Sandpiper 565

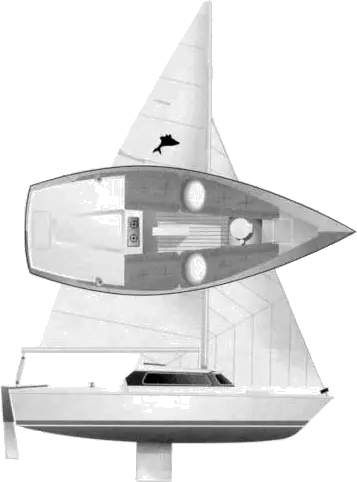

The sandpiper 565 is a 18.5ft fractional sloop designed by leonardo da costa sayago and built in fiberglass by c&l boatworks since 1972., 1500 units have been built..

The Sandpiper 565 is a light sailboat which is a high performer. It is stable / stiff and has a low righting capability if capsized. It is best suited as a day-boat.

Sandpiper 565 for sale elsewhere on the web:

Main features

Login or register to personnalize this screen.

You will be able to pin external links of your choice.

See how Sailboatlab works in video

We help you build your own hydraulic steering system - Lecomble & Schmitt

Accommodations

Builder data, other photos, modal title.

The content of your modal.

Personalize your sailboat data sheet

Great choice! Your favorites are temporarily saved for this session. Sign in to save them permanently, access them on any device, and receive relevant alerts.

- Sailboat Guide

Sandpiper 565

Sandpiper 565 is a 18 ′ 6 ″ / 5.6 m monohull sailboat designed by Leonardo da Costa Sayago and built by C&L Boatworks starting in 1972.

Rig and Sails

Auxilary power, accomodations, calculations.

The theoretical maximum speed that a displacement hull can move efficiently through the water is determined by it's waterline length and displacement. It may be unable to reach this speed if the boat is underpowered or heavily loaded, though it may exceed this speed given enough power. Read more.

Classic hull speed formula:

Hull Speed = 1.34 x √LWL

Max Speed/Length ratio = 8.26 ÷ Displacement/Length ratio .311 Hull Speed = Max Speed/Length ratio x √LWL

Sail Area / Displacement Ratio

A measure of the power of the sails relative to the weight of the boat. The higher the number, the higher the performance, but the harder the boat will be to handle. This ratio is a "non-dimensional" value that facilitates comparisons between boats of different types and sizes. Read more.

SA/D = SA ÷ (D ÷ 64) 2/3

- SA : Sail area in square feet, derived by adding the mainsail area to 100% of the foretriangle area (the lateral area above the deck between the mast and the forestay).

- D : Displacement in pounds.

Ballast / Displacement Ratio

A measure of the stability of a boat's hull that suggests how well a monohull will stand up to its sails. The ballast displacement ratio indicates how much of the weight of a boat is placed for maximum stability against capsizing and is an indicator of stiffness and resistance to capsize.

Ballast / Displacement * 100

Displacement / Length Ratio

A measure of the weight of the boat relative to it's length at the waterline. The higher a boat’s D/L ratio, the more easily it will carry a load and the more comfortable its motion will be. The lower a boat's ratio is, the less power it takes to drive the boat to its nominal hull speed or beyond. Read more.

D/L = (D ÷ 2240) ÷ (0.01 x LWL)³

- D: Displacement of the boat in pounds.

- LWL: Waterline length in feet

Comfort Ratio

This ratio assess how quickly and abruptly a boat’s hull reacts to waves in a significant seaway, these being the elements of a boat’s motion most likely to cause seasickness. Read more.

Comfort ratio = D ÷ (.65 x (.7 LWL + .3 LOA) x Beam 1.33 )

- D: Displacement of the boat in pounds

- LOA: Length overall in feet

- Beam: Width of boat at the widest point in feet

Capsize Screening Formula

This formula attempts to indicate whether a given boat might be too wide and light to readily right itself after being overturned in extreme conditions. Read more.

CSV = Beam ÷ ³√(D / 64)

The SANDPIPER 565 was first manufactured in 1972 by Sandpiper Marine Ltd. of Southampton, England. Later built by CL Sailboats (formerly C&L Boatworks) of Canada. (Royalties not paid) Another version was built under license in Sweden called OCKELBO OS 19.

Embed this page on your own website by copying and pasting this code.

Discover Related Sailboats

Sailfish 18

- About Sailboat Guide

©2024 Sea Time Tech, LLC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

- {{>productsMenu}} Products

- {{>trendsMenu}} News & Trends

- Catalogs >

- CL Sailboats >

- SANDIPIPER 565

- News & Trends

- Exhibitions

SANDIPIPER 565 19 Pages

Catalog excerpts

Rigging instructions and general information Reproduced with permission for C&L Boatworks, Fort Erie Ontario

(Rigging Instructions from the Original owners manual - circa 1973) The SANDPIPER 565 sailing sloop was first manufactured in 1972 by Messrs. Sandpiper Marine Ltd. of Southampton, England, and was built under licence by C&L Boatworks located in Fort Erie, Ontario This seaworthy and stable yacht has many desirable features, and with its' retractable keel is so adaptable for trailering, launching and beaching that its owners can enjoy sailing in many different waters. Outstanding amongst its characteristics is the carefully designed and extremely dry cockpit with its high coaming for...

Item numbers and description of parts 4 Sliding hatch cover 7 Jib sheet jamb cleat 9 Jib sheet slider block 28 Anchor & chain locker 34 Port quarter berth 38 Starboard quarter berth 39 Port forward berth 42 Main cabin floor 43 Starboard forward berth

GENERAL RIGGING INSTRUCTIONS FOR SANDPIPER 565 Introductory Comments: In order that these instructions may be comprehensible to comparative newcomers to sailing, they are written in elementary terms and an attempt is made to explain the meaning of nautical words when they occur. Most experienced sailors have their own ideas on how to rig their boat, but these instructions are intended to provide a basis from which the new owner of a SANDPIPER 565 can begin. The mast when "stepped", i.e. erected, is supported by three wire stays collectively called the standing rigging. All three have an eye...

Shroud wires A7 are both the same lengths. Attach eye end A6 to mast tang A19 on each side Of mast at 3/4 height from mast heel using headed clevis pins and split pins. Insert shrouds A7 into slot in outboard end of spreader tubes AB and secure with split pins. -Set spreaders at right angle to mast and with downward tension on shroud wires tape together tightly. Attach turnbuckle AIO right hand threaded fork end to lower end of shroud eye end A6 with clevis Pin and split pin. Forestay wire A9 attach eye end A6 to houndband AS using clevis pin and split pin. Attach turnbuckle AID right hand...

Reproduced with permission for C&L Boatworks, Fort Erie Ontario

2. Running Rigging and the Boom The running rigging comprises the halyards, which hoist the sails, and the sheets, which control their position when sailing. There are two halyards. One, which runs up the front face of the mast and down the back face, is the Main Halyard and consists of a wire with a braided rope tail, and is used to hoist the mainsail. The other halyard consists of a braided rope which runs outside of the mast through a swivel pulley located below the forestay wire mast tang. This the Jib Halyard and hoists the The boom is the spar, which is attached to the mast and to the...

The forward edge of the mainsail and jib is called the LUFF. In the case of the jib there is an internal wire running up the luff, whereas the mainsail has a rope edge (the luff rope) attached to the luff. The lower edge of the sail is called the FOOT, and the other edge the LEECH. There are four pockets extending into the mainsail from its leech and four battens are provided to stiffen the after edge of the sail. The corners of the sail are provided with eyes called CRINGLES. The top corner of each sail is its HEAD; the forward bottom corner its TACK and the aft bottom corner its CLEW. At...

5. Jibsheet and Mainsheet arrangements Reeve jibsheet F2 (3/8" x 40ft. Dacron line) through the jib clew El until it is even on both sides. Knot each side of the clew eye with a single overhand knot. Pass lines one each side of front face of mast and reeve each end through the jib sliding block F3 located on port and starboard side decks near cabin window. Pass- each sheet end through the jamb cleat combination block eye FI. Tie a figure eight knot close to the end of each sheet to stop it escaping the eye. Attach the swivel of the single sheave block Dl to the link plate B2 at the clew end...

open leech. If the sail has a very full luff, then a Cunningham line should be used to tighten the excess luff to flatten the sail for heavy airs. (b) Boom tackle: see figure 6 To control the extent to which the boom can lift when sailing, a tackle known as a kicking strap, or boom vang, is provided. In its simplest form it comprises a short wire strop attached to the mast bracket at one end and the other end of a vee jamb block with a "D" shackle and clevis pin. Another block with a special keyhole lug is snapped into the fitting underneath the boom. A lanyard is reeved through the two...

íiaíJisheet and kiclcinp strop airain^ ernenta, Item numberg and Description Boom vang assembly Single becket block i"lanyard Dacron line Wire strop Mainsbeet assembly D2 3/8" Dacron line (inaansheet) D3 Sister block and jatrib cleat

Having learned how to bend (rig) and hoist the sails by practicing ashore several times, the boat should be launched with the sails lowered. The boat should be secured to a dock or mooring. IT IS MOST IMPORTANT TO WATCH FOR LOW OVERHEAD HYDRO WIRES when stepping the mast prior to launching and again when lowering the mast after winching on a trailer, especially at an unfamiliar site. (a) Retractable Keel arrangement: see figure 7, The operation of the keel, which is raised and lowered manually, must be checked before preparation for sailing. Move the boat into minimum depth of 3 ft. of...

03 - Bidder Assembly Datila 8 JX m Retractabas keel as s enibjy details Reproduced with permission for C&L Boatworks, Fort Erie Ontario

In light weather you should experience very little trouble with full mainsail and genoa in handling all points of sailing with your SANDPIPER 565. If you have been used to a lighter boat you will find the SANDPIPER 565 will take just that much longer to tack, gybe or bear off, so do not at first get too close to moored, or other craft while In moderate to heavy weather the answer is to reduce sail by reefing and to use a small jib. The method of reefing the mainsail has already been explained. To change jibs when afloat is rather difficult as it means going on the foredeck to reach the...

Related Searches

- Marine sailboat

- Nautical sailing dinghy

- Dayboat sailboat

- Recreational sailing dinghy

- Single-handed sailing dinghy

- Regatta sailing dinghy

- Multiple sailing dinghy

- 4-berth sailboat

- Double-handed sailing dinghy

- Catboat sailing dinghy

- Instructional sailing dinghy

- Skiff sailing dinghy

- Asymmetric spinnaker sailing dinghy

- Single-trapeze sailing dinghy

- Symmetric spinnaker sailing dinghy

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- AboutVirtualExpo Group

Review of Sandpiper 565

Basic specs., sailing characteristics.

This section covers widely used rules of thumb to describe the sailing characteristics. Please note that even though the calculations are correct, the interpretation of the results might not be valid for extreme boats.

What is Capsize Screening Formula (CSF)?

The capsize screening value for Sandpiper 565 is 2.67, indicating that this boat would not be accepted to participate in ocean races.

What is Theoretical Maximum Hull Speed?

The theoretical maximal speed of a displacement boat of this length is 5.2 knots. The term "Theoretical Maximum Hull Speed" is widely used even though a boat can sail faster. The term shall be interpreted as above the theoretical speed a great additional power is necessary for a small gain in speed.

The immersion rate is defined as the weight required to sink the boat a certain level. The immersion rate for Sandpiper 565 is about 66 kg/cm, alternatively 370 lbs/inch. Meaning: if you load 66 kg cargo on the boat then it will sink 1 cm. Alternatively, if you load 370 lbs cargo on the boat it will sink 1 inch.

Sailing statistics

This section is statistical comparison with similar boats of the same category. The basis of the following statistical computations is our unique database with more than 26,000 different boat types and 350,000 data points.

What is Motion Comfort Ratio (MCR)?

What is L/B (Length Beam Ratio)?

What is Displacement Length Ratio?

What is SA/D (Sail Area Displacement ratio)?

Maintenance

Are your sails worn out? You might find your next sail here: Sails for Sale

If you need to renew parts of your running rig and is not quite sure of the dimensions, you may find the estimates computed below useful.

This section shown boat owner's changes, improvements, etc. Here you might find inspiration for your boat.

Do you have changes/improvements you would like to share? Upload a photo and describe what to look for.

We are always looking for new photos. If you can contribute with photos for Sandpiper 565 it would be a great help.

If you have any comments to the review, improvement suggestions, or the like, feel free to contact us . Criticism helps us to improve.

Attention! Your ePaper is waiting for publication!

By publishing your document, the content will be optimally indexed by Google via AI and sorted into the right category for over 500 million ePaper readers on YUMPU.

This will ensure high visibility and many readers!

Your ePaper is now published and live on YUMPU!

You can find your publication here:

Share your interactive ePaper on all platforms and on your website with our embed function

THE SANDPIPER 565 - Sailfish 18

- sailfish18.nl

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GRYC Sandpiper <strong>565</strong><br />

Rigging instructions and general information<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 1

<strong>THE</strong> <strong>SANDPIPER</strong> <strong>565</strong><br />

(Rigging Instructions from the Original owners manual - circa 1973)<br />

The <strong>SANDPIPER</strong> <strong>565</strong> sailing sloop was first manufactured in 1972 by Messrs.<br />

Sandpiper Marine Ltd. of Southampton, England, and was built under licence by C&L<br />

Boatworks located in Fort Erie, Ontario<br />

This seaworthy and stable yacht has many desirable features, and with its'<br />

retractable keel is so adaptable for trailering, launching and beaching that its owners<br />

can enjoy sailing in many different waters.<br />

Outstanding amongst its characteristics is the carefully designed and extremely dry<br />

cockpit with its high coaming for comfortable daysailing, with non-skid surfaces and<br />

extra large space for the helmsman and crewmembers.<br />

It can sleep two extra people under the optional cockpit canopy, and the large<br />

transom locker allows stowage of an outboard motor and fuel tank, as well as other<br />

items. The retractable outboard motor bracket is standard equipment and facilitates<br />

storage when sailing.<br />

All moulding is hand lay-up, with built-in buoyancy provided for additional safety.<br />

The side decks are wide enough to walk on with ease, and there are handrails on the<br />

cabin roof for added convenience in rough weather conditions.<br />

There is easy access to the cabin through the large sliding main hatch, and the cabin<br />

is light and airy with two large hatches and two plexiglass ports. Four large berths<br />

with deep, soft cushions allow for comfortable sleeping, and ample main storage is<br />

provided below the berths, with the handy port and starboard cave lockers so great<br />

for odds and ends. A convenient locker for storing the keel winch handle is also<br />

provided. There is excellent sitting headroom, and an optional drop-leaf table fits<br />

neatly onto the keel housing.<br />

All deck fittings are of the finest non-corrosive quality, including stemhead, roller,<br />

mooring cleat and fairleads. The anchor and chain locker is self-draining and the<br />

forward hatch is well positioned for access to the foredeck and ventilation. The bow<br />

pulpit is an attractive option, and a good safety feature especially when mooring,<br />

docking, setting spinnaker, dropping foresails or anchoring.<br />

The <strong>SANDPIPER</strong> <strong>565</strong> secures neatly on a trailer for mobility and can be trailed with<br />

ease. Launching and recovery is simple, allowing access to inland and coastal waters.<br />

The keel is recessed within the hull for trailing and storage. All these features make<br />

the <strong>SANDPIPER</strong> <strong>565</strong> the ideal yacht for family cruising a sit has full accommodations<br />

for four persons. For Class or Handicap racing, the addition of a spinnaker improves<br />

the performance and makes it exciting and fun to race.<br />

Please refer to fig. 1 for Illustrated Layout of component parts.<br />

Note: Item numbers noted are not used in subsequent detail layouts.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 2

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 3

GENERAL RIGGING INSTRUCTIONS FOR <strong>SANDPIPER</strong> <strong>565</strong><br />

Introductory Comments:<br />

In order that these instructions may be comprehensible to comparative newcomers<br />

to sailing, they are written in elementary terms and an attempt is made to explain<br />

the meaning of nautical words when they occur. Most experienced sailors have their<br />

own ideas on how to rig their boat, but these instructions are intended to provide a<br />

basis from which the new owner of a <strong>SANDPIPER</strong> <strong>565</strong> can begin.<br />

1. Mast and Fittings<br />

(a) Standing Rigging<br />

The mast when "stepped", i.e. erected, is supported by three wire stays collectively<br />

called the standing rigging. All three have an eye at their uppermost end, and<br />

adjusters, called turnbuckles, at their lower end.<br />

The two stays of equal length are called the shrouds and must be attached at their<br />

upper ends to tangs located on each side of the mast about 3/4 height from the mast<br />

foot. Two swinging type spreaders (metal tubes) must be attached to the mast side<br />

brackets located about centre of mast by means of large split pins provided. A<br />

shroud wire is then fitted into the slot on the outboard end of each spreader and<br />

secured with a split pin. The turnbuckles of the shrouds must be attached to the two<br />

steel shroud eyes, which protrude through the side deck near centre of cabin<br />

windows. The third longer stay is called the forestay, and must be attached at its<br />

upper end to the tang at the front of the mast located 3/4 height from mast foot.<br />

The turnbuckle of the forestay must be attached to the first hole in the bow deck<br />

fitting, located at the extreme bow of the boat using attached shackle, see figure 3,<br />

Attachment of the standing rigging is effected by headed clevis pins which are<br />

themselves secure" by split pins. The mast has a slotted hole at the centre of its butt<br />

end, or heel, and when it is being stepped, the slotted end is dropped over the<br />

stainless steel bolt located in the centre of the mast step channel on the cabin<br />

foredeck.<br />

(b) Rigging the Mast: see figures 2 and 3<br />

Lay Mast g on trestles or on the ground with the sail groove facing downwards Reeve<br />

(i.e. pass) the unspliced end of the main halyard A4 from back face of mast head<br />

sheave A3 and forward over the two sheaves (i.e.-: - pulleys), run down mast until<br />

the length is evened up and secure the other end with a "0" shackle A2 to mast cleat<br />

A14.<br />

Reeve the unspliced end of jib halyard A15 from front side of pulley block A1B run<br />

down mast until the length is evened up and secure the other end with a "D"-shackle<br />

to mast cleat.<br />

Attach spreader tubes AB one each side to mast attachment brackets A16 with large<br />

split pins.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 4

Shroud wires A7 are both the same lengths. Attach eye end A6 to mast tang A19 on<br />

each side Of mast at 3/4 height from mast heel using headed clevis pins and split<br />

pins. Insert shrouds A7 into slot in outboard end of spreader tubes AB and secure<br />

with split pins. -Set spreaders at right angle to mast and with downward tension on<br />

shroud wires tape together tightly. Attach turnbuckle A1O right hand threaded fork<br />

end to lower end of shroud eye end A6 with clevis Pin and split pin.<br />

Forestay wire A9 attach eye end A6 to houndband AS using clevis pin and split pin.<br />

Attach turnbuckle AID right hand threadedfork end to lower end of forestay eye end<br />

with clevis pin and split in. Reeve the unspliced end of topping lift A17 from aft side<br />

of "D" shackle then forward and down mast until ends are evened up and secure<br />

other end with a "D" shackle to mast cleat.<br />

(c) Stepping the Mast:<br />

Make sure that the boat is securely set, to avoid mishaps. Lay mast complete with<br />

rigging on the boat with the mast foot (heel) into the mast step A20 (mast slot<br />

down) on to the step pin bolt. Un-thread shroud and forestay turnbuckles and rethread<br />

barrels onto fork ends until approximately 3/S" has entered the barrel at both<br />

ends. Less than 3/B" is unsafe. Connect the shroud fork end to eye chainplate A24<br />

using clevis pin and split pin.<br />

NOTE: TIE <strong>THE</strong> SHROUD TURNBUCKLES UPRIGHT TO <strong>THE</strong> HANDRAILS ON <strong>THE</strong><br />

CABIN ROOF TO AVOID BENDING T HEM WHEN RAISING <strong>THE</strong> MAST.<br />

Raise the mast against the mast step pin from the cockpit and push upwards by<br />

walking forward to the cabin keel case until the mast is in a vertical position.<br />

A second person is required and can assist by pulling on the forestay to help<br />

raise the mast, then 'to connect the fork end of the forestay turnbuckle to the<br />

front hole in the bow plate A24 using clevis pin and split pin, while the first<br />

person keeps the mast upright.<br />

(d) Following is the identification of items referred to in (b) and (c) above.<br />

See also figures 2 and 3,<br />

Al Mast A14 Jib and Main Halyard Cleat<br />

A2 "D" shackle/or captive shackle AIS Jib Halyard<br />

A3 Mast Head Sheaves A16 Bracket for Spreader Tube<br />

A4 Main Halyard A17 Halyard Topping Lift<br />

AS Houndband A1S Jib Halyard Pulley<br />

A6 Shroud and Forestay eye ends A19 Shroud Tang<br />

A7 Shrouds - port & starboard A2D Mast step<br />

AB Spreader Tube A21 Shroud chain eye<br />

A9 Forestay A22 Rear Locker Cover<br />

AIO Turnbuckles - shroud & forestay A23 Bow Fairlead (or chock)<br />

All Heel slot A24 Bow Plate<br />

A12 Boom vang attachment plate A2S Anchor Locker Cover<br />

A13 Topping Lift Cleat A26 Mainsheet Traveller Track<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 5

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 6

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 7

2. Running Rigging and the Boom<br />

(a) Running Rigging:<br />

The running rigging comprises the halyards, which hoist the sails, and the sheets,<br />

which control their position when sailing. There are two halyards. One, which runs up<br />

the front face of the mast and down the back face, is the Main Halyard and consists<br />

of a wire with a braided rope tail, and is used to hoist the mainsail. The other halyard<br />

consists of a braided rope which runs outside of the mast through a swivel pulley<br />

located below the forestay wire mast tang. This the Jib Halyard and hoists the<br />

Foresail, or Jib.<br />

For Sheets, see section 5,<br />

(b) The Boom:<br />

The boom is the spar, which is attached to the mast and to the foot of the mainsail.<br />

It has a groove in it, similar to the groove in the mast. At one end of the groove<br />

there is a large split pin in a transverse hole, and at the same end there is a sliding<br />

strap type swivel gooseneck which is inserted in the special wide groove in the mast.<br />

The boom and gooseneck slide is pushed down into the normal mast groove, below<br />

the sail entry groove.<br />

3. Adjustment of Standing Rigging: see figure 4,<br />

This should be done with the boat on an even keel and in a correct attitude fore and<br />

aft. Leveling the boat on a trailer is not too practical and it is recommended that<br />

adjustments be carried out when the boat is in calm water. A weight should be<br />

attached to the main halyard A4 and used as a plumb line and sighted along the<br />

groove of the mast. Adjust the shroud turnbuckles, which were previously equalized<br />

when stepping the mast, until the mast is upright when viewed from the stern or<br />

when the halyard is hanging down and in line with the centre of the mast groove.<br />

The rake (the amount the mast leans forward or aft) can then be adjusted. The mast<br />

should first be raked vertical, (straight up and down) by adjusting the turnbuckles on<br />

the forestay and the two shrouds, which had previously been adjusted for side angle.<br />

Tighten or loosen shroud turnbuckles evenly, the same number of t~J1S, and adjust<br />

the forestay the same way until the main halyard plumb line is parallel distance from<br />

back face of mast. The exact amount of tension on the standing rigging is a matter<br />

of experience and personal preference. Increase the tension until the slack is<br />

reasonably tight - but not as tight as a drum. Finally, and VERY IMPORTANT, see that<br />

the turnbuckle lock nuts are securely tightened and that the turnbuckle fork ends<br />

have at 3/8" remaining in each end of the barrel to avoid rigging damage in severe<br />

conditions. To prevent damage to clothing and sails it is good practice to wrap<br />

adhesive tape around turnbuckles and pins.<br />

Further adjustment of the standing rigging is usually necessary after sailing in<br />

variable wind conditions. If heavy weather helm is noticeable in medium airs, then<br />

the mast rake must be moved forward. If a lea helm persists and the boat will not<br />

point well to weather then the mast rake must be increased aft. Adjustments to<br />

correct the problem should be made in stages. Reducing sail area in extremely<br />

strong winds will minimize weather helm.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 8

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 9

4. The Sails<br />

(a) Nomenclature:<br />

The forward edge of the mainsail and jib is called the LUFF. In the case of the jib<br />

there is an internal wire running up the luff, whereas the mainsail has a rope edge<br />

(the luff rope) attached to the luff. The lower edge of the sail is called the FOOT, and<br />

the other edge the LEECH. There are four pockets extending into the mainsail from<br />

its leech and four battens are provided to stiffen the after edge of the sail. The<br />

corners of the sail are provided with eyes called CRINGLES. The top corner of each<br />

sail is its HEAD; the forward bottom corner its TACK and the aft bottom corner its<br />

CLEW. At the head of the mainsail there is a small triangular stiffener, or headboard.<br />

The mainsail is attached to the mast by sliding the luff rope into the mast groove.<br />

and similarly to the boom by sliding the foot rope into the groove on top of the<br />

boom.<br />

The jib is attached to the forestay by clips or hanks secured to its luff wire, which<br />

can slide up and down the forestay, and the jib tack is secured by a "D" shackle to<br />

the aft hole of the bowplate. The topping lift is attached to the end of the boom with<br />

a "D" shackle and the other end cleated at the mast after leveling the boom<br />

horizontally.<br />

Bending the Sails: see figure 5,<br />

(b) Mainsail:<br />

Insert boom (gooseneck) on to the mast (refer to 2b)<br />

Thread the mainsail foot Cl into the groove of the boom by inserting the clew end of<br />

the foot into the tack end of the boom and pull along until fully drawn.<br />

Secure the tack of the mainsail (lower forward cringle) C2 by inserting the split pin<br />

through the boom fitting and sail cringe, then pull the foot of the sail taut, and<br />

secure the clew cringle C3 by attaching the cord outhaul C4 through the boom end<br />

fitting B2 and-cleat securely.<br />

Insert sail battens, three C5 and one C6 into the pockets on the leech of the<br />

mainsail. You will notice that the entrance slot for each batten is offset so that the<br />

end of Ithe batten- above the position ultimately occupies it.<br />

Connect the headboard of the mainsail C4 to the end of the main halyard A4.<br />

(c) Jibsail<br />

Attach the tack cringle E2 of the jib to the rear hole in the bowplate A24 using a "D"<br />

shackle.<br />

Snap jib hanks E3 onto forestay wire A9, and take care that none are fastened<br />

upside down as that would twist the luff wire of the jib.<br />

Attach the shackle of the jib halyard A15 to the head cringle E4 of the jib.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 10

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 11

5. Jibsheet and Mainsheet arrangements<br />

(a) Jibsheets: see figure 5,<br />

Reeve jibsheet F2 (3/8" x 40ft. Dacron line) through the jib clew E1 until it is even<br />

on both sides. Knot each side of the clew eye with a single overhand knot.<br />

Pass lines one each side of front face of mast and reeve each end through the jib<br />

sliding block F3 located on port and starboard side decks near cabin window. Pass-<br />

each sheet end through the jamb cleat combination block eye Fl. Tie a figure eight<br />

knot close to the end of each sheet to stop it escaping the eye.<br />

(b) Mainsheet: see figure 6,<br />

Attach the swivel of the single sheave block D1 to the link plate B2 at the clew end of<br />

the boom.<br />

Attach the swivel end of the 2-sheave sister jamb cleat block D3 to the slide on the<br />

mainsheet track A26 with a "D" shackle.<br />

Reeve the mainsheet (3/8" x 45 ft. dacron line) D2 by attaching one end to top<br />

sheave of block D3 with a bowline knot and then threading the other end through the<br />

back sheaves, per figure 6.<br />

6. Transom Track arrangement (sheet-horse): see figure 6<br />

The travel of the mainsheet track slide is controlled manually by two stops on the<br />

sheet-horse (track) A26. For light airs the stops should be moved up tight against<br />

each side of the slide in the centre of the track. In medium airs, set approximately 6"<br />

each side of the slide to allow a total travel of 12" for the slide. This can be increased<br />

if necessary for strong winds to the full extent of the track. For competitive racing<br />

the slide may be controlled by lines and jamb cleats to facilitate adjustments while<br />

sailing in variable wind conditions.<br />

Hoisting the sails<br />

(a) Always try to have the boat head to wind before hoisting the sails. The jib sail<br />

should always be hoisted first and hauling on the jib halyard until the sail is fully<br />

raised. The aim is make the luff of the jib as taut as possible. Failure to do this will<br />

inevitably be detrimental to sailing performance. It helps to have someone pull on<br />

the forestay when taking up the final tension before cleating the jib halyard. Some<br />

owners use a jib tensioner that is attached to the mast track.<br />

To hoist the mainsail the head of the luff rope should be introduced to the throat at<br />

the lower end of the luff rope groove on the mast. Loosen off the locking screw of<br />

the gooseneck slide and then hoist the sail fully up and cleat the main halyard<br />

securely. Pull down on the boom and the gooseneck until the luff of the sail is taut.<br />

Then tighten the thumbscrew on the gooseneck to lock it in the slide on the mast.<br />

Tautness of luff depends on wind conditions, therefore you should not try to force the<br />

boom down to exactly the same position on each occasion. In light winds the luff can<br />

be left slacker, and pulled taut in heavier winds. Adjust the boom topping lift loosely<br />

for light airs so that the leech of the mainsail remains taut. Tighten for heavy airs to<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 12

open leech. If the sail has a very full luff, then a cunningham line should be used to<br />

tighten the excess luff to flatten the sail for heavy airs.<br />

(b) Boom tackle: see figure 6<br />

To control the extent to which the boom can lift when sailing. a tackle known as a<br />

kicking strap, or boom vang, is provided. In its simplest form it comprises a short<br />

wire strop attached to the mast bracket at one end and the other end of a vee jamb<br />

block with a "D" shackle and clevis pin. Another block with a special keyhole lug is<br />

snapped into the fitting underneath the boom. A lanyard is reeved through the two<br />

blocks to provide a multi purpose tackle so that by pulling on the end of the lanyard<br />

considerable tension can be applied, to suit various wind conditions, i.e. the more<br />

wind the tighter the kicking strap should be. The lanyard is locked in the block with<br />

the vee groove.<br />

Reefing the mainsail see figure 7<br />

If the wind is too strong to permit use of the full mainsail, this can be reefed by<br />

rolling it around the boom. To do this the sail should be hoisted, then the boom<br />

should be withdrawn aft until it disengages from the squared end of the pin.<br />

This can be carried out by pulling from the clew end of the boom while the main<br />

halyard is eased off, and rotating the boom manually until the sail is reduced by the<br />

required amount. The boom should be snapped back onto the squared end pin to<br />

prevent it rotating under the pull of the reefed sail, and the main halyard secured.<br />

Rolling the sail around the boom covers up the kicking strap fitting on the<br />

underneath of the boom. A roller reefing strap must, therefore, be used. This is a<br />

triangular piece of canvas with a nylon ring in one corner, and which is rolled up in<br />

the sail in the area of the boom fitting. Lay the short side along the boom, with the<br />

vertical edge forward and the ring at the bottom. One complete revolution inside the<br />

sail will provide sufficient friction to keep the strap in place. Connect the kicking<br />

strap block to the nylon ring with a shackle, after removing the key lug.<br />

An alternative method is a clew ring rigged with a wire to the aft end of the boom, or<br />

a special reefing kicking strop device. Jiffy, or slab reefing is an efficient and easy to<br />

operate method.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 13

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 14

8. Getting Afloat<br />

Having learned how to bend (rig) and hoist the sails by practicing ashore several<br />

times, the boat should be launched with the sails lowered. The boat should be<br />

secured to a dock or mooring.<br />

IT IS MOST IMPORTANT TO WATCH FOR LOW OVERHEAD HYDRO WIRES when<br />

stepping the mast prior to launching and again when lowering the mast after<br />

winching on a trailer, especially at an unfamiliar site.<br />

(a) Retractable Keel arrangement: see figure 7,<br />

The operation of the keel, which is raised and lowered manually, must be checked<br />

before preparation for sailing. Move the boat into minimum depth of 3 ft. of water<br />

and lower the keel fully down using the hand crank supplied.<br />

Approximately 95/96 turns anti-clockwise are required to fully lower the keel.<br />

9. Rudder arrangement: see figure 8<br />

The rudder blade attached to the head pivots and should NOT be lowered down fully<br />

until the boat is in water deep enough to clear the bottom of the blade. To install,<br />

hang the rudder assembly § over the transom fittings G1 and G2, gudgeon and<br />

pintle, as shown in figure 5.<br />

Insert the tiller, G4 into the hood at the top of the rudder head and secure it with the<br />

retaining pin provided. To lower the rudder blade to its operating position pull the<br />

shockcord attached to the lanyard forward, and hook eye end of shockcord to<br />

underside hook on tiller. Make sure that rudder blade is fully down tightly. Re-adjust<br />

lanyard to shockcord if more tension is required.<br />

10. Final preparation<br />

Check that the mainsheet is not twisted and that it has been reeved through the<br />

sister block jamb cleat in the correct direction, otherwise it will lock incorrectly. Hoist<br />

sails and make sure the jibsheets are positioned correctly and the ends knotted.<br />

Decide which tack is best to sail out on and lower the keel a little if in shallow<br />

waters, leave the rudder blade up if necessary. Once in deep water lower the keel<br />

and the rudder blade fully.<br />

Note: as an alternative, motor out to deep water, then lower the keel and rudder<br />

blade, head into the wind and hoist the sails and tension the boom vang.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 15

Figure 7<br />

HINTS ON SAILING <strong>THE</strong> <strong>SANDPIPER</strong> <strong>565</strong><br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 16

In light weather you should experience very little trouble with full mainsail and genoa<br />

in handling all points of sailing with your <strong>SANDPIPER</strong> <strong>565</strong>. If you have been used to a<br />

lighter boat you will find the <strong>SANDPIPER</strong> <strong>565</strong> will take just that much longer to tack,<br />

gybe or bear off, so do not at first get too close to moored, or other craft while<br />

underway.<br />

In moderate to heavy weather the answer is to reduce sail by reefing and to use a<br />

small jib. The method of reefing the mainsail has already been explained. To change<br />

jibs when afloat is rather difficult as it means going on the foredeck to reach the<br />

stemhead fitting and the hanks on the forestay. It is, therefore, much better to start<br />

reefed if in doubt when setting out for a sail, than to set off with full sails and have<br />

to reef later. Practice reducing sail in calm weather until the drill becomes easy and<br />

you will have no fears when it does become a necessity.<br />

The <strong>SANDPIPER</strong> <strong>565</strong> handles well in strong winds with reduced sail area, but you<br />

should try to judge the moment to tack so as not to have a large wave prevent you<br />

coming round, but choose a flat spot, and this comes easily with practice.<br />

Running directly downwind can be a little frightening, but have the boomvang really<br />

tight. If rolling conunences pull the mainsheet in, and come up slightly towards the<br />

wind so as to regain control.<br />

Gybing in strong winds does need practice, but if you have plenty of room and it<br />

gives you more confidence, then you can always tack by coming up on the wind<br />

slowly, choose a calm (relative) patch and tack. If you are going to gybe in a strong<br />

wind it may be necessary because of a small change in course or wind direction, or<br />

else it may involve a much larger change in course such as rounding a buoy.<br />

In the former case sail well by the lee, pull in about a foot of mainsheet, choose a<br />

moment when the boat is not slowing or accelerating as the wind pressure on the<br />

sails will then be less, shout 'gybe-oh' when the crew will pull over; the boom, the<br />

boat is kept on a straight course, and as the boom crosses over allow the mainsheet<br />

to go out without a check, helmsman and crew move to the centre of the boat ready<br />

to counter any rolling, re-trim on course.<br />

When rounding a buoy pull the tiller up and execute the gybe in one movement, and<br />

as the boom comes across, the helmsman and the crew must move to windward to<br />

counteract the roll to leeward due to the centrifugal forces in mast and sails.<br />

Helmsman must check the tendency for the boat to come up into the wind, re-trim<br />

sails.<br />

Sailing under Genoa only Do not attempt to sail too close to the wind, gather way,<br />

bring her as close to the wind as she will lie. To tack, throw off the sheets and put<br />

the helm down, do not put the helm down until the sheets are thrown free then<br />

make use of the boats way to put her about. If for some reason (lack of practice)<br />

you cannot tack her, then gybe round, and once round bring her slowly into the wind<br />

again.<br />

Sailing under Mainsail only. Generally speaking in the lighter winds it is far easier<br />

to sail under main only than genoa only. Make sure you have plenty of way on before<br />

tacking. Gybing is done in the same manner as when the genoa is set as well as the<br />

main.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 17

Sailing without a Rudder. If this has to be done on occasion, e.g. rudder broken,<br />

an 8-ft. oar is loosely lashed to the top of the mainsheet track, the mainsheet is<br />

centered. Balance the boat carefully by sail trimming and weight distribution and it<br />

will be found that the boat can be sailed, tacked and qvbed with accuracy.<br />

In very strong winds it may be necessary to reef down to the spreaders in order to<br />

balance the sails.<br />

Sailing Single-handed. When sailing single-handed give yourself more time to<br />

make maneuvers. When tacking or gybing throw off headsail sheets in good time and<br />

sheet home at your leisure. In order to facilitate handling of foresheets tie them<br />

together and use a piece of tape to prevent the knot loosening.<br />

Point to note. When tacking up very narrow waterways in strong winds you will find<br />

that you make faster progress without a headsail than with one.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario <strong>18</strong>

SAILS<br />

GENERAL MAINENANCE - <strong>SANDPIPER</strong><br />

Sails should always be folded and bagged and stored in a clean dry place for<br />

maximum sail life. Never store sails wet and this applies especially to storing your<br />

spinnaker (or coloured sails) as either dyed Nylon or Dacron sail fabrics tend to bleed<br />

if stored wet and transfer colour to white, or even to a darker shade from a lighter<br />

shade. The wetter or more compressed the fabric the greater the bleeding, such as<br />

stuffed in a sailbag.<br />

WOODWORK<br />

At least twice a season woodwork should be allowed to dry and then thoroughly<br />

coated with boiled linseed oil, or teak oil and rubbed off with a clean soft cloth. If<br />

grain appears to be rough sand lightly with 400 grit sandpaper before oiling.<br />

Woodwork should be oiled before winter storage.<br />

HULL<br />

At the end of the season wash the boat off with warm soapy water, finishing with a<br />

protective coat of boat wax.<br />

MINOR GELCOAT REPAIRS<br />

Sandpaper the area to be repaired with *100 grit sandpaper. Large cracks can be<br />

grooved along the crack, with a pin or knifepoint, to enlarge. Add catalyst to gelcoat<br />

- approximately 5-8 drops per half eggcup. Small Dixie cups are ideal for this<br />

purpose.<br />

Apply catalysed gelcoat to area with small brush or knife. When cured and hard,<br />

sand using wet and dry paper in successively finer grades from #240 to #600. Polish<br />

with rubbing compound, and wax to restore shine. Acetone can be used to clean<br />

tools, brushes and fingers. Catalyse only sufficient gelcoat for immediate use.<br />

Store remainder in a cool place (life 3-4 months approx.)<br />

RETRACTABLE KEEL<br />

If it is found necessary to lubricate the keel screw mechanism, it is best<br />

accomplished in the following manner. With the boat on a trailer or cradle, remove<br />

the TEN screws - five per side - holding the keel casing/table.<br />

Block up the keel under the boat firmly. Remove keel casing/table. Drill out fo\lr<br />

rivets holding the stainless steel plate to the keel housing. Wind the keel handle anticlockwise.<br />

The screw will rise up in the cabin allowing application of grease or oil.<br />

Re-rivet the stainless steel plate to the housing and re-install casing/table.<br />

Reproduced with permission for C&L Boatworks, Fort Erie Ontario 19

- More documents

- Recommendations

GRYC Sandpiper <strong>565</strong> Rigging instructions and general information Reproduced with permission for C&L Boatworks, Fort Erie Ontario 1

- Page 2 and 3: THE SANDPIPER 565 (Rigging Instruct

- Page 4 and 5: GENERAL RIGGING INSTRUCTIONS FOR SA

- Page 6 and 7: Reproduced with permission for C&L

- Page 8 and 9: 2. Running Rigging and the Boom (a)

- Page 10 and 11: 4. The Sails (a) Nomenclature: The

- Page 12 and 13: 5. Jibsheet and Mainsheet arrangeme

- Page 14 and 15: Reproduced with permission for C&L

- Page 16 and 17: Figure 7 HINTS ON SAILING THE SANDP

- Page 18 and 19: Sailing without a Rudder. If this h

Extended embed settings

Inappropriate

You have already flagged this document. Thank you, for helping us keep this platform clean. The editors will have a look at it as soon as possible.

Mail this publication

Delete template.

Are you sure you want to delete your template?

DOWNLOAD ePAPER

This ePaper is currently not available for download. You can find similar magazines on this topic below under ‘Recommendations’.

Save as template?

- Help & Support

- tuxbrain.com

- ooomacros.org

- nubuntu.org

- Terms of service

- Privacy policy

- Cookie policy

- Cookie settings

Choose your language

Main languages

Further languages

- Bahasa Indonesia

Performing this action will revert the following features to their default settings:

Hooray! Your file is uploaded and ready to be published.

Saved successfully!

Ooh no, something went wrong!

ShortyPen.com

- Board Boats

- Day Sailors

- Pocket Cruisers

- Multihull Sailboats

- Contributors

- Shorty Articles

- Contact Shorty

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Roller Furling on a Sandpiper 565

- Thread starter Willybdriver

- Start date Sep 4, 2007

- Brand-Specific Forums

- Other Sailboats

Willybdriver

A friend and I recently acquired Sandpiper #907. There was a lot of extra gear supplied including the hardware for roller furling top and bottom fittings. The small manual mentions the gear but gives little information on its installation. My question is: do you use the cable in the fore sail to replace the forward stay or can the forward stay remain? The rigging is similar to my Hobie 14, which used the cable in the genoa as the fore stay. This leads to another question: do we need to remove the brass clips from the genoa if using it to replace the forestay?

Attachments

Can you identify the furling manufacturer? If you can, go to their website and read (or download) their installation manual. Just about every furling maker has their manual on line.

Sail Into The Sunset

Have You Talked To Guys On The CL Forum Hey Willybdriver have you tried the CL Sailboats Forum Lots of helpful guys there. www.clsailboats.com go to info centre then forum

roller furling Strongly suggest you do not remove the forstay. I have sailed a 565 for 20 years with the furling gear supplied by CL and have had little problem. Raise your sail with the top piece in place and hook the sail to the bottom with a hank so you can change sails when you want. If you use the sail as the forstay you would have to lower the mast in order to change a sail. Regarding the hanks --you may have to remove them if they get tangled,I have. Have fun

Great boat for Simcoe! How it's installed has a lot to do with the hardware you have. If you have just an upper swivel and the lower drum unit, I would suspect that you would use the sails luff. HOWEVER this wire for the furling is usually heavier than the normal wire luff. At least it was for mine. Like John said you'd have to drop the mast to change the sail. This was never a problem for me when I kept the boat ina marina. I had no need to change the sail. One consideration though, is that when the sail is partly furled, the shape isn't the greatest. Usually this setup is more for storage, ie sail fully set when sailing, and fully furled when not. You would need to have the hanks removed from the luff. Personally, I would stick to hank on sails, and sell the furler. Rig up a good main jiffy reef to reduce sail when there's a blow. Where are you going to sail her? I launched at the public ramp at Hawkstone beach once. Very shallow, and there's a hydro line to watch out for. Fair winds Eric

furling question for a Sandpiper Thank you for all your great responses. I will keep all of it in mind. As per your suggestions, I will be keeping the front stay, and using the jib cable for furling. I found a paragraph in the manual dealing with this and by reading between the lines, it basically says to do it this way. The raising of the sail with the halyard to be very tight could be achieved with a single pully on the sail top fitting, not mentioned in the manual. This arrangement is for the young woman who is going to be using the boat most often. She is not comfortable walking around on the fore deck. I like simplicity but must consider her needs. I live at the Hawkestone Yacht Club on the bottom of Mill St. with the road allowance and lake beside my house. This is where she will be launching until she becomes a member of our club and eventually gets a slip. For the moment she can trailer it home, just up the road, then maybe as a daysailer member keep it, mast up, in the back parking lot.

I'd be willing to look it over;D Will cost you a sail of course;D I rigged a simple jib downhaul, to quickly dowse the sail. Let me know if you need a hand. I'm just a short drive away! Cheers

Come have a sail Sandy and I have rigged the furling, lights and the hitch on her truck. The Honda 4 stroke has been a pain for it didn't come with a fuel tank or hose. The young lady found they leaked and thru it away. We have not been able to find a source for the Honda fitting for the new little tank she bought. Frustration has set in major but we are going to launch this boat tomorrow morning around 9:00am and have ourselves a sail. Then paddle to the club and tie up at their dock for a day or so until the motor issue gets resolved. You are most welcome to come over, it would be a privilege to have someone with knowledge about this sweet little boat. Sandy is the owner, she lives on Mill St. in Hawkestone, the boat is right in front in her driveway. Hope to see you tomorrow.

Sandpiper 565 sailboat Great Sandpiper 565 reference site

I own 909! Hi I own Sanpiper Sail 909 just bought in July. Live in Regina, SK Curious, what year is your boat?

I own 909! e-mail sorry my e-mail is [email protected] e-mail me. Thanks, Steve

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

Tip: There is also another method ( hit/miss ) of accessing older messages using search engines like trying this; go to www.google.com then type in your keyword to be searched followed by a space and then site:www.xxx.com Remember it is hit and miss, as all messages may have not have been indexed by the search engine. If the link to the page you want is missing, then click on the Cached page that was copied and stored on Google. -- For ex: hull site:www.sandpiper565.com will return 10 results for the word hull -- For ex: keel site:www.vaxxine.com/clsailboats will return 221 results for the word keel -- For ex: sandpiper site:www.sailboatowners.com will return 249 results for the word sandpiper -- For ex: sandpiper site:bbs.trailersailer.com will return 55 results for the word sandpiper " Personally", it doesn't feel the same as visiting any of the forums in person and conversing with all the community to acquire information, but if you are in dire need of technical help for a major problem or part, "you got to do, what you have to do".

× You are using an outdated browser. Please upgrade your browser to improve your experience.

We Ship Worldwide! | FREE SHIPPING! for US Continental orders over $99. Click for details.

Shopping Cart

Your cart is currently empty..

FREE SHIPPING! for US Continental orders over $99 click for details

Sandpiper - Sailboat Data, Parts & Rigging

Sailboat data directory for sailboats manufacturer or named Sandpiper. Follow the provided links for additional sailboat data, parts and rigging specs.

Sailboat Data directory for over 8,000 sailboat designs and manufacturers. Direct access to halyards lengths, recommended sail areas, mainsail cover styles, standing rigging fittings, and lots more for all cruising and racing sailboats.

MAURIPRO Sailing offers a full range of sailboat and sailing information to help you find the correct sailboat part, one that properly would fit your sailboat and sailing style. Our sailor's and sailboat owner support team are ready to talk with you about your specific sailing needs, coming regatta, or next sailing adventure.

From all at MAURIPRO, let's Go Sailing!

Copyright © 2024 MAURIPRO Sailing LLC.

IMAGES

VIDEO

COMMENTS

The SANDPIPER 565 was first manufactured in 1972 by Sandpiper Marine Ltd. of Southampton, England. Later built by CL Sailboats (formerly C&L Boatworks) of Canada. (Royalties not paid) Another version was built under license in Sweden called OCKELBO OS 19.

The Sandpiper 565 is trailerable sailboat that was designed by the British-based Portuguese naval architect Leonardo da Costa Sayago and first built in 1972. The design is out of production. ... A Sandpiper 565 mooring with the keel up, in shallow water Sandpiper 565. The Sandpiper 565 is a small recreational keelboat, ...

T he Sandpiper 565 was designed by Leonardo da Costa Sayago (C. Eng, M.R.N.A.) in Southampton England on December 16, 1971 as a fast week-ender sailboat. T he Sandpiper 565 was an English Channel Craft manufactured first by Messrs, Sandpiper Marine LTD. of Southampton, England in 1972, and then was built under licence by C & L Boatworks ...

The Sandpiper 565 is a 18.5ft fractional sloop designed by Leonardo da Costa Sayago and built in fiberglass by C&L Boatworks since 1972. 1500 units have been built. The Sandpiper 565 is a light sailboat which is a high performer. It is stable / stiff and has a low righting capability if capsized. It is best suited as a day-boat.

Sandpiper 565 is a 18′ 6″ / 5.6 m monohull sailboat designed by Leonardo da Costa Sayago and built by C&L Boatworks starting in 1972. ... The SANDPIPER 565 was first manufactured in 1972 by Sandpiper Marine Ltd. of Southampton, England. Later built by CL Sailboats (formerly C&L Boatworks) of Canada. (Royalties not paid)

SANDPIPER 565 SAILBOAT OWNERS GROUP www.sandpiper565.com, [email protected]: Specifications: Sandpiper 565 ... it is starting to be a heavy load to pull behind a family car. People interested in the Sandpiper 565 may also want to look at the Edel 540 or the Wegu 18.

The SANDPIPER 565 sailing sloop was first manufactured in 1972 by Messrs. Sandpiper Marine Ltd. of Southampton, England, and was built under licence by C&L Boatworks located in Fort Erie, Ontario. This seaworthy and stable yacht has many desirable features, and with its' retractable keel is so adaptable for trailering, launching and beaching ...

Catalog excerpts. Rigging instructions and general information Reproduced with permission for C&L Boatworks, Fort Erie Ontario. Open the catalog to page 1. (Rigging Instructions from the Original owners manual - circa 1973) The SANDPIPER 565 sailing sloop was first manufactured in 1972 by Messrs. Sandpiper Marine Ltd. of Southampton, England ...

The Sandpiper 565 is a small sailboat designed by the Portugees maritime architect Leonardo da Costa Sayago in the early seventies. A few thousand boats have been produced. ... The immersion rate for Sandpiper 565 is about 66 kg/cm, alternatively 370 lbs/inch. Meaning: if you load 66 kg cargo on the boat then it will sink 1 cm. Alternatively ...

Sailboats Built By C&L Boatworks ... SANDPIPER 565: 18.50 ft / 5.64 m: 1972: STEALTH: 14.47 ft / 4.41 m: 2006: ShipCanvas. KiwiGrip. Bruntons. Rudder Craft. ... We use technologies like cookies to store and/or access device information. We do this to improve browsing experience and to show (non-) personalized ads. ...

Complete Sail Plan Data for the Sandpiper 565 Sail Data. Sailrite offers free rig and sail dimensions with featured products and canvas kits that fit the boat. ... Sailboat Data ; Sandpiper 565 Sail Data ; Sandpiper 565 Sail Data. Pinit. SKU: X-SD-5118 . Quantity discounts available . Quantity Price; Quantity -+ Add to Cart . Details. Details ...

Sailboat data, rig dimensions and recommended sail areas for Sandpiper 565 sailboat. Tech info about rigging, halyards, sheets, mainsail covers and more.

Sandpiper 565 Sailboat 1984 - negotiable - w/trailer. Equipment: Retractable weighted keel, Draft 0.83' up, 2.90' down. 18.5 feet long, 7 feet wide. Weight 1200lbs. Asking $4200 USD or $4999 CDN. Fun, stable easily trailerable sailboat with roomy cockpit. Light enough to tow with many small cars.

The Sandpiper 565 is based on that same design but with some major differences. About 800 Sailfish 18's were built in England and even a very few Sailfish 19's were built. There is even a larger Sailfish sailboat design called the Sailfish 25's but its numbers produced were about 25.

Sandpiper Marine Ltd. of Southampton, England, and was built under licence by C&L<br />. Boatworks located in Fort Erie, Ontario<br />. This seaworthy and stable yacht has many desirable features, and with its'<br />. retractable keel is so adaptable for trailering, launching and beaching that its owners<br />.

2024-01-30 by: Frank I've owned two of these over many years of sailing and multiple boats. While not fast, they sail well and give the feeling of a much larger boat than their length or displacement would suggest.

Discussion of the Sandpiper 565 sailboat manufactured by C&L Boatworks.

You must be logged in to create new topics. Log In. Username:

Sep 6, 2007. 1. - - Gananoque. Sep 6, 2007. #4. roller furling Strongly suggest you do not remove the forstay. I have sailed a 565 for 20 years with the furling gear supplied by CL and have had little problem. Raise your sail with the top piece in place and hook the sail to the bottom with a hank so you can change sails when you want.

Pre-Spec sailboat sheets for your Sandpiper 565. Genoa, gennaker and spinnaker shets to fit your cruising or racing sailing style. Full range of options. MAURIPRO Rigging shop brings years of expertise to the sailing community. Our riggers are constantly working with sailboat owners to provide high-quality genoa, mainsail and spinnaker sheets ...

Sandpiper 565 Owners group. Related Sailboats: 1 Sailboats / Per Page: 25 / Page: 1. 0 CLICK to COMPARE . MODEL LOA FIRST BUILT FAVORITE COMPARE; SANDPIPER 565: 18.50 ft / 5.64 m: 1972: ShipCanvas. KiwiGrip. Bruntons. Rudder Craft. EWOL. SBD App Non-BR ...

Sailboat Owners, Forum Sandpiper 565: Trailer Sailor, Best to use keyword searches eg: sandpiper, 565, etc.. The Boaters, go to Groups & Forums, search for Sandpiper. Sailnet, Forum Sandpiper 565: Wikipedia Sandpiper 565, The free encyclopedia site that you can edit and add more information about Sandpipers.

Follow the provided links for additional sailboat data, parts and rigging specs. Sailboat Data directory for over 8,000 sailboat designs and manufacturers. Direct access to halyards lengths, recommended sail areas, mainsail cover styles, standing rigging fittings, and lots more for all cruising and racing sailboats.