- 2024 BOAT BUYERS GUIDE

- MIAMI BOAT SHOW

- Email Newsletters

- Fishing Boat Reviews

- Fly Fishing

- Marine Electronics

- Fishing Tackle

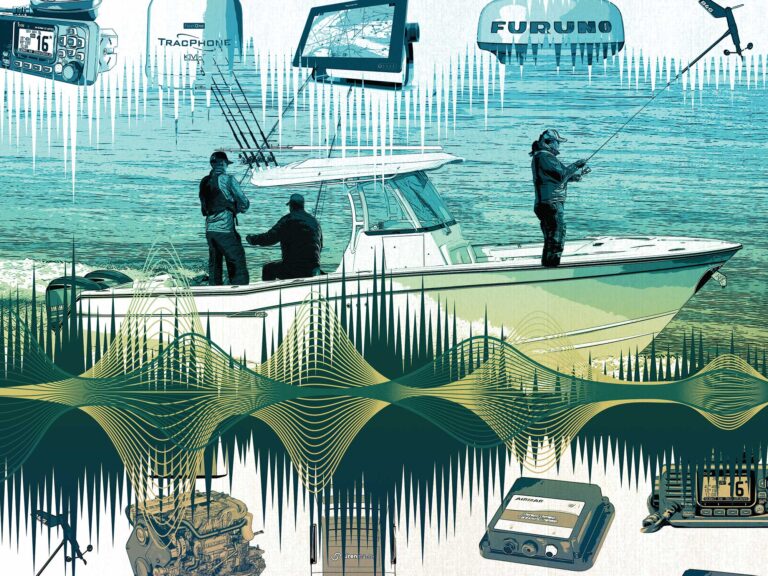

- Best Marine Electronics & Technology

- Fishing Destinations

- The Bahamas Fishing Guide

- Boating Safety

2023 Boat Buyers Guide: Catamarans

- By Karl Anderson

- December 27, 2022

The popularity of the multihull (aka catamaran or cat) fishing boats has never been greater, as more and more boatbuilders enter this growing segment of the market. The inherent stability of the catamaran design rolls less with the seas, making fishing offshore less tiresome and more comfortable. Available from 20 to 48 feet, catamarans typically offer a large fishing platform with generous storage and fishing amenities. They are available in a wide variety of deck layouts, including center-consoles, dual-consoles, and even pilothouse and express variants.

Big Picture

The large deck area of a catamaran enables many large underdeck storage lockers and insulated fish boxes in the sponsons. This gives anglers ample room for gear and the day’s catch. The catamaran’s stability, fishability, and smooth ride in rough seas make it attractive to anglers as well as day-cruisers. A center-console version adds 360 degrees of angler access to the rail. With the dual-console design, generous seating behind a beam-to-beam windshield makes for a great family fishing-friendly setup.

Live bait is one of the most popular types of fishing in virtually every coastal zone. To do it successfully requires optimal water capacity and proper flow. The minimum size of the outflow water plumbing should be twice the size of the inflow. The plumbing should have a drain at the bottom to shed scales at the end of the day, as well as a drain at the top of the well to adjust capacity and allow overflow. Above-deck transom-mounted wells should fully flood to the lids when running to keep baits from getting beat up.

Tip: A sump box with multiple pumps in case a pump fails is the best setup for first-rate livewells. Conveniently located inflow and outflow valves make it easy to optimize the flow without tiring your bait from swimming too much in the well.

Rod Storage

Having enough rod holders is essential to be successful for opportunity fishing. Look for vertical rod storage along the console and across the back of the T-top. Many models also have rod holders along the outboard transom wall. Having plenty of gunwale rod holders for drift- and kite-fishing is helpful.

Tip: Placing adjustable swivel rod holders by Gemlux makes deep-dropping, lure-fishing and drifting even easier because they allow your rods to face the direction the baits are fishing, yet they can be swiveled back to keep rods from sticking out of the boat while running and docking.

Manufacturers often offer multiple choices for horsepower, but whatever the choice, the engines must come in pairs. For example, you might order twin outboards (one for each sponson) or four outboards (two for each sponson), but single- or triple-outboard configurations are not common on a cat. Optimal selection should be made based on user load, weight of the boat, ride comfort , performance desires, and best case for resale. It’s a rare day when you can run wide open, but having more horsepower gives better torque at slower speeds and thus better control. Running larger engines slower gives better fuel efficiency too.

Tip: When possible, choose the highest horsepower offered because it typically leads to a better resale value with a shorter sales cycle.

Power steering from engine manufacturer Optimus or SeaStar is essential with the higher horsepower required for larger boats, and it makes installing and operating the upper station in a tower far more practical and comfortable.

With the power demands of electronics, livewell pumps, stereo amps and more, it is wise to have at least two house batteries, and for larger boats, a third or fourth with a multibank charger for dockside. Each engine should have its own dedicated battery as well.

Electronics

Typically choosing the largest screen or multiple screens that will fit on the console is best-case scenario for ease of use, ergonomics, and visibility. VHF radios, stereo controller, and equipment switches for lighting, pumps, and accessories should all be integrated with greatest visibility and ease of operator reach.

A Tale of Two Hulls

A catamaran rides on pair of hulls, or sponsons, each thinner and sharper than that of a similarly sized monohull boat. The narrow sponsons of the cat tend to slice easily through water to deliver a smooth ride, even in rough seas. At the same time, with the sponsons positioned out to the sides of the boat, cats tend to roll less, thus providing great stability to enhance crew comfort, security and safety. However, cats tend to corner more flatly than a monohull, and some hulls (but not all) tend to lean outward versus inward during a turn.

Experts Say

Newer designs such as Invincible’s Morelli and Melvin-designed semi-asymmetrical sponsons eliminate some of the negatives of the cat design, such as “sneezing,” where water sprays out the front of the boat when hitting a wave. They’ve also controlled the uncomfortable “outboard lean” sensation common in older designs when in a turn. Once transitioned to a catamaran, many become true believers and preach the benefits of the design.

Editor Says: Saltwater fishing cats not only offer superb stability and smooth ride, but some also display exceptional speed and range. I recall one trip out of Key West, Florida, aboard an Invincible 40 Cat with four 350 hp outboards to the Dry Tortugas. It was a 60-mile run, and we made it there in 70 minutes. We caught more fish than our arms could bear, and then dashed back to Key West, arriving in time for cocktail hour on the same day. -Jim Hendricks, Staff Editor, Boating and Fishing Group

- More: 2023 Boat Buyers Guide: More Resources , Boats

Salt Water Sportsman On Board: Boston Whaler 365 Conquest

Pathfinder 2200 TRS

EdgeWater 325CC

Pursuit OS 405 Offshore

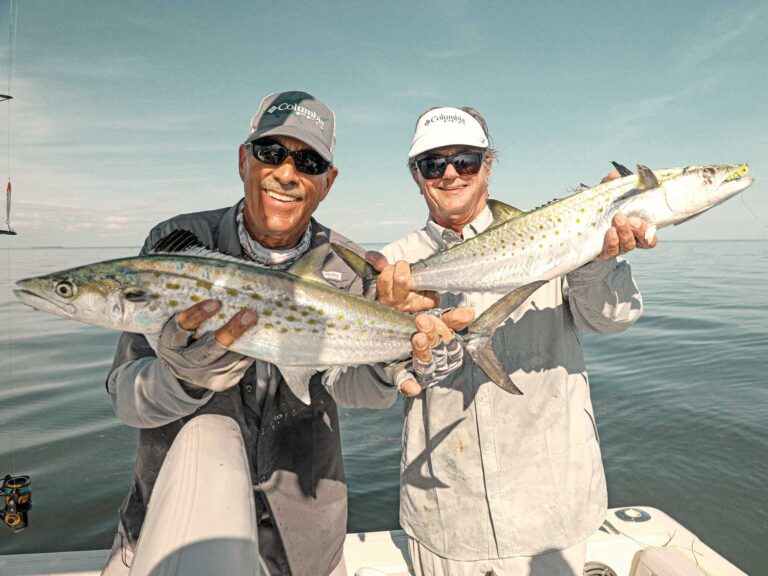

Top Spanish Mackerel Fishing Tips

What Can Boating Anglers Expect From NMEA OneNet?

10 Common Solutions for Boat Engine Problems

- Digital Edition

- Customer Service

- Privacy Policy

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Did You Know That We Offer Contract to Closing Services? Click Here to Find Out More.

Need Marine Financing? Apply Here With Our Partner, First Approval Source

- Catamaran Interviews

- Catamaran Reviews

- Buying Advice

- Selling Advice

- Woods Design Advice

- Americat 3014

- Balance 526

- Bali 40 Catspace

- Beneteau Blue II

- Broadblue 346

- Broadblue 38 Prestige

- Broadblue 385

- Broadblue 435

- Broadblue 46

- Catalac 10M

- Catalac 11M

- Catalac 12M

- Catalac 900

- Catana 42 S

- Chris White 48 Voyager

- Chris White 55

- Corsair F28 R

- De Villiers

- Dolphin 460

- Endeavour 30

- Endeavour 35 Victory

- Endeavour 36

- Endeavour 44

- Endeavour 44 TrawlerCat

- Fortuna 36 Island Spirit

- Fortuna 401 Island Spirit

- FP 32 Maldives

- FP 35 Tobago

- FP 37 Antigua

- FP 38 Athena

- FP 39 Fidji

- FP 40 Lavezzi

- FP 40 Lucia

- FP 40 Summerland MY

- FP 41 Lipari

- FP 42 Astrea

- FP 42 Venezia

- FP 43 Belize

- FP 44 Helia

- FP 44 Orana

- FP 46 Bahia

- FP 46 Casamance

- FP 48 Salina

- FP 56 Marquises

- FP 57 Sanya

- FP 60 Eleuthera

- FP Saona 47

- Gemini 3000

- Gemini 3200

- Gemini 3400

- Grainger 420 Mystery Cove

- Hirondelle 7M

- Lagoon 37 TPI

- Lagoon 42 TPI

- Lagoon 43 PC

- Leopard 39 PowerCat

- Leopard 45 Classic

- Leopard 47 PowerCat

- Leopard 51 PowerCat

- Leopard 53 PowerCat

- Maine Cat 30

- Maine Cat 41

- Matrix 450 Vision

- Matrix 760 Silhouette

- Maverick 400

- Maverick 420

- Maverick 440

- Nautitech 40

- Nautitech 442

- Nautitech 46 Open

- Nautitech 47

- Outremer 40

- Outremer 45

- Outremer 50 Standard

- Outremer 55

- Privilege 37

- Privilege 39

- Privilege 42

- Privilege 43

- Privilege 435

- Privilege 45

- Privilege 465

- Privilege 48 Transcat

- Privilege 482

- Privilege Serie 5

- Prout 31 Quest

- Prout 33 Quest

- Prout 34 Event

- Prout 35 Snowgoose

- Prout 37 Snowgoose

- Prout 37 Snowgoose Elite

- Prout 38 Manta

- Prout 39 Escale

- Royal Cape 45

- Royal Cape 530 Majestic

- Royal Cape Majestic 500

- Sailcraft 30 Iroquois

- Sailcraft 32 Comanche

- Sailcraft 35 Cherokee

- Sailcraft 41 Apache

- Sailcraft 44 Apache

- Wildcat 350

- Seawind 1000

- Seawind 1160

- Seawind 1200

- Seawind 1260

- Seawind 1600

- Solaris 36 Sunrise

- Solaris 36 Sunstar

- St Francis 44

- St Francis 48

- St Francis 50

- Stealth 11.8

- Heavenly Twins 26

- Ocean Twins 38

- Voyage 380 Maxim

- Voyage 400 Norseman

- Voyage 430 Norseman

- Voyage 450 Cabriolet

- Voyage 47 Mayotte

- Wharram 38 Tiki

- AMI 320 Renaissance

- Woods 22 Wizard

- Woods 35 Banshee

- Woods 35 Flica

- Woods 36 Scylla

- Woods 36 Vardo

- Woods 38 Transit

- Woods 40 Meander

- Xquisite X5

- Xquisite X5+

Catamaran Construction – Hulls, Laminates, and Composites

- Post author By BJ Porter

- Post date October 15, 2020

- 3 Comments on Catamaran Construction – Hulls, Laminates, and Composites

It’s a given that catamarans are more sensitive to weight and loading than monohulls. Catamaran builders strive to build the lightest boats they can without sacrificing strength and stiffness, and have adapted new building techniques and materials to meet this target. Cutting weight allows more passengers and gear without sacrificing performance.

And the marketing materials reflect it–they load every review and website with polysyllabic technical jargon describing the design and production choices each builder made to deliver the best boat they can.

But when you’re reading a brochure and you come across phrases like “ hand laid bidirectional GRP ” or “ vacuumed bagged e-glass with vinylester resin over a Divinycell core ” do you know what that really means?

All modern production catamarans are made with “FRP” construction (for Fiber Reinforced Polymer). Composites aren’t new–it’s just using materials together to strengthen the whole assembly. Straw was added to bricks centuries ago, and steel reinforced concrete is a staple of construction over the last century. For boats, it’s the use of stranded fibers and cured resins which make FRP different.

The term “FRP” doesn’t get into the technical detail of which fibers and which plastics, and how they’re put together to build your hull. There’s a wide variety of fiber types which can be stranded, woven, chopped or sprayed in a varied of patterns then combined with several types of resins to make hulls with different characteristics.

Some FRP techniques produce lighter, stronger shapes, while others are quicker to build and less expensive to produce. The choice of technique is a function of many factors, from the number of hulls and parts to be built, the type of parts, the budget for the project, and many design specific requirements for weight and strength.

1. FRP Basics

The principle behind all FRP construction is the same – you lay our fibers in the shape you need, then saturate them with resin, removing all the air and voids you can. Resin is left to cure, then the piece is ready to finish and use.

The reality is more complex, since building a boat isn’t like making a flat board or a simple door. You’ve got a complex shape with a designed set of curves to build. “Tooling” is the set of shapes to make the boat parts; molds to cover with fiberglass to get the right shapes.

That’s what makes FRP so effective – you can make almost anything out of it. But to do so requires a lot of choices about what you need for the project at hand.

There isn’t a “best” all around material or technique choice for all jobs, and sometimes a lower cost technique or easier to work with material may be the better solution to the problem.

A. Fiber types

Fiber choices in the last few decades have expanded past the glass fibers used in the first mass produced boats in the 1960s. FRP construction wasn’t new even then, they built the first composite boats using modern fiberglass in the 1940s.

The major fibers used in marine construction fall into three categories – glass, aramids, and carbon. The primary differences are in the strength to weight ratios of the fibers, durability, elasticity, and cost. Some construction may use blends of fiber types to combine performance characteristics.

Glass – the most common material still, because of its low cost and versatility. The most common variety used in GRP (Glass Reinforced Polymer) is “E-glass” which refers to its strand size and mineral content. Other grades have different and sometimes better mechanical properties, but may be more expensive and less appropriate for boat building use. Fiber sizes run 10 to 25 microns for E-glass, though other grades may be smaller.

Brands like Leopard, Lagoon, and most higher production volume builders use E-glass.

Aramids – this includes brand names like Kevlar, Technora and Twaron. They have higher tensile strength than E-glass, and resistant abrasion and punctures. Kevlar is a common choice for bullet proof body armor, and can built a tough, lightweight hull. The materials can be difficult to work with, as it is very tough to cut the cloth. It is often blended with carbon fiber or other materials – Catana is known for using Twaron blends in hull construction.

Carbon – the ultimate in lightweight, strong construction material. Carbon fiber is the most expensive fiber, and is available in a variety of weights, grades and strengths. Fibers are smaller than glass – down to 5 Micron.

The lightest, most expensive hulls are made from carbon, but a catamaran builder may use carbon in places other than the hull to add strength and stiffness. Carbon boards, rudders, and reinforcing structures can enhance performance without driving the price of the boat beyond reach. Carbon is the fiber of choice for many custom builds, racing cats, and Gunboat.

B. Mats, Strands, Roving, Direction, and Weights

Fibers are woven into matting and cloth for construction. Depending on the application, different weights of cloth and cloth patterns and weaves may be more appropriate for the job.

Cloth weight refers to the weight per square yard (or meter) of the cloth. A square yard of nine ounce cloth weighs nine ounces. The heavier the cloth, the stronger it is in a laminate.

Fibers carry loads along their length, so cloth weaves have directionality to their strength. Most builders use several layers of cloth with different orientations to give good universal strength to hulls. Specific FRP applications with strict load-path requirements may have more unidirectional fiber layering – for example, a chainplate manufactured from carbon fiber may use unidirectional fiber.

Cloth – fiberglass cloth is commonly used on outer layers of composites. Cloth may have unidirectional or bidirectional strength. Bidirectional cloths have maximum load strengths in two perpendicular directions. Variations on weaves like a modified twill allow a more flexible cloth for better shaping around complex molds.

Mat – is omnidirectional strands of fiber compressed into a cloth. This is often held together with a resin soluble glue, which makes mat great at conforming to mold shapes without folding and bunching as it collapses when wetted. Because the strands do not align, fiber strength is the same in all directions.

Woven Roving – a heavier cloth made from larger bundles of strands. Woven roving allows for quicker buildup of material and strand weight.

Most FRP layups include multiple layers of different cloth and mat. Finished layers may be finer cloth over courser cloth, over woven roving and mat.

Three primary resins are in common use in marine construction – polyester , vinylester , and epoxy . All resins have materials safety concerns and require care in their use and handling.

Polyester is the least expensive and requires breathing protection because of the VOC emission (Volatile Organic Compounds…nasty, smelly fumes). It doesn’t have good bonding/gluing capability, and should only be used with glass fibers for structural building. Some polyester resins are referred to as “isophthalic” resins.

Vinylester is chemically similar to a hybrid of polyester and epoxy, and performs best with fiberglass. It shouldn’t be used in high strength applications with carbon or aramid fibers. It has some adhesive qualities which polyester lacks, it shrinks less during curing, and has better impact resistance.

The added strength of vinylester coupled with increased water resistance makes it an attractive option for many catamaran builders. It costs less than epoxy, but still has better performance than polyester.

Epoxy is the most expensive, but is three times the strength of the others. It offers the best adhesion and the only resin for building structural elements with carbon and aramid. It resists water intrusion better than the other resins, resists blisters, emits no VOCs, and shrinks less. The major drawback is it is more brittle if it takes an impact.

While epoxy is “the best” in terms of strength and ease of building, there are many applications where other resins are appropriate. Budget is a big driver – a boat made from E-Glass doesn’t need epoxy resin, and considerable cost savings to meet a construction price target may drive the choice.

They can build quality boats from all material combinations, but price and performance will drive materials choices to keep some boats more affordable.

2. Cored Construction

What’s the best way to make fiberglass strong? To a point, you can make it thicker. As it gets thicker, it gets heavier. A hollow shape can take more compressive load than a solid one of the same weight, and the same principle applies to fiberglass construction.

Consider an I-Beam used in building construction. It has the same strength (or more) as a solid rectangular beam of similar mass. The compressive load on the beam is supported by the outside edges of the material, the metal in the middle doesn’t contribute much to the strength. So we can remove metal to get the “I” shape while still keeping those sides rigid, making a lighter girder with less material.

The same principle applies to cored construction with fiberglass. Making a sandwich of two layers of fiberglass with a light core between them allows for the greater strength with weight savings.

There are drawbacks – the biggest risk is damage which breaks the skin, which can let water into the core. Earlier cored construction used materials prone to saturation and rot if they got wet. Some builders opt to do cored construction above the waterline and solid below to minimize some of these risks.

But the advantages in weight savings and increased stiffness offset the drawbacks, and there may be a few other side effects like sound and temperature insulation. Like resins and fibers, core materials offer distinct advantages, disadvantages and price points.

Most builders have adopted a hybrid approach, building solid hulls below the waterline, and cored hulls and decks above. This gives a balance of weight and safety.

A. Balsa Core

Balsa is light and inexpensive. The first cored construction used balsa, but it has the disadvantage of being wood. As a natural material, if it gets wet it can rot and break down. Builders use “end grain” balsa – shorter cross cut sections – to prevent wicking of water if there is an intrusion.

B. Foam Core

Closed cell foam cores give good strength to weight savings while minimizing water intrusion. If you get water in the core, it won’t spread very far. Divinycell is a popular PVC foam core, though there are several choices with different densities and compressive strengths.

Some foam cores are not suitable for heat treatment, but infused or vacuum bagged boats like the Outremer and PDQ do well with it.

C. Honeycomb

Honeycomb cores are often the most expensive, but also give some of the best strength to weight ratios. Honeycombed cells made from resin cured aramid papers are some of the best, but also among the most costly. They offer good stiffness, but can be hard to shape. Aluminum and other resin-infused papers are other core materials builders can choose from.

3. Construction and Resin

When building a hull, there are optimal ratios of fiber to resin saturation for target strength and weight. Too little resin and you may not have enough strength (or worse, voids and gaps), and too much, and you’re just adding weight without adding strength. Resins are also a significant material cost in building the boat, so over application not only increases weight but adds cost.

There are many ways to assemble the cores, fibers and resins to build a finished laminate hull – we’re addressing the most common in boat building. Each approach has strengths and limitations, and an impact on the bottom-line cost to build the boat. Any voids or air pockets in the laminate can be disastrous; these techniques have been developed to increase saturation and reduce the risk of voids.

A. Hand Layup / Open Molding

As the name implies, this is the application of resin by hand to cloth as it’s laid into a mold. Wetting is done with a brush, and the laminate is rolled out to remove any air pockets and voids. This is the simplest way to lay up fiberglass, but also the least precise and consistent and will use the most resin.

Skilled craftsmen have built some of the finest vessels in the world this way. Though it’s more popular with monohulls, which are less sensitive to weight, many catamarans built with hand layups on open molds are still out cruising and performing well.

B. Spraying

Using chopped-strand fiber mixed with resin, a “chopper gun” can spray the mixture into a mold to lay down the composite. A consistent thickness can be difficult, but this is a low cost construction technique which makes a very resin-rich laminate. Using sprayed fibers gives lower strength in all directions compared to meticulously laid down mat and bi-directional cloth. But it is a quick technique popular with mass produced, smaller boats.

It is an excellent technique for parts with complex geometry where weight is not an issue, but you will not see it often in catamaran construction. It’s heavy with resin without any resultant increase in strength.

C. Vacuum Bagging (Wet layup)

When an open molded component has been laid up and wetted with resin, vacuum bagging takes the process a step further. After the wetting is complete, air tight plastic bagging is secured around the wetted area, and the air is pumped out of the bag. The vacuum pulls excess resin out and collapses air pockets.

The goal is to get thorough wetting and produce as strong a laminate as possible without excess resin. Knysa and Leopard are two builders that use vacuum bagging on their hulls to reduce weight.

D. Resin Infusion

For resin infusion the cloth, matting and core is laid in place dry, then sealed in an air-tight bag. A vacuum pump attaches to one side of the bag, and on the other a feed for resin. The vacuum sucks the air out of the dry cloth stack, then pulls the resin through the stack, infusing and wetting it.

Resin infusion, when done right, gives the lightest, strongest laminates with no voids and the minimum resin weight for maximum strength. SCRIMP is a variant of the resin infusion process used by some builders, including TPI which build many early Lagoon cats.

E. Pre-preg

Using pre-preg (for “Pre Impregnated”) cloth for your laminating gets rid of the resin bucket. They manufacture cloth with a partially catalyzed resin pressed into it, then it’s chilled or frozen to stop the curing process. There is no need for seperately mixed resins, and there’s no worry your resin might “go off” and harden before you’re done wetting the cloth. Instead, the cloth is assembled, vacuumed, then heated to kick off the curing process.

There are both advantages and disadvantages to using pre-preg for your laminate work. The big disadvantage is the cost; it is most expensive material to use. You also need to chill and store the cloth until you need it, though some can be at room temperature for a couple of weeks without kicking off. And you need an oven which requires some clever tricks if you’re building a forty or fifty foot boat.

But the strength to weight ratio will always be perfect. High tech honeycomb cores are best suited to pre-preg lamination, and without racing against resin cure times, you can ensure perfect cloth placement and precise layout in the build process.

The primary use for pre-preg in boating is high performance race boats. With catamarans, pre-preg may be used high load parts, like Gunboat does for foils and rudders.

4. Industry Examples

Across the catamaran building industry you’ll find almost all the above techniques and materials used, though some are less common. You aren’t likely to find chopped strand sprayed layups in ocean going cats, and hand layups can lead to heavier hulls than weight sensitive catamaran designers prefer. Most manufacturers have moved to vacuum bagging or resin infusion, with a few of the highest end boats using pre-preg for key components.

Built by Robertson & Caine in South Africa, the hull material is vacuum bagged, end-grain balsa-cored E-glass with polyester.

Hand laid, bagged vinylester over an Airex foam core in the hulls.

Earlier Prout catamarans like the Snowgoose 34 featured hand laid solid FRP hulls and decks. Over time they switched to foam or balsa cores for decks and above the waterline.

Older PDQ boats were made from vacuum bagged vinylester – solid below the waterline and cored with CoreCell foam above the waterline and in decks. Newer PDQ models switched to epoxy resin.

All glass is vacuum bagged. Below the waterline is solid E-glass and vinylester. The rest is unidirectional, bidirectional, and triaxial cloths over a Nida-Core polypropylene honeycomb core with isophthalic and vinylester resins.

The Gemini cats are built with a solid hand layup of woven roving and fiberglass mat and polyester resin. Decks are cored with end grain balsa. The Gemini 3200 introduced vinylester resin into the layup to prevent blistering.

Older Lagoons were SCRIMP infused vinylester with and end grain balsa core above the waterline and in the decks.

Newer Lagoon catamarans use polyester and vinylester resins, also infused with balsa cores above the waterline and solid below.

With a carbon fiber inner skin, Catana also uses Twaron aramid fibers in the sandwiched hull over a foam core.

Fontaine Pajot

Primary hull construction is resin-infused vinylester with a balsa cored hull and deck.

Beneath the waterline, Outremer uses a single layer, solid vinylester laminate for safety. The hulls and deck are vinylester with a Divinycell foam core. They stiffen certain components with carbon for rigidity and durability.

Gunboat hulls are epoxy infused carbon fiber with a Nomex honeycomb core. They build dagger boards and other high load components with pre-preg carbon.

- Tags Buying Advice

By BJ Porter

Owner of Hallberg Rassy 53; world explorer.

3 replies on “Catamaran Construction – Hulls, Laminates, and Composites”

Excelent. Thank you for this I learned allot. Johan

Very straight forward information. Thankyou for doing this.

Damn…What an Amazingly Informative Article. *Cheers*

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

1065 Island Avenue, Tarpon Springs, Florida 34689 USA tel:727-934-6055 - fax: 727-937-0650

Catamaran Coaches Party Boats

Lightning Power Boats

Tour & Work Boats

Fishing/Diving

Wheelchair Accessible

Welcome to Catamaran Coaches!

Catamaran Coaches manufacturers Custom Fiberglass Pontoon Boats, Trimarans, Fish/Dive Boats to fit your lifestyle. Whether you want to enjoy weekends with the family at the sandbar, or run offshore to fish and dive, we have the pontoon boat for you! These boats are stable, have plenty or room for family and friends and are pet friendly! With the rear platform getting on and off at the sandbar is a breeze.

Catamaran Coaches is a family owned and operated manufacturer of Quality Custom Fiberglass Pontoon Boats, TriToons, Fiberglass Fish/Dive boats, Work/Party Boats and more. These boats are custom built to your lifestyle and there are no two boats alike. Have questions about our custom Fiberglass Pontoon Boats?

Call Us! (941) 896-4904

FOLLOW US

Leave a Reply Cancel reply

You must be logged in to post a comment.

Established in 1995

Welcome to A&M Manufacturing

Welcome to the ice wolves, the coolest hockey team in town.

The Leading Name in Commercial Fiberglass Catamarans

COI BOATS MADE FOR SALT AND FRESHWATER : Place your order in today for Delivery in 2024 !

Elevate your boat tour business with our state-of-the-art commercial vessels.

Semi-custom, Full composite, build to last

At A&M Manufacturing, we’re not just building boats; we’re crafting experiences. Our range of commercial catamarans, including specialized options like commercial tiki boats and ferry boats, are engineered to transform your boat tour agency into a beacon of maritime excellence.

Semi-Custom Fiberglass Catamaran

Work with our in-house expert team of naval architect to design a boat that will work for you!

Easy Maintenance and Durability

Built tough and designed smart: our boats are crafted from the ground up for enduring performance and effortless maintenance in commercial use.

Factory Direct Purchase from A&M Manufacturing

Skips the dealers and go factory direct for the best price and quickest delivery.

why choose us

We know the Charter and « COI » industry !

On-Time Delivery

We value your time. Rely on A&M Manufacturing for on-schedule delivery, ensuring your commercial pontoon boat or motor catamaran is ready when you are.

Expert Team Support

With a team comprised of a commercial boat operator, a naval architect, and a retired USCG officer, expertise is our promise. We’re dedicated to transforming your vision into a floating reality.

Composite Fiberglass Construction

Step into the future with our wood-free, composite fiberglass vessels. Each commercial boat for sale is a testament to durability and modern engineering.

USCG COI READY

Safety is paramount. Our passenger vessels meet and exceed USCG standards, ensuring peace of mind for you and your guests.

Explore Our Range

Crafted with commercial applications in mind, our fleet embodies core principles of full composite construction, durability, and ease of maintenance. Our philosophy is simple: we build boats that work for you, ensuring that you spend less time on upkeep and more time on what matters. Experience the difference with boats designed not just to perform, but to excel in meeting your needs.

Pontoon boats

Designed for the rental

Fiberglass composite construction

Durable and Low Maintenance

21ft single & 26ft double decker with rooftop and slide

Salt and Freshwater Friendly

Passenger vessels

Semi Custom

Durable & Low Maintenance

Offered in 3 sizes

Tiki “Package” Option paired with Pontoon, Passenger, and Home Extension

Powder coated rails, Colored gelcoat, Wood-style countertop, optional slide

Full composite Thatch roof

Full Custom

Built to carry, push, and operate with precision

Crane boats, LED Boats, Camera Boats

House Boats

Semi-custom

Sturdy, Stable, Stylish Design

Advanced Composite Fiberglass Construction

A&M CRAFTSMANSHIP

Our work in picture.

Witness what Current clients are using to work everyday across the country!

A&M Manufacturing is Your Partner in Commercial Passenger Catamarans and Custom Fiberglass pontoons

Ready for a Voyage towards Success?

Embark on a journey with A&M Manufacturing and see how our custom-built, commercial passenger vessels can propel your business to new heights. Connect with us to start your maritime adventure.

Factory Direct Pricing

Swift & Guaranteed Delivery Date

Advanced Composite Fiberglass construction

10yrs Commercial Hull Warranty

We’re Here to Help You Set Sail on Your Next Adventure

Whether you’re interested in enhancing your fleet with a commercial catamaran, a tiki boat, or a custom fiberglass barge, our team at A&M Manufacturing is ready to assist. Let us help you turn your maritime visions into reality.

Feel the form right here or contact us by phone or mail.

Mail : [email protected]

© 2024 | anmmanufacturing.com | All right reserved

Fiberglass Multi-Hull Platforms for Work and Play

Pontoons & Tri-toons - Tiki Boats - Event Boats - Houseboats - Floating Heli Pads & Emergency Responder Support

Cruising Speed

Stay high and dry, nothing else like it, discover the beauty of sanibelcat, charters starting spring 2024.

COMING SOON SPRING 2024.

Book a boat charter with us!

Perfect for Parties, Bachelor/Bachlorette Parties, Family Outings

Fiberglass Catamaran Hulls

Catamaran hulls.

High-Volume Catamaran Hulls - Stay High & Dry!

Modern Fiberglass Hull Construction

High Buoyancy Eliminates Bow Diving

40' Built For Saltwater & Big Lakes

40'XL Twin Catamaran Hulls

40' Built for Saltwater & Big Lakes

40'XL Tri-toon Hulls

40'xl tiki hut / houseboat / event boat hulls.

40' long w/ over a 7-tonne payload!

Airex Coring, Bulkheads Throughout

Each Hull Has Transom for Outboard Engine

Built for Saltwater & Big Lakes

100% Custom Built

Ready for the Lake, Sandbar, Beach or Cove

Create a Party Space or the Ultimate Fishing Platform

40' Floating/Mobile Helipad & Emergency Support

Floating Heli Pad or Emergency Support

40' long; with beam 10' to 25'

Mobile capabilities to be closer to where support is needed, whether as an active base or cache location.

Construction

Hat channel structural cross members.

Our Hat Channel cross members are far stronger, more stable, and spaced closer together than other manufacturers c-channel, thus providing superior chassis strength.

Hand Laid Fiberglass

Hand laid, not blown, fiberglass hull construction is the key to lighter, high-volume hulls. The shape and buoyancy result in super shallow draft -- amazing for getting into tidal areas for beach visits. The wide-set outer chines of each hull result in 36% more stable platform than a tin-log pontoon boat of the same width.

Unique Hull Design

XXL Volume Pontoon Hulls. Built for buoyancy and aqua dynamics, our plumb, wave-piercing bows slip efficiently and quietly through the water.

Our hulls give a 'high & dry' ride -- 28" above the waterline.

Premium Furniture

Marine grade furniture throughout. Let us help you design and build a layout that fits your unique lifestyle.

Order your High-Volume Fiberglass Pontoon Hulls today!

Distributed by Okeanos Engineering, LLC

Drop us a line!

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Connect With Us

This website uses cookies..

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.

Call Us: (253) 851-2126 Mon-Fri 9-5 Pacific Time

- 12′ Scamp

“I have to say it’s the biggest little boat I’ve ever sailed.”

– 48 north magazine.

The Scamp is a seaworthy 12′ sailboat that can handle a good dose of adventure.

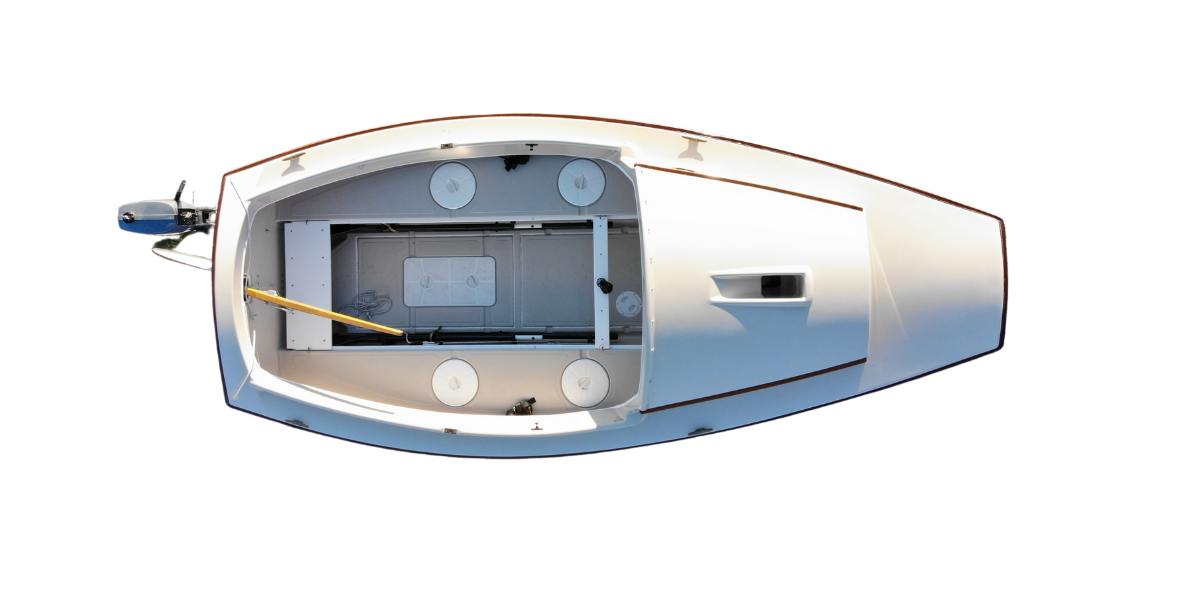

Just under 12 feet in length, Scamp boasts an unusual combination of features that give her the unique ability to explore waters too shallow for a larger boat, while retaining most of the bigger boat’s comforts and capabilities. An offset centerboard opens up the cockpit and an 8′ 3″ sleeping area, and 172 pounds of water ballast provide exceptional stability. The cockpit is self-bailing, and a pair of grounding skegs on her flat bottom keep Scamp perfectly upright when landing on a beach or when the tide goes out.

Originally designed as a wood boat by John Welsford, Gig Harbor Boat Works worked closely with the designer and staff from Small Craft Advisor to create a fiberglass version. Scamp #1 hit the water for its first sea trial in July of 2013!

As a specialized boat, the Scamp has some different options than the rest of our boats. We have had quite a few questions about Scamp’s option list so I thought it best to go into more detail below about the various choices. Be sure to check out the “Scamp Options” tab below for photos and descriptions of all the available options.

I’d like to emphasize the fact that we build and sell all of our boats complete, ready to sail. Our “basic’” Scamp is sail ready with exactly the same top quality parts and materials as a “fancy” Scamp — you don’t have to add anything to go for a satisfactory sail. Our ‘Base’ boat’s level of completion is the same as specified in the Scamp plans or kit for DIY home builders. Options are exactly that… individual choices made by the owner to suit their cosmetic desires and refine performance.

Fiberglass SCAMP Overhead View

Shown with optional floor storage hatch and optional wood trim. Motor not included.

12' Scamp Full Specifications

Scamp photo gallery (click to enlarge):, more about the scamp:.

- 48 North Review

- SCAMP Options (as of Jan 2016)

Gig Harbor Boat Works, known for their strong, esthetically pleasing rowing boats, has already shipped a number of the new SCAMPS all over the country and overseas. “The kit boat has a lot of intricate details that the home builder may not have the talent or tools to build,” says Dave Robertson, owner of GHB. “With the fiberglass version, they can enjoy using the boat right away.” The GHB boat is truly sail-away complete; from oars to sails.

There are many innovations designed into the SCAMP that make it truly a big little boat. One thing that usually takes up a lot of cockpit room of most small boats is the centerboard. The SCAMP’s centerboard, very heavy but swings up easily for trailer or grounding, is offset to starboard so that it doesn’t intrude into the cockpit. I’ll let you call Dave to explain the physics of the offset. Suffice it to say that we didn’t notice a difference on either tack. The result is it opens up the cockpit which feels more like that of a of a San Juan 24.

The boat was surprisingly quick and very stable. “This boat can’t be just 12’long,” I thought. I stood up and rocked it side to side with minimal affect. It felt like 20-footer. Sailing the SCAMP made me a believer that it actually would be a safe and enjoyable way to explore the San Juans, as well as just knocking around the bay for a fun day of sailing. The SCAMP had lots of surprises, all good. I have to say it’s the biggest little boat I’ve ever sailed.

See the price list for current pricing of Scamp options

Cosmetic options

Hull color change ( white hull exterior is standard).

This option allows you to customize the hull exterior to the color of your choice. For the best balance of pizzazz and reasonable maintenance, we recommend that color only be added to the top strake and the balance of the hull be left white. Why? A white underbody doesn’t show scratches like a dark color, it is easy to repair, and Scamp has high freeboard so a darker sheer strake lowers the apparent freeboard. If you add color to the top strake, we will extend the color across the top of the bow and leave the stern all white for best visual balance.

Deck and interior color change (Bisque Tan deck and interior are standard)

The Bisque color is neutral so goes with any accent color – it also doesn’t show scratches and is easy on the eyes. However, we can make the topsides any color you want; for more than a basic color change the price varies with color and pattern.

Bronze Deadlights (white nylon deadlights standard)

Mahogany gunwale trim (standard gunwale trim is tan vinyl).

This wood trim option also includes mahogany ‘eyebrows’ on the cabin sides. Other wood trim such as coaming or seat top overlay is available on a custom basis.

Custom Sail Color (standard is ‘Egyptian cotton)

Any color available, price varies with color and pattern.

Hull options

Stainless steel keel guards.

Over 90% of the boats we build are specified with stainless steel keel protection. Fiberglass is a wonderful boatbuilding material; easy to conform to compound shapes, hard smooth finish, eminently repairable; but it is NOT abrasion resistant. Pulling a boat onto a beach is asking for grief, especially if parts of the boat have a sharp edges forming high pressure areas…. like the keelsons on Scamp. Protecting the keelsons is a lot cheaper than fiberglass repair.

Floor storage hatch

There is a lot of usable, easily accessible space under the cockpit floor. This optional storage is a sealed chamber approximately 18″ wide x 30″ long with depth varying from about 8″ at the forward end to 4″ aft. The hatch accessing the storage is a rectangular Armstrong style with 14″ x 21″ opening. If you plan to add electric propulsion or accessories this is an ideal location for batteries!

Bilge pump, handheld manual style

Rain and spray is contained in the cockpit sump at the transom. This can be scooped or sponged out easily. However, if you somehow get water inside the seats or underfloor that is a relatively inaccessible area. Although chances of getting much water in this area are slim, it helps to have a portable handheld pump handy.

Outboard motor bracket

Removable outboard motor bracket

Bolts to outside of transom. Owners have noted that a permanent motor mount on Scamp is, well, ugly. So we researched a removable mount that has only a flat plate permanently bolted to the transom. The actual motor carrier clips onto the plate with a simple quick pin, no tools required to install or remove the bracket.

Bronze 5″ cleats

Bronze cleat

Stainless steel pop–up cleats

Pop-up cleat

Performance / operational options

Trailer, galvanized, custom designed for scamp.

Scamp is very difficult to fit correctly on a trailer; the twin keelsons, wide chines and flat bow just don’t work with any standard trailer. We designed a custom trailer specifically for this hull. It is 100% galvanized and has three aft rollers to accommodate self centering on the keelsons. Scamp has a tendency to skate sideways when loading, so we install carpeted side guides and a central crossmember roller to make loading simple. Forward is a carpeted transverse bunk to support the fairbody, and finally a special twin chock winch pedestal. Oh yeah, bearing buddies are standard too.

Swiveling mainsheet cleat with removable base

The mainsheet cleat is fastened to a transverse board between the seat tops. You can adjust the position of the board and cleat fore or aft the length of the cockpit or remove it entirely by pulling two stainless steel fastpins.

Jiffy reefing

Three Reef points in the sail are standard, but there are no reefing lines or cleats. If you want jiffy reefing we”ll set up two complete ready to use reefs.

Compass, bulkhead mounted Richie #RITV57.2

Oars, 9’4″ 2-piece fiberglass shaft with bronze oarlocks.

Scamp’s high freeboard and wide beam requires 9’+ oars which are impossible to stow in Scamps’ cockpit. We have engineered high quality, strong 2 piece 9’4″ spoon blade oars that disassemble and store concealed inside the cockpit coamings. Another practical storage area is on the vertical seat sides, clipped into modified fishing rod holders.

Cover for trailering/storage

Top Notch fabric, custom sewn for Scamp. Protects deck and cockpit during trailering and storage.

Bimini/Camping style cockpit cover

Fully enclosed bimini cockpit enclosure with zippered windows and side curtains. Sides zip off individually for fully-customized protection from the weather.

Scamp spar and sail bag

We are always looking for ways to simplify sailing, and one of the most vexing chores is the assembling the rig. Wouldn’t it be nice to be able to pull the completely assembled, ready to hoist sail and spars out of a bag? This special bag is 12′ long and has two long pockets; the lower pocket is for the two-section mast. The upper pocket has a full length zipper so you can store the sail lashed to the yard and boom with even the jiffy reefing in place. Just pull the mast with halyard attached from the bag and plop into the cabin-top ‘Scamp Ramp.’ Then fasten your halyard to the Yard and hoist the whole rigged sail out of the bag. All you have left to do is run the halyard and downhaul to their respective cleats, clip the mainsheet and lazy jacks to the boom and away you go. 10 minutes, done.

Stirrup reboarding system

Transom boarding ladder ….. still under development.

- 17′ Jersey Skiff

- 17′ Salish Voyager

- 16.5′ Melonseed

- 15′ Lobster Boat

- 14′ Whitehall

- 12′ Point Defiance

- 10′ Navigator

- 9.5′ Captain’s Gig

- 8′ Nisqually

- Available Now!

- New In Stock

SCAMP Rigging Tutorial

If you’re not familiar with balanced-lug rigging, here’s a great tutorial showing how to set up this simple and intuitive rig.

Imagining your ideal boat?

Take a turn through our online quote creator to see the possibilities. No haggling, no commitment.

Explore More Boats

Livingston 12 Foot

Specs, features & options.

How to Build a Catamaran Boat? (Step-by-Step Guide)

Building a catamaran boat from scratch is a rewarding and challenging endeavor.

It takes a combination of skill, dedication, and hard work to craft a seaworthy vessel.

In this step-by-step guide, you’ll learn how to design and size your catamaran, gather the necessary materials, cut and assemble the pieces, lay fiberglass and apply epoxy, make finishing touches, add hardware and paint, and rig the boat.

With the right tools, planning, and patience, you can make your dream of sailing in a catamaran a reality.

Table of Contents

Short Answer

Building a catamaran boat requires a lot of patience and skill.

The first step is to choose the right materials for the hull, such as fiberglass, wood or aluminum.

Then, you will need to build the frame of the boat, which includes the crossbeams and the main hull.

After that, you will need to install the decking, the rigging, and other components.

Finally, you will need to paint and varnish the boat, as well as install the outboard motor and other accessories.

Design & Size Considerations

When it comes to building a catamaran boat from scratch, the first step is to determine the design and size of the boat.

This should take into account the intended use of the boat, such as sailing, fishing, or leisurely cruising.

The size of the boat will depend on the number of passengers and the type of activities the boat will be used for.

For instance, a larger boat may be needed if passengers will be standing or participating in watersports.

The design of the boat is also important and should be chosen based on the intended use.

If you are looking to build a sailboat, you will need a design that is optimized for sailing.

On the other hand, if you are looking to build a fishing boat, you will need a design that is optimized for fishing.

There are a wide variety of boat designs available, so it is important to research and choose the one that best suits your needs.

In addition to the design and size, you will also need to consider the materials used for construction.

The most common materials for building a catamaran boat are wood, fiberglass, and epoxy.

Each material has its own advantages and disadvantages, so it is important to research them and determine which one is best for your project.

Finally, you will need to consider the cost of the project.

Building a catamaran boat from scratch can be a costly endeavor, so it is important to have a budget in mind before you begin.

The cost will depend on the type of materials used and the complexity of the design.

It is also important to factor in the cost of any tools that may be needed for the project.

By taking into account the design and size, materials, and cost of the project, you can be sure to build a catamaran boat that meets your needs and budget.

With the right amount of patience and attention to detail, you can build your own catamaran boat in no time.

Gathering Materials

Gathering the materials needed to build a catamaran boat from scratch can be a daunting task, but it is essential for creating a sturdy and safe vessel.

Before starting the building process, it is important to have an accurate and detailed plan for the boats design and size.

Once a plan is in place, it is time to begin sourcing the necessary materials.

The most common materials used to construct a catamaran boat are wood, fiberglass, and epoxy.

When choosing wood, it is best to select a species of timber that is strong and durable, such as mahogany, teak, or cedar.

Additionally, the wood should be clear and free of knots, splits, and other defects.

Fiberglass is a lightweight fabric that is resistant to water and provides additional strength to the boats hull.

Epoxy is a waterproof adhesive that is used to seal the boat and ensure that it is watertight.

It is important to ensure that the materials are of high quality, as this will help to ensure the boats longevity.

Additionally, it is important to purchase the necessary materials in the correct amount and size.

Too little or too much of a material can be a costly and time-consuming mistake.

Finally, it is important to keep any leftover materials for future repairs or modifications.

With the right materials gathered, the next step is to cut the wood and begin the assembly process.

Cutting & Assembly

Cutting and assembly are the most important steps when it comes to building a catamaran boat from scratch.

The first step is to decide the design and size of the boat.

This will determine the type of materials you need to gather and the amount of effort that needs to be put into the project.

After deciding on the design and size, you will need to cut the wood to fit the design.

This includes cutting the wood to the desired size, as well as cutting any additional pieces that may be needed to complete the design.

It is important to ensure that all the pieces fit together correctly and securely, as any mistakes could lead to a weak boat.

Once the wood has been cut, it is time to assemble the pieces together.

This involves attaching the pieces together with glue, screws, and nails, and ensuring that the pieces fit together securely.

It is important to be careful and patient when assembling the pieces, as any mistakes could result in a weak and unstable boat.

Once the frame is ready, it is time to lay the fiberglass, and apply the epoxy to seal the boat.

This is an important step, as it will make sure that the boat is waterproof and durable.

Finally, you can add the finishing touches, such as the hardware, paint, and rigging.

With the right amount of patience and attention to detail, you can have your own custom catamaran boat in no time.

Laying Fiberglass & Applying Epoxy

When laying the fiberglass and applying epoxy, it is important to take your time and be precise.

Fiberglass and epoxy are key components of a catamaran boat, as they provide the strength and waterproofing necessary to keep the boat afloat.

Start by laying the fiberglass over the frame of the boat.

Make sure to cut the fiberglass to size and overlap the edges for a strong seal.

Once the fiberglass is in place, mix the epoxy and begin to apply it.

It is important to apply the epoxy in a thin, even layer to ensure a proper seal.

Make sure to move the epoxy around to get it into all the nooks and crannies of the boat.

Allow the epoxy to cure and then you can begin to add the finishing touches.

Finishing Touches

Once the frame of the catamaran boat is built, it is time to add the finishing touches.

This includes adding the necessary hardware, painting, and rigging the boat.

Hardware: Before adding the hardware, it is important to ensure that the frame is stable and secure.

Add the appropriate hinges, screws, and nails to the frame.

Make sure that the screws and nails are the correct size and do not exceed the recommended load capacity of the frame.

Painting: Once the hardware is added, it is time to paint the boat.

Choose a paint that is suitable for the materials used in the construction.

Make sure that the paint is applied evenly and that the frame is completely dry before applying the next coat.

Rigging: The last step is to rig the boat.

This involves attaching the sails, running rigging, and standing rigging to the masts and booms.

Make sure that the rigging is properly tensioned and secured.

Once all of these steps are complete, your catamaran boat is ready to sail.

Hardware & Paint

The last step in building a catamaran boat is to add the hardware and paint.

This step is often the most rewarding, as it is the finishing touch.

Depending on the design of your boat, there are various types of hardware you may need.

Some of the most common items are cleats, winches, fasteners, and decking.

After selecting the required hardware, you will need to install them on the boat.

It is important to use the correct type of screws and bolts, and to secure them tightly.

Once the hardware is installed, it is time to apply the paint.

The type of paint and color you choose will depend on the design of your boat.

It is important to use a high-quality marine grade paint that is designed to handle the extreme environment of the ocean.

If you are up to the challenge, you can add some custom artwork or detail to your catamaran boat.

Adding the hardware and paint is the final step in building a catamaran boat.

With patience and attention to detail, you can create a beautiful and unique boat that will last for many years.

Be sure to take your time and enjoy the process of constructing your own boat.

Once you have finished the frame, fiberglass, and epoxy of your catamaran boat, you will need to move onto the rigging.

This is a crucial step in the construction process, as it will keep your boat safe and secure on the water.

When rigging a catamaran, there are a few key components that must be taken into account.

First, you will need to determine the type of rigging you will be using.

Typically, catamarans use a combination of standing and running rigging.

Standing rigging consists of cables and lines that stay in a fixed position to provide stability and strength to the boat, while running rigging consists of lines that are used to adjust the sail and mainsheet.

Additionally, you will need to choose the right type of rope and hardware for your rigging setup.

The rope should be strong and durable, and the hardware should be made of stainless steel and be corrosion-resistant.

Once you have chosen the type of rigging and hardware, you can start assembling the rigging lines.

This process involves carefully measuring and cutting the lines to the proper lengths, and then attaching them to the mast and boom.

Depending on the type of rigging setup, you may also need to attach the lines to the hulls and deck.

It is important to inspect the rigging lines and hardware regularly to ensure that everything is secure and in proper working order.

Rigging a catamaran boat can seem like a daunting task, but it is essential for the safety and comfort of your vessel.

With the right tools, materials, and attention to detail, you can successfully and safely rig your catamaran boat.

Final Thoughts

Building a catamaran boat is a rewarding experience that requires patience and attention to detail.

With the right plan, materials, and steps, you can build your own boat in no time.

Now that you know the basics of how to build a catamaran boat, why not grab your tools and get started on your very own project? With the right motivation and dedication, you can make your dream of owning a catamaran boat a reality.

James Frami

At the age of 15, he and four other friends from his neighborhood constructed their first boat. He has been sailing for almost 30 years and has a wealth of knowledge that he wants to share with others.

Recent Posts

Does Your Boat License Expire? Here's What You Need to Know

Are you a boat owner looking to stay up-to-date on your license requirements? If so, youve come to the right place! In this article, well cover everything you need to know about boat license...

How to Put Skins on Your Boat in Sea of Thieves? (Complete Guide)

There is a unique sense of pride and accomplishment when you show off a boat you customized to your exact specifications. With Sea of Thieves, you can customize your boat to make it look like your...

Sailboat Hulls: Steel Vs Fiberglass

Last Updated by

Jacob Collier

August 30, 2022

For decades, sailors and boat owners have been having hotly contested debates about the merits of steel hulls vs fiberglass hulls in sailboats.

The major benefits of boats with steel hulls are that they are very strong, durable, and can be repaired easily. On the other hand, a fiberglass hull offers your boat a smooth and sleek look that is very pleasing. They are also lighter, faster, and require less maintenance than steel boats.

Whether you are building your own sailboat or thinking of buying one, getting the right material for the hull is of paramount importance. Your choice of material should depend on consideration of multiple factors, including its durability, stability, maintenance, repairs, weight, comfort, safety, and cost.

We have a team of sailing experts who have spent decades on the water and have set sail on boats built of all types of materials available. So who better to walk you through the pros and cons of steel and fiberglass hulls?

Table of contents

Steel Hull vs Fiberglass Hull: Top 10 Factors to Consider

Let us take a look at some of the major factors that can help you determine whether a boat with a steel hull or fiberglass hull will be a better choice for you.

Sailboats with steel hulls are much more durable and stronger than those with fiberglass hulls. Steel sailboats have a more rigid structure and are quite robust so they can better understand grazes, rubs, and bumps when out in the open water.

In case of impact, a steel hull will bend and may become dented; however, a fiberglass hull has a higher possibility of breaking. That’s because steel is more ductile and can withstand strong blows without losing its toughness.

Fiberglass is a lighter material than steel, making fiberglass boats lighter. Many people prefer this quality since it means that the boat will travel faster on water and will require less power and wind energy to move than a boat with a steel hull. This means lower fuel consumption and more savings. However, a fiberglass boat will be more prone to be buffeted by the winds since it is lighter.

Anti-Corrosion Properties

The sailboat manufacturing industry now uses state-of-the-art technology and makes use of the best quality materials to make the hull. Steel corrodes when exposed to the atmosphere. However, if the right alloy is used for making the hull, it will resist saltwater corrosion, without even needing special paint.

Steel boats also experience electrolytic or galvanic corrosion, but they can be avoided with the use of insulated electrical connections and sacrificial anodes.

Fiberglass does not corrode. However, it can still suffer from osmosis if the fiberglass had air bubbles at the time of lamination. This can cause water to collect in the void, forming blisters that can weaken the hull. Fiberglass may also become damaged from ultraviolet radiation.

Since steel boats are heavier than fiberglass boats, it means they are more stable on the sea, particularly if you experience choppy waters. A fiberglass boat, on the other hand, is lighter, and hence sailors may experience a rougher journey on choppy waters.

In addition, due to its extra weight, steel boats drift slower and more predictably, which is particularly useful for anglers.

Maintenance

Many steel boats require greater maintenance since they are more prone to corrosion. Galvanic corrosion can occur when two different metals are placed together. Hence, it is important that you ensure that high-quality materials, joints, and screws are used on the hull. It is important to rinse the hull with fresh water once it is out of the sea.

Fiberglass boat hulls do not have welds and rivets and you do not need to worry about the hull rusting. However, it can experience osmosis issues, which can cause serious problems if they are not treated in time.

Both fiberglass and steel boats require antifouling application to prevent barnacles, algae, and other sea organisms from sticking to the hull. However, antifouling can be more expensive for steel boats.

It is easy to repair small dents in steel boats. However, if the damage is extensive, it can be more complicated and costly to repair or replace large sections of steel hulls. Welding a boat hull is a specialized job that requires trained professionals.

It is easier to repair a broken fiberglass hull, but it may never have the same strength and durability as the original hull since the structural tension will not be equal at all points.

Fiberglass boats are made of petroleum-based products that are flammable. Hence, in case of a fire, they will burn easily and quickly. A steel boat is much safer since it cannot burn. In addition, a significant impact from an unidentified floating object can result in a breach in a fiberglass hull easily and open up a waterway into the boat that can cause it to sink. Steel, on the other hand, can withstand larger impacts without compromising the integrity of the boat.

Steel boats operate much louder than fiberglass boats, especially in turbulent seas at high speed. Steel is also a good conductor of heat and if it is not well-insulated during construction, it can become uncomfortably warm in the summer and cold in the winter. On the other hand, boats with fiberglass hulls do not transmit heat well and are more comfortable.

When it comes to aesthetic appeal, fiberglass hulls have a sleeker, shinier, and more polished look. Steel hulls often have marks of reinforcements on their hulls and they need to get a nice paint to look good. In most cases, steel hulls are covered with putty to hide any construction defects. This putty should be polished so that the boat has a nice finish and is done in a controlled environment to keep out dust.

As you can imagine, this process is complex, costly, and drives up the price of the boat.

It is easier to manufacture fiberglass hulls and mold them into more complex shapes. This can lead to faster production and lower construction costs. Sailboats with steel hulls are more expensive, as we mentioned before because they require welding, heavy-duty grinding , and specialized cutting tools and are more labor-intensive.

When Should You Choose a Steel Boat?

Steel hulls are stronger, durable, and more impact-resistant than their fiberglass counterparts. Dents in steel hulls can be repaired easily and although steel is prone to corrosion, this can be managed by special paints, insulation, and some regular maintenance.

If you are deciding on a circumnavigation or want to go out on a long spree in the water, you need a solid and dependable boat that you can rely on when you venture into new territories.

A well-maintained sailboat gives you the confidence to enter into unfamiliar rocky coasts and reduce your worries about hitting UFOs. However, keep in mind that steel boats may be slower than fiberglass boats, particularly if they are smaller vessels.

When Should You Choose a Fiberglass Boat?

Fiberglass boats are generally prettier than steel boats since they have a smooth and polished hull. They also do not require protective paint on their hull since they are corrosion-free and hence quite low maintenance. In addition, they are lighter and faster than their steel counterparts and do not cost as much.

However, one big concern of a fiberglass hull is that it is not as strong as a steel hull. If the boat hits a hard object, the fiberglass may break, which can be dangerous on the open seas, particularly in choppy waters.

Still, fiberglass boats are an excellent option for racing and even long-distance cruising in areas that do not have sharp rocks.

The type of sailboat you choose depends on your sailing style and your needs. So make sure you consider all the factors before you invest in a steel or fiberglass boat.

Related Articles

Types of Sailboat Hulls

What Is a Sailboat Hull?

Born into a family of sailing enthusiasts, words like “ballast” and “jibing” were often a part of dinner conversations. These days Jacob sails a Hallberg-Rassy 44, having covered almost 6000 NM. While he’s made several voyages, his favorite one is the trip from California to Hawaii as it was his first fully independent voyage.

by this author

Learn About Sailboats

Most Recent

What Does "Sailing By The Lee" Mean?

Daniel Wade

October 3, 2023

The Best Sailing Schools And Programs: Reviews & Ratings

September 26, 2023

Important Legal Info

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies.

Similar Posts

Affordable Sailboats You Can Build at Home

September 13, 2023

Best Small Sailboat Ornaments

September 12, 2023

Discover the Magic of Hydrofoil Sailboats

December 11, 2023

Popular Posts

Best Liveaboard Catamaran Sailboats

December 28, 2023

Can a Novice Sail Around the World?

Elizabeth O'Malley

June 15, 2022

4 Best Electric Outboard Motors

How Long Did It Take The Vikings To Sail To England?

10 Best Sailboat Brands (And Why)

December 20, 2023

7 Best Places To Liveaboard A Sailboat

Get the best sailing content.

Top Rated Posts

Lifeofsailing.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon. This site also participates in other affiliate programs and is compensated for referring traffic and business to these companies. (866) 342-SAIL

© 2024 Life of Sailing Email: [email protected] Address: 11816 Inwood Rd #3024 Dallas, TX 75244 Disclaimer Privacy Policy

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

50'+ fiberglass catamaran design plans

Discussion in ' Boat Design ' started by mariobrothers88 , Mar 6, 2022 .

mariobrothers88 Senior Member

Hi guys does anyone have any recommendations for pure fiberglass catamaran design plans in the 50-60' range? I don't want to use plywood or any core materials like pvc foam, etc. Thanks for any advise or tips!

bajansailor Marine Surveyor

I cannot recommend anything as such, but the first that springs to mind is the Derek Kelsall designs - Catamarans - Kelsall Catamarans - Sail Design Range Over 46 Foot http://www.kelsall.com/Designs/KSSSailOver46.htm Correction, I think that most, if not all, of his designs have cores. I think you will be very limited in choice really re finding plans for a single skin catamaran of this size. What do you want to use it for? Why does it 'have' to be single skin fibreglass?

Hi Bajansailor thanks for your reply! It doesn't have to be but it is very difficult to get things like pvc foam core to my location. Bringing in just fiberglass and resin is logistically much easier and I like the fact that it requires less maintenance since it won't suffer from rot or water intrusion issues like plywood and foam core.

messabout Senior Member

For a 50...60 footer, aluminum or steel begin to enter the realm of practicality. Neither of those will absorb water and does not rot. Steel or Aluminum is easier to repair, does not develop gel coat cracks, and several other advantages,........... cost among other things.

fallguy Senior Member

Building a mould for an all glass boat is as much work as the boat, no?

Mario, have you finished the Woods cat (I think she is a Romany?) that you were building? I would agree with Messabout, re aluminium for a 'one off' boat of this size - it is (IMHO) pretty much the most logical way to go. And re Fallguy's comment above, why would you want to build a mould for a one off boat? You already have to build two hulls; assuming that they are symmetrical you would then have to build three (and then some).

Alik Senior Member

I don't see any advantages in single-skin composite catamaran hull. Will be too heavy! Besides all, full set of molds/tooling will be required.

wet feet Senior Member

I am not sure there is a diplomatic way to explain the reality,several have posted pointers that hint at the essence of the matter.If plans don't exist,a designer would be needed and he will require payment for the work.A set of moulds will be needed and in order to get there,a set of plugs will need to be built.We don't know the enquirer's actual level of experience of these processes or his financial capability to undertake the project.I would guess-a very wild guess-that a couple of million dollars would get a boat built.There are catamarans for sale for less and they have enough of a reputation in the marketplace to have some resale value.Does a first time amateur build have much value?

wet feet said: ↑ I am not sure there is a diplomatic way to explain the reality,several have posted pointers that hint at the essence of the matter.If plans don't exist,a designer would be needed and he will require payment for the work.A set of moulds will be needed and in order to get there,a set of plugs will need to be built.We don't know the enquirer's actual level of experience of these processes or his financial capability to undertake the project.I would guess-a very wild guess-that a couple of million dollars would get a boat built.There are catamarans for sale for less and they have enough of a reputation in the marketplace to have some resale value.Does a first time amateur build have much value? Click to expand...

Hey guys thanks for all the great replies and advice! Is it possible to set up bulkheads and stringers like a typical plywood/epoxy /fiberglass build and instead of using plywood, use flat panels of fiberglass? I can make a flat sheet of several layers of fiberglass that would be relatively stiff but still bendy enough to make the hulls then reinforce it with more fiberglass once it's on the structure. I can make long flat panels of fiberglass pretty easily with hdpe sheets as the "mould". I know that it would be heavier but I'm not too concerned with efficiency since this would be for coastal cruising at most and would never likely have to cross any oceans. I figure there must be a good reason why this wouldn't work but I can't think of it.

Cats are weight sensitive. It is gonna get too heavy solid frp. You can't say weight doesn't matter.

fallguy said: ↑ Cats are weight sensitive. It is gonna get too heavy solid frp. You can't say weight doesn't matter. Click to expand...

TANSL Senior Member

fallguy said: ↑ Cats are weight sensitive. Click to expand...

Thanks for the reply tansl! By monolithic so you mean pure fiberglass? Also what do you mean by sandwich prf?

- Advertisement:

The monolithic is formed by several layers of fiber assembled by resin. In the sandwich construction, a central core is placed, which is very light and not very resistant to tension/compression, and layers of fiber on both sides of the core.

ABS Fiberglass Yacht

Strength of Fiberglass/composite Repairs

Reversible connection of structural fiberglass components

steel reinforced fiberglass?

Fiberglass over plywood vs all fiberglass hull

Fiberglass Rudder Shoe

Fiberglass repair on a rowboat

Rebuilding a 14 foot 1960s or 1970s Pigeon Marine fiberglass runabout...

Fiberglass tape size for a plywood rowing shell

fiberglass foam sandwich mast

- No, create an account now.

- Yes, my password is:

- Forgot your password?

- Vessel Reviews

- Passenger Vessel World

- Offshore World

- Tug and Salvage World

- Maritime Security World

- Specialised Fields

- Marine Projects World

- Small Craft World

- Tanker World

- Dry Cargo World

- Boxship World

- Aquaculture World

- Trawling World

- Longlining World

- Seining World

- Potting World

- Other Fishing Methods

- Regulation & Enforcement

- Feature Weeks

- Classifieds

- Book Reviews

VESSEL REVIEW | Sinichka – Electric commuter boats designed for Russia’s Moskva River

A series of three new electric monohull commuter ferries have already begun operational sailings on the Moskva River in the Russian capital Moscow.

Built by Russian shipyard Emperium, sister vessels Sinichka , Filka , and Presnya – all named after rivers in Moscow – are being operated by the Moscow Department of Transport and Road Infrastructure Development (Moscow Deptrans). They are the first units of a planned fleet of 20 vessels that will serve the capital city and other nearby communities. The new ferry system will be the water transport system to be operated on the Moskva River in 16 years.

Each vessel has a welded aluminium hull, an LOA of 21 metres, a beam of 6.2 metres, a draught of only 1.4 metres, a displacement of 40 tonnes, and capacity for 80 passengers plus two crewmembers. Seating is available for 42 passengers on each ferry, and the main cabins are also fitted with USB charging ports, wifi connectivity, tables, toilets, and space for bicycles and scooters. The cabin layout can be rearranged to allow the operator to adjust the distances between the seats and to install armrests of varying widths.

An open upper deck is also accessible to passengers and is the only area on each ferry where smoking is allowed.

The ferries are all of modular construction with each ferry’s wheelhouse, main cabin, and other structural elements being built as complete, separate components. This enables the ferries to be easily dismantled for transport to anywhere in Russia by rail and then quickly re-assembled within seven days.

The ferries are also ice-capable. Recently completed operational trials on the Moskva showed that the vessels can also easily navigate under mild winter conditions with broken surface ice, though year-round operations are planned for the entire fleet.

The ferries are each fitted with 500kWh lithium iron phosphate battery packs that supply power to two 134kW motors. This configuration can deliver a maximum speed of 11.8 knots, a cruising speed of just under 10 knots, and a range of 150 kilometres.

Emperium said the transfer of rotation of electric motors to the propeller is carried out by direct drive. As a propulsion installation, a pulling rotary propeller-steering column with double screws is used. The installation of double pulling screws, with similar power, allows an operator to increase the efficiency of the propulsion system to deliver a slightly higher speed or to reduce energy consumption. This arrangement also provides the ferries with enhanced manoeuvrability necessary for navigating in close quarters.

The batteries themselves have projected service lives of 10 to 12 years and are fitted with safety features such as built-in fire extinguishers and gas vents. Quick-disconnect features allow the batteries to be easily removed for replacement or maintenance.

Some of our readers have expressed disquiet at our publication of reviews and articles describing new vessels from Russia. We at Baird Maritime can understand and sympathise with those views. However, despite the behaviour of the country’s leaders, we believe that the maritime world needs to learn of the latest developments in vessel design and construction there.