- Paddle Board

What Is a Sailboat Rudder? An Overview of Its Function and Design

Sailboats have been used for thousands of years to traverse water. They have undergone many changes and improvements over the years, and one of the essential components of a sailboat is the rudder.

Quick Facts

Understanding the sailboat rudder.

The rudder is a vital component of a sailboat that plays a crucial role in steering and maneuvering the vessel. The rudder works by changing the direction of the water flow around it, which moves the boat in the opposite direction. Without a rudder, it would be impossible to navigate a sailboat effectively, especially in different water and wind conditions.

Components of a Sailboat Rudder

A sailboat rudder comprises several components, each with a unique function that contributes to the rudder’s overall effectiveness. The stock is the main vertical shaft that connects the rudder blade to the boat’s helm. It is usually made of stainless steel or aluminum alloy and is designed to withstand the forces exerted on the rudder during navigation.

The blade is the flat portion of the rudder that faces the water current and directs the water flow in the opposite direction to steer the boat. The blade is typically made of fiberglass-reinforced plastic or aluminum alloy and is designed to be lightweight and durable. Pintles and gudgeons are the two connections between the rudder and stern that allow for easy installation and removal of the rudder. Pintles are the vertical metal pins that fit into the gudgeons, which are the horizontal metal brackets attached to the boat’s stern.

Different Types of Rudders

There are several types of rudders used in sailboats, each with its advantages and disadvantages. Transom-mounted rudders are the most common type of rudder, and they are mounted on the stern of the boat. Skeg-mounted rudders are attached to a fixed fin called a skeg, which provides additional stability to the rudder.

Keel-mounted rudders are attached to the boat’s keel, which is the central structural element that runs along the bottom of the hull. Spade rudders are free-standing rudders that are not attached to any part of the boat and are commonly used in racing sailboats. The type of rudder used depends on the boat’s size, design, and intended use.

Materials Used in Rudder Construction

Rudders can be made from various materials, each with its advantages and disadvantages. Wooden rudders are the traditional choice and are still used in some sailboats today. However, they are relatively heavy and require regular maintenance to prevent rot and decay.

Aluminum alloy rudders are lightweight and durable, making them an excellent choice for racing sailboats. Stainless steel rudders are also durable but are heavier than aluminum alloy rudders. Fiberglass-reinforced plastic rudders are the most common type of rudder used today, as they are lightweight, durable, and require minimal maintenance.

The sailboat rudder is an essential component that plays a crucial role in steering and maneuvering a sailboat. Understanding the different types of rudders, their components, and the materials used in their construction can help sailors choose the right rudder for their boat and navigate more effectively in different water and wind conditions.

The Function of a Sailboat Rudder

Steering and maneuvering.

The primary function of a sailboat rudder is to steer and maneuver the boat. The rudder’s blade directing the flow of water in a specific direction allows for the steering of the boat as the blade changes direction. Sailors can use the rudder to turn the boat in any direction they choose, allowing them to navigate through narrow channels or around obstacles in the water. It is essential to note that the rudder works in conjunction with the sails to control the boat’s direction and speed.

Balancing the Sailboat

The balance of the sailboat is critical to ensure safe maneuvering, and the rudder plays a crucial role in achieving this. A balanced rudder helps in keeping the boat steady, reducing drag, and preventing unwanted turning. Sailors can adjust the rudder’s angle to keep the boat balanced and on course, especially in rough water conditions. A well-balanced rudder also helps to reduce the risk of capsizing or losing control of the boat .

Rudder Effectiveness in Different Conditions

Rudder effectiveness varies depending on the boat’s size, weight, and water and wind conditions. A larger boat may require a bigger rudder for proper maneuvering, while a smaller boat can work with a smaller rudder. Sailors must also consider the water and wind conditions when choosing the right rudder for their boat. In calm waters, a smaller rudder may be sufficient, but in rough water, a larger rudder may be necessary to maintain control of the boat. Additionally, the rudder’s effectiveness can be affected by the boat’s speed, with higher speeds requiring more significant rudders to maintain control.

It is also important to note that the rudder’s effectiveness can be impacted by external factors such as weeds or debris in the water. These factors can reduce the rudder’s ability to steer the boat and require sailors to make adjustments to maintain control. Additionally, the rudder’s effectiveness can be impacted by the sailor’s skill level, with more experienced sailors able to make more precise adjustments to the rudder to control the boat’s direction and speed.

Design Considerations for Sailboat Rudders

Sailboat rudders are an essential component of a boat’s steering and maneuvering system. A well-designed rudder can make all the difference in a boat’s performance , especially in challenging weather conditions. In this article, we will explore some of the key design considerations for sailboat rudders.

Rudder Size and Shape

The size and shape of a rudder play a crucial role in determining its effectiveness in steering and maneuvering a boat. A larger rudder provides more leverage and maneuverability, allowing the boat to turn more sharply. However, a larger rudder may also produce more drag, which can slow down the boat’s speed.

The shape of the rudder is also important. A well-designed rudder should be streamlined to reduce drag and turbulence. The thickness of the rudder should be carefully considered to ensure that it is strong enough to withstand the forces exerted on it while remaining lightweight.

Rudder Placement and Configuration

The placement of the rudder on the boat can significantly affect its performance. A rudder that is too far forward can cause the boat to become unstable, while a rudder that is too far aft can make it difficult to steer. The location of the rudder must also take into account factors such as the propeller’s placement and the boat’s shape.

The configuration of the rudder can also determine its effectiveness and balance. A single rudder is the most common configuration, but some boats have twin rudders to provide more steering control. The angle of the rudder blade can also be adjusted to optimize its performance.

Hydrodynamic and Aerodynamic Factors

The design of a rudder must take into consideration the hydrodynamic and aerodynamic factors affecting the boat’s performance. Hydrodynamic factors include water flow, pressure, and turbulence, which can significantly affect the rudder’s performance. The shape and placement of the rudder must be carefully designed to minimize these effects.

Aerodynamic factors consider the wind and air resistance’s impact on the boat’s performance. The rudder’s size and shape must be designed to minimize the wind’s effect on the boat while providing sufficient steering control.

The design of a sailboat rudder is a complex process that requires careful consideration of many factors. The size and shape of the rudder, its placement on the boat, and its configuration must be optimized to provide effective steering and maneuverability. By taking into account the hydrodynamic and aerodynamic factors affecting the boat’s performance, a well-designed rudder can significantly improve a sailboat’s overall performance.

Rudder Maintenance and Repair

The rudder is a crucial component of any sailboat, providing steering and control. As such, it’s essential to keep it in good working order through regular maintenance and inspections.

Inspecting Your Rudder

Regular inspection of the rudder is essential to ensure its continued performance and longevity. A thorough inspection includes checking for cracks, wear and tear, and loose components such as hinges, pins, and screws. It’s also important to check the rudder’s alignment and ensure it moves smoothly and without any obstructions.

During your inspection, be sure to check for signs of corrosion, particularly on metal components. Corrosion can weaken the rudder and cause it to fail, so regular cleaning and maintenance are essential to prevent this.

If you notice any issues during your inspection, it’s important to address them promptly. Small cracks or damage can often be repaired, but if the damage is extensive, it may be necessary to replace the rudder entirely.

Common Rudder Issues and Solutions

One common issue with rudders is corrosion, particularly on metal components. Regular cleaning and maintenance help prevent corrosion and ensure the rudder’s longevity. If you do notice signs of corrosion, it’s important to address it promptly to prevent further damage.

Another common issue is damage to the blade or stock. This can be caused by impact with debris or other boats, or simply wear and tear over time. If the damage is minor, it may be possible to repair the rudder. However, if the damage is extensive or compromises the rudder’s structural integrity, it may be necessary to replace it entirely.

Loose components such as hinges, pins, and screws can also cause issues with the rudder. These should be checked regularly and tightened or replaced as needed.

When to Replace or Upgrade Your Rudder

Sailboat rudders can last for many years, but at some point, replacement or upgrade may be necessary. This includes upgrading to a newer design or larger rudder to improve the boat’s performance or replacing a damaged or worn-out rudder that is beyond repair.

If you’re considering upgrading your rudder, it’s important to consult with a professional to ensure that the new rudder is compatible with your boat and will provide the desired performance improvements.

Regular maintenance and inspections are essential to ensure the continued performance and longevity of your sailboat’s rudder. By staying on top of any issues and addressing them promptly, you can ensure that your rudder will continue to provide reliable steering and control for many years to come.

A sailboat’s rudder is a crucial component that helps steer and maneuver the boat safely. The size, shape, placement, and construction materials must all be taken into consideration when designing or replacing a rudder. Regular maintenance and inspection help ensure its continued performance and longevity.

Rudder FAQS

How does a sailboat rudder work.

A sailboat rudder works by changing the direction of the water flow past the boat’s hull, which in turn changes the direction of the boat. The rudder is attached to the stern of the boat and can be turned left or right. When the rudder is turned, it creates a force that pushes the stern in the opposite direction and turns the bow towards the direction the rudder is turned. This is how a rudder steers a boat.

What is a rudder and its purpose?

A rudder is a flat piece, usually made of metal or wood, attached to the stern of a vessel such as a boat or ship. The main purpose of the rudder is to control the direction of the vessel. It does this by deflecting water flow, creating a force that turns the vessel. Without a rudder, steering a vessel would be significantly more challenging.

Can you steer a sailboat without a rudder?

Steering a sailboat without a rudder is challenging but not impossible. Sailors can use the sails and the keel to influence the direction of the boat. By trimming the sails and shifting weight, it’s possible to cause the boat to turn. However, this is a difficult technique that requires a deep understanding of sailing dynamics and is usually considered a last resort if the rudder fails.

What controls the rudder on a sailboat?

The rudder on a sailboat is typically controlled by a steering mechanism, like a tiller or a wheel. The tiller is a lever that is directly connected to the top of the rudder post. Pushing the tiller to one side causes the rudder to turn to the opposite side. On larger boats, a wheel is often used. The wheel is connected to the rudder through a series of cables, pulleys, or hydraulic systems, which turn the rudder as the wheel is turned.

How do you steer a sailboat with a rudder?

To steer a sailboat with a rudder, you use the tiller or wheel. If your sailboat has a tiller, you’ll push it in the opposite direction of where you want to go – pushing the tiller to the right will turn the boat to the left and vice versa. If your sailboat has a wheel, it operates like a car steering wheel – turning it to the right steers the boat to the right and turning it to the left steers the boat to the left.

How do you steer a sailboat against the wind?

Steering a sailboat against the wind, also known as tacking, involves a maneuver where the bow of the boat is turned through the wind. Initially, the sails are let out, and then the boat is steered so that the wind comes from the opposite side. As the boat turns, the sails are rapidly pulled in and filled with wind from the new direction. This maneuver allows the boat to zigzag its way upwind, a technique known as “beating.” It requires skill and understanding of sailing dynamics to execute effectively.

John is an experienced journalist and veteran boater. He heads up the content team at BoatingBeast and aims to share his many years experience of the marine world with our readers.

What to Do If Your Boat Engine Won’t Start? Common Problems & How to Fix Them

How to launch a boat by yourself: complete beginner’s guide, how to surf: complete beginner’s guide to get you started.

Comments are closed.

Type above and press Enter to search. Press Esc to cancel.

My Cruiser Life Magazine

All About the Rudder on a Sailboat

The rudder on a sailboat is one of those important parts that often gets overlooked. It’s hidden underwater most of the time and usually performs as expected when we ask something of it.

But when was the last time you seriously considered your sailboat rudder? Do you have a plan if it fails? Here’s a look at various designs of sail rudder, along with the basics of how it works and why it’s there.

Table of Contents

How are sailboat rudders different than keels, how does the rudder work, wheel steering vs. tiller steering, full keel rudder sailboat, skeg-hung rudders, spade rudder, variations on designs, emergency outboard rudder options, looking to sail into the sunset grab the wheel, steer your sail boat rudder, and get out there, sail boat rudder faqs.

What Is a Boat Rudder?

The rudder is the underwater part of the boat that helps it turn and change direction. It’s mounted on the rear of the boat. When the wheel or tiller in the cockpit is turned, the rudder moves to one side or another. That, in turn, moves the boat’s bow left or right.

When it comes to sailing, rudders also offer a counterbalance to the underwater resistance caused by the keel. This enables the boat to sail in a straight line instead of just spinning around the keel.

Sailboat hull designs vary widely when you view them out of the water. But while the actual shape and sizes change, they all have two underwater features that enable them to sail–a rudder and a keel.

The rudder is mounted at the back of the boat and controls the boat’s heading or direction as indicated by the compass .

The keel is mounted around the center of the boat. Its job is to provide a counterbalance to the sails. In other words, as the wind presses on the sails, the weight of the ballast in the keel and the water pressure on the sides of the keel keeps the boat upright and stable.

When sailing, the keel makes a dynamic force as water moves over it. This force counters the leeway made by air pressure on the sails and enables the boat to sail windward instead of only blowing downwind like a leaf on the surface.

The rudder is a fundamental feature of all boats. Early sailing vessels used a simple steering oar to get the job done. Over the years, this morphed into the rudder we know today.

However, thinking about a rudder in terms of a steering oar is still useful in understanding its operation. All it is is an underwater panel that the helmsperson can control. You can maintain a course by trailing the oar behind the boat while sailing. You can also change the boat’s heading by moving it to one side or the other.

The rudders on modern sailboats are a little slicker than simple oars, of course. They are permanently mounted and designed for maximum effectiveness and efficiency.

But their operating principle is much the same. Rudders work by controlling the way water that flows over them. When they move to one side, the water’s flow rate increases on the side opposite the turn. This faster water makes less pressure and results in a lifting force. That pulls the stern in the direction opposite the turn, moving the bow into the turn.

Nearly all boats have a rudder that works exactly the same. From 1,000-foot-long oil tankers to tiny 8-foot sailing dinghies, a rudder is a rudder. The only boats that don’t need one are powered by oars or have an engine whose thrust serves the same purpose, as is the case with an outboard motor.

Operating the Rudder on a Sailboat

Rudders are operated in one of two ways–with a wheel or a tiller. The position where the rudder is operated is called the helm of a boat .

Ever wonder, “ What is the steering wheel called on a boat ?” Boat wheels come in all shapes and sizes, but they work a lot like the wheel in an automobile. Turn it one way, and the boat turns that way by turning the rudder.

A mechanically simpler method is the tiller. You’ll find tiller steering on small sailboats and dinghies. Some small outboard powerboats also have tiller steering. Instead of a wheel, the tiller is a long pole extending forward from the rudder shaft’s top. The helmsperson moves the tiller to the port or starboard, and the bow moves in the opposite direction. It sounds much more complicated on paper than it is in reality.

Even large sailboats will often be equipped with an emergency tiller. It can be attached quickly to the rudder shaft if any of the fancy linkages that make the wheel work should fail.

Various Sail Boat Rudder Designs

Now, let’s look at the various types of rudders you might see if you took a virtual walk around a boatyard. Since rudders are mostly underwater on the boat’s hull, it’s impossible to compare designs when boats are in the water.

Keep in mind that these rudders work the same way and achieve the same results. Designs may have their pluses and minuses, but from the point of view of the helmsperson, the differences are negligible. The overall controllability and stability of the boat are designed from many factors, and the type of rudder it has is only one of those.

You’ll notice that rudder design is closely tied to keel design. These two underwater features work together to give the boat the sailing characteristics the designer intended.

The classic, robust offshore sailboat is designed with a full keel that runs from stem to stern. With this sort of underwater profile, it only makes sense that the rudder would be attached to the trailing edge of that enormous keel. On inboard-powered sailboats, the propeller is usually mounted inside an opening called the aperture between the keel and rudder.

The advantages of this design are simplicity and robustness. The keel is integrated into the hull and protects the rudder’s entire length. Beyond reversing into an obstacle, anything the boat might strike would hit the keel first and would be highly unlikely to damage the rudder. Not only does the keel protect it, but it also provides a very strong connection point for it to be attached to.

Full keel boats are known for being slow, although there are modern derivatives of these designs that have no slow pokes. Their rudders are often large and effective. They may not be the most efficient design, but they are safe and full keels ride more comfortably offshore than fin-keeled boats.

Plenty of stout offshore designs sport full keel rudders. The Westsail 38s, Lord Nelsons, Cape Georges, Bristol/Falmouth Cutters, or Tayana 37s feature a full keel design.

A modified full keel, like one with a cutaway forefoot, also has a full keel-style rudder. These are more common on newer designs, like the Albergs, Bristols, Cape Dorys, Cabo Ricos, Island Packets, or the older Hallberg-Rassys.

A design progression was made from full keel boats to long-fin keelboats, and the rudder design changed with it. Designers used a skeg as the rudder became more isolated from the keel. The skeg is a fixed structure from which you can mount the rudder. This enables the rudder to look and function like a full keel rudder but is separated from the keel for better performance.

The skeg-hung rudder has a few of the same benefits as a full keel rudder. It is protected well and designed robustly. But, the cutaways in the keel provide a reduced wetted surface area and less drag underwater, resulting in improved sailing performance overall.

Larger boats featuring skeg-mounted rudders include the Valiant 40, Pacific Seacraft 34, 37, and 40, newer Hallberg-Rassys, Amels, or the Passport 40.

It’s worth noting that not all skegs protect the entire rudder. A partial skeg extends approximately half the rudder’s length, allowing designers to make a balanced rudder.

With higher-performance designs, keels have become smaller and thinner. Fin keel boats use more hydrodynamic forces instead of underwater area to counter the sail’s pressure. With the increased performance, skegs have gone the way of the dinosaurs. Nowadays, rudders are sleek, high aspect ratio spade designs that make very little drag. They can be combined with a number of different keel types, including fin, wing keels , swing keels, or bulb keels.

The common argument made against spade rudders is that they are connected to the boat by only the rudder shaft. As a result, an underwater collision can easily bend the shaft or render the rudder unusable. In addition, these rudders put a high load on the steering components, like the bearings, which are also more prone to failure than skeg or full keel designs. For these reasons, long-distance cruisers have traditionally chosen more robust designs for the best bluewater cruising sailboats .

But, on the other hand, spade rudders are very efficient. They turn the boat quickly and easily while contributing little to drag underwater.

Spade rudders are common now on any boat known for performance. All racing boats have a spade rudder, like most production boats used for club racing. Pick any modern fin keel boat from Beneteau, Jeanneau, Catalina, or Hunter, and you will find a spade rudder. Spade rudders are common on all modern cruising catamarans, from the Geminis to the Lagoons, Leopards, and Fountaine Pajots favored by cruisers and charter companies.

Here are two alternative designs you might see out on the water.

Transom-Hung or Outboard Rudders

An outboard rudder is hung off the boat’s transom and visible while the boat is in the water. Most often, this design is controlled by a tiller. They are common on small sailing dingies, where the rudder and tiller are removable for storage and transport. The rudder is mounted with a set of hardware called the pintle and gudgeon.

Most outboard rudders are found on small daysailers and dinghies. There are a few classic big-boat designs that feature a transom-hung rudder, however. For example, the Westsail 38, Alajuela, Bristol/Falmouth Cutters, Cape George 36, and some smaller Pacific Seacrafts (Dana, Flicka) have outboard rudders.

Twin Sailing Rudder Designs

A modern twist that is becoming more common on spade rudder boats is the twin sailboat rudder. Twin rudders feature two separate spade rudders mounted in a vee-shaped arrangement. So instead of having one rudder pointed down, each rudder is mounted at an angle.

Like many things that trickle down to cruising boats, the twin rudder came from high-performance racing boats. By mounting the rudders at an angle, they are more directly aligned in the water’s flow when the boat is healed over for sailing. Plus, two rudders provide some redundancy should one have a problem. The twin rudder design is favored by designers looking to make wide transom boats.

There are other, less obvious benefits of twin rudders as well. These designs are easier to control when maneuvering in reverse. They are also used on boats that can be “dried out” or left standing on their keel at low tide. These boats typically combine the twin rudders with a swing keel, like Southerly or Sirius Yachts do. Finally, twin rudders provide much better control on fast-sailing hulls when surfing downwind.

Unbalanced vs. Balanced Rudders

Rudders can be designed to be unbalanced or balanced. The difference is all in how they feel at the helm. The rudder on a bigger boat can experience a tremendous amount of force. That makes turning the wheel or tiller a big job and puts a lot of strain on the helmsperson and all of the steering components.

A balanced rudder is designed to minimize these effects and make turning easier. To accomplish this, the rudder post is mounted slightly aft of the rudder’s forward edge. As a result, when it turns, a portion of the leading edge of the rudder protrudes on the opposite side of the centerline. Water pressure on that side then helps move the rudder.

Balanced rudders are most common in spade or semi-skeg rudders.

Sail Rudder Failures

Obviously, the rudder is a pretty important part of a sailboat. Without it, the boat cannot counter the forces put into the sails and cannot steer in a straight line. It also cannot control its direction, even under power.

A rudder failure of any kind is a serious emergency at sea. Should the rudder be lost–post and all–there’s a real possibility of sinking. But assuming the leak can be stopped, coming up with a makeshift rudder is the only way you’ll be able to continue to a safe port.

Rudder preventative maintenance is some of the most important maintenance an owner can do. This includes basic things that can be done regularly, like checking for frayed wires or loose bolts in the steering linkage system. It also requires occasionally hauling the boat out of the water to inspect the rudder bearings and fiberglass structure.

Many serious offshore cruisers install systems that can work as an emergency rudder in extreme circumstances. For example, the Hydrovane wind vane system can be used as an emergency rudder. Many other wind vane systems have similar abilities. This is one reason why these systems are so popular with long-distance cruisers.

There are also many ways to jury rig a rudder. Sea stories abound with makeshift rudders from cabinet doors or chopped-up sails. Sail Magazine featured a few great ideas for rigging emergency rudders .

Understanding your sail rudder and its limitations is important in planning for serious cruising. Every experienced sailor will tell you the trick to having a good passage is anticipating problems you might have before you have them. That way, you can be prepared, take preventative measures, and hopefully never deal with those issues on the water.

What is the rudder on a sailboat?

The rudder is an underwater component that both helps the sailboat steer in a straight line when sailing and turn left or right when needed.

What is the difference between a rudder and a keel?

The rudder and the keel are parts of a sailboat mounted underwater on the hull. The rudder is used to turn the boat left or right, while the keel is fixed in place and counters the effects of the wind on the sails.

What is a rudder used for on a boat?

The rudder is the part of the boat that turns it left or right

Matt has been boating around Florida for over 25 years in everything from small powerboats to large cruising catamarans. He currently lives aboard a 38-foot Cabo Rico sailboat with his wife Lucy and adventure dog Chelsea. Together, they cruise between winters in The Bahamas and summers in the Chesapeake Bay.

Leave a comment

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

What is a Sailboat Rudder?

Last Updated by

Daniel Wade

June 15, 2022

A sailboat rudder steers the boat. A rudder is a hinged fin or blade mounted on the stern of the vessel that turns side to side, and it's controlled by a tiller or a helm.

A rudder is one of the primary controls of a sailboat. When the boat moves forward through the water, the rudder causes friction on one side and changes the direction of the boat. Rudders are controlled by moving a tiller side to side or by a helm and a complex linkage system. Rudders are delicate and sometimes flush with and protected by the keel.

Table of contents

Identifying the Rudder

Rudders are connected to the sailboat using a hinge or a shaft. The rudder is always located in the water behind the boat, but some rudders have part of their structure exposed above the waterline. Rudders that aren't visible above the waterline are usually underneath the stern and controlled by a vertical shaft that descends through the bottom of the boat.

Rudder Design

Rudder design varies widely between boats. Some vessels have large, ornate rudders that are exposed above the waterline. Large rudders are common on catboats, canoe yawls, and other traditional designs.

Many modern boats use small, blade-like rudders that are hidden from view. The size of a rudder doesn't necessarily correlate with its effectiveness, but an improperly sized rudder can cause significant issues.

How Does a Sailboat Rudder Work?

Sailboat rudders are simple devices. Rudders are essentially deflectors, as they deflect water to port or starboard as the boat moves along. When the rudder is amidships or in the middle and aligned with the keel, the boat goes straight. Rudders also help keep the boat on a straight track as they increase the area of water moving down the length of the boat.

Rudders only work when the boat is moving. If there's no moving water to deflect, the rudder can do little to direct the vessel. Rudders also don't work when the boat is blown sideways. Maneuvering is only possible when the boat is moving forward.

Can a Sailboat Rudder Steer in Reverse?

But what about moving in reverse? Rudders can be used to steer the boat in reverse, but they're significantly less effective when pushed backward through the water. The distance required to make a turn in reverse is usually much higher than when moving forward, and steering input is less precise. In some cases, sailboat rudders can break off when moving too quickly in reverse.

Sailboat Steering Characteristics

Sailboats steer much differently than cars, and there aren't any brakes to slow down with. Sailboats tend to steer from the middle; picture a fan blade spinning slowly on a motor, and you'll get the picture. As a result, steering too aggressively in tight quarters can cause your bow or stern to hit something that's beside you.

Speed is generally helpful for steering, especially when you want to make precise movements quickly. However, speed is a double-edged sword, as slight rudder movement at speed can dramatically and rapidly alter the course of the boat. But remember, you can't steer without moving forward.

Tiller Steering

Sailboat rudders are often controlled by a tiller. Tillers are a long rod connected to the rudder. Sailors move the rod side to side from the cockpit to turn the rudder directly. Tillers are the simplest form or rudder control, and they're highly reliable. Tillers point in the opposite direction that the boat will travel.

Tiller steering is found most often on small boats. This is because the forces involved in steering boats of greater size can be too difficult to manage with a tiller. That said, there are some relatively large boats with cockpit configurations that allow for the use of a tiller. Sailboats with tillers range in size between 10 feet and 30 feet.

Benefits of a Tiller

Tillers have numerous benefits. Tillers offer precise control of the boat because they connect the rudder directly to the person steering the boat. Additionally, tillers are extremely simple and robust. Many blue water sailors prefer tiller steering, as it's difficult to break and easy to repair.

Over the years, sailors have developed many creative ways to make tillers more useful. Many boats feature tiller extensions that allow the sailor to steer from further away. Tillers also respond much faster than helms, which is great for racing and pushing the limits of the boat.

Tiller Self-Steering

Bluewater sailors developed an extremely useful way to multitask onboard a tiller-equipped sailboat. Self-steering is possible on vessels with a tiller, and no electronics or complex machines are necessary. Self-steering involves connecting the jib sheet to a series of pulleys and opposing bungee cord (or surgical tubing).

As the tension on the jib increases, it'll tighten the jib sheet and pull the tiller and change the course of the boat. The opposite is also true. This keeps the boat at the right angle to the wind and is useful for solo travel. GPS-guided self-steering equipment is also available for tiller-equipped sailboats, and it's relatively easy to install.

Helm Steering

A helm is essentially a large nautical steering wheel. Steering a boat with a helm is somewhat similar to driving a car, as the boat moves in the direction that you steer (unlike a tiller, which moves in the opposite direction). Sailboats equipped with tillers are usually larger. Some larger sailboats have two helms placed side-by-side in the cockpit.

The helm consists of a steering wheel and a pedestal which is mounted to the deck. Helm pedestals often feature a marine compass to make navigation possible from one location. Engine controls are often located nearby as well. Sailboat helms are often large in diameter, sometimes 30 inches or more. Large wheels make steering easy and precise.

Helm-equipped sailboats are generally 30-feet long and larger. Tillers are excellent for large boats, as they enable precise movement and require little effort to use. This is especially important at speed when the force of water rushing by a large rudder can be too difficult to overcome with a tiller.

The helm is connected to the rudder mechanically or hydraulically. Some high-end sailboats incorporate power steering, but this is unusual on most consumer vessels. Mechanical helm linkage typically utilizes a cable (or multiple cables and pulleys) that stretches from the helm to the rudder.

Hydraulic Rudder Control

Most sailboat helms are hydraulic. These helms use pressurized hydraulic fluid and small diameter lines to replicate the wheel movements at the rudder. Hydraulic systems often include a fluid reservoir and a pressure cylinder, along with mechanical parts to transfer the force at the wheel and the rudder.

Rudder Maintenance

Rudder maintenance is fairly simple and should be performed regularly. As with the hull, rudders are an ideal habitat for all kinds of unwelcome marine life. Within a year or less, your rudder can be completely encapsulated in barnacles, plants, and other organisms. Marine growth will negatively impact your speed and steering, so it must be scraped off regularly.

Maintaining the steering system is also essential. Tillers are relatively easy to maintain, as they use very few moving parts. Look for grease fittings, and make sure your tiller and rudder are fastened tightly. Helms are more complex, and the hydraulic system should be inspected, repaired, and topped off if necessary.

What to Do if the Rudder is Damaged

Rudder damage is a sailor's worst nightmare, and it's akin to a hole in the hull or losing a mast. So what should you do if your rudder gets damaged or breaks off? First, call for help! But if help isn't available, there are a few makeshift ways to steer the boat without the rudder.

If you have an outboard motor, use it to steer. If not, then a run-of-the-mill rowboat oar makes an excellent rudder substitute. Simply lash the oar to the back of the boat with the end in the water, and use it like a tiller. It's not ideal, but it worked for the Romans, and it should work for you. Some sailors have fashioned makeshift rudders from interior cabinet doors, hatches, scrap metal, and whatever else is on hand.

Losing a rudder is a worst-case-scenario, and it doesn't often happen when sailors keep up with maintenance and stay away from dangerous water. Preventative maintenance and proper navigation are the best ways to keep your rudder in good shape.

Related Articles

I've personally had thousands of questions about sailing and sailboats over the years. As I learn and experience sailing, and the community, I share the answers that work and make sense to me, here on Life of Sailing.

by this author

Sailboat Parts

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

How Does the Rudder Work?

- During turns the boat pivots around a point near its midsection—roughly at the mast on a sloop. The stern moves one way, the bow moves the other way, as the boat changes direction. In very close quarters it’s important for the helmsman to remember this, and make allowances for the swinging stern to avoid bumping into other boats, docks, buoys, etc. Most new sailors make this mistake, but rarely more than once.

- Most smaller sailboats (under 30 feet or so) use a “tiller” to turn the rudder. This is basically a stick made of wood or, sometimes, aluminum, attached to the top of the rudder. The tiller provides leverage to turn the rudder against the pressure of the water moving across it. This pressure can be substantial, so even on a small boat the tiller is usually three or four feet long; in strong winds the helmsman will often wish it were longer still. Therefore, larger boats generally use a wheel, attached to the rudder by cables and a steel “quadrant” to provide sufficient leverage. While steering with a wheel takes less effort, a tiller is better for folks learning to sail, since it provides instant response and feedback: if the sails are trimmed incorrectly, the skilled helmsman will feel it through the tiller. Because of this, some expert racing sailors prefer a tiller, even on large sailboats.

Join Our Newsletter!

Get community news, buying bargains, and how-to guides at your fingertips.

- Understanding boat rudders: Navigating the key component for smooth sailing

Navigating a boat requires a complex interplay of various components, and one of the most crucial elements is the rudder. In this comprehensive guide, we will delve into the world of boat rudders, exploring their functionality, importance, and role in steering a ship to smooth sailing.

What are boat rudders?

Boat rudders are an essential component of the vessel's steering system. They are hydrofoil-like structures located at the stern (rear) of the boat, underwater. The primary function of the rudder is to control the direction of the boat by redirecting the flow of water as the boat moves forward.

The role of boat rudders in steering

Boat rudders play a vital role in steering a ship. When the helmsman turns the wheel or tiller, the rudder changes its angle, redirecting the water flow on one side of the boat, creating more resistance on that side, and causing the boat to turn in the opposite direction.

Types of boat rudders

Spade rudders: Spade rudders are simple and streamlined rudders attached directly to the hull. They are commonly found in modern sailboats and provide excellent maneuverability and responsiveness.

Skeg rudders: Skeg rudders are partially submerged and supported by a skeg, a vertical extension of the hull. These rudders offer increased protection and are often used in larger motorboats and trawlers.

Balanced rudders: Balanced rudders have a portion of the rudder forward of the pivot point, which balances the force applied by the helmsman. This design reduces the effort required to steer the boat.

Barn door rudders: Barn door rudders are large, flat, and wide rudders resembling barn doors. They are commonly seen in traditional fishing vessels and provide excellent control in rough seas.

Spade hung rudders: Spade hung rudders are free-floating rudders attached to the boat only at the top, allowing them to swing freely. They are commonly used in high-performance sailing yachts.

Read our top notch articles on topics such as sailing, sailing tips and destinations in our Magazine .

Components and mechanics of boat rudders

A typical boat rudder consists of several key components:

Rudder blade: The rudder blade is the flat, vertical surface responsible for redirecting the water flow. It is the most critical part of the rudder and comes in various shapes and sizes.

Rudder stock: The rudder stock is a sturdy vertical shaft that connects the rudder blade to the steering mechanism. It provides the necessary support and stability for the rudder.

Tiller or wheel: The tiller or wheel is the steering control operated by the helmsman. When turned, it causes the rudder to change its angle and steer the boat.

Rudder bearings: Rudder bearings are the mechanisms that allow the rudder to pivot smoothly on the rudder stock. Properly lubricated and maintained bearings ensure easy steering.

Steering linkage: The steering linkage consists of rods or cables connecting the tiller or wheel to the rudder stock. It transmits the helmsman's steering inputs to the rudder.

Steering a ship: The interaction between rudder and helm

The process of steering a ship involves a coordinated effort between the rudder and the helm. When the helmsman turns the wheel or tiller, the rudder angle changes, causing a difference in water flow on either side of the boat. This creates a force imbalance, turning the boat in the desired direction.

The effectiveness of the steering system depends on various factors, such as the rudder's size, shape, and angle, the vessel's speed, and the water conditions. Proper coordination between the helmsman and the rudder is essential for precise maneuvering.

Maintaining and repairing boat rudders

Regular maintenance is crucial to ensure the optimal performance and longevity of boat rudders. Here are some maintenance tips:

Inspect for damage: Regularly inspect the rudder blade, stock, and bearings for any signs of wear, damage, or corrosion.

Lubrication: Ensure the rudder bearings are well-lubricated to prevent friction and allow smooth movement.

Antifouling: Apply antifouling paint to the rudder to prevent marine growth, which can negatively impact performance.

Check steering linkage: Inspect and adjust the steering linkage regularly to maintain precise control.

Address issues promptly: If any problems or abnormalities are detected, address them promptly to prevent further damage.

Rudder design innovations

Advancements in technology have led to innovative rudder designs aimed at improving performance and efficiency. Some notable innovations include:

Hydrodynamic profiles: Rudder blades are now designed with advanced hydrodynamic profiles to reduce drag and enhance maneuverability.

Rudder fins: Some rudders are equipped with additional fins or foils to improve stability and minimize yawing motion.

Retractable rudders: Certain sailboats feature retractable rudders, which can be raised when sailing in shallow waters, reducing the risk of grounding.

Steer-by-wire systems: Modern vessels are adopting steer-by-wire systems, replacing traditional mechanical linkages with electronic controls for smoother steering.

The influence of rudder size and shape on turning radius

The size and shape of the rudder directly impact the vessel's turning radius. Larger rudders with greater surface area provide more steering force and can turn the boat more quickly. However, larger rudders also create more drag, which can affect overall speed and fuel efficiency. The optimal rudder size depends on the boat's size, weight, and intended use.

Rudder efficiency and hydrodynamics

The hydrodynamics of the rudder significantly affect its efficiency. Smooth and streamlined rudder designs minimize drag and turbulence, resulting in improved performance and fuel economy. Advanced hydrodynamic analysis and simulation tools help optimize rudder shapes for various vessels and operating conditions.

Common rudder issues and troubleshooting

Like any mechanical component, boat rudders can experience issues over time. Some common problems and troubleshooting tips include:

Stiff steering: If the steering feels stiff or unresponsive, check for obstructions in the rudder bearings or linkage.

Vibrations: Vibrations during steering may indicate misaligned rudder blades or bent rudder stocks.

Leaking bearings: Leaking rudder bearings require immediate attention to prevent water ingress and corrosion.

Excessive play: Excessive play in the rudder could be due to worn steering linkage or loose connections.

Reduced maneuverability: Reduced maneuverability may result from a fouled or damaged rudder blade.

Rudder steering systems

Various steering systems are employed in conjunction with rudders, each offering unique advantages:

Tiller steering: Common in smaller boats, tiller steering directly connects the tiller to the rudder stock, providing direct and responsive control.

Wheel steering: Larger boats often use wheel steering, which utilizes a mechanical or hydraulic system to transfer steering inputs to the rudder.

Hydraulic steering: Hydraulic steering systems offer smooth and effortless steering, ideal for larger vessels.

Electric steering: Electric steering systems, also known as electro-hydraulic steering or electronic power steering (EPS), utilize electric motors to assist in steering the boat. These systems work in conjunction with hydraulic components, making steering more effortless and responsive for the boat operator.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite sailing destinations .

FAQs about rudders

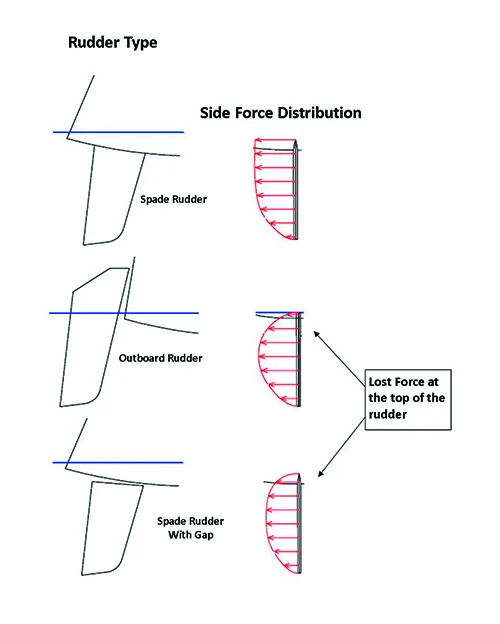

The Types of Sailboat Rudders

- Snowboarding

- Scuba Diving & Snorkeling

Full Keel Rudder

On a sailboat , as the rudder is moved to one side by means of the tiller or steering wheel, the force of the water striking one edge of the rudder turns the stern in the other direction to turn the boat. Different types of rudders have different advantages and disadvantages. The type of rudder is often related to the boat’s type of keel.

Rudder on Full-Keel Sailboat

As shown in this photo, the rudder of a full-keel boat is usually hinged to the aft edge of the keel, making a continuous surface. The engine’s propeller is usually positioned in an aperture between the keel and rudder.

Advantages of Full Keel Rudder

The primary benefit of this rudder configuration is the strength and protection provided to the rudder. It is hinged at top and bottom, well distributing the forces on the rudder. Rope (such as lobster pot warps) or debris in the water cannot snag on the rudder.

Disadvantage of Full Keel Rudder

Because the sideways force of the water on the rudder is entirely behind the rudder’s pivoting point at its leading edge, putting all the force on one side of the rudder, it takes more energy to move the rudder. This is one reason why larger boats seldom have tillers—because it can require much force to “push” the rudder out against the water streaming past the keel.

Spade Rudder

Most fin keel boats have a spade rudder, which extends straight down from the aft hull section. The rudder post comes down through the hull into the rudder itself, allowing the entire rudder to rotate to either side, pivoting around the post.

Advantages of Spade Rudder

The spade rudder is self-standing and does not require a full keel or skeg for its mounting. The rudder post inside the rudder can be moved aft from the leading edge (see next page on Balanced Rudder) so that the force of the water is not all on one side when the rudder is turned. This requires less energy to steer than with a keel- or skeg-mounted rudder.

Disadvantage of Spade Rudder

A spade rudder is more vulnerable to debris or objects in the water, which may strike the rudder and exert a force on the rudder post, the only structure supporting the whole rudder. Even the force of water when the boat “falls” off a wave can exert damaging stress on a spade rudder. If the rudder post is bent, the rudder may jam and become useless.

Balanced Spade Rudder

Note the clear air space at the top of the leading edge of this balanced spade rudder. The rudder post is several inches back from the front of the rudder. When the rudder is turned, the leading edge rotates to one side of the boat while the trailing edge rotates to the other side. While the turning action on the boat is the same, the forces on the helm are more nearly balanced, making it very easy to steer.

Skeg-Mounted Rudder

Some fin keel sailboats have a skeg-mounted rudder like the one shown. The skeg offers the same advantages as a keel mounted rudder: the rudder is protected from objects in the water and has more structural strength than a rudder mounted only on the rudder post.

It also has the same disadvantage: because it is not “balanced” as a spade rudder may be, with water forces distributed on both sides, it requires more force to turn the rudder.

Outboard Rudder

An outboard rudder is mounted outside the hull on the boat’s stern, such as shown in this photo, rather than below the hull using a rudder post or hinges to the keel or skeg. Most outboard rudders are turned with a tiller rather than a steering wheel since there is no rudder post to which to gear a wheel.

Advantages of Outboard Rudder

An outboard rudder does not require a hole through the hull for a rudder post and thus is less likely to cause trouble if damaged. The rudder can often be removed or serviced while the boat is still in the water. Hinges at the top and bottom of the rudder section may provide more strength than a single rudder post.

Disadvantages of Outboard Rudder

Like a spade rudder, an outboard rudder is vulnerable to being struck by or caught in objects or rope in the water. Unlike a spade rudder it cannot be balanced in the water flow, so the force of water is always on one side of the pivot point, requiring more energy for turning the rudder.

A rudder is often related to keel shape .

- Choosing a Centerboard or Fixed Keel Sailboat

- Learn How to Sail a Small Sailboat – 1. The Parts of the Boat

- Control Your Tiller Without a Tiller-Tamer

- Choosing an Inboard or Outboard Engine

- 6 Types of Boat Engines

- How to Tow a Dinghy Behind a Sailboat

- How to Heave To a Sailboat

- The Sunfish: A Perfect Lake or Urban Sailboat

- How to Anchor a Sailboat

- Do It Yourself Boat Trailer Tongue Extension

- Simple Reefing System for Sailors

- How to Rig a Preventer Line

- How Brake Calipers Work

- How to Frog Kick

- RC Airplane Parts and Controls

- From A-Z: A Star Wars Glossary

Professional BoatBuilder Magazine

The rudimentaries of rudders.

By Steve D'Antonio , Jul 12, 2018

Even stoutly constructed rudders are vulnerable to deterioration over time, especially when mild steel or high-carbon-stainless steel is buried in composite foil sections, which inevitably become saturated with seawater.

Like other systems and gear aboard cruising and commercial vessels, rudders have terms to identify their parts and functions. When measuring a rudder, the span and chord are the vertical height and fore-and-aft width, respectively, while the top of portion closest to the hull is referred to as the root , and the bottom is called the tip . Another term frequently used when discussing rudder design, particularly for sailing vessels, is aspect ratio —simply the square of the rudder’s span divided by the rudder’s area. As a rule of thumb, longer, narrower rudders are more efficient than short, wide rudders, and the aspect ratio describes precisely this relationship. Thus, rudders on high-performance sailing vessels are said to have a high-aspect ratio. Walking around a boatyard one day and measuring a few cruising sailboat rudders, I came up with aspect ratios of between 1.7 and 2.1, while one high-performance sailing vessel’s rudder came in at 3.5. The 20-knot semi-displacement lobster yacht’s rudder I measured yielded an even 2.0 aspect ratio, which is considered respectable for this application.

More identifiable rudder components include the stock ; web or armature ; rudderport or log ; stuffing box or compression tube ; bearing ; gudgeon ; and pintle . Not every rudder has all these components.

Rudderstocks

The rudderstock is essentially a shaft or tube that protrudes from the top and sometimes the bottom, depending upon type, of many rudder designs. Because this component provides the primary connection between the rudder’s blade (the flat section that imparts the steering force) and the vessel’s steering system, its design, construction, and material are consequential.

Most stocks are made of stainless steel, bronze, or aluminum, while some are carbon fiber, and they may be solid or hollow. Stainless steel is by far the most common, but it has a penchant for crevice corrosion when exposed to oxygen-depleted water. Insidiously, corrosion nearly always occurs in places where it cannot easily be seen—such as inside many composite (fiberglass and core material) rudder blades and beneath flax-type stuffing-box packing (the problem is exacerbated when the vessel is used infrequently).

This all-stainless rudderstock and webbing is well crafted and ready to be covered with its composite shell.

Of the stainless steel alloys, some resist this corrosion better than others. Stainless-steel rudderstocks should be manufactured with strong, highly corrosion-resistant proprietary shafting alloys such as A22. The next best choice is 316L stainless steel, which also resists crevice corrosion well. Critically important is the L suffix, meaning “low carbon,” a requirement if it is to be welded, as nearly every rudderstock must be, to the support within composite rudders, or to all-metallic plate-steel rudders. Failure to source low-carbon stainless steel for the stock or the web leads to weld decay, sometimes referred to as carbide precipitation, where the region around the weld loses its resistance to corrosion and rusts when exposed to water.

Aluminum rudderstocks are nearly always tubular. Common on aluminum vessels to reduce the likelihood of galvanic corrosion, aluminum stocks are also relatively common on fiber reinforced plastic (FRP) vessels, particularly large ones. Rudder blades, particularly on aluminum vessels, are often fabricated from aluminum. Of the various aluminum alloys, only a few possess the necessary corrosion-resistance and strength necessary for use as rudderstocks. Of these, the 6000 series, and 6082 in particular—an alloy of aluminum, manganese, and silicon—are popular for this application.

Because aluminum, like stainless steel, suffers from corrosion, it should not be used as stock or web material in composite rudders. Referred to as poultice corrosion, it occurs when aluminum is exposed to oxygen-depleted water. Because oxygen is what allows aluminum to form its tough, corrosion-resistant oxide coating, the metal should never be allowed to remain wet and starved of air as it would be inside a composite rudder blade after water makes its way in around the stock and pintle.

Rudderstock material can corrode in way of the oxygen-starved environment around the packing in a stuffing box.

Bronze, a once popular rudderstock material, is no longer common in today’s production vessels. Although strong and exceptionally corrosion resistant (immune to crevice corrosion), bronze is not easily welded to attach to a rudder’s internal structural webbing, and has thus been supplanted by stainless alloys. Bronze rudderstocks, particularly those that have seen many sea miles, are also known for wearing, or hourglassing, within stuffing boxes, where the flax rides against the stock. If a bronze stock rudder is chronically leaky, disassemble the stuffing box and check for excessive wear. The same is true for stainless and aluminum stocks: chronic leakage is often an indication of corrosion at the packing. Finally, because of their galvanic incompatibility, neither bronze nor copper alloys should be used aboard aluminum vessels for rudderstocks or any other rudder or stuffing box components.

Mild-steel webbing welded to a stainless-steel rudderstock is a recipe for eventual corrosion and failure.

The webbing, or internal metallic support system, in most composite rudders must be strong enough to carry the loads of service and be made of the appropriate material. At one time, many rudders were built using stainless-steel stocks and ordinary, rust-prone mild or carbon-steel webbing. Inadvisably, some still are. The union between a stainless stock and FRP rudder blade is tenuous at best (the two materials expand and contract at different rates) and stainless steel’s slippery surface makes adhesion to the laminate resin a short-lived affair. Once water enters the gap between these two materials, it will reach the webbing and associated welds. Thus, all the materials within this structure must be as corrosion- and water-resistant as possible, and the core material must be closed-cell—often foam—and nonhygroscopic.

This destroyed foam-core and stainless-steel rudder reveals the conventional construction of such appendages.

Additionally, where possible, the stock should consist of a single section of solid or tubular material; i.e., it should not be sleeved, reduced, or otherwise modified or welded unless done so in an exceptionally robust manner. The webbing must be welded to the stock, but the structure of the stock should not rely on a weld that would experience cyclical, torsional loading.

The webbing in the form of a plate or grid should be welded to the stock with ample horizontal gussets (small wedges welded where the stock and webbing interface), which will reinforce welds 90° to the primary web attachment.

Whether the rudder is spade (supported only at the top) or skeg hung (supported at the top and the bottom), the stock must pass through and be supported by the hull. This is usually accomplished by a component known as a rudder log, or port. In its simplest form it’s a tube or pipe through which the stock passes. Nearly all logs incorporate two other components—a bearing and a stuffing box. The bearing may be as simple as a bronze or nonmetallic bushing or tube inside of which the stock turns; or it may be as complex as a self-aligning roller-bearing carrier that absorbs rudder deflection and prevents binding.

This rudder log is leaking, corroded, and poorly supported, with washers compressing into the backing plate and gelcoat cracking off.

The log transfers tremendous loads and must be exceptionally strong and well bonded to the hull. Fiberglass vessels should rely on a well-tabbed-in purpose-made tube (its filaments are wound and crisscrossed and thus quite strong) that is supported with a series of vertical gussets that distribute the load to the hull’s surrounding structure. On some spade rudder installations, particularly where the log is not, or could not, be long enough, an additional bearing is used at the top of the stock, above the quadrant, where it is supported by the vessel’s deck.

On metal boats the design is similar but with a metal tube welded in place, supported by substantial gussets. For vessels with skeg-hung rudders, the strength of the rudder log is still important. However, because the loads are not imparted by a cantilevered structure, logs used in these applications may be less substantially supported.

Stuffing Box

Unless the rudder log’s upper terminus is well above the waterline or on the weather deck, it is typically equipped with a stuffing box similar to those used for propeller shafts. But unlike a shaft stuffing box, the rudder’s stuffing box shouldn’t leak much, if any, seawater. Because the rudder turns slowly, friction and heat are not a problem. Packing (i.e., waxed-flax packing like that in traditional stuffing boxes) can typically be tight enough to stem all leakage, and lubricating it with heavy water-resistant grease will reduce friction and leakage.

Stuffing boxes that are above the waterline while the vessel is at rest, such as those on many sailboats, are often the most chronically leaky, because the packing tends to dry out and contract. To avoid this, liberally apply grease to the packing material itself; this requires partial disassembly of the stuffing box. Alternatively, a galvanically compatible (316 stainless or Monel for bronze stuffing boxes) grease fitting may be installed and periodically pumped with grease to keep the packing lubricated.

Rudder Bearings

Well-engineered rudder bearings support and lubricate the rudderstock.

Rudder bearings range from the basic rudderstock turning inside a bronze log, to the sophisticated aluminum, stainless, or nonmetallic roller bearings installed in a self-aligning carrier. For most cruising vessels, the choice of bearing is not as important as knowing which type of bearing is in use and its strengths, weaknesses, and maintenance needs. The simple shaft that turns inside a bronze log is durable and reliable but more friction-prone than roller bearings. If lubrication access or a grease fitting is available, it should be pumped with grease periodically, although most rudders rely solely on seawater for lubrication, which is perfectly acceptable.

This synthetic upper bearing worked fine in cool temperatures, but when it heated up in the sun, the material expanded and caused binding in system.

Nonmetallic sleeve and roller bearings, often made of ultra high molecular weight polyethylene (UHMWPE), require no maintenance, are extremely slippery, and will not absorb water, an essential attribute for nonmetallic bearings. Delrin and nylon, for instance, will absorb water, expand, and lead to rudder binding. On several high-performance sailing vessels, I’ve had to replace nylon or similar bearings with UHMWPE to restore the steering to its proper specification and effort level.

Propeller Removal

Shaft removal should be possible with the rudder in place. This conventional skeg-hung rudder has a hole to facilitate shaft removal when the rudder is swung hard to port or starboard.

Whether a rudder is a spade or skeg-hung design, it’s important to determine how it will affect the removal of the propeller or the propeller shaft. Is there enough clearance between the shaft’s trailing end and the leading edge of the rudder to allow the propeller to be removed or to use a propeller removal tool? Can the shaft be slid out without removing the rudder? Some rudders are equipped with shaft-removal holes, while others are installed slightly offset from the centerline; or the rudder’s leading edge has an indentation to allow the shaft to be removed. The propeller should be removable without having to unship the rudder. The dimensional rule of thumb calls for clearance of at least the prop’s hub length between the aft end of the shaft and the leading edge of the rudder.

Rudder Stops

The rudder’s movement should be unimpeded as it swings approximately 35° in either direction, making no contact with hull or propeller. Just as important as the rudder travel is how its movement is checked. Other than for the smallest runabouts with jacketed cables, all inboard rudders should rely on hydraulic cylinders to check rudder travel (provided they are designed to do so, and most are) or be equipped with robust stops. Stops must be integral to the hull, supported by substantial tabbing or a welded and through-bolted structure for fiberglass vessels, or by welded angle and shelves for metallic hulls.

About the Author: For many years a full-service yard manager, Steve now works with boatbuilders and owners and others in the industry as Steve D’Antonio Marine Consulting. He is an ABYC-certified Master Technician, and sits on that organization’s Hull and Piping Project Technical Committee. He’s also the technical editor of Professional BoatBuilder .

Read more Repair articles

Quick Custom Molds

Making one-off composite parts in the shop.

Repairing Bent Props with TrueProp Software

With all the advances in automation and electrification of boat propulsion systems, propellers remain critical to the task of converting power into propulsion. Made of bronze, nickel, aluminum, stainless steel,… Read more »

VacPuc Checks Your Vacuum Bags

It’s possible to monitor houses, cars, cats, and boats by smartphone, so why not check vacuum bags during resin infusion? Now composite technicians have this option with VacPuc, a new… Read more »

Recent Posts

- Candela’s Faith in Foiling Ferries

- Australia II Wing Keel Controversy – Part 2

- Australia II Wing Keel Controversy – Part 1

- Learn Electrical Systems from Nigel Calder

- PRO-SET Epoxy Named an Official Supplier for New York Yacht Club American Magic, Challenger for the 37th America’s Cup

- Companies (83)

- Construction (105)

- Design (159)

- Drawing Board (10)

- Education (24)

- Environment (16)

- Events (21)

- Materials (48)

- Obituary (17)

- People/Profiles (48)

- Products (16)

- Propulsion Systems (31)

- Racing (16)

- Repair (37)

- Rovings (314)

- Short Cuts (3)

- Sponsored Partner News (13)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

- Types of Sailboats

- Parts of a Sailboat

- Cruising Boats

- Small Sailboats

- Design Basics

- Sailboats under 30'

- Sailboats 30'-35

- Sailboats 35'-40'

- Sailboats 40'-45'

- Sailboats 45'-50'

- Sailboats 50'-55'

- Sailboats over 55'

- Masts & Spars

- Knots, Bends & Hitches

- The 12v Energy Equation

- Electronics & Instrumentation

- Build Your Own Boat

- Buying a Used Boat

- Choosing Accessories

- Living on a Boat

- Cruising Offshore

- Sailing in the Caribbean

- Anchoring Skills

- Sailing Authors & Their Writings

- Mary's Journal

- Nautical Terms

- Cruising Sailboats for Sale

- List your Boat for Sale Here!

- Used Sailing Equipment for Sale

- Sell Your Unwanted Gear

- Sailing eBooks: Download them here!

- Your Sailboats

- Your Sailing Stories

- Your Fishing Stories

- Advertising

- What's New?

- Chartering a Sailboat

- Sailboat Rudder

Making a Sailboat Rudder for s/y Alacazam

It's not enough just for a sailboat rudder to steer the boat effectively, it should also contribute to the keel's job of providing lift to windward, and for it to do this it must be designed as a hydrodynamic foil.

Of course a rudder doesn't have to provide lift, but it's a wasted opportunity if it doesn't.

As with an aircraft's wing, to develop lift the sailboat rudder must have water flowing over its leading edge at an angle of attack.

Fortunately for us sailors, the pressure of air on the windward side of the sails, pushes the boat bodily off course slightly and it's this leeway that provide the angle of attack - or angle of incidence- that enables our keels and rudders to provide lift.

But What Type of Sailboat Rudder would be Best for Alacazam ?

First, we considered twin transom-mounted rudders. The usual argument for twin rudders is:

- as the boat heels, the leeward rudder is more deeply immersed and provides better control, and

- the boat, resting on the keel and two rudders can dry-out upright.

But in the end we decided against the twin rudder arrangement because:~

- with Alacazam's deep draught (7 feet, or 2.2m) the twin rudders wouldn't be deep enough to achieve the drying-out upright benefit, and

- the mechanical complexity of tiller steered twin rudder system went against one of our key design principles - keep it simple, and

- with no propwash flowing over the rudders, manoeuvring under power in tight situations would be a little too interesting for my tastes.

So the conventional single rudder approach it was to be. But what type of sailboat rudder?

A Transom-Hung Rudder

We liked the simplicity of this arrangement, but it didn't suit Alacazam's hull design at the stern. We wanted a sugar-scoop design with a bathing platform to allow easy access from the dinghy which ruled out a transom hung rudder. Similarly, it meant that mounting the servo-pendulum self-steering gear would be unnecessarily complicated.

Spade Rudder

The spade rudder is the most efficient of all sailboat rudders, which is why you're unlikely to see any other design on racing yachts.

The absence of a skeg means that all of its area is used to apply a turning force to the hull, minimizing wetted area and associated drag.

The area ahead of the stock helps to balance the rudder, making life easier for the helmsman.

But it's not the most robust design, being entirely dependent on the strength of rudder stock to resist impact damage.

Theoretically it's just a matter of engineering, but high performance spade rudders just aren't thick enough to incorporate a rudder stock of sufficient diameter for ultimate security.

Skeg-Hung Rudder

Other than those rudders hung on the following edge of long keels, the skeg hung rudder - supported top and bottom on a full length skeg - is the most robust design.

Without a portion forward of the stock, there's no balancing force to take the load of the helmsman's arms - so loads can be quite heavy in some designs.

Nevertheless, it's a very popular design for offshore cruising boats.

Semi-Balanced Rudder

This design of sailboat rudder is something of a compromise between the spade rudder and the full skeg rudder.

Supported at its mid-point by a half-depth skeg, it benefits by the area forward of the stock, below the skeg.

This applies a balancing force as the rudder is turned making the steering lighter than it would otherwise be. And it was this design we chose for Alacazam's rudder.

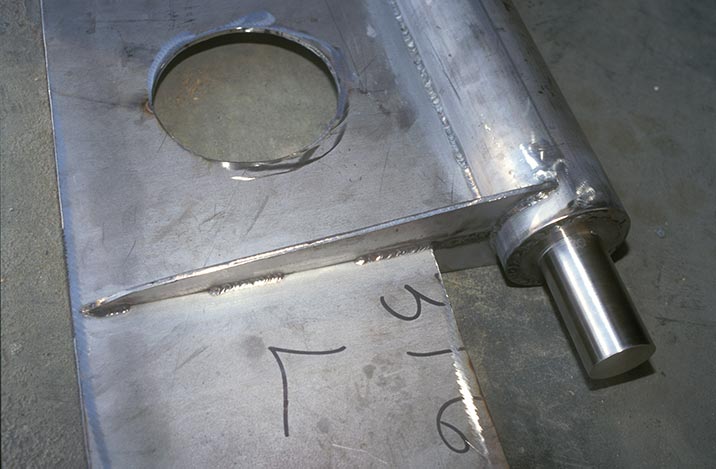

Making Alacazam's Rudder

A typical productions boat's rudder is likely to have been fabricated as shown here, with two GRP mouldings 'clamshelled' around a foam core.

Not the most reliable arrangement you might think - and you'd be right.

We wanted something a little more robust for Alacazam's rudder.

But first, the rudder stock.

We fabricated this from a 2" (50mm) diameter stainless steel solid bar and welded on flat stainless tangs that would be embedded within the rudder.

The Admiralty Bronze casting will eventually connect the rudder to the skeg.

With the rudder stock fabricated, we began the construction of the rudder core.

It was made up from half inch (12mm) marine ply sheets, cut to shape and incorporating cut-outs for the tangs, screwed and glued together.

The rudder and skeg was built up as a single unit at this stage.

The rudder design software generated coordinates for various stations along the rudder, and we used these to cut templates so that we could get the shape right.

Shaping the rudder profile was done by hand, initially with a plane to remove the excess, then with a file and diminishingly coarse grades of sandpaper.

Once the rudder profile matched the appropriate template we removed the section that would form the skeg.

Next, the rudder was fitted to the stock with any gaps between the tangs and the ply taken up with high-strength epoxy 'gloop'.

Finally both the rudder and the skeg were sheathed in several layers of epoxy-glass rovings before being filled and faired with epoxy fairing compound.

Fitting the Sailboat Rudder

The skeg was letter-boxed through a slot cut in the hull, securely braced internally and bonded to it with fillets of high-strength epoxy and epoxy glass rovings.

Inside the hull we had constructed a GRP tube to contain the stock, and the skeg was also bonded to the lower end of that.

The rudder was then securely fitted to the stock via the bronze bearing, and located at the top of the rudder by a stainless steel bearing.

That's it, we now have a very robust and efficient rudder securely attached to Alacazam's hull.

Recent Articles

'Natalya', a Jeanneau Sun Odyssey 54DS for Sale

Mar 17, 24 04:07 PM

'Wahoo', a Hunter Passage 42 for Sale

Mar 17, 24 08:13 AM

Used Sailing Equipment For Sale

Feb 28, 24 05:58 AM

Here's where to:

- Find Used Sailboats for Sale...

- Find Used Sailing Gear for Sale...

- List your Sailboat for Sale...

- List your Used Sailing Gear...

Building Alacazam...

But why go to the bother of building your own boat?

Copyright © 2024 Dick McClary Sailboat-Cruising.com

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

How Dangerous is Your Shore Power?

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

Gonytia Hot Knife Proves its Mettle

Where Winches Dare to Go

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Rhumb Lines: Livin’ the Wharf Rat Life

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Boat Maintenance

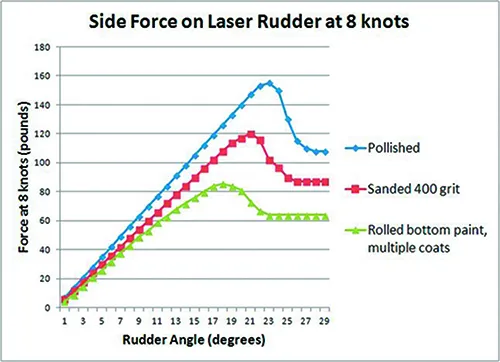

Building a Faster Rudder

Boost performance with a bit of fairing and better balanced helm..