Rigging - Turnbuckles , Toggles , Wire & Rod Components, Norseman Cones & Fittings.

Furling Systems - Systems and replacement parts from a variety of Manufacturers.

Traveller Systems - Adjustable Track Systems for Mainsheet and other applications.

Sailboat Hardware - Rope Clutches, Blocks, Track & Fittings, Winches, etc.

Custom Parts - Custom items, or those out of production or otherwise unavailable.

Consultation - Special projects, research, or information not detailed on-site.

Copyright 1996 - 2024, Rig-Rite, Inc. Disclaimer Web Site maintained by The WATER Group

- Navigating the High Seas: A Comprehensive Guide to Sailboat Masts

Sailboat masts are the unsung heroes of the sailing world, silently supporting the sails and ensuring a smooth journey across the open waters. Whether you're a seasoned sailor or a novice, understanding the intricacies of sailboat masts is essential for a safe and enjoyable voyage. In this comprehensive guide, we will delve into the world of sailboat masts, discussing their types, maintenance, and everything in between.

Types of Sailboat Masts

Sailboat masts come in various configurations, each with its advantages and drawbacks. The two primary types are keel-stepped and deck-stepped masts.

Keel-Stepped Masts

Keel-stepped masts are the most common type, extending through the deck and resting on the boat's keel. They provide excellent stability and are suitable for larger sailboats. However, they require careful maintenance to prevent water intrusion into the boat's cabin.

Deck-Stepped Masts

Deck-stepped masts rest on the deck of the boat, making them easier to install and remove. They are commonly found on smaller sailboats and are more forgiving in terms of maintenance. However, they may offer slightly less stability than keel-stepped masts.

Components of a Sailboat Mast

To understand mast maintenance better, it's essential to know the various components of a sailboat mast. The key parts include the masthead, spreaders, shrouds, and halyard sheaves.

The masthead is the topmost section of the mast, where the halyards are attached to raise and lower the sails. It also often houses instruments such as wind indicators and lights.

Spreaders and Shrouds

Spreaders are horizontal supports attached to the mast to help maintain the proper angle of the shrouds (cables or rods that provide lateral support to the mast). Properly adjusted spreaders and shrouds are crucial for mast stability and sail performance.

Mast Materials: Choosing the Right One

Sailboat masts are typically constructed from three primary materials: aluminum, wood, and carbon fiber. Each material has its unique characteristics and is suited to different sailing preferences.

Aluminum Masts

Aluminum masts are lightweight, durable, and relatively easy to maintain. They are commonly used in modern sailboats due to their cost-effectiveness and longevity.

Wooden Masts

Wooden masts, while classic and beautiful, require more maintenance than other materials. They are best suited for traditional or vintage sailboats, where aesthetics outweigh convenience.

Carbon Fiber Masts

Carbon fiber masts are the pinnacle of mast technology. They are incredibly lightweight and strong, enhancing a sailboat's performance. However, they come at a premium price.

Mast Maintenance

Proper mast maintenance is essential for safety and longevity. Regular cleaning, inspection, and addressing minor issues promptly can prevent costly repairs down the line.

Cleaning and Inspection

Regularly clean your mast to remove salt, dirt, and grime. Inspect it for signs of corrosion, wear, or damage, paying close attention to the masthead, spreaders, and shrouds.

Common Repairs and Their Costs

Common mast repairs include fixing corroded areas, replacing damaged spreaders, or repairing shrouds. The cost of repairs can vary widely, depending on the extent of the damage and the materials used.

Extending the Lifespan of Your Mast

Taking steps to prevent damage is essential. Avoid over-tightening halyards, protect your mast from UV radiation, and keep an eye on corrosion-prone areas.

Read our top notch articles on topics such as sailing, sailing tips and destinations in our Magazine .

Check out our latest sailing content:

Top 10 reasons boaters contact their insurers

The best cruises from Biograd na Moru

Yachting Away from Ourselves: A Voyage to Inner Peace

Sail to the 7 most beautiful sights in Greece

What skipper's licence do I need?

From Lefkada or Corfu to Paxos and Antipaxos

Discover the paradise of Paxos and Antipaxoss

Discover Corfu: sailing adventure in the Ionian

Sextant and navigation: survival without GPS

5 best sailing routes in the Bahamas

Yachting guide to the Bahamas

The ultimate yacht cleaning kit

Introduction to chartering with a skipper

Traditional sailor tattoos: Meaning of the swallow

The most popular catamarans of 2023

Fishing and sailing: where to sail for the best catches?

Lighthouses you won't forget

New Year's resolution: let's sail more eco

British Virgin Islands: sailing paradise

How to get kids to enjoy sailing?

How to sail a yacht on a tailwind

How to sail a yacht in crosswinds

Götheborg: the greatest sailing ship

How to have a nautical Christmas

What to pack for a tropical sailing

How to sail a yacht against the wind

Sailing the Maldives: paradise

Interview: is ocean pollution irreversible?

How to gear up for the 2024 sailing season

Medicanes in Greece

Stepping and Unstepping a Mast

Stepping and unstepping a mast is a crucial skill for any sailboat owner. This process involves removing or installing the mast on your boat. Here's a step-by-step guide for safe mast handling.

Step-by-Step Guide for Safe Mast Handling

- Gather the necessary tools and equipment.

- Disconnect all electrical and rigging connections.

- Use a crane or mast-stepping system to safely lower or raise the mast.

- Secure the mast in its proper place.

- Reconnect all electrical and rigging connections.

When and Why to Unstep a Mast

You may need to unstep your mast for various reasons, such as transporting your sailboat or performing extensive maintenance. It's crucial to follow the manufacturer's recommendations and ensure a safe unstepping process.

Sailboat Mast Boot: Protecting Your Mast

A mast boot is a simple yet effective way to protect your mast from water intrusion and damage caused by the elements. Here's what you need to know.

The Purpose of a Mast Boot

A mast boot is a flexible material that wraps around the mast at the deck level. It prevents water from entering the cabin through the mast opening, keeping your boat dry and comfortable.

Installing and Maintaining a Mast Boot

Installing a mast boot is a straightforward DIY task. Regularly inspect and replace it if you notice any signs of wear or damage.

Replacing a Sailboat Mast

Despite your best efforts in maintenance, there may come a time when you need to replace your sailboat mast. Here's what you should consider.

Signs That Your Mast Needs Replacement

Common signs include severe corrosion, structural damage, or fatigue cracks. If your mast is beyond repair, it's essential to invest in a replacement promptly.

The Cost of Mast Replacement

The cost of mast replacement can vary significantly depending on the type of mast, materials, and additional rigging needed. It's advisable to obtain multiple quotes from reputable marine professionals.

Yacht Masts: Sailing in Style

For those looking to take their sailing experience to the next level, upgrading to a yacht mast can be a game-changer.

Differences Between Sailboat and Yacht Masts

Yacht masts are typically taller and offer enhanced sail performance. They are often equipped with advanced rigging systems and technology for a more luxurious sailing experience.

Upgrading to a Yacht Mast

Consult with a marine professional to determine if upgrading to a yacht mast is feasible for your sailboat. It can be a significant investment but can transform your sailing adventures.

Sailboat Mast Steps: Climbing to the Top

Mast steps are handy additions to your mast, allowing easier access to perform maintenance or enjoy panoramic views. Here's how to use them safely.

Using Mast Steps Safely

Always use proper safety equipment when climbing mast steps. Make sure they are securely attached to the mast and regularly inspect them for wear or damage.

The Advantages of Mast Steps

Mast steps provide convenience and accessibility, making sailboat maintenance tasks more manageable. They also offer an elevated vantage point for breathtaking views while at anchor.

Mast Maintenance Tips for Beginners

If you're new to sailboat ownership, these mast maintenance tips will help you get started on the right foot.

Essential Care for First-Time Sailboat Owners

- Establish a regular maintenance schedule.

- Seek advice from experienced sailors.

- Invest in quality cleaning and maintenance products.

Preventing Common Mistakes

Avoid common pitfalls, such as neglecting inspections or using harsh cleaning agents that can damage your mast's finish.

Sailing with a Mast in Top Condition

A well-maintained mast contributes to a safer and more enjoyable sailing experience. It enhances your boat's performance and ensures you can rely on it in various weather conditions.

How a Well-Maintained Mast Improves Performance

A properly maintained mast helps maintain sail shape, reducing drag and improving speed. It also ensures that your rigging remains strong and secure.

Safety Considerations

Never compromise on safety. Regularly inspect your mast, rigging, and all associated components to prevent accidents while at sea.

Sailboat masts are the backbone of any sailing adventure, and understanding their intricacies is crucial for a successful voyage. From choosing the right mast material to proper maintenance and upgrading options, this guide has covered it all. By following these guidelines, you can sail the high seas with confidence, knowing that your mast is in top condition.

So what are you waiting for? Take a look at our range of charter boats and head to some of our favourite sailing destinations.

I am ready to help you with booking a boat for your dream vacation. Contact me.

Denisa Nguyenová

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

Replacing Your Sailboat Rigging

- By Wendy Mitman Clarke

- Updated: March 23, 2020

Whether you’re buying a used sailboat that’s new to you or you’ve owned your boat for decades, the standing rigging is what keeps the mast in place, and thus requires particular attention. How do you know when it’s time to re-rig? There are some obvious answers to this one — for instance, if your wire rigging has broken strands or if it’s suffering from “candy-striping,” i.e., rust-colored streaks swirling down the wire. The latter may indicate two things: one, that it’s simply surface rust, which you should be able to polish off, or two, that as the wire was being manufactured, a strand might have picked up some contamination during the process and is compromised, which is cause for concern. A third visual indicator are cracks in swaged fittings, some of the most common end fittings for wire. Cracks are hard to see (use a magnifying glass), and sometimes marks that look like cracks can be left by the machine used to create the swage. Then there’s just age, and this factor as a reason to re-rig is more subject to a boat’s history than anything else.

“There’s a rule of thumb, but it varies rigger to rigger,” says Steve Madden, co-owner of M Yacht Services in Annapolis and the head of its M Rigging division. “My belief is that you should be replacing your sailboat’s standing rigging every 10 to 15 years.” But this time frame also is variable, depending on the boat’s purpose and use. For instance, for an offshore bluewater boat, Madden recommends 10 years, and for a serious coastal cruiser, more like 12.

“The biggest thing we like to have is the history of the boat: what kind of boat it is, how it’s been sailed and where has it been sailed,” says Jay Herman, owner of Annapolis Rigging. “That history will affect what kind of life you get out of your standing rigging.” Some insurance companies, he says, will require a re-rig if you’re purchasing a used boat that has standing rigging older than 15 years.

Either way, Jimmie Cockerill, co-owner of the Rigging Company in Annapolis, recommends that for a sailboat with wire rigging, the mast should be pulled and all fittings and wire visually inspected every five to six years. And although rod rigging may be able to last longer than wire, it too needs to be serviced every five to six years to get the most life out of it. Sticking to the 10-year rule, Madden says, means that for the most part, any corrosion or failure points will be eliminated with a re-rig.

How the rigging has been tuned is also part of a boat’s story. For instance, Madden says, he recently had a customer whose 46-foot cutter had a rigging failure at six years. The customer had had the boat re-rigged, and during a trip to the BVI, the new wire stretched. The owner didn’t adjust the rigging to compensate for the stretch for several seasons. “That was a case of not knowing that the worst thing you can do to standing rigging is have it loose on the leeward side,” he says. “Sailboat rigging very rarely fails from being overloaded. There’s such a safety margin in rigging. So you’re sailing offshore and you’re looking at the windward shroud that’s taut, and that’s not the one to worry about. It’s when the leeward side starts flopping around that you’re asking for trouble.”

Stainless steel has a finite number of cycles — essentially, movements, whether fore and aft or side to side. “The theory is that it can take 10 to 15 years of cycling, but this continual motion when it’s unloaded is what fatigues the wire,” Madden says. “There’s no real way of measuring that. Die testing won’t pick it up, and it’s rare that a wire will give you warning before breaking.”

So how often should standing rigging be replaced? For all of these reasons, most riggers agree that when your sailboat’s standing rigging approaches 15 years old, it’s a good time to consider replacing it.

Wire or Rod Sailboat Rigging?

Riggers say the question of whether to rig with wire or rod is usually fairly easily answered: Run what you brung. In other words, if your boat already has rod rigging, with all of the end fittings to terminate the rods both on deck and in or on the mast, then sticking with rod will ultimately be less expensive than making the switch to wire. Likewise, if you already have wire with fittings that accommodate your boat and mast, stick with wire. Aside from the relative cost differences between rod and wire (rod is more expensive), what also makes a switch pricey is having to significantly modify the mast to accept the different rigging.

Although rod rigging is more common on racing boats, many well-known cruising-boat builders, such as Valiant, Bristol, J/Boats and Hinckley, have rod-rigged models. The benefits of rod are less stretch, less weight, less windage, and arguably longer life than wire, because there’s less possibility for corrosion of the rod itself.

That said, some sailors prefer wire over rod for a number of reasons. First, it’s easier to fix in remote places and on your own. With a spare mechanical end fitting, wire and the proper tools, you can replace a stay pretty much anywhere. Similarly, it’s easier to find usable replacement parts far from busy ports. Wire rigging is generally less expensive and easier to handle. Finally, rod rigging requires a particular type of terminus — called a cold head — that can be fabricated only with a purpose-built machine, which only a rigging shop will have. You cannot use a mechanical fitting on rod rigging.

In the past, long-distance cruisers typically chose wire rigging with mechanical fittings for all of these reasons. They also would carry a piece of wire as long as the longest stay on the boat — coiled and stowed, which undeniably was sometimes easier said than done — as well as spare end fittings and the tools needed to replace a broken shroud or stay. Today, with the advent of super-strong synthetic line such as AmSteel and Dyneema, the need for that extra wire and gear is eliminated. For instance, the Rigging Company makes a spare-stay kit that can accommodate either wire or rod rigging repairs, Cockerill says. It has a synthetic stay with an eye splice, a toolless turnbuckle (the Handy Lock, made by C. Sherman Johnson), quick-release fast pins with an attached lanyard, several high-strength Dyneema loops, and even a heavy-duty zip tie to fish loops in and out of holes in a mast.

“The idea is you come on deck with this small canvas bag and make it happen,” Cockerill says. “Let’s say you ripped a tang out of the mast; you can use a Dyneema loop to create another attachment point. A smaller loop is a makeshift chainplate attachment — you can attach it to a neighboring chainplate and attach the stay to it. It’s good enough to get you to safety and someplace you can make a more permanent repair.” Riggers say very few sailors re-rig from wire to rod or the reverse, but if switching is on your mind, have a professional make a full assessment first.

There are so many variables in the system — types of end fittings, types of masts, types of attachment points — that each boat will have its own specific requirements that can affect cost. For that reason, it’s difficult to give an accurate estimate of the cost of making the switch, even for an average 40-footer.

End Fittings for Sailboat Rigging

All standing rigging, whether rod or wire, has to end in a fitting that attaches to the deck and mast. The three most commonly used types of attachments are swaged and mechanical fittings for wire, and cold heads for rod. Generally, end fittings fall into a few classes: studs, eyes, forks and hooks, each of which comes in a dizzying array of sizes and configurations. There are multiple combinations and variations: For instance, if your mast has double tangs, most likely the end fitting will be an eye — although it can be a marine eye or an aircraft eye, which differ primarily in shape. All rod rigging terminates in a cold head, which accommodates the end fitting or is encapsulated by the end fitting. This could be a marine eye, a marine fork, a T-head or a J-hook, among others.

A swaged fitting is a terminus that’s attached using a machine called a swager. It rolls the end fitting through two opposing dies and compresses the fitting on the wire so tightly that it can’t pull out. “The theory is that you’ve crushed it so tightly that all the wires inside have just merged into one solid piece of stainless,” Madden says. Swaging must be professionally done, and the result is extremely strong and generally has a long life. Top manufacturers of swaged fittings are Hayn Marine Rigging Products, Alexander Roberts and C. Sherman Johnson.

Mechanical fittings can be applied using a few common hand tools by the mechanically handy DIY sailor, which is one reason they’re popular. The two primary manufacturers of mechanical fittings presently are Sta-Lok and Petersen Stainless, which produces Hi-MOD. Both are located in the U.K., and the products are distributed in the U.S. through vendors like Hayn, West Marine, Defender, and local chandleries and riggers. Generally, they consist of either three or four parts (Sta-Lok has three; Hi-MOD has four), including a sleeve; a cone; in Hi-MOD’s case, a crown wheel; and the terminal (an eye, fork, stud, etc.). If you follow directions, they are fairly straightforward to install, although not especially easy. “The mechanical fasteners are great in that you can terminate and then look inside to be sure it’s formed correctly, so you do have a way of inspecting your work,” Madden says.

However, they generally cost more than a swaged fitting; Herman says while Hi-MOD’s newer mechanical fittings are “definitely more user-friendly to assemble, they’re twice the cost of a swaged fitting.” Some riggers will recommend swaged fittings for the mast end of the rigging and mechanical fittings at the deck level: Corrosion is less prevalent at the top of the mast, and you can more easily and regularly inspect mechanical fittings at deck level, where they’re frequently subjected to salt water

Should You Replace Your Sailboat’s Rigging Yourself?

So you’ve determined your sailboat’s standing rigging needs work. Do you hire a pro or go it alone? Good question. Yes, doing it yourself will theoretically save money. For an average 40-foot boat, Cockerill estimates about $100 per foot to re-rig with wire rigging ($4,000), as well as the round-trip cost to haul and launch the boat and unstep and step the rig (an additional $2,500 or so). By taking on the labor yourself, you’ll probably save as much as $2,000 on the re-rigging cost, he says. Madden says that cost isn’t linear, though; as you go up in size (a bigger boat needs heavier wire and larger fittings), you’ll spend more. He’d estimate more like $4,600 for a 40-foot boat, but all of these numbers depend on how much is involved: Are there furlers? What kind of end fittings? Are the chainplates sound? Depending on the answers to those questions and others, a professionally done re-rig for a 40-footer could be closer to $6,000 or more.

If you go DIY, you will be limited to mechanical end fittings unless you hire a rigger to swage your end fittings. The Rigging Company gears much of its sales to DIY sailors and is beginning an e-commerce site to cater specifically to handy individuals. But Cockerill says it quickly becomes evident whether an owner feels comfortable enough to do the work. “You should be mechanically inclined,” he says, “and the way to find that out is if I start talking all this technical jargon and you decide whether you’re suited to handle that at all.”

Additionally, a DIY sailor needs to do plenty of research, particularly when it comes to wire quality, which is something professional sailboat rigging companies watch like hawks. Although anyone can walk into a local chandlery and buy wire, that doesn’t mean the wire is of the highest quality. Marine-suitable stainless wire is called 316 grade, but even that doesn’t mean you’re necessarily getting high-quality wire. Much depends on where it is manufactured; Herman and other riggers say the best wire today is coming from South Korea through a manufacturer called KOS, making wire to military specifications. It’s imported and sold through distributors like Alps Wire Rope.

“We only sell guaranteed-content, guaranteed-process wire,” Herman says. “There are other wires out there that are cheaper, but they’re not guaranteed.”

As for sources of wire and fittings, there are many, including major chandleries and vendors, like West Marine and Defender, as well as some private riggers, like Annapolis Rigging and the Rigging Company, which will work with you to define what you need and help you source parts and materials.

One thing all the riggers I spoke with expressed emphatically was that stainless steel needs oxygen to create a fine film of oxidation that protects the metal. The fastest route to crevice corrosion is to cover the metal with plastic or leather turnbuckle covers or to coat the fittings in tape. Enough tape to cover a cotter pin suffices; otherwise, leave the metal open to the air. Likewise, if you are re-rigging your sailboatboat, use the opportunity to check your chainplates (easily the subject of another article entirely), since that’s one of the most common points of rigging failure.

Another factor in your DIY decision-making process is simple: peace of mind. “Most of my clients say to me without any prompting, ‘This is one area I feel should be done by a professional,’’’ Madden says. “You’re out there offshore and there’s a squall coming and you start worrying about the craziest of things, and you don’t want to have any unknowns.” That’s especially true of the system that keeps the mast and sails up.

Wendy Mitman Clarke is currently between passages. She’s the director of media relations at Washington College in Chestertown, Maryland, and she and her family continue to pine and plan for the day they can return to the cruising life.

- More: How To , mast , Refits , rig , rigging , sails and rigging , Upgrades

- More How To

Cruising with a Pet

Fatty Goodlander: Have Little, Want Less

How to Ride a Wave

How To Prioritize Your Sailboat’s Spring Checklist

A Big, New World

Cruising World On Board: Windelo 50

Into the Mystic: A Pacific Northwest Adventure

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

How to Perform Your Own Pre-Buy Inspection

C&C 40 Used Boat Review

Sabre 386 Used Boat Review

What You Can Learn on a Quick Test Sail

Preparing Yourself for Solo Sailing

Your New Feature-Packed VHF Radio

Preparing A Boat to Sail Solo

Solar Panels: Go Rigid If You have the Space…

Ground Tackle Inspection Tips

Shoe Goo II Excels for Quick Sail Repairs

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

An Unusual Sailboat Shines a Light On A Sustainable Future

Is It Time to Get an Electric Dinghy Motor?

Worship Your Universal M-Series Diesel With the Marinized Kubota Block

Taking Care of Your 12-Volt Lead-Acid Battery Bank

Battle of the Teak Cleaners — Snappy Teak-Nu vs. Star Brite

New Seacocks for the Offshore Sailor

Bottom Paint Care

Quick and Safe Sail Cleaning

Are E-bikes Worth the Extra Weight and Cost?

How to Handle the Head

The Day Sailor’s First-Aid Kit

How to Select Crew for a Passage or Delivery

Re-sealing the Seams on Waterproof Fabrics

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Boat Maintenance

DIY Mast Boot

Four simple ways to waterproof the mast-deck connection..

With a little imagination and some inexpensive materials, you can put together a leakproof mast boot in a few hours.

1 Roofing Rubber

One reliable boot sealer is self-adhesive ethylene propylene diene monomer (EPDM), a common rubber-membrane roofing material. Sold at local building supply stores, the rubber is black in color and comes in a roll that is 5 inches wide. (Dont confuse it with ice and water shield, which is much thinner.) Peeling the plastic backing from the underside of the EPDM material exposes the sticky side. Arrange precut strips prior to permanent installation. We suggest using American-made products as the imported stuff doesn’t adhere well to itself.

2 EPDM + plastic sheeting

A white, heavy, PVC plastic sheet can be installed over the EPDM for cosmetics and additional protection, or you can use it by itself. You can seal all of the overlapping seams at the mast with a medium-strength adhesive caulk like 3M 4000 UV. You also can seal any material held in place with hose clamps with butyl caulk (easier for disassembly later). Some cruisers have successfully installed only the plastic sheet as a mast boot.

3 Bandage Boot

Surprisingly, a common Ace bandage can be used to make a mast boot. Simply wrap the bandage around the mast, starting at the bottom and going up to 6 inches above the deck. Apply a thin coat of Hypalon paint (commonly used to waterproof RV roofs; Geocel is a common brand) to waterproof the bandage. To further protect the Hypalon from the suns ultraviolet (UV) rays, it might be worth applying a coat of exterior acrylic house paint, which will expand and contract and has better UV properties than an oil-based paint. (The mast boot pictured has lasted over four years without a leak.)

4 Truck tire tube

You can cut up an old truck-tire inner tube and wrap it around the mast, sealing the contact edges with butyl sealant. Seal the top with self-bonding rigging tape and secure the bottom with heavy monofilament fishing line. Seal the overlapping tube with contact cement or an adhesive sealant.

If you decide to go the retail route, there are very nice-looking, factory-made, contoured mast boots. But be sure to seal the area that joins the mast, under the retaining clamp, with butyl caulk rather than silicone. Butyl is far easier to remove with mineral spirits where silicone will need to be cut, scraped, and sanded from the mast. Where the mast boot overlaps, seal the seams with contact cement or an adhesive sealant.

RELATED ARTICLES MORE FROM AUTHOR

Or you can use Flex Seal.

Just removed my boot because the fabric cover was falling apart. Underneath was a car or truck inner tube that was cut to take advantage of the tube’s shape and overlapped at the back side. This was taped to the mast to seal the top. The bottom was not clamped. This was then covered with a fabric wrap using velcro and draw strings top and bottom. Surprisingly it never leaked.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Tayana 37: What You Should Know | Boat Review

Monitor Your Whole Boat From Home On A Mobile App

Beneteau 423: What You Should Know | Boat Review

Buying A Sailboat Is Scary! Yacht Broker Interview

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Aluminum Sailboat Mast Refinishing

Since tall masts are subjected to huge stresses from constant motion, unseen internal corrosion and subsequent structural weakening is always a distinct possibility, esp if the boat has ever sailed in salt water. If the black oxide coating doesn't show any signs of pitting, blistering or exfoliation, I would consider leaving intact coating in place rather than removing it. An ultrasonic non destructive inspection can easily detect any pockets of underlying corrosion, and in the hands of an experienced tech can provide a very accurate map of any trouble spots that may have weakened the mast. Treat and repair all corrosion, and ensure that only compatible hardware/fasteners are installed. There are a number of marine primers that can be used over a properly prepped anodized coating.

About/Contact - Privacy Policy - ©1995-2024 finishing.com, Pine Beach, New Jersey, USA - about "affil links"

Preventing and Repairing Broken Masts: A Comprehensive Guide for Sailors

Table of Contents

Introduction

Sailing is a thrilling and adventurous sport, but it is also one that comes with its fair share of risks. One of the most significant risks that sailors face is dismasting, which occurs when a sailboat’s mast breaks or falls. Disasters caused by broken masts can be dangerous and even deadly, especially if they happen at sea. In this post, we’ll discuss the causes of broken masts, how to prevent dismasting, and the steps to take when repairing a broken mast at sea.

What is Dismasting?

Dismasting is when a sailboat’s mast breaks or is removed from the boat.

What causes broken masts?

A broken mast can be caused by a variety of factors, including:

- Overloading : Too much weight on the mast or the rigging can cause it to fail.

- Fatigue : The continuous movement of the boat can cause the mast to weaken over time.

- Impact : Collisions with other boats, objects in the water, or docks can cause the mast to break.

- Corrosion : Exposure to saltwater and other corrosive elements can cause the mast to deteriorate.

- Age : As the mast ages, it may become more brittle and susceptible to failure.

How to prevent dismasting

- Proper Maintenance : Regularly inspect and maintain your mast and rigging to ensure that they are in good condition.

- Reduce Overloading : Avoid overloading the mast or rigging by reducing the weight on the boat.

- Avoid Collisions : Be vigilant when sailing and avoid collisions with other boats, objects in the water, or docks.

- Use High-Quality Materials : Use high-quality materials when building or replacing your mast and rigging.

- Avoid Exposure to Corrosive Elements : Store your boat in a dry location when not in use and avoid prolonged exposure to saltwater and other corrosive elements.

How to repair a broken mast at sea

If your mast breaks at sea, you must act quickly to prevent further damage and ensure the safety of the boat and crew. Here are the steps to follow when repairing a broken mast at sea:

- Secure the mast : The first step is to secure the mast to prevent it from causing further damage to the boat. Use any available rigging or lines to secure the mast in place.

- Assess the Damage : Assess the damage to the mast and rigging to determine the extent of the repair needed.

- Gather Materials : Gather any materials needed for the repair, such as spare parts, lines, or tools.

- Make the Repair : Make the necessary repairs to the mast and rigging. This may involve splicing lines, replacing damaged parts, or reinforcing weak areas.

- Test the Repair : Test the repair to ensure that it is secure and will hold up under sailing conditions.

- Resume Sailing : Once the repair is complete, resume sailing at a reduced speed to test the mast and rigging further.

Consequences of failing to Repair Broken Mast

A broken mast is a serious issue for sailors and can have severe consequences, especially if left unrepaired. Here follows the consequences of failing to repair broken masts and why it’s essential to take care of this issue as soon as possible.

Consequences of failing to repair broken masts

- Reduced Stability : A broken mast can cause a boat to become unstable, making it difficult to sail in rough seas or high winds. This can put the crew’s safety at risk and make the boat vulnerable to capsizing.

- Further Damage : A broken mast can cause additional damage to the boat if left unrepaired. The rigging and other parts of the boat may become damaged, which can be costly and time-consuming to fix.

- Increased Risk of Disasters : A broken mast can increase the risk of disasters, especially if the boat is unable to sail effectively. This can lead to accidents, collisions with other boats or objects, or even grounding.

- Decreased Performance : A broken mast can severely impact a boat’s performance, making it difficult to sail and navigate. This can be frustrating for the crew and may even ruin a sailing trip.

- Decreased Resale Value : A boat with a broken mast will have a decreased resale value. This can be a significant issue for boat owners who plan to sell their boat in the future.

A broken mast is a serious issue that should not be taken lightly. Failing to repair a broken mast can have severe consequences, including reduced stability, further damage to the boat, an increased risk of disasters, decreased performance, and decreased resale value. It’s essential to address the issue as soon as possible to ensure the safety of the crew, prevent further damage, and maintain the value of the boat. Regular maintenance and inspections can help prevent broken masts from happening in the first place.

When should you consult professional help for fixing your sailboat’s mast?

- Extensive Damage : If your mast has extensive damage, it’s best to seek professional help. A professional can assess the extent of the damage and determine if it’s repairable or if it needs to be replaced.

- Lack of Experience : If you lack experience with mast repairs, it’s best to consult a professional. Mast repairs require specialized knowledge and expertise that may be beyond the scope of a novice sailor.

- Safety Concerns : If you have safety concerns, it’s best to consult a professional. A professional can ensure that the mast is repaired correctly, and the boat is safe to sail.

- Time Constraints : If you have time constraints, it’s best to consult a professional. Mast repairs can be time-consuming, and a professional can ensure that the repair is done quickly and efficiently.

- Insurance Purposes : If the mast is damaged due to an accident or other incident that’s covered by insurance, it’s best to consult a professional. They can provide the necessary documentation and ensure that the repairs are done correctly and to the satisfaction of the insurance company.

Sailing is an exciting sport, but it is also one that comes with risks. Dismasting is one of the most significant risks that sailors face, but it is preventable with proper maintenance and care. If a mast does break at sea, it is essential to act quickly to prevent further damage and ensure the safety of the boat and crew. By following the steps outlined in this post, you can repair a broken mast at sea and resume sailing safely. Remember, prevention is the best course of action, and regular maintenance can help prevent dismasting from happening in the first place.

Mark Alexander Thompson

Mark Alexander Thompson is a seasoned sailor with over five years of experience in the boating and yachting industry. He is passionate about sailing and shares his knowledge and expertise through his articles on the sailing blog sailingbetter.com. In his free time, Mark enjoys exploring new waters and testing the limits of his sailing skills. With his in-depth understanding of the sport and commitment to improving the sailing experience for others, Mark is a valuable contributor to the sailing community.

Recent Posts

Lagoon vs Leopard Catamaran: Which Sailboat Is Right for You?

Introduction When it comes to cruising on the open waters, catamarans have gained immense popularity for their stability, space, and comfort. Two of the leading catamaran manufacturers, Lagoon and...

How to Determine Sailboat Weight: A Comprehensive Guide

Introduction Sailing is a thrilling and adventurous activity that has captivated humans for centuries. Whether you are a seasoned sailor or a novice looking to set sail for the first time,...

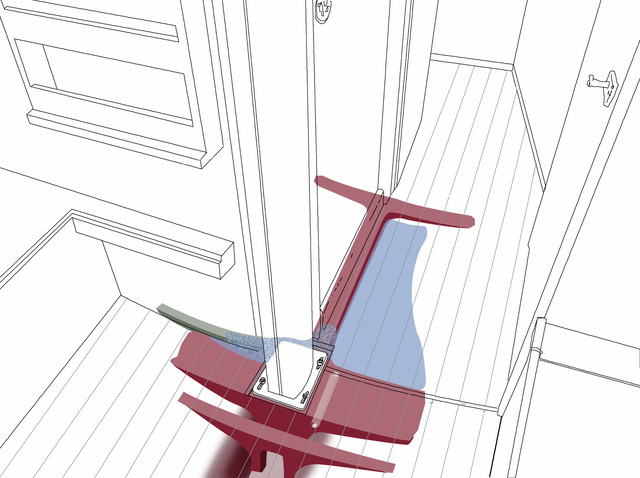

Starting the Mast Step Repair

This will be the first in a series of posts about replacing the mast step on our sailboat, a 1989 Sabre 36 named Glendi. The information here is both a summary of dozens of email discussions and phone calls with Sabre owners who have already dealt with this as well as an archival of my experience fixing the issue. My hope is that this can serve as a guide for anyone who encounters this problem to save some frustration and maybe even a few boats.

Distant early warnings

Do you have a Sabre that is keeled stepped? If yes, read on. Note, this is probably more expansive than necessary as the issue does seem to be limited to certain models and years, however better safe than sorry.

The first indication that we had suffered the dreaded mast step rot, or mast step disease, was a cracked mast step plate. We noticed this when launching the boat in the Spring. Note, we had purchased the boat just a year prior and:

- I knew about the issue when we bought it

- It was inspected by a surveyor

- My broker was a fellow Sabre owner

We all missed it.

This issue hides itself very well, and although the symptoms below are early warning signs, the only way to definitively tell is to remove the mast and drill test bores. If the bores come up wet, you’re cooked. If they are dry, thank Poseidon, throw some epoxy in the hole, and go sailing.

What are all the symptoms?

- Smelly bilge water when on a tack

- Deflection of the step itself

- Visible water damage to the sole around the step, usually in front of the head

- Visible water damage to the bulkhead next to the step

- Visible water damage to the step itself

- The step bulging out on the aft side that is visible when the floorboards are removed

- Cracked mast step plate (this happens because the step is deflected)

Why? Why?!!

Everyone worth their salt knows Sabres are very well made boats. So how could this happen? Why does it happen? Well, plain and simple it is a massive design flaw, and one that could have been very easily avoided. There are differing opinions as to how the water gets into the step itself, but simply put, water comes down the mast, and spreads out over the area around the step in all directions. It is not directed properly into the bilge and over time, finds a way to penetrate the wood inside the step. Since the wood is mostly sealed, it does not rot, but over decades it gets soft and eventually will fail.

Here’s a good photo compliments of another Sabre owner that shows what lies beneath the sole and where the water acculumates.

And here’s a photo that shows just how backed up the water can get inside the bottom of the mast. The owner drilled a hole in the mast and water came flowing out.

This is the most catastrophic failure I have seen which happened while the owner was sailing and ended up in a scrapped boat. You can easily see in this photo the result of the wood softening over time and the mast eventually compressing it into a pulp.

The problem could have easily been avoided is Sabre had installed a three-sided dam around the step to direct the water aft into the bilge and more effectively sealed the step. Something like this.

Not much to explain here. You will have to remove a relatively significant portion of the sole to get to the step and the two stringers that are fore and aft of the step. Some owners have chosen to replace the entire sole. This can easily double or triple the effort involved with this job. In our case the sole is in decent condition. The plywood under layer forward of the step is wet, however it is not structural and the topmost holly and teak cosmetic portion is dry. I’m going to minimize the sole I cut and try to get creative with how it gets covered up. I’m considering making a new floorboard to fit in the space so I can inspect the area in the future to ensure the issue does not happen again.

The next article will be about measuring to ensure I can place the new step, after I rip everything out, exactly where the old one was. I plan on building a jig (suggestion from a listserv member), hanging a plumb bob, and measuring to various fixed points in the boat to ensure I have a number of ways to verify that the new step is exactly where the old one was before.

Here are all the articles about the mast step issue from the Sabre owners group :

- Mast step question

- Mast step box fix

- Cabin Sole Replacement S 34-II

- Mast step disease - all models?

- Base of mast protection

- Mast step rot

- S34 # 67 Step replacement & bhead repair

Similar Posts

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Mast refinishing

- Thread starter Mike Mckendry

- Start date Mar 23, 2000

- Catalina Owner Forums

- Ask A Catalina Owner

Mike Mckendry

I am getting ready to step my mast and refinish it. I learned that they want 1500 to 2000 to strip and paint the mast. Does anyone have any opinion regarding brush painting the mast to save money?

LaDonna Bubak - Planet Catalina

Spendy There's a reason that's an expensive job. There's a lot of time involved in stripping metal & getting it smooth enough to paint again. Not to mention all those little fittings. If you're going to do it, I'd talk with a number of people who actually have done it before. My guess is that any corrosion left on the aluminum would "corrupt" any paint you applied over it. I'll have to bet that the myriad boat repair books out there would cover this. Good luck! LaDonna

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

- Forum Listing

- Marketplace

- Advanced Search

- About The Boat

- Gear & Maintenance

- SailNet is a forum community dedicated to Sailing enthusiasts. Come join the discussion about sailing, modifications, classifieds, troubleshooting, repairs, reviews, maintenance, and more!

Broken Mast - Sleeve or Replace?

- Add to quote

For that size boat, new mast. Measure and pull off all hardware and reinstall on a new spar. Not worth your time to try and sleeve it.

Lotta masts on e-bay right now shouldn't be hard to find a straight replacement...

New mast for sure. Once bent - it will be much weaker and prone to collapse at the worst possible time on water. Get a mast that is the same length or longer and cut it to your designed size so you can use the same sails. If they want too much for the mast - get a junker boat which has a similar size mast, strip it clean for parts and put a chainsaw to the hull. You will be surprised how cost effective that can be in the long haul. Been there, done that.

I'm a recent college graduate, so I have an access of time but my supply of money is pretty low right now. I could probably get the sleeve from dyer for about $100 and don't have any problem spending a few days putting it on to do it right. I just need to know if that's safe. I don't want to be risking my life or any of my friends/family members. I've been searching all over for a used replacement mast that I can get to Dallas for under $500 but have yet to find anything. Lots of masts on ebay but they aren't the same dimensions or sail track as mine. For instance this one is only $100 http://www.ebay.com/itm/Sailboat-al..._Accessories_Gear&hash=item5afd2cb50c&vxp=mtr Its the same height but the base dimensions and sail track are different. How would I go about using this on my boat?

campbmic said: Its the same height but the base dimensions and sail track are different. How would I go about using this on my boat? Click to expand...

BTW, that is an excellent deal in the ad you are listing, IMO. Lots of usable hardware. I would jump on it. I have no doubt you can make that work on your boat.

Would you not want to fix it because of the bend or the break? My masthead is trashed as well. If I use the masthead from the ebay listing will it work for my boat? I have two jib sails in front of my main sail... could that cause a problem? Also how would I be able to tell if the shrouds from that boat will work on mine? Ya its a super great deal, but Its a 2,000 mile roundtrip for me.

Both, but mostly the bend - and that bend is serious and deforming. There are some very serious forces up there when sails are up and mast that was bent once just does not have the proper strength to take them. Ever used nails that were bent and straightened out? Most of them bend right back as soon as you hit them on the head with a hammer. A mast is like that once bent nail being hit on the head every time when there is a gust of wind.

I get what your saying, but if I add say a 4' long sleeve at the break wouldn't that take all of the stress instead of the bent part? If I did sleeve the mast and it failed what would that be like? I paid $1200 for the boat I don't care about being stranded out in the lake or anything I just dont want to get anyone killed.

I wish I could give you encouraging news. Masts need to be absolutely straight (no kinks). Masts work in compression. If they are out of column, the rig can come down especially with a side load in the direction of the out of column. Even at rest, the mast is in compression from the he tension of the stays and shrouds (they are tensioned to 10% of the wire’s breaking strength). . If the splice is in the vicinity of the spreaders/lower shrouds, you are especially susceptible to a mast failure. To fix, you would have to cut the entire bent section out, then sleeve. Then relocate and mount stays, spreaders etc. I’m just not sure you can make a long enough sleeve so the loads are evenly distributed down the length of the mast. You could try this but be forewarned, your mast is compromised and could probably fail again while you are under sail. Look around for a Catalina 22 that is being parted out. Unfortunately, Dallas isn’t the center of the sailing universe. You might try putting in a Craiglist ad locally and also in Houston. That mast from the 28 footer is wrong for your boat. It is made for a substantially bigger rig. It is too heavy, too massive. You would need to step it with a crane. The re-rigging fittings alone would be a budget breaker besides leaving your boat top heavy and probably too tender to sail effectively.

A 4 foot long sleeve riveted or welded tightly to the old parts should take the loads expected on a boat this size under most lake conditions. I would watch it closely for any signs of separation or deforming and refrain from putting too much stress on it - as in reefing early when winds are strong.

George might be right about the weight of the mast from that ad. It is definitely a factor to consider. So is the 2000 mile trip. Lots of fuel to burn.

I read that the mast on the catalina 22 was 25'. My mast is 28' The mast in the ad is 28', not the length of the boat. The other dimensions of how long the spreaders are, where they attach, and where the boom attaches are all within a few inches of my mast. Just wondering, why would this mast be so much heavier and not work? Thanks! Kriss, I would love to just be able to sleeve it. I'd also love to not worry about my little sisters getting hurt and hopefully eventually be able to sail it in the ocean too... So, I'm just feeling pretty cautious about sleeving it at this point.

campbmic said: Kriss, I would love to just be able to sleeve it. I'd also love to not worry about my little sisters getting hurt and hopefully eventually be able to sail it in the ocean too... So, I'm just feeling pretty cautious about sleeving it at this point. Click to expand...

The mast in the ad looks like a bit more heavy duty type and thus likely heavier than yours. If it is heavier you might be able to add a bit more ballast to your boat to balance the rig. Newport Venture (if that is your boat) has about 30% ballast to displacement ratio which is not bad for lake sailing. A sleeve job will only work if it is near perfect to a straight line.

I thought that the butt of the mast in the ad looked broken. That would explain the shortness of it. The masthead and spreader assembly are way too massive for your 23 footer. That amount of weight aloft would make your boat very top heavy. The stays to support it would be twice your size and you would have to salvage the turnbuckles and buy stalock or norsman fittings for the salvaged wire. The increased compression loads would probably deform your compression post and deck. Your main's bolt rope won't fit the mast slot so you will be converting your mainsail to slugs. All in, you might be spending about the same as a proper used mast and still wind up with a "frankenboat". If a C22 mast is too short, look for one off of a C25. There is a very active owner's community out there and you might find one being parted out. Sadly, the cost cost of replacing a mast on an older, small boat can be more than the the boat is worth. You may want to cut your losses and try to sell the hull.

Doesn't my boat already have slugs on it? Slugs are the part that attaches the sail to the channel on the mast and go up and down right?

Yes, you likely have slugs on your sail but they come in different sizes. If they are too small for the new mast they may pop out of the track. But changing them is easy and not that expensive.

Well it looks like the Catalina 25, Mac 25-26, and hobie 18 all use a 28' mast. So I will continue looking for a local donor boat. As long as I get a mast step I should be able to use any of those masts correct? Should I use the spreaders and shrouds from my mast on the donor mast? Thanks for all your help so far by the way!

campbmic, Your Venture had slugs and not a bolt rope? You need to ask the seller a couple of things. 1) distance along the mast from the top of the spreader to the hounds (where the upper shrouds attach), 2) the diameter of the wire of the upper and lower shrouds and fore and back stays. 3) Ask the seller of it was deck stepped and if he has the deck step. You will do the same measurements on your boat. The Arizona mast's spreaders may go through the mast and cannot be moved. You will want to keep the same geometry as your old rig. If you go this route, you will wind up spending a fair amount of money and probably wind up with something not very sailable in the end so proceed with caution. Masts are pretty boat specific and if that mast was custom to that boat it wouldn't be worth much. It may have too many holes and slots cut into it to be worth much as a "blank". We need to get hold of Smackdaddy. His original Smacktanic was a "Frankenboat" and we want to consult with him on particulars like handling. You will be engaging in some pretty serious riggers work without the benefit of experience or training.

I might be wrong, but I think they are slugs from the images I saw on google. It looks like on my boat the spreaders attach to the outside of the mast with a single boat that runs all the way through the mast. So as long as its 28' can't I just drill a hole on the new mast to put my spreaders there? I'm going to pass on the Arizona deal for awhile and try to search more locally a bit longer. Hopefully I can find a Mac 25 or 26. The only alternative I have from this would be paying around $1500 for the DM-6 from dwyer shipped to my house.

A friend of mine lost his mast on a 26' foot boat. He just found a crap boat about the same size on Craigslist and paid $250 for it. After taking the mast off the donor boat, along with the winches and all the other hardware, we loaded it up on a low boy flatbed, and took it to a scrap dealer for the lead in the keel. In the end, he actually made money on the deal.

My vote would be on the used replacement. But I want to hear the story! Man I'll bet you had to clean your pants after that. Where you on the trailer, launching or on the water. Where the sparks flying. Gotta tell us.

Well I found a 27' mast off a venture 21' for free. Its a 1400 mile round trip. How could I use this? or should I pass on the deal?

look for a mac 25 mast

campbmic There is a place here in Massachusetts called Massmarineparts.com they strip older sailboats mainly and sell every thing I've been there a couple of times. Their prices are approx half of new, but then again when some one has a lot of stuff to get rid of maybe you can work a deal. They advertise on Craigs list Boston, there is also a guy up in Eliot/york, Maine area that advertises Craigs list Maine, NH. Mass. Ri. his prices are really cheap. I just went thru Craigs Maine back a week and could not locate so it should be time for him to advertise again. Why don't you contact boat yards and see if they have any thing hanging around? You would be supprised what some have in the back lots

I think you will have to cut the mast on both ends to match the boom position (and sail feed spot) to your old mast. You might have to move the spreaders as well. It is definitely heavier mast so you may have to add some weight to your bilge. You will have to modify the mast step as well. You will then have to adjust to proper length the standing rigging (stays). You may be able to use the stays from the new mast if they are stronger than your old stays (as your mast is heavier).

- ?

- 174.3K members

Top Contributors this Month

- Share full article

The Most Decorated Battleship in U.S. History Gets an Overdue Face-Lift

It has been 34 years since the Battleship New Jersey was last pulled out of the water for maintenance.

Roughly 45,000 sailors and Marines served on the U.S.S. New Jersey’s decks in World War II, the Korean and Vietnam Wars, the Lebanese Civil War and the Iran-Iraq Tanker War. Credit... Rachel Wisniewski for The New York Times

Supported by

By Tracey Tully , Rachel Wisniewski and Erin Schaff

- May 1, 2024

The most decorated battleship in the history of the United States is done with war.

The engines of the vessel, the Battleship New Jersey, are no longer permitted to operate, by order of the U.S. Navy.

But on a windy afternoon in March, tugboats pushed and pulled the ship away from land for the first time in more than 20 years. It left its berth in Camden, N.J., en route to Philadelphia, where it was guided into dry dock to undergo two months of repairs that can only be completed out of water.

Muriel Smith was there to watch.

“You’ll get me crying,” Ms. Smith, 87, said, describing the emotions she felt as a mammoth American flag was hoisted aloft during the shifting of colors before the Battleship New Jersey left the dock on March 21. Ms. Smith, a writer who lives in New Jersey, was on hand in 1999, too, when the ship made its way through the Panama Canal, headed toward its new career as a museum and memorial .

At each event, she said, she thought about her children, two of whom served in the U.S. Marines and one, Tracie Smith-Yeoman, who retired from the Navy as a commander.

“I feel like my own kids are being honored,” Ms. Smith said about the financial commitment that enabled the monthslong maintenance project.

“All the lives that served on her,” added Ms. Smith-Yeoman, who now teaches naval science at a magnet school on the Jersey Shore. “All that she did to secure the freedoms of so many people.

“It’s important that we never, ever forget that.”

No other U.S. battleship served in more military campaigns. Christened on the first anniversary of the attack on Pearl Harbor, Dec. 7, 1942, it went on to earn 19 battle stars during 21 years of active service . Roughly 45,000 sailors and Marines served on its decks in World War II, the Korean and Vietnam Wars, the Lebanese Civil War and the Iran-Iraq Tanker War.

The ship arrived at its permanent dock in Camden in October 2001, just after the Sept. 11 attacks. For security reasons, it was a hush-hush affair. “They moved her in the middle of the night without anybody on board,” Ryan Szimanski, the museum’s curator, said.

As a museum, the battleship has become known for its hands-on military history tours and for the Scout sleepovers, retirement parties and high school proms that help to pay its bills.

It was years overdue for the routine maintenance required to keep it safely afloat for the next couple of decades in the Delaware River. And preparations for pulling the 887.7-foot ship about six miles, from Camden to Paulsboro, N.J., and then to Philadelphia, were complete even before the $10 million it will cost to finish the job was secured.

To get to Philadelphia, the battleship had to pass under the Walt Whitman Bridge, which has a low-tide clearance 26 feet shorter than the ship’s tallest point, Mr. Szimanski said.

A mast and antennas had to be removed to make it fit. And as the battleship neared Philadelphia, its onboard tanks were flooded with water to weigh it down enough to shimmy it into Dock No. 3 of the Philly Shipyard .

It took three days to drain the slip, leaving the hull fully visible for the first time in 34 years.

For weeks, workers have been hunched underneath the battleship welding waterproof caps and replacing anodes as others perch on equipment high overhead, pressure-washing and painting the hull.

Before returning to Camden in late May, the ship will have been sprayed with six coats of epoxy in three distinct colors — layering that will help museum officials track the underwater erosion process.

Weekend tours have allowed ticket holders from as far away as China and South America to walk beneath its underbelly. One man flew back and forth from California within 24 hours for the opportunity to climb down five flights of stairs into the cavernous boat basin where the work is being done.

“They don’t do this, anywhere, very often,” said Libby Jones, the museum’s director of education. “If you’re into this kind of stuff, this is it — this is the Super Bowl.”

Along the way, Mr. Szimanski has stumbled into internet fame.

A YouTube channel he and Ms. Jones created at the start of the pandemic to offer programming while the museum was closed now has nearly 240,000 subscribers. Tickets for the dry-dock tours that Mr. Szimanski leads are selling for $1,000. (Tours led by other guides are $225.)

“I think it’s crazy!” said Mr. Szimanski, 34, who grew up in Baltimore and has been working on museum battleships since he was a teenager.

He is driven, he said, by a desire to offer an authentic window into the country’s military history, including the 1,600-room battleship’s capacity for devastation and the sacrifices that have accompanied it home from war.

“Maybe that will be enough,” he said, “to remind us not to do it all over again.”

Tracey Tully is a reporter for The Times who covers New Jersey, where she has lived for more than 20 years. More about Tracey Tully

Erin Schaff is a photojournalist for The Times, covering stories across the country. More about Erin Schaff

Advertisement

IMAGES

VIDEO

COMMENTS

A sailboat mast is like a long electrical fuse: one bad spot and the show is over. Critical failures are usually linked to standing rigging failures and can occur at toggle or tang attachment points, on the spar itself or at spreader tips and roots. Upper shroud tang fittings, near the masthead, need a close look.

Refinishing masst. Rick,u000b One of the many things I do in my repair business is refinish boats and masts etc.. Alumiprep-33 Etching Solution is a pre-treatment for bare aluminum. Prior to painting and after sanding and wiping down the mast you'd apply the Alumiprep. It's acid based and cleans and etches the metal.

If your mast just needs a good cleaning and polish, then a non-abrasive cleaner/wax will work fine. Our most comprehensive report on cleaner-polishes was Metal Cleaners (PS June 2006 online), in which we tested 16 different products. Wed opt for one of the liquid cleaner-waxes like Collinite No. 850 Metal Wax, a non-abrasive cleaner-wax is in the same family as Collinite No. 885 Marine.

Since 1961, RIG-RITE has engineered, manufactured and distributed Spars, Rigging and Hardware Systems for Sailboats. RIG-RITE stocks the largest variety of related Systems and Hardware available anywhere, Specializing in original replacement parts for Systems on yachts built the world over. Spars - Masts, Booms, Spreaders, Spinnaker Poles ...

Sailboat masts are the unsung heroes of the sailing world, silently supporting the sails and ensuring a smooth journey across the open waters. ... If your mast is beyond repair, it's essential to invest in a replacement promptly. The Cost of Mast Replacement. The cost of mast replacement can vary significantly depending on the type of mast ...

Even though aluminum has long since replaced Sitka spruce as the material of choice for a sailboat mast, there are plenty of wooden masts still in service. Many of the Taiwanese-built boats of the 70s and 80s had wooden masts, and of course, a wide range of U.S.-built classics still have their original wooden masts. ... If you are refinishing ...

Greetings, I am in the process of stripping down my H23's Kenyon mast and refinishing it. I am removing all hardware and plan on applying an acid-etching primer and a two-part polyurethane paint, probably Interlux perfection. I noticed most of the corrosion issues on the mast (they are...

Many of the Taiwanese-built boats of the 70s and 80s had wooden masts, and of course, a wide range of U.S.-built classics still have their original wooden masts. In a recent PS Advisor, we laid out some options for refinishing a mast and tried to explain why we are not big fans of sealing wood with epoxy. Here's the gist of that report:

Good question. Yes, doing it yourself will theoretically save money. For an average 40-foot boat, Cockerill estimates about $100 per foot to re-rig with wire rigging ($4,000), as well as the round-trip cost to haul and launch the boat and unstep and step the rig (an additional $2,500 or so).

Well there were too many rainy weekends this year so my 28.5 was not launched. Instead of a short sailing season, I have decided to go down the to-do list and fix or upgrade everything that needs it. Sort of a mini re-fit.\u000B\u000BOne item on the list is that the mast's anodyzing is shot...

3 Bandage Boot. Surprisingly, a common Ace bandage can be used to make a mast boot. Simply wrap the bandage around the mast, starting at the bottom and going up to 6 inches above the deck. Apply a thin coat of Hypalon paint (commonly used to waterproof RV roofs; Geocel is a common brand) to waterproof the bandage.

5. 3/16 SS rivets have a shear strength of 1000# each and the least amount used on my boat was 4 on some exit box's , the high stress areas like the boom yoke mount used 6 ... See my mast refinish by clicking my link below. Scott T-Bird. Oct 26, 2008 6,081 Catalina 320 Barnegat, NJ May 4, 2009 #16 For your size mast and boomboat, painting would ...

The mast is a proctor, which is 47' and only 6"x4" and has a good deal of flex. Even with running backs secured, there is flex to some degree through the entire mast, and especially above the running backs while sailing hard to weather. The mast is ~ 1/8" thick, and the plate is a good 1/16 thicker than the mast walls.

Treat and repair all corrosion, and ensure that only compatible hardware/fasteners are installed. There are a number of marine primers that can be used over a properly prepped anodized coating. I am purchasing a 44 Swan sailboat. The 58-foot mast has peeling paint along the slot and need refinishing.

Consequences of failing to repair broken masts. Reduced Stability: A broken mast can cause a boat to become unstable, making it difficult to sail in rough seas or high winds. This can put the crew's safety at risk and make the boat vulnerable to capsizing. Further Damage: A broken mast can cause additional damage to the boat if left ...

Starting the Mast Step Repair. This will be the first in a series of posts about replacing the mast step on our sailboat, a 1989 Sabre 36 named Glendi. The information here is both a summary of dozens of email discussions and phone calls with Sabre owners who have already dealt with this as well as an archival of my experience fixing the issue.

I am getting ready to step my mast and \u000Brefinish it. I learned that they want 1500 to 2000 to strip and paint the mast. Does anyone have any opinion regarding brush painting the mast to save money?

Sailboat DIY And Repair Tips. Sailboat DIY And Repair Tips. Know-how: Adding Windvane Steering and a Hydrogenerator. ... Experience: Up the Mast. I gazed aft over Hazel James' port quarter and patted her well-travelled 31ft hull. "It's time to sail, girl. We've got a long way to go," I said.

Please support us at https://www.patreon.com/marzipanproductionsEverything you need to know to get started on improving your mast's performance

1) distance along the mast from the top of the spreader to the hounds (where the upper shrouds attach), 2) the diameter of the wire of the upper and lower shrouds and fore and back stays. 3) Ask the seller of it was deck stepped and if he has the deck step. You will do the same measurements on your boat.

This is a repair of a 2.4mR sailboat aluminum mast. It broke at the deckline as a result of too many weakening rivet holes, and a collision with a concrete p...

Originally Posted by nfbr. 27yo white painted aluminium mast is losing paint / showing surface corrosion at most rivet / screw points. This basically means the stainless hardware wasn't installed right the first time. Unless it is all removed and installed with Ted-Gel or Duralac you can expect a repeat. Quote:

A mast and antennas had to be removed to make it fit. And as the battleship neared Philadelphia, its onboard tanks were flooded with water to weigh it down enough to shimmy it into Dock No. 3 of ...