[email protected]

Category: Our Catamaran Build Kits

Recommended equipment.

Quality suppliers & manufacturers

The schionning team have a lot of contact with equipment suppliers and manufacturers, and hear feedback on certain brands or systems from our many customers. there are many schionnings cruising the world and testing products longevity and the customer service offered by the manufacturer., on this page we will list products and companies that we know to provide above average quality and service. it is always growing, and if your company provides equipment used on our designs and you would like to be included - please contact us., engines & drive systems.

Visit: https://oceanvolt.com

Batteries, Power Management

LITHIUM POWER (VIC)

Back in 2013 I knew that my boat batteries were reaching the end of their lives, I had been researching LiFePO4 cells for a few years and decided that I should install them. Unfortunatly I was unable to find a local supplier. So Lithium Power was established.

Technical Information

The technical information page is a collection of documents (mostly in pdf format) on the materials and systems used in schionning catamarans. including data sheets, engineering information, strength comparisons of each core material and informative articles from jeff outling the design of certain system such as engine choices and main sheet systems., detailed engineering data for your research, we understand that getting your head around the process of building your own boat, or having one built, can take a little while. to gain a greater understanding of the materials used in our designs, the below data sheets have been supplied by atl composites, and contain all of the technical data you could need regarding the composites we use. in addition are articles or documents written by jeff about certain systems used on our designs and why., all technical information and data sheets on west system/duflex/durakore provided courtesy of atl composites. for more information please see the atl composites website here., documents library.

Information Sheet – CE CERTIFICATION PROCESS

- Mainsheet Systems for Catamarans

- Motor Choices for Schionning Designs

- Weight and Weight Distribution Schionning Designs

- Schionning Designs Sailing Performance and Tips

- Hull Shapes and Performance – Power Designs

- Outboard Engines VS Diesels – Written by Ross McCombe

- An Outboard Installation That Works – Ross McCombe Follow up

- Data Sheet – DUFLEX BALSA for Catamaran Kit Builds

- Data Sheet – DUFLEX FOAM

- Data Sheet – FEATHERLIGHT Paper Honeycomb

- Data Sheet – WEST SYSTEM R105

- Data Sheet – PUMP SYSTEMS

- Data Sheet – MICROFIBRE BLEND 403

- Data Sheet – MICROLIGHT 410

- Data Sheet – MICROSPHERES 411

- Information Sheet – USING FILLERS

- Data Sheet – KINETIX RESIN Thixotropic

- Information Sheet – DURAKORE PLANKS 413

- Data Sheet – DURAKORE PLANKING 414

Kit Materials Contents

Kit materials' contents, so if you order a schionning kit, what exactly is going to arrive see an overview of the materials you will receive, and what each is used for during the build process. fibreglass cloth or tapes microspheres, microballoons or microfibers take a closer look and you can answer these questions., our schionning kits are a no nonsense, common-sense approach to building a boat. we offer great service, fast delivery and access to anything you could need for your boat straight from the supplier to your door. our construction plans and kits are sold with 100% professional boatbuilder support via phone and email, any time you're unsure or just need a second opinion, we're here..

Our kits contain all of your basic materials to build your boat to a faired shell stage, ready for painting and fit-out. We have sail-away costing estimates available for all of our standard designs, and this will give you an accurate idea of the overall cost of your project. This costing varies depending on your level of finish, as you can imagine different options vary greatly in price.

Below is a quick glance at what your Schionning Kit will include and what each item is primarily used for, we hope this is helpful and if you should require more detailed information please don’t hesitate to contact our office.

What do I actually receive?

DUFLEX PRE-LAMINATED PANELS

DuFlex pre-laminated panels are the main and most important material used in our kits, predominantly in the flat panel designs, however they are used in Strip-planked designs also, though to a lesser extent. These panels are 2400mm x 1200mm and are CNC routed to speed up build time on our Wildernes X Series, as well as some of our power designs. For internal furniture, a paper honeycomb core is used instead of the end-grain balsa wood core that is used for main structural areas. The use of this is purely to save weight in the shell and therefore produce a faster, more responsive catamaran.

KINETIX LAMINATING RESIN & HARDENER

WEST SYSTEM EPOXY RESINS

FIBREGLASS TAPES (DOUBLE BIAS)

CARBON FIBRE CLOTH

FIBREGLASS CLOTH

The kit process, building your own boat can be a daunting prospect, however to demonstrate each step in the kit assembly process, we've created this guide for you to study. as you can see our kits are the ultimate in building efficiency and have been streamlined over 30+ years to ensure that you're on the water faster and with less effort., how does it all go together.

The first step to building your dream catamaran begins with a strongback – this is a square frame used to position the temporary frames that will be used to form the hull shape. This frame will be set up and must be square and accurate, a string or laser level can be used to achieve this.

The forebeam is now installed along with the striker attachment fitting, as shown above. The bridgedeck is installed shortly after and taped onto the bulkheads with webs installed, this now completes what is a quite stiff and strong platform to work on.

Now that the bridgedeck is in place, the forward webs and dash will be fitted. At this stage, all furniture and internal work begins, with the main panels left off for ease of access when working.

Material Choices

Schionning material choices, solutions that work best for catamarans & why, our designs are based on cored composite construction techniques using west system epoxy resin and knitted fabrics. but given the range of today's composite technologies, which solution works best for catamarans and why written by jeff schionning, selecting the correct materials, resin choices.

It also fully protects the boat against water absorption and it can not develop the dreaded Osmosis.

We choose ATL Composite’s resin systems for their superior quality, reliability and value for money.

Having worked closely with the ATL Composites team and their products for many years, we know we can stand by their material solutions, and rely on great service should something unexpected happen.

This may not seem important but when working with a material for an extended period of time, the small things make all the difference.

CORES Which One to Use?

- End-Grain Balsa – 150kg per cubic metre

- Superlight Balsa – 94kg per cubic metre

- Western Red Cedar – 360-380kg per cubic metre

- Foam – 80kg per cubic metre

BALSA END GRAIN (150 kg/cubic metre)

Balsa has very good values and we can produce a shell using a very light laminate. It will be very stiff and very resilient to fatigue.

It has exceptional qualities including very high compression strength, extremely good sheer capabilities and fantastic sheer stiffness.

Compressive strength is the resistance to collapsing when pressure is applied perpendicular to the surface as when pushing directly onto the material with the point of your finger. Balsa is far stronger than Foam (80kg/cubic metre) in compression.

Balsa is also very strong in shear. This is when the core sample is held flat between your hands, one hand slid one way and the other slid the opposite way, when the core tears through the middle the core has failed in sheer. The amount of stretch you feel before the core shears is shear stiffness. To compensate for sheer weakness the core is made thicker. So 13mm Balsa may be equal in sheer to 19mm Foam.

(80 to 200 kg/m³)

There are many boats sailing that are built from foam as it’s mechanical properties are good for boat building.

- Initially one would expect this cat shell to be lighter as it is ½ the weight of Balsa. We do have to compensate for its weaknesses and will then add to the reinforcement the reinforcement on the outside to spread that compression load over more core and need a triaxial type weave to compensate for the veneer content that runs fore and aft on the Durakore.

- Secondly, we need to increase the Core thickness to compensate for the shear value, usually neutralizing the weight advantage.

- We only use structural foam core that is closed-cell and cross-linked.

The end result using foam core amounts to a very similar total boat weight. Professional builders can achieve a good result but usually use vacuum bagging and very good molds to achieve this.

Secondary Issues

Balsa can absorb water. It needs extreme neglect to rot (very unusual). Water soaks along the end grain quickly. It travels very slowly across the grain. We use balsa under the waterline especially because of it’s high compression strength for beaching etc. any core type must be sealed. Damage to all cores results in the same sort of repair. Notice a damp spot remaining when drying out to anti-foul… simply grind back the surface glass exposing the core, dry it out and re-glass – it’s that easy.

Timber cores are cheaper than Foam in most cases.

A light, high tech cat returns a far better (often 2 – 3 times) re-sale than lower tech materials. Often saving $10,000 on materials initially, loses $200,000 on re-sale – a serious reality.

Our boats can be built using Balsa, Foam or Western Red Cedar. Combine strength, stiffness, lightness and cost, with ease of use – it just makes good sense!

- BUILDING RAKU FROM A KIT

- Duflex Kit Construction in 9 Steps

BUILD YOUR RAKU CAT WITH A DuFLEX KIT BY FOLLOWING THESE NINE BASIC STEPS

Step 1. Kit Design

Work with us to finalise the details of the design you have chosen including any design options or additional modules to be included in the kit.

We will determine the laminates, the number of panels required for each laminate, create the cutting files and prepare a quote for the kit if it is not already priced.

Once the design details and pricing are confirmed you are ready to place your order.

Step 2. Unpacking

2. The kit arrives at your workshop door, usually by container, as a stack of 1.2m x 2.4m routed composite panels ready to be joined. The shipment will normally include additional reinforcements, resins, and ancilary products as specified.

Unpack the shipment and stack the panels out of the way of the space where the panels will be joined.

If you have purchased a joined kit many of the panels will already be joined up to the length that can be shipped in a container (12m).

Step 3 Joining the Panels

Set up the work space where the panels are to be joined.

The panels have a scarf join called a Z join that facilitate the join without needing tapes.

The joining can be done with a heated Z press that cures the epoxy join quickly. Alternatively they can be joined with clamping pressure.

If the panel are are being joined with the Z press you will need an elevated work bench the full length of the longest panels you are using. (image below).

If you are joining them with a clamping technique the space can be on the factory floor.

A nesting booklet is provided with the kit to show how the panels are joined (right)

Joining the panels with clamping pressure

Panels are being joined into a single long panel by painting the surfaces of the scarf join with epoxy screwing through plywood battens that have a release film applied to one side.

Joining the panels with the Z Press

Step 4 Stacking Joined Panels

Once the joins are cured the panels are stacked to one side until they are needed for the job. The inividual parts should not be cut free of the panels until they are required.

Bulkhead and floor panels will be needed before the hull sides and cabin top so they should be left to the front of the stack wherever possible.

Step 5. Separating the Parts

When assembly is ready to begin the individual parts are separated from the panels by cutting the joining tabs. It is likely you will be building onto moulded hull bottoms that have been built from strip planking or another method of building moulded components. The process for building moulded components is described in another article.

Step 6. ASSEMBLY

As the joined panels are assembled onto the job you will need to apply glass tapes to the joins as specified in your plans.

Panels can be surfaced and coated inside and out with high build while they are on the workshop floor to minimise fairing time once they are assembled to the boat. The paint on the panels shown here has been kept back from the edges to provide a good bond for the tapes.

Smaller items such as steps, seats and dagger cases are nested into the kit and for the more complex parts diagrams are provided to assist with the assembly process.

Step 7. Interior

Interior kits can be ordered with the primary kit, or they can be ordered later when final decisions have been made about the interior arrangement.

A compromise solution is to order the interior as a set of plain planels that can be cut to shape on site after finalising the layout.

Step 8 Fairing, Painting, Hardware Installation

8. The DuFLEX construction process goes a long way to minising the amount of fairing that has to be done, but inevitably any boat that has not come out of a female mould will require some level of fairing and surface preparation prior to painting.

The fillers and resin systems required for the fairing work are normally supplied as part of the kit.

Hardware installation is the same as for any other form of construction using high density core inserts or consolidated laminate in way of fittings.

Step 9. Sailing

Go Sailing. This Barefoot 40 Catamaran was built entirely with a Duflex kit in Foam/Glass and Epoxy resin systems from ATL Composites

DuFLEX Kits are manufactured and supplied world wide by ATL Composites

atlcomposites.com.au

And in Europe by VDL Composites

www.vonderlinden.de/her/28/vdL-Composites-GmbH

For more information on DuFLEX and associated Products

atlcomposites.com.au/category/27/DuFLEX

Join the Newsletter

- Scroll to top

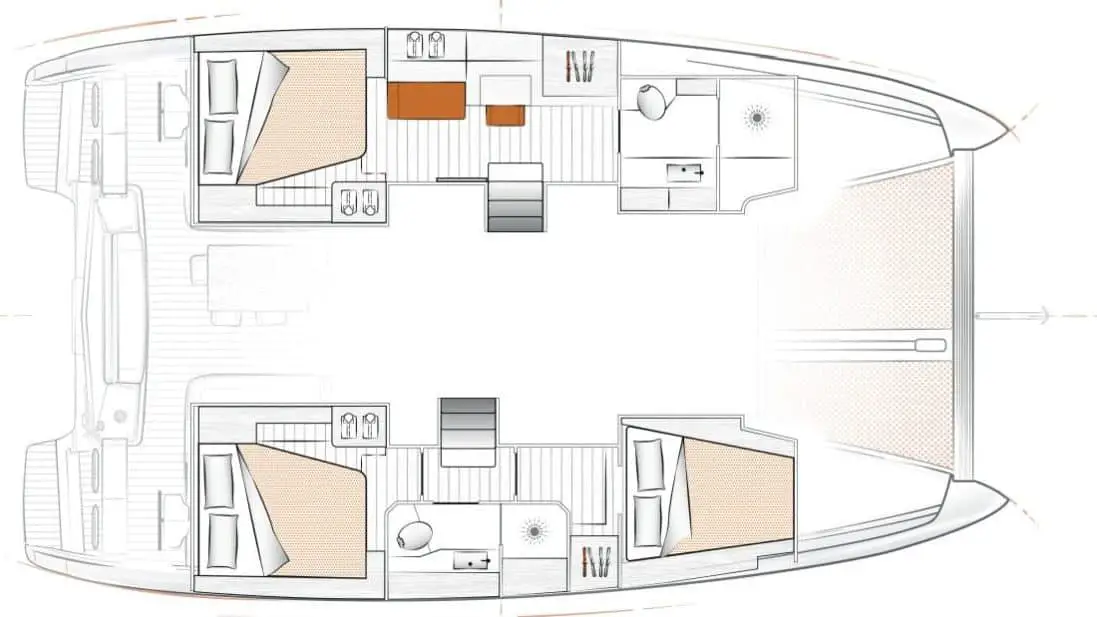

How To Create the Perfect Cruising Catamaran Layout

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

More than ever before, sailing fans are gaining an interest in catamaran layouts and designs that define performance. Many others are also looking into either buying a cruising catamaran or designing and building one. While building a catamaran is no piece of cake, this article shows you how to create the perfect cruising catamaran layout.

To create the perfect catamaran layout, carefully consider factors like a good hull design, optimal helm station placement, boat stability, and adequate load-carrying capacity. Excellent galley positioning, ease of handling, and spacious living and sleeping quarters are also crucial.

The modern cruising catamaran is a far cry from the simple Polynesian double canoe of old. That’s because structural innovations and new composite materials have resulted in multihulls with impressive cruising abilities. Keep reading to learn more about exceptional catamaran layouts.

The Changing Trends in Catamaran Designs

The early cruising catamaran designs resulted in boats that could sail much faster than traditional sailing boats. In addition, they could glide with ease in shallow waters and required less wind and crew. Unfortunately, these cruising cats were heavy, had small, cramped interiors, and boasted somewhat challenging handling abilities.

Today’s cruising catamarans are different. They boast the utmost comfort, high speeds, and the safety of a well-designed cruising yacht. They are also more exciting, visually appealing, deliver the smoothest of rides, and sport more spacious interiors.

Have a look at the below video showcasing the top ten cruising catamarans:

Features To Look Out for in Catamaran Design Layouts

Cruising catamaran designers understand what most sailors look for in a cruising vessel. They, therefore, design cruising multihulls that address these pertinent issues and more. Some of the features you might want to consider having in your dream boat include the following:

- Responsive performance. Outstanding performance allows for pleasurable cruising and ensures your safety since you have more options during difficult weather.

- Excellent load-carrying ability . This allows you to have an extended cruising vacation or ocean crossing.

- Boat stability . Go for lightweight, robust construction, which results in a lot of buoyancy.

- A low center of gravity for smooth rides and enhanced performance. Centering weight around a low center of gravity improves the overall sailing quality, reduces pitching movement and reduces the risk of capsizing .

- Adequate bridgedeck clearance to reduce slamming and provide better performance in rough conditions. A high bridgedeck also means less noise and slapping action from the waves hitting the boat bottom, thus ensuring a quieter, smoother ride.

- Comfortable sailing. To enjoy a quality life on board, you need comfort while at sea. Thus, elements like gentle movement, no creaks or groans, no bridgedeck slamming, and minimal pitching are essential for quality, peaceful and restful sleep.

Now that you know what a cutting-edge catamaran features, let’s look at how to create the perfect cruising catamaran layout.

Build a Larger-Sized Catamaran

The early catamarans ranged between 36-42 feet (10.9-12.8m). At the time, this appeared to be a good size in terms of safety and ease of handling. However, the boats were heavy, and the additional drag and displacement adversely affected their performance and windward ability.

It’s now possible to make the new generation catamarans lighter, larger, and more spacious with excellent power-to-weight features. The current trend is larger-sized catamarans in the 45-50 feet (13.7- 15.2) range. Composite engineering and technologically advanced equipment such as furling systems, electric winches, and autopilot make it easier for a smaller crew to sail larger boats with confidence. And to do so without compromising safety or stability.

Get the Best Catamaran Hull Design

A cruising catamaran’s performance depends on three main aspects; its length, the sail area, and the boat’s weight. Long boats are generally fast. A light boat with more sail area is also faster than a heavier boat with less sail area. In other words, you can make a multihull faster by making it longer, lighter, or adding more sail.

However, there are exceptions to this rule; a boat with too much sail area is more likely to capsize if there are brisk winds. Also, if the boat’s design makes it too light, it’ll be unable to handle much punishment, while a hull design that’s too slim would make the vessel incapable of carrying any significant loads. But that’s not all; if the boat is too long or too large, it’ll become grossly exorbitant. Narrow hull shape might also mean smaller cabins.

Nonetheless, these three factors alone are not enough to determine a cruising catamaran’s performance. While faster boats boast finer hulls, the wetted surface area tends to increase as fineness increases; thus, fine hulls end up becoming less fast in low wind speeds. Also, very wide hulls mean a reduction in actual performance.

The Prismatic Coefficient (Cp), a measure of how full the ends of the hull get, is the most essential design hull shape factor for any catamaran. A high Cp equals high speeds, although you can still use a lower Cp if you have fine hulls. Nevertheless, the key to a good Catamaran design is a higher Cp for fast sailing.

To achieve a high Cp, there are several things you can do:

- Fit bulb bows . Unfortunately, the bulb bows tend to slam in a seaway when you do this.

- Have an extensive planning aft section . However, this can increase the wetted surface area, WSA and lead to additional challenges.

- Flatten out the hull rocker and add a bustle aft. This helps to add displacement aft.

Build Convertible Main Living Spaces

The open cockpit is now a thing of the past. Instead, pioneering designers for catamaran manufacturers like Nautitech, Gunboat, and Catana now replace traditional-style salons, cockpits, and cabins with spacious indoor and outdoor living spaces. The concept involves merging separate saloon and cockpit areas with duplicate lounge spaces and the use of hard-wearing composite materials.

You can also design the cabin to suit your preferences. You may decide to add a cabin or remove one, add a bathroom, have the forward berth in the hull or on the wing deck.

- The design enhancements boost usable space while opening up the living areas.

- It reduces time and costs for interior maintenance and cleaning.

- Large windows bring in more light, increasing visibility.

- Luxurious, spacious, and airy owners’ cabins provide more comfortable living space.

Bulkhead Helm Stations vs. Twin Stern Steering

Many catamaran owners have traditionally preferred bulkhead steering. This helm position remains popular, but twin stern steering positions come with more advantages since they provide greater sails visibility. The twin stern positions are also best suited for racing or day sailing since they often lack adequate protection for extended cruising.

Exposed helms are not ideal for a long ocean passage. Go for a safe, secure, and well-protected helm station that provides good visibility and comfortable space for long watches. Again, it’s best to have all control lines at the helm to establish a static control station. Also, have all push-button-controlled winches, instruments, windlass, and autopilot prominently located inside the cockpit.

- Twin stern steering positions give you a better view of the sails

- You get a better feel for overall sailing conditions.

- Twin stern steering positions lack the necessary protection for extended cruising.

Go for the Flybridge Design

The flybridge design is appealing because it offers excellent visibility, more comfort, and additional entertainment and lounging space for everyone on board. Unfortunately for smaller boats – those below 50 feet (15.24m), there is minimal protection from the elements. As such, you might want to consider adding enclosures to offer protection. The flybridge, thus the helm, remains cut off from the vessel, which makes communicating with the crew a challenge.

- It provides great visibility.

- It offers comfortable spacing.

- It might be unsafe to move from the cockpit to the flybridge in bad weather.

- It isn’t easy to communicate with the crew.

Daggerboards vs. Fixed Keels

Average cruising catamarans typically utilize fixed keels while high-performance cats have daggerboards . Fixed keels allow you to beach your catamaran easily, and your hull remains intact if a collision occurs. While you lose some angle when sailing upwind, you gain more interior space in the hulls that you can put to good use.

Daggerboards are essential in a performance cruising catamaran since they guarantee that the boat delivers good upwind sailing, including during difficult situations. During long passages, they allow you to point better upwind though the drawback is that they consume much interior space within the cruising catamaran’s hulls.

Since flying on foils ( hydrofoils ) isn’t that practical on cruising catamarans, designers of larger-sized boats have also come up with modified daggerboards. These daggerboards produce lift and prevent leeway, too, thereby improving performance significantly, as seen with the Catana 59’s curved daggerboards. These foil-like daggerboards lift the boat ever so slightly upon reaching higher speeds, making it feel less heavy and much faster.

At the end of the day, calculating the performance of a boat sailing in a wide range of varying seas and winds might not be easy – despite a daggerboard or fixed keel configuration. This is because upwind speed depends not only on the sails’ quality but also windage and the height of the bridgedeck beyond the water.

- The design innovations -curved daggerboards and hydrofoils- improve catamaran performance significantly.

- Daggerboards enable you to access otherwise inaccessible anchorages.

- Daggerboards take up hull space in the hulls of your vessel.

Galley Up vs. Galley Down

Galley layout are becoming more and more important as more people, including families, start sailing regularly. While at sea, your galley needs to be a safe place, well-ventilated, and functional. Everything should be well-thought-out for the sailor’s comfort, including handholds to make it safer to move around the boat.

While the galley location can either be up the bridgedeck or down in the hull, galley up appears to be the most popular trend. This makes the galley the focal point of both the living space and entertainment areas.

If you have a family, this placement is ideal since you make your meals from the galley and get to spend most of your time here. Many cruising families and couples prefer this arrangement and find separating the galley down the hull unappealing. Besides, carrying hot food up and down the staircase is unsafe.

Still, galley down is ideal for charter boats since it offers a private cooking area and uses up hull space efficiently.

- Having the galley on the bridgedeck is ideal for families and cruising couples.

- Placing the galley on a similar level with the serving area and cockpit is safer and less tiring.

- There’s better ventilation on the bridgedeck, making for comfortable cooking.

- There’s less kitchen privacy galley up.

- On smaller catamarans, this layout can impact the size of the saloon seating area significantly.

Production Catamaran vs. Custom

The choice of either a production catamaran or a custom design might seem pretty straightforward. Production catamarans from major brands come backed by proven designs, dependable construction, solid warranties, and many years of experience. The catamarans are easy to service, source for parts, and most – particularly the owner’s versions – hold on to their value, making them much easier to resell.

On their part, custom boats are fantastic in that you can tailor them to your exact needs. However, they might be more challenging to maintain or service. That’s because of parts unavailability and lack of construction knowledge.

Choose Quality Construction Materials

The best quality materials to use on your catamaran are both light and robust. While carbon fiber is great, plywood, plywood/epoxy, and strip-cedar are excellent materials too. What’s more, they are also affordable, so you don’t have to get too hung up on cutting-edge building materials. What matters is build quality; thus, a well-built plywood catamaran boat can last as long as a boat made from more high-tech materials.

Combining various materials also helps combat some of the issues that plague plywood boats in terms of resale value. At times, the design tends to make the boats appear pretty dated.

- Plywood and strip-cedar materials are affordable and provide excellent build quality.

- Plywood boats may have a lower resale value than those built with modern materials.

Consider Ease of Handling

An important factor in handling a cruising catamaran is deck layout. Most cruising catamarans sailed short-handed , so if your boat has one helm, all lines should run back here to allow for a static control station for the entire boat.

The other essential element is visibility from the helm. The 360 degrees of visibility while maneuvering, docking, or underway is crucial to your boat’s safety, as well as life and property. As such, you should be able to view both bows, or at least the pulpits and sterns, while standing at the helm. If not, you may have challenges handling the boat due to blind spots.

Consider the Load Carrying Capacity

A well-designed catamaran is enjoyable to sail in all weather conditions. It’s also much easier to handle than a monohull because of its widely spaced twin engines. But when you immerse extra hull depth, the vessel gets sluggish and moves slower, maneuvering in tight spots or when docking becomes more challenging. Furthermore, the hull submersion reduces bridge deck clearance, leading to hull slamming.

To allow for adequate load carrying capacity, you need a design that provides a generous displacement. This helps to ensure that you maintain reasonable bridge deck clearance even when fully loaded. It also allows you to avoid digging big holes in the water as you drag your transoms.

Displacement refers to the amount of buoyancy designed into the hulls, which essentially means that your boat will cruise better if its weight is less than your designed displacement.

Note that an overloaded catamaran not only loses out on performance but eventually, on safety too. To counter this, choose a lightweight catamaran with hulls bearing cored construction and interiors made of lightweight materials.

Remember, when you go cruising, you will need to carry fuel, extra water, supplies, equipment, and amenities, translating into thousands of extra pounds. Therefore, try and avoid the following design errors to ensure that your catamaran has an adequate load-carrying capacity:

- Avoid putting in place too much accommodation space.

- Avoid building a heavy boat ‐ use low-tech construction materials.

- Avoid installing inboards in a small boat.

- Lightly constructed catamarans perform faster and carry more weight.

- Cored construction makes for a strong and stiff catamaran, thus enabling good performance.

Final Thoughts

A well-designed cruising catamaran is a joy to behold. Today’s modern technological advancements mean that you can buy or build a light but strong cruising catamaran. And as you can see from this article, there are many excellent cruising catamaran layouts that you can choose from.

However, whichever layout you decide on needs to fit your sailing needs and purposes to ensure you remain comfortable and safe while at sea. Above all, ensure that you go for a vessel that you can handle with ease in all weather conditions.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

How To Build A Catamaran? (A Step-By-Step Guide)

Are you excited about the prospect of building your own catamaran? With a little research, planning, and the right tools, you can turn your vision into reality in no time.

In this step-by-step guide, well show you how to make the most of this incredible boatbuilding project.

From selecting the materials and planning the design to constructing the hulls and deck and outfitting the boat, well walk you through everything you need to know to build a catamaran of your own.

So, grab your tools and lets get started!

Table of Contents

Short Answer

Building a catamaran requires careful planning and a lot of patience.

The first step is to decide on the design and the materials you will use.

You will need plans for the project, along with lumber and other materials such as fiberglass and epoxy.

The next step is to build the catamaran frame, which involves cutting and fitting the wood pieces together to form the hulls and decks.

Finally, you will need to attach the decking, add the rig and sails, and finish the project with paint and varnish.

Benefits of Building a Catamaran

Building a catamaran can be a very rewarding experience.

Not only will you have the satisfaction of creating something with your own hands, but you will also have a boat that is uniquely yours.

Catamarans offer many benefits over traditional monohull boats, making them an ideal choice for those looking for a reliable and efficient ride.

These benefits include greater stability, more space, improved fuel efficiency, and greater speed.

Stability is one of the biggest advantages of catamarans.

The two hulls provide a wider base that helps to keep the boat from rocking and rolling in rough waters.

This makes for a much smoother and safer ride, even in choppy waters.

Additionally, the two hulls create an open area between them that is perfect for storing equipment, making it ideal for longer trips.

Catamarans are also more fuel efficient than monohulls.

This is because the two hulls provide lift, allowing the boat to glide through the water more easily.

This means you won’t need to use as much fuel to power your boat, allowing you to save money in the long run.

Finally, catamarans are faster than monohulls.

This is due to the increased surface area of the two hulls, which allows the boat to move more easily through the water.

This makes them ideal for those who want to travel quickly and efficiently.

Overall, building a catamaran can be a fun and rewarding experience.

With the right materials and tools, you can create a boat that is unique to you and offers many benefits over traditional monohull boats.

With the right planning and construction process, you can create a catamaran that will be the envy of your peers.

Selecting the Materials

Selecting the right materials is a crucial step in building a catamaran.

The type of material you choose will depend on the size and type of catamaran you are building, as well as your budget and experience.

Catamarans are typically constructed from wood, aluminum, or fiberglass.

Each of these materials has unique advantages, so it is important to research the pros and cons of each before making a decision.

Wood is the traditional material used to build catamarans and is often the most cost-effective option.

Wooden catamarans are strong and stable, and they can be custom-built to any size or shape.

However, wood requires a lot of maintenance and can be susceptible to rot and water damage.

Aluminum is a great option for larger catamarans, as it is lightweight and resistant to corrosion.

It is also relatively easy to work with and can be welded together to create a strong and durable structure.

However, aluminum is a more expensive material and is not as flexible as wood or fiberglass.

Fiberglass is the most popular material for building catamarans, as it is lightweight, strong, and resistant to corrosion.

Fiberglass is also relatively easy to work with and can be shaped to create unique designs.

However, fiberglass is also the most expensive option and can be difficult to repair if damaged.

Once you have selected the material, it is important to purchase the right amount for the project.

Make sure to measure the catamaran carefully and purchase enough material to account for any mistakes or waste.

It is also important to purchase high-quality materials that will last for years.

With the right materials, you can build an amazing catamaran that you will enjoy for years to come.

Planning the Design

When planning the design of your catamaran, youll need to consider a variety of factors, including the size, shape, and type of material youll be using.

Consider the size and weight of the catamaran and the type of water it will be used in.

Youll also need to think about how the catamaran will be used, such as for recreational or commercial purposes.

When it comes to the shape of the catamaran, the most common design is the two-hulled V-shape.

This shape is ideal as it offers stability and is easy to maneuver.

However, depending on the type of use, other shapes, such as the three-hulled catamaran, may be better suited.

The material you choose for your catamaran will also play a role in the design process.

Common materials used to build catamarans are wood, fiberglass, aluminum, and composites.

Each material has its own advantages and disadvantages, so its important to research and select the best material for your project.

Finally, when planning the design, youll need to consider the outfitting of the boat.

This includes items such as decking, seating, and a helm station.

Make sure to think about the type of equipment youll need for your catamaran, and consider how it will be installed.

By taking the time to plan the design of your catamaran, you can ensure that you get the best possible outcome.

Doing your research, selecting the right materials, and choosing the right outfitting will all help you create an amazing catamaran that will last for years to come.

Constructing the Hulls and Deck

Constructing the hulls and deck of a catamaran is perhaps the most important and time-consuming step in building a catamaran.

You will need to plan the design of the hulls and deck carefully to ensure that your catamaran is strong, stable, and seaworthy.

When constructing the hulls, you will need to use strong and light materials that are suitable for marine environments.

Fiberglass is a good choice for this, as it is strong and lightweight.

You will need to cut and shape the fiberglass to fit the shape of the hulls, and you will need to use a strong adhesive to bond the pieces together.

The deck of the catamaran will need to be strong and stable enough to support the weight of the passengers and cargo.

You will need to construct the deck out of marine-grade plywood, and you will need to use a strong adhesive to bond the pieces together.

You may also need to add extra support beams to the deck for added strength.

Once the hulls and deck have been constructed, you will need to sand and finish them to ensure a smooth and watertight surface.

You may need to use a sealer or primer to protect the wood and fiberglass from the elements.

Finally, you will need to attach the hulls and deck together.

This can be done with bolts, screws, or other fasteners.

You may also need to use a water-resistant sealant to ensure a watertight connection between the hulls and deck.

Outfitting the Boat

Outfitting a catamaran is an essential part of the build process.

Once the hulls and deck are constructed, you’ll need to ensure that all the necessary components are in place for a successful voyage.

This includes items such as masts, sails, rudders, and outriggers.

It is critical to ensure that the boat is outfitted with the right components for its size and purpose.

For example, if you are building a small catamaran for speed and agility, you’ll need to outfit it with a light and responsive mast and sail.

If you are building a larger craft for comfort and luxury, you’ll need to outfit it with a heavier and more resistant mast and sail.

Additionally, you’ll need to select the right outriggers and rudders for the catamaran’s size and purpose.

Outfitting a catamaran can be a complex process, and it is important to do the research and plan ahead.

Taking the time to select the right materials and components will ensure that your boat is outfitted for success.

Additionally, it is important to use quality materials and components to ensure a safe and successful voyage.

With careful planning and quality components, you can outfit your catamaran for a successful journey.

Acquiring the Right Tools

When it comes to building a catamaran, having the right tools can make all the difference.

To get started, you’ll need a variety of hand tools, including saws, drills, sanders, and screwdrivers.

You’ll also need power tools like routers, biscuit joiners, and angle grinders.

It’s also important to have safety equipment like safety glasses, ear protection, and respirators.

You’ll also need a variety of measuring tools, such as rulers, calipers, and tape measures.

Finally, you’ll need a selection of glues, adhesives, epoxies, and sealants.

With the right tools, you’ll be able to complete your catamaran project safely and efficiently.

Researching and Planning Your Build

Researching and planning your build are essential steps in the process of building a catamaran.

The first step is to become familiar with the design and construction of catamarans.

Start by researching different types of catamarans, from the small and lightweight recreational boats to the larger and more luxurious cruising vessels.

Learn about the advantages and disadvantages of the different types of catamarans and determine which type is best suited to your needs.

Once you have a good understanding of the different types of catamarans, you can begin researching the materials and tools you will need for your project.

You will need to choose the type of wood you will use for the boats hulls and deck, as well as the type of fiberglass and resin you will use for the hulls and deck.

You will also need to choose the type of engine you will use and the type of rigging and sail you will use.

Once you have selected the materials and tools you will need for your project, you will need to create a plan for the construction of your catamaran.

You will need to determine the size and shape of your boat, the types of joints you will use to construct the hulls and deck, and the type of engine and rigging you will need.

You should also plan out the sequence of construction steps, so that you can build the catamaran in the most efficient way.

Finally, you will need to research the best ways to protect your catamaran from the elements.

You will need to determine what type of paint or varnish to use on the hulls and deck, and you will need to research the most effective ways to protect your boat from the sun, wind, and water.

By taking the time to research and plan your build, you will be able to create a catamaran that is well-built, efficient, and beautiful.

With the right research and planning, you can create an amazing catamaran that will be the envy of your friends.

Final Thoughts

Building a catamaran is a rewarding experience that can be achieved with the right approach and materials.

With a clear plan, the right tools, and a good understanding of woodworking and fiberglass techniques, you can build an amazing catamaran to share with your family and friends.

So what are you waiting for? Get started on your own catamaran build today and all the rewards that come with it!

James Frami

At the age of 15, he and four other friends from his neighborhood constructed their first boat. He has been sailing for almost 30 years and has a wealth of knowledge that he wants to share with others.

Recent Posts

Does Your Boat License Expire? Here's What You Need to Know

Are you a boat owner looking to stay up-to-date on your license requirements? If so, youve come to the right place! In this article, well cover everything you need to know about boat license...

How to Put Skins on Your Boat in Sea of Thieves? (Complete Guide)

There is a unique sense of pride and accomplishment when you show off a boat you customized to your exact specifications. With Sea of Thieves, you can customize your boat to make it look like your...

Did You Know That We Offer Contract to Closing Services? Click Here to Find Out More.

Need Marine Financing? Apply Here With Our Partner, First Approval Source

- Catamaran Interviews

- Catamaran Reviews

- Buying Advice

- Selling Advice

- Woods Design Advice

- Americat 3014

- Balance 526

- Bali 40 Catspace

- Beneteau Blue II

- Broadblue 346

- Broadblue 38 Prestige

- Broadblue 385

- Broadblue 435

- Broadblue 46

- Catalac 10M

- Catalac 11M

- Catalac 12M

- Catalac 900

- Catana 42 S

- Chris White 48 Voyager

- Chris White 55

- Corsair F28 R

- De Villiers

- Dolphin 460

- Endeavour 30

- Endeavour 35 Victory

- Endeavour 36

- Endeavour 44

- Endeavour 44 TrawlerCat

- Fortuna 36 Island Spirit

- Fortuna 401 Island Spirit

- FP 32 Maldives

- FP 35 Tobago

- FP 37 Antigua

- FP 38 Athena

- FP 39 Fidji

- FP 40 Lavezzi

- FP 40 Lucia

- FP 40 Summerland MY

- FP 41 Lipari

- FP 42 Astrea

- FP 42 Venezia

- FP 43 Belize

- FP 44 Helia

- FP 44 Orana

- FP 46 Bahia

- FP 46 Casamance

- FP 48 Salina

- FP 56 Marquises

- FP 57 Sanya

- FP 60 Eleuthera

- FP Saona 47

- Gemini 3000

- Gemini 3200

- Gemini 3400

- Grainger 420 Mystery Cove

- Hirondelle 7M

- Lagoon 37 TPI

- Lagoon 42 TPI

- Lagoon 43 PC

- Leopard 39 PowerCat

- Leopard 45 Classic

- Leopard 47 PowerCat

- Leopard 51 PowerCat

- Leopard 53 PowerCat

- Maine Cat 30

- Maine Cat 41

- Matrix 450 Vision

- Matrix 760 Silhouette

- Maverick 400

- Maverick 420

- Maverick 440

- Nautitech 40

- Nautitech 442

- Nautitech 46 Open

- Nautitech 47

- Outremer 40

- Outremer 45

- Outremer 50 Standard

- Outremer 55

- Privilege 37

- Privilege 39

- Privilege 42

- Privilege 43

- Privilege 435

- Privilege 45

- Privilege 465

- Privilege 48 Transcat

- Privilege 482

- Privilege Serie 5

- Prout 31 Quest

- Prout 33 Quest

- Prout 34 Event

- Prout 35 Snowgoose

- Prout 37 Snowgoose

- Prout 37 Snowgoose Elite

- Prout 38 Manta

- Prout 39 Escale

- Royal Cape 45

- Royal Cape 530 Majestic

- Royal Cape Majestic 500

- Sailcraft 30 Iroquois

- Sailcraft 32 Comanche

- Sailcraft 35 Cherokee

- Sailcraft 41 Apache

- Sailcraft 44 Apache

- Wildcat 350

- Seawind 1000

- Seawind 1160

- Seawind 1200

- Seawind 1260

- Seawind 1600

- Solaris 36 Sunrise

- Solaris 36 Sunstar

- St Francis 44

- St Francis 48

- St Francis 50

- Stealth 11.8

- Heavenly Twins 26

- Ocean Twins 38

- Voyage 380 Maxim

- Voyage 400 Norseman

- Voyage 430 Norseman

- Voyage 450 Cabriolet

- Voyage 47 Mayotte

- Wharram 38 Tiki

- AMI 320 Renaissance

- Woods 22 Wizard

- Woods 35 Banshee

- Woods 35 Flica

- Woods 36 Scylla

- Woods 36 Vardo

- Woods 38 Transit

- Woods 40 Meander

- Xquisite X5

- Xquisite X5+

Catamaran Hull Design

- Post author By Rick

- Post date June 29, 2010

- 2 Comments on Catamaran Hull Design

Part 1: Notes from Richard Woods

Since the America’s Cup experimented with going multihull, there’s been a lot of interest in catamaran performance and the catamaran hull designs that define performance. Many guys are investigating whether to buy a catamaran or design and build their dream boat. Let it be said here that building a large catamaran is not for the faint of heart. People begin building 100s of boats a year, yet few are ever completed, as life always seems to have a way of interfering with a good boat build.

Never the less, since the rest of this website is about selecting and buying a boat , it only seems fair to have at least one webpage that covers catamaran design. This page contains notes on boat hull design goals and an accompanying page from Terho Halme has mathematical formulas used in actual catamaran hull design. It has become a popular research stop and an important reference to the catamaran design community.

The content of this page was reproduced from the maestro of Catamaran designs, renown British naval architect, Richard Woods, who not only designs catamarans, he sails them across oceans…. repeatedly. He has a lot to say on the subject of catamaran hull design.

“…When it’ all said and done, the performance of a sailing catamaran is dependent on three primary specs: length, sail area and weight. If the boat is longer it generally means it’ a faster boat. If she has more sail area, it means she’ a faster boat and if she’ light it means she’ a faster boat. Of course, there are limits: Too much sail area capsizes the boat in brisk winds. If the boat is designed too light, she will not take any kind of punishment. Too slim a hull design and the boat becomes a large Hobie Cat capable of only carrying your lunch. Of course, too long and large and you’d have to be Bill Gates to afford one. Then there are lot of additional and very important factors like underwater hull shape, aspect ratios of boards and sails, wet deck clearance, rotating or fixed rigging and so on….” Richard Woods

All Catamarans are not equal, but all sailboats have two things in common: They travel on water and they’re wind powered, so the Catamaran design equations in the 2nd part should apply to every catamaran from a heavy cruising Cat to a true ocean racer.

Richard Wood’s comments on catamaran design:

We all know that multihulls can be made faster by making them longer or lighter or by adding more sail. Those factors are the most important and why they are used as the basis of most rating rules. However using just those figures is a bit like determining a cars performance just by its hp and curbside weight. It would also imply that a Tornado would sail as fast forwards as backwards (OK, I know I just wrote that a Catalac went faster backwards than forwards)

So what next?? Weight and length can be combined into the Slenderness Ratio (SLR). But since most multihulls have similar Depth/WL beam ratios you can pretty much say the SLR equates to the LWL/BWL ratio. Typically this will be 8-10:1 for a slow cruising catamaran (or the main hull of most trimarans), 12-14:1 for a performance cruiser and 20:1 for an extreme racer.

So by and large faster boats have finer hulls. But the wetted surface area (WSA) increases proportionately as fineness increases (for a given displacement the half orange shape gives the least WSA) so fine hulls tend to be slower in low wind speeds.

The most important catamaran design hull shape factor, is the Prismatic Coefficient (Cp). This is a measure of the fullness of the ends of the hull. Instinctively you might think that fine ends would be faster as they would “cut through the water better”. But in fact you want a high Cp for high speeds. However everything is interrelated. If you have fine hulls you can use a lower Cp. Most monohulls have a Cp of 0.55- 0.57. And that is about right for displacement speeds.

However the key to Catamaran design is you need a higher Cp if you want to sail fast. So a multihull should be at least 0.61 and a heavy displacement multihull a bit higher still. It is difficult to get much over 0.67 without a very distorted hull shape or one with excessive WSA. So all multihulls should have a Cp between 0.61 and 0.65. None of this is very special or new. It has been well known by naval architects for at least 50 years.

There are various ways of achieving a high Cp. You could fit bulb bows (as Lock Crowther did). Note this bow is a bit different from those seen on ships (which work at very specific hull speeds – which are very low for their LOA). But one problem with them is that these tend to slam in a seaway.

Another way is to have a very wide planing aft section. But that can increase WSA and leads to other problems I’ll mention in a minute. Finally you can flatten out the hull rocker (the keel shape seen from the side) and add a bustle aft. That is the approach I use, in part because that adds displacement aft, just where it is most needed.

I agree that a high Cp increases drag at low speeds. But at speeds over hull speed drag decreases dramatically on a high Cp boat relative to one with a low Cp. With the correct Cp drag can be reduced by over 10%. In other words you will go 10% faster (and that is a lot!) in the same wind and with the same sails as a boat with a unfavorable Cp. In light winds it is easy to overcome the extra drag because you have lots of stability and so can fly extra light weather sails.

The time you really need a high Cp boat is when beating to windward in a big sea. Then you don’t have the stability and really want to get to your destination fast. At least I do, I don’t mind slowly drifting along in a calm. But I hate “windward bashing”

But when you sail to windward the boat pitches. The sea isn’t like a test tank or a computer program. And here I agree with Evan. Immersed transoms will slow you down (that is why I use a narrower transom than most designers).

I also agree with Evan (and why not, he knows more about Volvo 60 design than nearly anyone else on the planet) in that I don’t think you should compare a catamaran hull to a monohull, even a racing one. Why chose a Volvo 60/Vendee boat with an immersed transom? Why not chose a 60ft Americas Cup boat with a narrow out of the water transom??

To be honest I haven’t use Michelet so cannot really comment. But I have tested model catamarans in a big test tank and I know how inaccurate tank test results can be. I cannot believe that a computer program will be better.

It would be easy to prove one way or the other though. A catamaran hull is much like a frigate hull (similar SLR, L/B ratios and Froude numbers) and there is plenty of data available for those. There is also a lot of data for the round bilge narrow non planing motorboats popular in the 1930’-50’s which again are similar to a single multihull hull.

One of the key findings I discovered with my tank test work was just how great the drag was due to wave interference between the hulls. Even a catamaran with a modern wide hull spacing had a drag increase of up to 20 % when compared to hulls at infinite spacing. One reason why just flying a hull is fast (the Cp increases when you do as well, which also helps). So you cannot just double the drag of a single hull and expect to get accurate results. And any speed prediction formula must include a windage factor if it is to give meaningful results.About 25 years ago we sailed two identical 24ft Striders next to each other. They were the same speed. Then we moved the crew of one boat to the bow. That boat IMMEDIATELY went ½ knot faster. That is why I now arrange the deck layout of my racing boats so that the crew can stay in front of the mast at all times, even when tacking or using the spinnaker.

I once raced against a bridge deck cabin catamaran whose skipper kept the 5 crew on the forward netting beam the whole race. He won.

Richard Woods of Woods Designs www.sailingcatamarans.com

- Tags Buying Advice , Catamaran Designers

Owner of a Catalac 8M and Catamaransite webmaster.

2 replies on “Catamaran Hull Design”

I totally agree with what you say. But Uli only talk sailing catamarans.

If only solar power. You need the very best. As limited watts. Hp.

The closer to 1-20 the better.

Closing the hulls to fit in cheaper marina berth. ?

You say not too close. But is that for sailing only.

Any comment is greatly appreciated

Kind regards Jeppe

Superb article

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Time For a Catamaran Adventure

Isn't Time For Yours?

Building Your Own Catamaran

Building your own catamaran is another option to getting into your own boat. In this page we will go over the advantages, considerations, and a detailed history and journal of our boat-building adventure with Light Wave . We hope this will give you a clear picture of what lies ahead if you go this route, including:

- Construction methods

- 9 essential design features

- Review of the four leading catamaran designers for home builders

- Construction times

- Budget: How much did it cost to build a basic cruising catamaran?

- Layout of our catamaran, LightWave , and lots of pictures

- Carllie’s article from September 2000 Multihulls Magazine: “The Boat Builder’s Wife “

- Equipment outfitting

- Radio and communication outfitting

- Dinghy selection and considerations

- Having a boat custom-built for you

Because of the huge dollars needed to buy a new or even a used catamaran, we would never have gotten a catamaran if we hadn’t built it ourselves.

Let’s start by saying that building any type of larger boat, especially a catamaran, can be one of the most intellectually and physically challenging things you will ever do.

It has been said that building a large boat is the closest a man can come to giving birth to a baby. In other words there is going to some discomfort and pain along the way; you will question yourself on whether this was such a good idea; it’s very difficult to reverse the decision; and though friends will support you, you will be on your own most of the time with your significant other if he/she is game.

Know your boat

You will intimately know every part of your boat. You will know where every wire, hose, bolt, bulkhead, rib, and support is because you installed them!

Pride of ownership

We have often thought what it would be like to just buy a boat from a manufacturer, and know that while owners who have spent a lot of cash (or future life to pay off the lien) their often possessive and competing-with-the Joneses could not begin to compare to our quiet glow of happiness and akinship we feel with Light Wave .

Our boat is like part of the family. So much time was spent on her that we have a major emotional investment. Every time we see our vessel – from a distance at anchor or approaching her in our marina, we say, “What a pretty boat! I can’t believe we built it!” Then that sense of accomplishment settles back in and we feel we have indeed earned the privilege of all of the beautiful experiences we have had sailing, cruising, exploring the beautiful BC Coast and much further a field (or should we say “an ocean”?).

You will be able to pay for the materials as you go and “donate” your time to the cause.

Get a newer design

Many of the production boats that are out there are designs of many years ago because the manufactures have to recoup their capital investment on the mold and production setup. When you build your own you have much newer designs to draw from.

Details on Our Boat Building Adventure

We had sailed our first boat Wave Dancer for five years and had many adventures on the British Columbia coast. In May 1996, I had just returned from a little one-week solo trip in the Gulf Islands of BC when I bought the book, The Cruising Multihull by Chris White (Future link to book review on our web site).

This is the book that got me going (Carllie was not yet convinced). I must have read it a half dozen times over the next 6 months, each time becoming more convinced that this was the way to go for our next boat. It was really still pre-internet web site days so I wrote to all the designers that were listed in the back of the book. Over the next several weeks packages of information started appearing in the mailbox (there is just something about getting packages in the mail – I guess it’s the anticipation). I would pour over these preliminary printed pages with pictures and accommodation layouts. Next, I put a few dollars down to buy the information packages and study plans from the top prospects.

I waited patiently for the study plans. It was like the night before Christmas when I was kid. Oooh the wait! Finally they came, and again I carefully scrutinized the next level of detail. Things were getting a little more serious. The top contenders were:

- Richard Woods

- Chris White

- James Wharram

Click here to read my comments and reviews on their catamaran designs as well as those of Jeff Schionning.

I remember initially drooling over the Atlantic 42 by Chris White, still one of my favorite designs. It seemed to be so seaworthy (by the way if I run into about $800,000 USD any time soon, I am going to buy an Atlantic 55). The most important piece of advice that came out of the material was from Richard Woods:

“Build the smallest boat you‘d be happy with it.”

Axiom #1: The hours to build a catamaran is in almost in direct proportion to its weight.

Which brings us to Axiom #2:

Axiom #2: It takes about 1 hour to create 1 pound of finished boat.

In our case we spent 3,500 hours ( click here for full details on the construction hours ) to build a 4,000 lb. boat (just a little less than 0.9 hours per pound). If a boat’s empty weight is 8,000 lbs., it will probably take about 6,000 hours to build.

When you think about it, you can only mix and handle so much material per hour. More boat weight, more material, more hours. Sure there are some economies of scale on a bigger boat, but usually the systems become more complex and these take longer to install.

This decision process took 8 months and I figured we’d launch in 6 months. It was now January of 1997. Little did we know it would be 26 months and 3,500 hours between the two of us until we launched on June 5, 1999. We ordered the full plans and we were off and running.

We were ready to build, but where would we start the process? First of all, we live in a tiny 480 sq. ft. apartment in Vancouver. Back-yard building wasn’t exactly an option so I found a small garage nearby that we rented for 5 months.

After about 4 months in the garage, I had made all the small parts and it was time to build the hulls. This meant that we had to go larger facilities. We found space at Shelter Island Marina and Boatyard in Richmond. This is the biggest boat yard in the Vancouver area with dozens of commercial and private projects, big and small, under way.

We were out of money by then, so we sold our first boat so we could buy resin and fiberglass. It was a traumatic time as we said goodbye to our beloved Wave Dancer . We were now committed. We than had all the foam for the hull cores, barrels of resin, and huge rolls of matting and roving needed for the fiberglass skins delivered to our “domed stadium”. We kicked ourselves many times that we didn’t take a picture of this raw material stacked in one corner of the empty shed, so we could later show “before” and “after” photos. It was time to build the hulls.

Over the next several months we proceed to join the hulls with the beams I had built in the garage, and then to install the cuddy cabin, cockpit, and decks. By the spring of 1998, it was staring to look like a catamaran. Through the spring and summer of 1998, we continued with the major structural components: mini-keels, hatches, stairs, and interior. Then we went on to the very laborious work of fairing the boat before painting. Don’t under estimate that job!

By October 1998 we were ready to prime the boat and start painting. I really thought this would go quickly. I forgot that I would have to do two more complete sandings to sand off and finish the two layers of primer application. In addition we had to fill countless pinholes – a laborious process somewhat like hiking up a mountain – each time you get to what you think is the top, you see another summit!

The boat seemed to get bigger and bigger. Believe me, there is a lot of surface area on a catamaran. I clearly remember that last sanding: I had reached the end of my physical and mental endurance – I was exhausted. I was ready to move on to the next phase – any phase but more sanding!

We now started spray-painting the hulls bright yellow. It was around this time we decided on our boat name of Light Wave . The painting took over a month: the hulls being the easy part, it was the topsides, the nonskid, and all the masking and prep that seemed to take forever. Happily, the worst of the dust was gone.

By March 1999 we were in the home stretch. The center bridge deck cabin was completed so we took a week off from our paid jobs and lived on the boat in the shed so we could work all day and not waste time commuting. March, April and May were frantic months as we finished all the final touches: engine installation, rudders, windows, deck fittings, electrical, plumbing, mast, and rigging. See our outfitting page (for more details on what we picked and why, and things we would do differently now.

Initially, our electronic systems were relatively basic but included GPS and autopilot see the following link for all our electronic outfitting choices and reasoning for more details.

It was May 22, 1999 and we decided that Saturday, June 5th would be “Launch Day” so we could send invitations to all of our friends. On the Friday night before Launch Day, we still had a number of final things to do, many of them outside. Unfortunately it was pouring rain. We were tired and very wet but the boat had to go into the water next day so we persevered on till everything was ready.

The moment of truth came as Light Wave was lowered into the water. While still in the slings of the Travelift, I jumped aboard to check for leaks. Of course there weren’t any! More food and laughs and tours of the boat for all attending. It was a great day.

Emotionally drained that night, we slept in Light Wave in the water for the first time. It was another week before we actually went out for our first trip as we had to sell the shed, setup sails, and install some final deck hardware.

To sum it up, building a catamaran was a great experience. We learned a lot. Carllie and I grew closer together through it all. We had a great time doing it. We had a beautiful catamaran to show for it. Now it was time for a catamaran adventure !

HOME / INDEX PAGE

The challenge of building a trimaran from beachcat hulls

Hi Mike! Let me first say I appreciate the depth of information on your web site :)

I've been ‘oogling’ it for years. But now I have a question regarding the potential of building a trimaran out of some old 18' cat hulls. How would you suggest I proceed and what might I expect from the result ?

….. Josh from Kalispell, MT.

ANSWER : Tks Josh … always pleased to hear my work is proving of value to others.

I first need to say that using cat hulls is not a perfect fit for either the vaka (center hull) or even the amas (floats) but sometimes we can make something work as a fun project. The vaka will be the biggest challenge. I could briefly answer your question with just a list of do’s & don’ts , but I think a more detailed reply will give you some specifics and cover a broader range of related questions, so here we go.

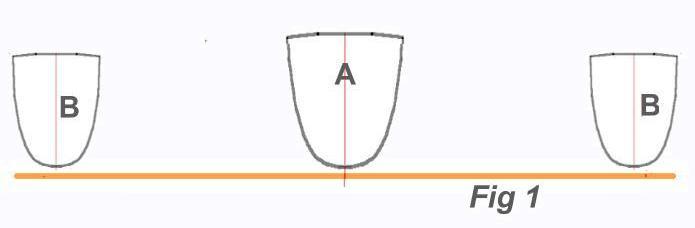

First step is to make a weight estimate starting with what a ship designer would call the “Lightship weight” (boat ready to sail, but no supplies, crew or their personal equipment). You then need to decide what weight you wish to tack-on to form the Design Displacement . This we call the ‘Deadweight’. The very minimum would be for solo day sailing .. say 200 lbs added to the Lightship weight, but for an 18footer, this will likely be more like 350lbs as an absolute minimum.

So let’s assume the boat and its rig and gear weigh 550 lbs. Now with 350lbs added, the required Design displacement will now be 900lbs. The volume to support that will be 900/64 = 14 cu.ft. (1 cuft displaces 64 lbs of seawater, or use 62.4 for fresh water)

The difficulty with a trimaran over a beachcat, is that there is initially only ONE hull to provide this buoyancy volume, compared to two for a catamaran, so right away, one can see why a single catamaran hull is WAY too small for a vaka. Let’s say these are your 3 hulls.

Place the widest one with most volume in the center.

Obviously, if you kept the hull in this level position, your trimaran would be dragging 3 hulls through the water with far more drag than for a catamaran.

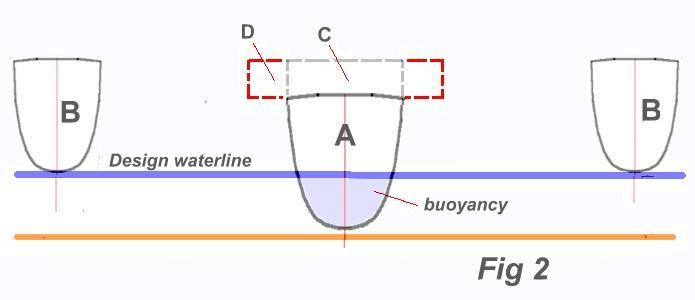

So you need to lower the central hull, so that it will support your 900 lbs .. requiring 14 cu.ft volume under the waterline. It will clearly not have the volume needed so what can be done ? There are 3 basic ways to go. You can lengthen it, widen it, or sink it deeper. Using all three would be best if designing a new vaka but I suggest that sinking it deeper will be the easiest, as you can then just raise the sides. But you will probably need some frames to support the deeper hull section as the hull will now have to accept more hydrostatic pressure.

It will now look more like this:

You can either raise the sides (C) or a better solution would be to combine this with side extensions (D) to give yourself some form of central cockpit as well as more width to later attach your cross beams (akas). Exactly how deep this central hull will need to go, will decide how practical this whole ‘conversion’ will be, and it’s quite possible you will need to do some major surgery to this central hull (or build a new one) to get the buoyancy volume you need. If you are not already familiar with how to calculate this, I suggest you study this page from the design section.

https://www.smalltridesign.com/Trimaran-Articles/design/simpsons-rule.html

A very rough idea of the sectional area (marked as ‘buoyancy’ in the above sketch) can be obtained by assuming a Block Coefficient* of 0.5. For this, double your required volume and divide by your waterline length .

- Block Coefficient is the ratio of actual hull volume to an encompassing ‘block’, that has dimensions equal to: your waterline length: your waterline beam: and underwater water depth (design draft)..

So in this case, this will be 2 x 14 / 17.5 or 1.60 sqft, which will roughly require a beam and draft of (1.60 0.5 ) or 1.265 ft for both waterline beam and for draft .

If your hull is much smaller, you either have to go deeper than 1.3ft draft OR find ways to widen that hull to get the cross-sectional area you need. (Typically, a central trimaran hull has a waterline width of about double that of the ama beam).

Moving forward .. let’s assume you now have chosen your best workable solution for the vaka.

As far as the overall beam is concerned, the issues involved and a way to select a suitable beam is already explained in this Q&A from earlier this month.

We now need to connect the amas with the main hull using beams. As I understand you are planning to use a similar folding system to my W17 and using my design of fiberglass hinge and latch , I will explain what you will need.

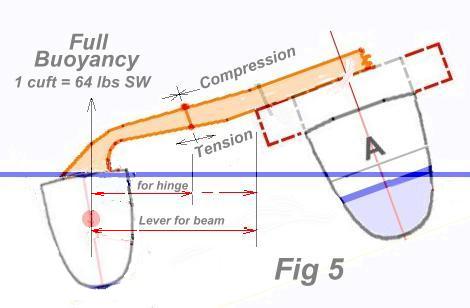

Beam and latch strength will be defined by the maximum righting moment that the ama can apply, plus a safety factor.

As a safety factor, it is common to apply the full buoyancy of the ama (when fully underwater) to the main beam ... and multiply by the Beam Lever (shown here), which might be ~4ft in this case. IF the full ama volume is say 800 lbs, then the bending moment on the beam would be 3200 lbs.ft

Once you have fixed the hinge location, you can calculate the bending moment at the hinge, using the same 800 lbs (just assumed for this example) but with a smaller lever. Let’s assume it is 2.5ft in this case, so the Bending Moment will now be 2.5 x 800 or 2000 ft lbs. This would mean that IF your vertical distance between the upper hinge and the lower latch is 5” deep (0.42ft), that the latch will need to take 2000/0.42 or 4762 lbs in tension, for the hinge to be as strong as the beam. This shows the important value of 'beam depth' with a hinge system.

There will also be a download on the upper hinge, due to whatever crew weight you place on the flying windward ama (plus the weight of the ama and outer beam itself). With a large volume ama, this download is typically about 70-80% of the upload, so the hinge is a little less stressed in tension than the lower latch, but with a small ama, it could be the reverse, so you need to do the maths..

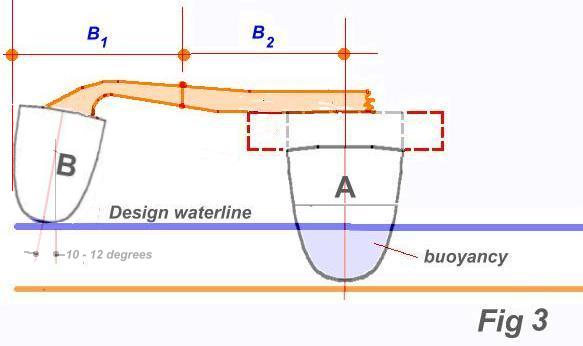

In Fig 3. note that I show the amas inclined out at 10-12 degrees. If this is not done, they are more side-loaded when heeled and this adds an unnecessary load to their beam attachment as well as making the ama more resistant to push through the water, so personally, I consider some outward angle is essential.

In addition to their location in the above sectional view, the outer hulls that will work as amas, also need to be positioned in profile view , relative to the central hull.

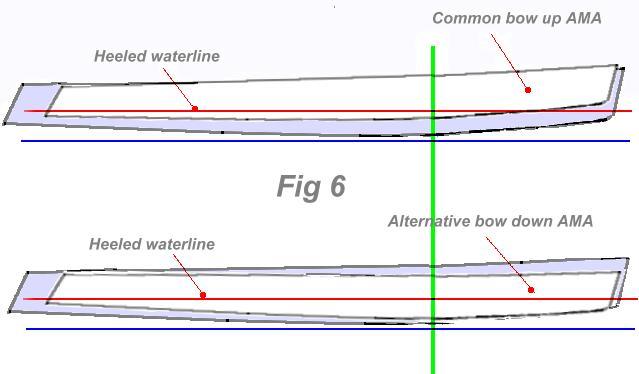

In the sketch below, they are shown with slight lift of the bow that some designers in the past have incorporated with the assumption of less resistance and 'to ride over the waves'. In the 1970’s many amas were then banana shape d and even back then, Hobie 16 hulls were sometimes used as trimaran floats. Having sailed on one a few times, I found such boats (like Newick’s Tremolino for one) were very jittery in any seaway, were very wet, and also pitched excessively. Even using the straighter and therefore more suitable H18 hulls, their stability role for a trimaran is still compromised if installed as shown here in Fig 6.

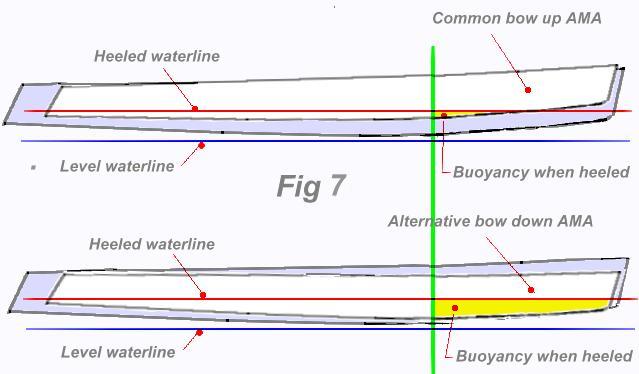

Just compare these two sketches in Fig 7 that both show an identical assumed heeled water line (in red) and you can see that IF the bow of the ama is raised that the ama will not give any bow lift UNTIL the whole bow drops, severely increasing the risk of pitch-poling, so unless the bow is very full with a wide vee, its more effective and safer to actually LOWER the buoyancy of the ama bow so that it quickly immerses, to provide more effective lift when heeled.

So what can be done to make the beachcat hull more like this ama? The bow is deep and narrow, not vee’d. Think of the Hazelett mooring buoy that is a vertical tube. While it still offers buoyancy, it moves very little in waves. When a bow is like that, its not easily launchied in the air to only fall again, over and over again. It just stays quiet and cuts horizontally through waves and it certainly increases the waterline length. Early rockered amas, had short waterline lengths and were also vee’d … two things I advise against. After all, we are ’sailing’ on this ama and need it to act like an efficient boat hull. But as it would be complicated to deepen the forefoot of an existing beachcat hull, its easier to lower the bow as shown above and then raise the deck forward of the forward beam.

As a picture is a 1000 words …, check out what I would do. 3 days of 4 hours could see both done if you plan your work.

You might find a collision bulkhead inside that will need cutting across, but it should not be hard to raise that with rigid foam, so that the raised deck can be bonded to it and keep it watertight. The ¾” holes in the sides will stop the end of the cut from splitting and cracking, and will be filled and covered over by the fill piece.

This should give one enough to make the important decisions and calculations, but as can be seen, catamaran hulls are not ideally interchangeable with Trimaran hulls, so their use like this will always be a compromise.

You also have to decide which hull will hold a centerboard or daggerboard. It’s much easier to reach one in the center hull, but this is your choice and dilemma. Either can be made to work but do not use ama boards unless you are operating in deep water, or you may end up IN the water while trying to adjust them from an ama, especially in rough water.

As far as the end result , it depends on so many things that it’s hard to predict. But it could be made to perform quite well in relatively flat water and give you some fun at least … but it will not be a dry boat like the W17, nor as comfortable or have as low leeway, as the round hulls are just not as ideal for slicing waves with minimum disturbance as the W17 hulls are. While rounded hulls are very effective in lowering surface friction, they seldom slice waves as well and certainly do not provide the leeway resistance of the W17 hulls.

It's also frequently forgotten (or just not understood) that often, the greatest resistance from a small boat is wave resistance or wave making … being the most critical in the 4 to12kt range. Optimizing for this range with non-round hulls can more than make up for their added skin drag. See this article for more on this, where there is a chart showing what proportion of residuary (wave) resistance applies at what speed.

Hope this helps to get you going in the right direction, and good luck with your project.

Also note that there was an earlier question of using the reverse ... Trimaran hulls for a Catamaran and as my graph showing the proportion of residuary resistance versus the total is also there, it may be of some interest too.

Mike ... March 2022