eyebolts for lifting and installation. Every switchboard’s metallic parts, particularly the frame, the shutters and the other panels are smooth to eliminate welding surplus and have an excellent finish.

Measurement instruments provided on the switchboard can work with vibrations and are of well-known suppliers.

Emergency switchboard

The emergency switchboard is located in the wheelhouse, fed by emergency batteries. The em.cy switchboard fed all navigation, communication and emergency lights’ 24V users. The em.cy switchboard doesn’t have frontal parts under power and is provided with switches and/or uses for the protection against overcharges or short circuits for all connected users.

Galley distribution panel

**The galley’ switchboard is located in the pantry and fed the following main users**

Exhaust fan

Cocking appliances

Fridges

Lights Sub panels

All the distribution sub panels for power, lights and engines and Yacht’ services have a metallic frame and metallic panels with shutters to operate on the switches. Automatic switches are used for power circuits at 220V and stotz for lights and services circuits.

Switchboard with subpanels for signals and 220Vac/24Vdc devices’ control are located in the wheelhouse.

Bridge 24V control panel

Situated in the wheelhouse, the panel includes all the needed switches to control and protect the instruments and the devices of the wheelhouse. It is provided with voltage meter, ammeter and insulation test to control the bonding connection.

Saloon and cabins have dimmer halogen spot lights on the ceiling (24Vdc or 220Vac). Ceiling recesses are provided with led lights.

Navigation lights

Navigation lights are in compliance with the COLREGS Rules 1972. On the touch screen situated in the wheelhouse, a dedicated page representing the profile of the Yacht for the control and switch of the lights is provided. Every light has an independent circuit with switch, protection’s fuse, test lamp and disconnectable acoustic alarm. The Shipyard will supply and electric search light, remotely controlled from the wheelhouse MARINE LIGHTS or equivalent.

Fire detectors

An alarm and control panel is installed in the wheelhouse with a disconnectable acoustic and visual alarm connected to the heat and smoke detector network.

Bilge alarm

A control panel and an alarm are installed in the wheelhouse with a visual and acoustic disconnectable alarm connected to a network of bilge water detectors. Every compartment have minimum a detector.

Fresh water system

A fresh water circuit is provided. It sucks water from the two fresh water tanks and delivers it to showers, sinks, WC, bidet, galley, pantry, etc. A Hot water (made from two boilers) circulation circuit ring delivers it to bathrooms, shower, sinks, bidet, etc. To immediately serve the passengers and crew.

Two boilers make the hot water. The water delivery is done through a central manifold, insulated in the engine room space, fed from two autoclaves that keep the internal circuit pressure between 2 and 2.5 kg x sqcm. Fresh water embarkation to relative tanks is done through connection on aft main deck. Fresh water system serves also the wheelhouse windows’ washing wipers. Fresh water tanks are structural and are located in the garage. Their capacity is indicated in chapter 00.03. The tanks are provided with electronic level detector with signal showed on a monitoring system in wheelhouse. The vent pipes and the overflow end on main deck. The fresh water tanks are filled by the fresh water maker installed in the garage.

For the fresh water service is provided and installed the following items:

n. 2 centrifugal E/pumps with an appropriate capacity and prevalence from cold water circulation (one is provided as reserve).

.2 E/pumps with an appropriate capacity and prevalence for the hot water circulation

N.1 hot water maker with 2 electric boilers, power and capacity appropriate for the number of the users.

n.1 fresh water maker (combo type) with inverse osmosis, provided with all the accessories for a correct functioning

n.1 UV sterilizer

n.1 salt fresh water softener

Grey water & Scuppers

To guarantee an excellent discharge of the sea water from the decks, the Shipyard install on board an appropriate number of scuppers equipped with filter. The scuppers will be realized in stainless steel in the steel part of the hull and in aluminium and PVC in the aluminium part of the boat. Those scuppers discharge the sea water by the thru-hull piping, above the water line.The sea water is discharge also by the freeing ports provided on the bulwark.

Grey Water Tank:

The grey water of toilets, galleys and pantry are discharged in the tank by the means of gravity. From there, the grey water can be discharged outboard or treated by the treatment system. If a zone can’t discharge by gravity, the grey water is collected in a dedicated tank and then pumped to the main tank.

To avoid and limit the smell, all the discharges, side user, are equipped with siphon.

Piping and fittings

Piping and fittings are made in PE HD (Geberit) for drainage and for the connections to the grey water tanks. The scuppers under the main deck are made in appropriate thickness steel pipes.

Black water system

The black water plant is a domestic type system and is Tecma supplied (or equivalent). The WC discharges are collected in a dedicated structural tank located in the engine room equipped with a vent flexible pipe with an anti-smell active carbon filter in the mast and they are treated with an automatic depuration system (similar to Mini-Biocon), designed for the number of person that could be on board.

The system is provided with e/pumps, valves, switchboard and the working essential accessories. The system doesn’t require slopes for the discharge, in order permit maximum liberty in the installation.

The collected black water can be discharged outboard or, through a dedicated international adaptor, at specifically equipped docks through the same pump used for void creation.

Air conditioning system

The system is composed by n.1 water refrigerator block, with heater and Freon R407 gas . The fan coils are located for air/water treatment.

Two UTA units for external air treatment are provided in order to thermically process the external air and distribute it in the lower deck accommodations. DARWIN 95'

Appropriate capacity extractors are installed in the bathrooms and in the galley. The winter heating system works by a diesel fed water heater. The hot water will be circulated also through the towel heaters located in the lower deck cabin bathrooms.

Cooling system-

The sea chests are realized with a steel pipe of adequate thickness welded to hull’s bottom plate and flanged to the seacock. Where necessary, the sea chests have a scoop appendage. All filters are made of bronze. Those connected to the engines have a rubber joint. The Piping is made in CuNiFer 90/10 for sea water services of main engines, electric generators and other equipment.

Propulsion and Steering

The Yacht is provided with two shaft lines composed by shaft made of Aquamet 17, stern tube and coupling. The shaft has the diameter indicated by Classification Society’s Rules. The flanges are made in stainless steel and are connected to transmission flange with bolts.

The stern tubes are made in Fe510 with bushes in antifriction metal on supports fixed with chock fast 12 t.l.

The propellers are made in bronze, nickel, aluminum alloy.

Steering system

Two balanced streamlined spade rudders are installed in the propeller’s wake. Each rudder is made of a steel plate and a Aquamet 17 steel shaft or equivalent. The helm’s ports are welded to the hull’s structure, adequately reinforced and contain two bushes of insulating material, the bronze stuffing box is fixed to the superior extremity of the helm’s port. The arms are made of stainless steel.

The electro-hydraulic steering system is composed by:

Main transmitter to wheelhouse

Emergency electronic transmitter to wheelhouse

Control panel for wheelhouse for mode selection

Alarm panel for wheelhouse

One amp with relays box for the electronic switch ON/OFF

Automatic bypass valve

Pilot by pass valve

Two hydraulic actuators

Controls from wheelhouse, fly bridge and aft cockpit.

Bow thruster- Into the bow is installed one electric tunnel thruster with a power of 35kW. Into the stern is installed one electric tunnel thruster with a power of 25kW. Thrusters are controlled with joysticks.

Stabilizers- The adaptive and 0-speed stabilizer system is composed from two fins (one for one side) moved electrically from engines controlled from inertial platform signals.

Helm stations - The main helm station is located in the wheelhouse and is provided with:

Main engines’ controls

Bow and stern thrusters’ controls

Rudders’ wheel

Navigation and communication devices

* *A second & third helms are located on the wings stations and are provided with**:

Main engines’ controls

Rudders’ controls

**A fourth helm station is located in the aft main deck**

Bow thrusters’ controls

Rudders’ controls

Communication and Navigation Equipment. - STELL DEL NORD

Radar, Furuno Navnet 3D MPU-001 BB 64 miles, open antenna Radar , Furuno Navnet 2D M1834C BB 36 miles, closed antenna, N° 3 monitor Furuno 19” MU-190 GPS, Furuno GP-33 Ecosounder, Furuno DFF1 – 525ST Remote display, RD33 Wind station, Furuno WX 150 Satellite compass, Furuno SC50 Autopilot, Simrad or Furuno Navpilot-700 Electronic compass, Furuno PG-500 Magnetic compass, SS-5000 black Magnetic compass for the fly bridge, SS-2000 white Plotter repeater for the fly bridge, Navnet 3D display MFD12 Autopilot repeater for the fly bridge, FAP-7011 Epirb + SART Satellite telephone Thuraya+ docking station Configuration for V-SAT V7

Communication System- STELL DEL NORD

VHF FURUNO FM 2721

VHF FURUNO FM 89005 (IMO GMDSS)

Entertainment & WFIF - STELL DEL NORD

Owner’s cabin: n.1 - 42” set

VIP cabin: n.1 - 22” set Saloon: n.1 - 42” set Galley and dinette: n.1 – 22” set Guest cabins: n.1 – 22” set each cabin

Closed Circuit TV system

The system is composed from two RGB cameras, located as above mentioned:

One fixed on the main deck exterior ceiling looking aft

One motorized with zoom in the engine room

HI-FI SYSTEM

A radio/CD with two speakers is installed in the wheelhouse. In the saloon is installed a central unit that diffuse sounds to speaker located in:

One infra-red camera FLIR M324L installed on the mast

The control unit and main monitor are located in the wheelhouse and they allow a selection of each camera’s framing or the framing sequence of each connected camera.

Main deck aft exterior

Upper deck exterior

Saloon (Dolby surround system 5+1)

WI-FI SYSTEM- STELLA DEL NORD

The entire Yacht has a WI-FI data transmission system.

Supply and installation is provided for: a modem router NETSKIPPER 3 Wan access/door for WI-FI antenna/gsm/sat on top of the WI-FI antenna for shore connection.

CENTRALIZED TV antenna N.1 sat antenna with KVH TRACK VISION M7 with signal distributed to cabins with decoder.

Phone system

A phone system Panasonic TDA30 with n.4 external telephone lines, n.1 telefax line, and 10 internal extensions with the possibility to make internal calls to every single room and external calls from each telephone. The supply includes No. 11 telephones including the needed activities of the programmer.

Monitoring system- A monitoring system with 15” touch screen is installed in the wheelhouse. A further 15” touch screen is installed in the engine room, located in the main switchboard. The system will monitor the following:

Bilge water level for each compartment

Fuel Tanks and double bottom levels

Fresh water tanks levels

Black and grey water tanks levels

Low charge level of the emergency batteries

Extractor and fan stop

Fire/bilge pumps start and stop

Portholes status

Smoke/fire/heat detector monitoring

Anchors, Windlasses and Chain Lockers

Anchoring and mooring systems are complying with Classification Society’s Rules. Following items are installed and provided:

N.2 HHP anchors in galvanized steel of 180kg each, including the swivel anchor ring.

N. 12 length (6 for each anchor) of chain; diameter 14mm (therefore bigger of what is normally quired by the Classification Society’s Rules), with stud, in galvanized steel, grade. U2, for a total length of about 330m.

The two anchors are stowed in a hawse produced in 12mm thick stainless steel AISI316L, of semi-recessed type, on portside and starboard side. The chain locker is so arranged to permit chain to be self-sowing and have a suitable drainage. Access to chain locker is through a hatch on the foredeck.

Windlasses Two electrical windlasses (Maxwell or Equivalent) are provided on the foredeck and are fed from 380V ac, 3 phases, 50Hz, with a power of 3,5Kw with barbotin adequate for the chain dimension and a capstan for mooring operation.

Hull- STELLA DEL NORD

The vessel has displacement round bilge hull, without bulb, with twin screw and skegs, transom stern and a bow flare area. The Yacht has excellent navigation skill in order to keep a good cruise speed also in bad weather and sea condition and a stability complying with the CE classification rules and a good manoeuvrability in narrow space. Hull bottom paint is 3 coats of Hempels hard racing 76486 120 Micron. The Hull Top sides are painted with Hempels Profiller Fine 35330

HULL - STELLA DEL NORD

The hull is built in welded carbon steel. Painted with 3 layers of Alex Seal Premium Top Coat 501 200 micron. The superstructure is built in carbon steel and aluminium alloy grade 5083 connected to the structure by the means of bi-metallic joint to limit the displacement and lower the centre of gravity increasing the Yacht’ stability. Structure’s materials and dimensions are in accordance with requirements of 94/25/CE and 2003/44/CE recreational craft directive.

Painting - STELLA DEL NORD

Hull Underwater

Description Layer Thickness

Hempadur Quattro 17634 2 400 micron

Hempadur 45182 1 80 Micron

Hempel's hard racing 76484 3 120 Micron

Hull, Top Side :

Quattro 17634/Proprimer LT 45554 1 100 Micron

Hempel's ProFair 35290 1 1000 Micron

Hempel's ProFiller Fine 35330 1 200 Micron

Alex Seal SUPER BUILD 302 1 125 Micron

Alex Seal FINISH PRIMER 442 1 75 Micron

Alex Seal PREMIUM TOPCOAT 501 3 50 Micron

Superstructure’s Construction

The superstructures are made with grade carbon steel and aluminium alloy 5083, with planar bulkheads and decks. All parts are designed in accordance with the Rules. Thickness will vary from 4 to 5mm and in any case will be according to the scantling plan approved by RINA.

Superstructure’s description continued.

Hull’ structure is essentially longitudinal with two continuous girders from stem to stern, with transversal reinforcement spaced out by 500mm and longitudinal plates. Deck’ structure is composed from a grate made by two girders and beams. The welding inside the chain locker, the engine’s room bilge and the lazzarette bilge will be continuous.

Shell Plating

The external shell plating is composed from plates generally located in the longitudinal way, with hull’s plate’s thickness in accordance with regulation. Every opening has rounded corners. Reinforcement’ supports are located close to hatches and opening. Local reinforcements are located where necessary in the zone supporting the superstructure together with pillars and reinforcement in the correspondence of concentrated loads.

Local stiffeners are of T or L section of commercial size. Alternatively can be used plates. Bulkhead’s vertical supports are aligned with decks longitudinal and in the bottom are connected at the transversal structures where bottom longitudinal brackets are supported. Supporting plates are provided in longitudinal crossover.

Double bottom

It is of boxed type, with watertight elements or not in accordance with internal partition. In the double bottom, underneath the accommodations and the engine room, are positioned the bilges, sludge, overflow, oil and fuel tanks which could be used for any deposit and ballast necessary.

All tanks are structural. Suitable holes are provided on the girders, floors and stringers to permit an easy drainage of the liquids. The tanks are provided of a suitable number of manholes for cleaning and inspection. Fresh water’s tanks are treated with products proper to drinking water’s conversation.

Fuel transfer system

The deposit fuel tanks are located in the double bottom and the two daily tanks are located in the engine room. The tanks have a vent pipe on the main deck and connection for the refuelling, the discharge and the drainage. The level indicator is of electronic type and the signal is showed on the monitoring screen in the wheelhouse.

The bunkering manifold and the delivery manifold are located in the engine room. The deposit tanks’ bunkering can be done through the diesel refuelling connection in the engine room’s entrance on main deck. Main engines and gensets are equipped with appropriate filters (Racor type or equivalent). The fuel transfer between the deposit tanks can be done through a dedicated pump.

Daily and deposit fuel tanks are provided with quick closing valves actuated from main deck. The system is studied to avoid that fuel overflow can go to bilges. Fittings are in steel with bronze or steel valves. A stripping system for the fuel will be provided and realized with dedicated pipes of small diameter with a manual pump. The stripping system will be capable to suck any eventual water which should sit in the lower part of the structural tanks. A small non structural overflow box will be provided in the engine room with a glass inspection window and level alarm.

Lube oil system

The lube oil for the main engines and the gensets is located in two structural tanks (dirty and clean oil) in the double bottom of the engine room. Their capacity is indicated in the chap. 00.03. The tanks are provided with two hand pumps connected to flexible pipes for embarkment/disembarkment of the lube oil.

Watertight bulkhead

The hull has three transversal watertight bulkheads. They are located from bottom to main deck. The WT Bulkheads are plane type entirely welded.

Bilge/Fire/Chain and deck wash systems

Bilge system

The bilge system is composed from a main manifold in CuNiFe 90/10 so arranged as to pump water from all watertight compartments located under the maximum water line, except for the liquid containing tanks.

The suction from every single compartment is done by a pump connected with semi- automatic valves remote controlled from a monitoring screen in wheelhouse, and separate piping for each compartment. The bilge is discharged in the bilge tank, situated in the engine room, or directly outboard. The compartments situated fore of the anti-collision bulkhead are drained through an adequate separate manual pump and/or through an adequate electric pump.

- For this service are provided and installed the following machinery: n.1 centrifugal self-priming e/pump with a capacity and prevalence in accordance with the Rules as follows.

n. 1 hand pump located in the garage

n. 1 centrifugal self-priming e/pump in the chain locker compartment

n. 1 hand pump in the chain locker compartment

**For emergency operation, the fire pump can be used to replace the failed bilge pump**

Fire system

The main fire fighting system, sea water fed, is composed from a manifold at pressure (CuNiFe 90/10) with two connections, one fore and one aft on the main deck. The system is fed from a centrifugal self-priming pump, located in the engine room, with a capacity defined on the Rules.

The bilge pump can be used to serve the fire fighting system. Fire hose and nozzles are placed in the same boxes of the connections.

The chain wash system is fed both from the bilge e/pump located in the chain locker compartment, which conveys the water sucked by a dedicated sea chest to two nozzles located inside the howses and by the autoclave which feeds fresh water to the various users on board conveying fresh water to two more nozzles located inside the hawses at an higher position in respect to the two nozzles fed by sea water, so that the chain entering the chain locker will be “sweetened”. Alternatively a “rain system” will be evaluated with fresh water on top of the chain locker, in case this will be considered more efficient.

Handling systems & Gangway

A recessed electro-hydraulic gangway with walkable width of 395mm, 24V, (OPACMARE mod. 1133/44 with a length of the mobile part of it of 4.125mm or equivalent) is installed behind the second last step, stepping down the portside stairway from main deck to swimming platform.

The gangway is controlled from a local panel or from a remote control (two are supplied). The gangway’s useful length is about 4m. The stanchions are automatic for one side and manual for the other side. The gangway has a lighting system on the walkway.

A manual passerell will be supplied for alongside embarkment (TREM or equivalent) or a manual Marquip passerell with self levelling steps at Owner’s choice.

Swimming platform

It is installed an extension of the swimming platform of a longitudinal length of 0.6mt with a manual swimming ladder and a hot/cold water shower. The swimming platform will be protected by adequate stainless steel removable stanchions. In the central area of the swimming platform an OPACMARE “Transformer” mod.3381.40 will be installed.

In the submerged area of the transom in correspondence of the swimming platform 4 LED underwater lights will be installed.

Moving systems for tender and toys

A dedicated electro-hydraulic crane with a max load of 1150kg and a maximum reach of 6.1mt is installed for the hauling/launching of the tender and the toys (tender is Owner’s supplied).

Lifesaving equipment

2 life rafts, including hydrostatic release hook, of 10 person capacity for each one, are provided and installed on the upper deck. N.20 Adult lifejackets and n.4 Child lifejackets are stored in appropriate compartments. N.4 lifebuoys including lines and floating lights. Lifesaving equipment will be in any case in accordance with the Italian flag’s rules.

Cabins/Bathrooms/Day Head/ Crew Quarters

Cantiere delle Marche Darwin Exploration Yacht

Owner’s, VIP and Guests Cabins (1) Master stateroom Owner’s bed is 1.80 x 2.00mt . (2) VIP bed: 1.80 (head) – 1.40 (feet) x 2.00mt.

(3/4) Guests’ beds are 0.80 x 1.95mt. Only the double beds are provided with a gas spring lift able slat bases to access storage underneath. The guest’s cabins are equipped with a pullman bed with security lock and balanced and frictioned movement.

Bathrooms. Owner’s cabin

WC: Tecma mod. Silence std. Head: Tecma model. Bathroom top: covered in SILESTONE. Sink: Above top

Taps and fittings: Paffoni taps Walls: Are all in ALPI smooth, painted open pore. Joinery visible surfaces: Are made of ALPI and painted open pore. Doors and drawers all have push lock closing system.

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 4 of 28

Crew Quarters- Walls: Marine plywood panels laminated in ivory colour with angles and finishings in solid Iroko.

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 6 of 28

Flooring: Wooden floor with 100mm planks in iroko, installed longitudinally from bow to stern painted open pore, natural. Internal doors: in laminated marine plywood. Curtains recess: lacquered.

Mattresses: in polyurethane with non removable lining, fire resistant, anti-acarus

Crew Mess. -

Flooring: Porcelain stoneware or similar product with anti slip treatment for safety.

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 5 of 28

Main Deck and Upper day toilets - Tecma model and Silence std. Sink: Is round and in stainless steel Taps: Paffoni Walls: smooth in whitewashed oak painted open pore

Galley/ Household Appliances

Visible surfaces of the furniture aft of the wheelhouse: Marine plywood panels are finished in Oak. Doors and drawers all have push locks. Doors and drawers are flush mounted with external framing in solid wood, flat with no moldings. The veneering of the furniture will are at 90° in respect to the one of the walls. The Flooring is Porcelain stoneware with anti slip treatment for safety. Internal doors: Are sliding, laminated marine plywood, oak finishing on the internal side. Same finishing of the corridor on the external side.

Ceilings: Flat removable panels in marine plywood, lacquered. Curtains recess which is lacquered. The Skirting board is marine plywood finished with laminated oak.

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 7 of 28

Household Appliances-

Range hood: 1 Miele Marine DA 3190 Insinkerator: General Electric GFC 701F Dishwasher: 1 Miele Marine G1252 SCI

Exterior/Main/ Cockpit Decks/ Sun deck

Internal wheelhouse lounge features the following. Drawer fridge Vitri Frigo model DW100RFX.

Sundeck Fridge: Vitri Frigo model DW100RFX. Exterior Areas & Main deck

Table: 10 seat table by (270x90/125) in marine plywood teak veneer, specifically painted for external use. Cylindrical bases are in stainless steel.

Ceilings: Flat removable panels in marine plywood, lacquered.

Table: 12 seat table (300 x 90/120) in marine plywood teak veneered specifically painted for external provided with an extension and stainless steel gas pop up base.

Sun Deck- STELLA DEL NORD

Jacuzzi: On the aft part of the sundeck a Jacuzzi tab model Jacuzzi Nova for 3 people with external diameter of 1.8mt, 400lt capacity, 63cm is the height.

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 8 of 28

Sun Bed: n. 2 structural sun bed (PTS) with storage space underneath. Cushions with close cell padding, covered by acrylic upholstery. Sun bed portside of the pilot station. Sofa: Is a L shaped sofa (with side table and coffee table) starboard side (behind pilot station).

Teak Decks The main deck, the upper deck, the sun deck, the foredeck and the swimming platform are covered with teak, with staves of 12mm of thickness on a suitable leveling material. The coamings are filled with black rubber

Pilot Station: Structural seating and pilot station in alloy or composite material for three people.

Electrical & Batteries

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 11 of 28

Main engine starting batteries MMPP: by their own alternators and emergency battery charger through an isolator.

Port side diesel generator DG1: by their own alternator and from starting battery charger through an isolator

Starboard side diesel generator DG2: by their own alternator and from starting battery charger through an isolator.

Electrical Distribution 380Vac circuit (3ph)

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 12 of 28

Fire System

Cantiere delle Marche Darwin Exploration Yacht

Switchboard & Generality

Switchboard & Generality

N.1 fire pump

N.1 bilge pump

N.1 black water discharge pump

N.1 fresh water pump distribution and toilet grey waters autoclave

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD

N.1 engine room fan

N.1 fuel transfer pump

N.2 hot water boilers

N.1 diesel separator

N.1 steering pump

N.1 air compressor 7 bar

N.1 fresh water maker

N.1 power pack for tender’s crane

N.2 windlasses

N.2 capstans

N.1 power pack for gangway

N.1 battery charger for engines starting

N.2 battery chargers for emergency’s batteries and main engines starting

Air conditioning for crew and guests areas

N.1 switchboard for shore line/genset distribution

N.1 switch to wheelhouse distribution panel

N.1 switch to lower deck distribution panel

N.1 switch to saloon distribution panel

N.1 switchboard for air conditioning

N.1 switch to galley distribution panel

N.1 stabilizer system

Lighting system

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 14 of 28

• • • •

The main switchboard is fed also from shore line through an insulation transformer adequate for the service of all users that can be operating in harbor: toilets, heating/ air conditioning, galley, refrigerators, laundry, entertainment, radio. For the generators are used selective switches for short-circuit (on gensets) and magneto thermic switches for overcharge protection.

Galley distribution panel **The galley’ switchboard is located in the pantry and fed the following main users** Exhaust fan

Cocking appliances Fridges Lights Sub panels

Bilge alarm

Page 15 of 28

Fresh Water System/ Tanks

Fresh water system

Two boilers make the hot water. The water delivery is done through a central manifold, insulated in the engine room space, fed from two autoclaves that keep the internal circuit pressure between 2 and 2.5 kg x sqcm. Fresh water embarkation to relative tanks is done through connection on aft main deck. Fresh water system serves also the wheelhouse windows’ washing wipers. Fresh water tanks are structural and are located in the garage. Their capacity is indicated in chapter 00.03. The tanks are provided with electronic level detector with signal

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 16 of 28

showed on a monitoring system in wheelhouse. The vent pipes and the overflow end on main deck. The fresh water tanks are filled by the fresh water maker installed in the garage.

n. 2 centrifugal E/pumps with an appropriate capacity and prevalence from cold water circulation (one is provided as reserve).

N.1 hot water maker with 2 electric boilers, power and capacity appropriate for the number of the users.

n.1 fresh water maker (combo type) with inverse osmosis, provided with all the accessories for a correct functioning

Grey water & Scuppers

To avoid and limit the smell, all the discharges, side user, are equipped with siphon. Piping and fittings

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD Page 17 of 28

The system is provided with e/pumps, valves, switchboard and the working essential accessories. The system doesn’t require slopes for the discharge, in order permit maximum liberty in the installation.

Cantiere delle Marche Darwin Exploration Yacht – STELLA DEL NORD

Air Conditioning/ Cooling System

The system is composed by n.1 water refrigerator block, with heater and Freon R407 gas. The fan coils are located for air/water treatment.

Two UTA units for external air treatment are provided in order to thermically process the external air and distribute it in the lower deck accommodations. DARWIN 95'

Cooling system-

The sea chests are realized with a steel pipe of adequate thickness welded to hull’s bottom plate and flanged to the seacock. Where necessary, the sea chests have a scoop appendage. All filters are made of bronze. Those connected to the engines have a rubber joint. The Piping is made in CuNiFer 90/10 for sea water services of main engines, electric generators and other equipment.

Yacht name «STELLA DEL NORD» – Cantiere delle Marche is for sale and located in Venice , Italy - North Coast, ITALY.

Mega Yacht «STELLA DEL NORD» built by manufacturer Cantiere delle Marche in 2016 — available for sale. Yacht location: ITALY. If you are looking to buy a yacht «STELLA DEL NORD» or need additional information on the purchase price of this Cantiere delle Marche, please call: +1-954-274-4435 (USA)

Only deal with professionals!

Yacht, IMO 9853785

- VesselFinder

- miscellaneo

La nave NORD (IMO 9853785, MMSI 273610820) è una nave Yacht costruita nel 2021 che naviga attualmente sotto bandiera della Russia.

| Predicted ETA | - |

| Distance / Time | - |

| Direzione / Velocità | |

| Pescaggio attuale | 5.2 m |

| Navigation Status | - |

| Position received | |

| IMO / MMSI | 9853785 / 273610820 |

| Callsign | UBSX4 |

| Bandiera | Russia |

| Lunghezza / Larghezza massima | 142 / 22 m |

Posizione della carta & Weather

Ultima toccata, dati principali.

| Numero IMO | 9853785 |

| Nome dell'imbarcazione | NORD |

| Tipo di imbarcazione | Yacht |

| Bandiera | Russia |

| Porto base | - |

| GT | 10154 |

| DWT (t) | - |

| Lunghezza complessiva (m) | 142 |

| Larghezza massima (m) | 20 |

| Pescaggio (m) | - |

| Anno di costruzione | 2021 |

| Costruttore | |

| Luogo di costruzione | |

| Cantiere |

| TEU | - |

| Volume per greggio (bbl) | - |

| Gas (m3) | - |

| Grano | - |

| Balle | - |

| Classification Society | - |

| Proprietario registrato | |

| Owner Address | |

| Owner Website | - |

| Owner Email | - |

| Manager | |

| Manager Address | |

| Manager Website | - |

| Manager Email | - |

Posizione attuale e storico delle toccate sono ricevuti dall'AIS. I dettagli sulle specifiche tecniche, sul tonnellaggio e sulla gestione sono derivati dal database di VesselFinder. I dati sono solo per scopi informativi e VesselFinder non è responsabile per l'accuratezza e l'affidabilità dei dati di NORD.

- Frank Magazine

- Denison History

- Virtual Tours

- --> --> -->