- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Bob Perrys Salty Tayana 37-Footer Boat Review

Tartan 30: An Affordable Classic

Ericson 34-2 Finds Sweet Spot

How to Sell Your Boat

Preparing A Boat to Sail Solo

Solar Panels: Go Rigid If You have the Space…

Leaping Into Lithium

The Importance of Sea State in Weather Planning

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

Taking Care of Your 12-Volt Lead-Acid Battery Bank

Hassle-free Pumpouts

What Your Boat and the Baltimore Super Container Ship May Have…

Check Your Shorepower System for Hidden Dangers

Waste Not is the Rule. But How Do We Get There?

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Boat Maintenance

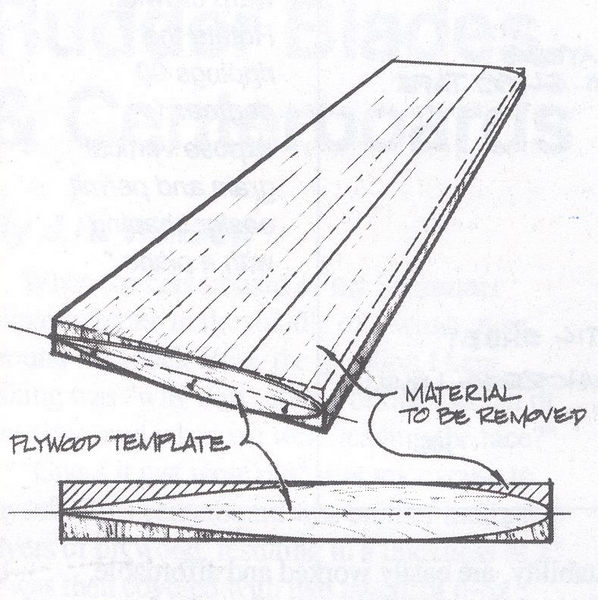

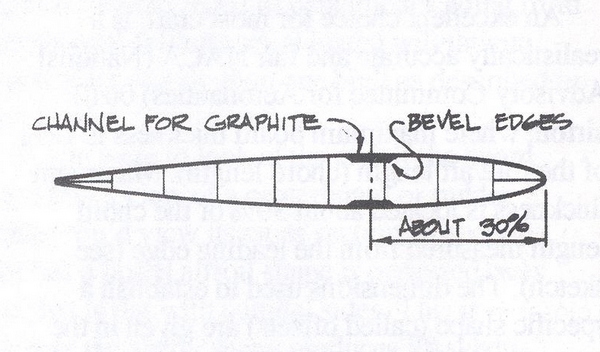

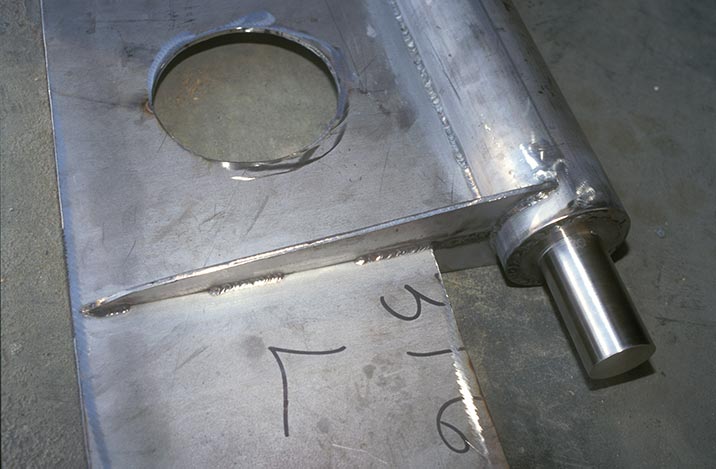

Building a Faster Rudder

Boost performance with a bit of fairing and better balanced helm..

We’re cruisers not racers. We like sailing efficiently, but we’re more concerned with safety and good handling than squeezing out the last fraction of a knot. Heck, we’ve got a dinghy on davits, placemats under our dishes, and a print library on the shelf. So why worry about perfection below the waterline?

The reason is handling. A boat with poorly trimmed sails and a crudely finished rudder will miss tacks and roll like a drunkard downwind when the waves are up. On the other hand, a rudder that is properly tuned will agilely swing the boat through tacks even in rough weather, and provide secure steering that helps prevents broaching when things get rolly. The difference in maximum available turning force between a smooth, properly fitted rudder and the same rudder with a rough finish and poor fit can be as much as 50% in some circumstances, and those are circumstances when you need it the most. It’s not about speed, it’s about control.

It Must Be Smooth

Smooth is fast. That’s obvious. But it makes an even bigger difference with steering. Like sails, only half of rudder force comes from water deflected by the front side of the blade. The rest results from water being pulled around the backside as attached flow. How well that flow stays attached is related to the shape of the blade, which we can’t easily change, and to the surface finish of the blade, which we can.

Remember the school experiment, where you place a spoon in a stream of water and watched how the water would cling to the backside of the spoon? Now, try the experiment again as a grown-up, but with a different set of materials.

Try this with a piece of wood that is smooth and one that is very rough; the water will cling to the smooth surface at a greater angle than the rough surface. Try piece of smooth fiberglass or gelcoat; the water will cling even better because the surface is smoother. Try a silicone rubber spatula from the kitchen. Strangely, even though the surface is quite smooth, the water doesn’t cling well at all. We’ll come back to that.

Investigators have explored this in a practical way, dragging rudders through the water in long test tanks (US Navy) and behind powerboats.

If we are trying to climb to windward, it’s nice to get as much lift out of the rudder as practical, before drag becomes too great or before it begins to stall with normal steering adjustments. If the boat has an efficient keel and the leeway angle is only a few degrees, the rudder can beneficially operate at a 4-6 degree angle. The total angle of attack for the rudder will be less than 10 degrees, drag will be low, and pointing will benefit from the added lift. If the boat is a higher leeway design—shoal draft keels and cruising catamarans come to mind—then the rudder angle must stay relatively low to avoid the total angle (leeway + rudder angle) of the rudder from exceeding 10 degrees. That said, boats with truly inefficient keels but large rudders (catamarans have two—they both count if it is not a hull-flying design) can sometimes benefit from total angles slightly greater than 10 degrees—they need lift anywhere they can get it.

How can you monitor the rudder angle? If the boat is tiller steered, the tiller will be about 0.6 inches off center for every degree or rudder angle, for every 3 feet of tiller length. In other words, the 36-inch tiller should not be more than about 2 inches off the center line. If the boat is wheel steered, next time the boat is out of the water, measure the rudder angle with the wheel hard over. Count the number of turns of the wheel it takes to move the rudder from centered to rudder hard over, and measure the wheel diameter. Mark the top of the rim of the wheel when the boat is traveling straight, preferably coasting without current and no sails or engine to create leeway.

The rim of the wheel will move (diameter x 3.146 x number of turns)/(degrees rudder angle at hard over) for each degree of rudder angle. Keep this in the range of 2-6 degrees when hard on the wind, as appropriate to your boat. It will typically be on the order of 4-10 inches at the steering wheel rim. A ring of tape at 6 degrees can help.

How do we minimize rudder angle while maintaining a straight course? Trimming the jib in little tighter or letting the mainsheet or traveler out a little will reduce pressure on the rudder and reduce the angle. Some boats actually sail to weather faster and higher, and with better rudder angles, by lowering the traveler a few inches below the center line.

On the other hand, tightening the mainsheet and bringing the traveler up, even slightly above the center line on some boats, will increase the pressure and lift.

Much depends on the course, the sails set, the rig, the position of the keel, the wind, and the sea state. Ultimately, some combination of small adjustments should bring the rudder angle into the appropriate range. Too much rudder angle and you are just fighting yourself.

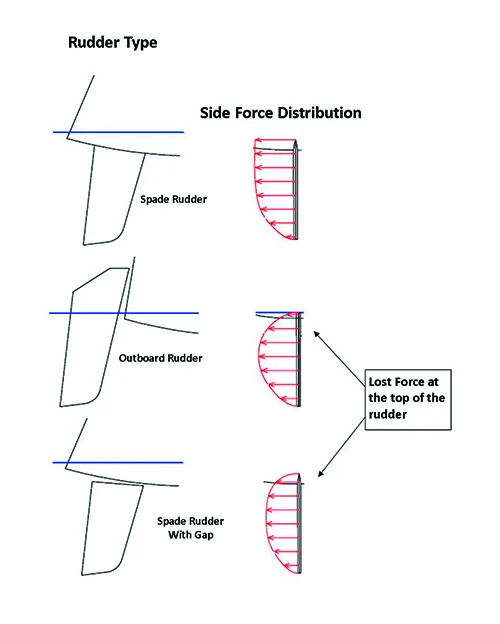

- Turn this rudder just 10 degrees and the end plate is lost, reducing the amount of lift generated.

- This rudder might as well be transom hung, the way that the end cap just disappears.

- Stern-hung rudders, and spade rudders with large gaps between the hull and the top of the rudder will lose their lift at the “tip” of the blade near the surface.

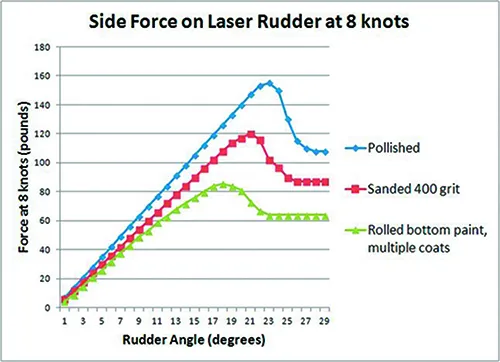

Surface roughness affects the lift from the rudder in two ways. A rougher surface has slightly lower lift through the entire range of angles, the result of a turbulent boundary layer instead of smooth flow over the entire surface. More dramatically, rougher blades stall at lower angles and stall more completely. The difference between a faired rudder with a polished finish and a rudder carrying a 10-year accumulation of rolled-on antifouling paint can be as much is 35 percent (see “Rudder Savvy to Boost Boat Performance,” above).

What can we do? If your rudder is a lift up type, don’t use bottom paint. Fair the blade within an inch of its life and lay on a gloss topside paint as smoothly as possible, sanding between coats. If you use a brush, stroke the brush parallel to the waterline, not along the length of the blade.

Which is faster, a gloss finish or one that has been dulled with 1000 grit sandpaper? Opinions go both ways, and we believe it may depend on the exact nature of the paint, which leads to the question, “Should we wax the blade?” The answer is a resounding, no.

Wax is a hydrophobic (readily beads water), like the silicone rubber spatula you tested, and as a result, water doesn’t always cling as well. Thus, whether the paint should be deglossed or not depends on the chemistry of the paint, but in all cases the final sanding should be 1000 grit or finer.

If the rudder stays in the water, antifouling paint is required. Sand the prior coat perfectly smooth. There should be no evidence of chips, runners, or any irregularity at all. Using a mohair roller, lay the paint on thin, and apply multiple coats to withstand the scrubbing you will give your rudder from time to time.

Even if you use soft paint on the rest of the boat, consider hard paint for the rudder. Sure, it will build up and you will have to sand it off periodically, but the rudder is small and no part of your boat is more critical to good handling. Take the time to maintain it as a perfect airfoil.

Close the Gap

Ever notice the little winglets on the tips of certain airplanes? As we know, those are intended to reduce losses off the tip of the wing. The alternatives are slightly longer wings or slightly lower efficiency. At the fuselage end of the wing, of course, there is no such loss because the fuselage serves as an end plate. The same is true with your rudder.

There’s not much you can do about losses from the tip; making the rudder longer will increase the chance of grounding and increase stress on the rudder, rudder shaft, and bearings. Designers have experimented with winglets, but they the catch weeds and the up-and-down motion of the transom makes them inefficient. However, we can improve the end plate effect of the hull by minimizing the gap between the hull and the rudder.

In principle it should be a close fit, but in practice the gap is most often wide enough to catch a rope. Just how much efficiency is lost by gap of a few inches? The answer is quite a lot. A gap of just an inch can reduce lift by as much as 10-20 percent, depending on the size and shape of the rudder and the speed. A gap of 1-2 mm is quite efficient, but normal flexing of the rudder shaft may lead to rubbing.

If the gap is tight, the slightest bend from impact with a submerged log can cause jamming and loss of steering, though in my experience once the impact is sufficient to bend the shaft, a small difference in clearance is unlikely to make much difference; the shaft will bend until the rudder strikes the hull. Just how tight is practical depends on the type of construction, fitting accuracy, and how conservative the designer was in their engineering.

Carbon shafts, tubular shafts, and rudders with skegs flex less, while solid shafts generally flex more, all things being equal. Normally a clearance of about 1/4-inch per foot of rudder cord is practical, and performance-oriented boats often aim for much less. If you can reach your fingers through, that’s way too much. Hopefully the hull is relatively flat above the rudder so that the gap does not increase too much with rudder angle.

Practical Sailor’s technical editor Drew Frye is the author of the books Keeping a Cruising Book for Peanuts and Rigging Modern Anchors. He blogs at his website, sail delmarva.blogspot.com .

RELATED ARTICLES MORE FROM AUTHOR

What your boat and the baltimore super container ship may have in common, 22 comments.

How happy to see good technical information about the science of boat speed and control. This information is valuable to everyone, but the “mainly just cruising” cohort usually doesn’t get enough in an easily understandable form. I always suggest some club level racing as the best way to learning how to sail, but many prospective racers have been put off from the sport or haven’t had good opportunities to join the fleets. Technical seminars are generally either too advanced for beginners to understand properly, and the beginner classes are frequently too basic to inspre those who would benefit from a deeper knowledge base in the science of sailing. Good on you, Practical Sailor, for your technical stories hitting the “sweet spot,” getting this information to those we’ll benefit most.

Great article. How about considering modifying a rudder to make it a hydrodynamically balanced rudder. I did it to my boat and the difference is outstanding. If I remember correctly 7% of the rudder area is forward of pivot center. It is a skeg hung rudder that now turns like it’s a spade rudder.

I’m “skeg hung” also. Would you be so kind as to posting a link or providing info as to you accomplished this feat. Thanks!

A very clear explanation of some quite complicated hydrodynamics – thank you! I am surprised by the US Navy results showing benefit of sanding further than 400 grit. Most other experimental data suggest there is negligible advantage in going beyond about 360 grit. Is the original reference publicly available? On Michael Cotton’s comment, a couple of points: Firstly, the amount of balance (i.e how far back you put the stock in the blade) has no impact on the hydrodynamic performance of a spade rudder. What it does do is change the feel of the rudder; a well balanced rudder will be easier to use, thereby probably allowing the steerer to sail the boat better. For a skeg rudder, the hydrodynamic impact of changing the balance depends very much on how the skeg/blade combination is configured. Secondly, 7% of rudder area forward of the stock is not enough for most rudders. The position of the centre of pressure is dependent on a lot of factors (aspect ratio, rudder angle etc.), but it is usually at least 15% back from the leading edge on a spade rudder, more often 20%. A balance somewhere between 10% and 15% is likely to give just enough feel without too much weight. However, rudder balance is still a bit of a black art, it really does depend on the rudder geometry.

the statement that one doesn’t want a silicone/silane coated ( super-smooth, hydrophobic: silicone-silane is just the example I am choosing, since it is now in use as a massively-speeding hull-coating, ttbomk ), as it *induces* flow-separation…

looks to me like conflating cavitation with flow-separation.

People have no problem teflon/ptfe-coating aviation-wings, as a means of *preventing* flow-separation.

the super-slick shape of a Cirrus’s composite wing, if made super-smooth/polished & super-slippery, “air-phobic”, as it were, *improves* its performance, not detracts from it….

Flow is always 1. laminar, then 2. turbulent, then 3. flow-separation.

unless the angle-of-attack ( AoA ) is small-enough to prevent separation.

The Gentry Tufts System, for *seeing* when a separation-bubble begins, on a sail, is brilliant ( Arvel Gentry was a fluid dynamicist, & realized that once one has a *series* of tufts, from luff on back, about 1/4 up the luff, one can *see* the beginning of a flow-separation-bubble, & tune the sail to keep it *just*-beginning, because *that* is MAX lift. Wayback Machine has his site archived, btw )

The aircraft designer Jan Roskam wrote of a DC-10 crashing because pebbled-ice as thick as the grit on 40-grit sandpaper had formed on the upper wings…

obviously, engineered to require laminar, there, but having turbulent, cost all those lives.

iirc, it was Arvel Gentry, or “Principles of Yacht Design”, that stated it takes a ridge of about 0.1mm, only, to trip the flow around a mast from laminar to turbulent…

Given how barnacles & such are generally 100x or more as thick as that, when removed from a hull, I think laminar-flow is something that exists only for the 1st day or so after launching!

I now want to see experiment showing polar curves for rudders coated normally, uncoated, & ailicone-silane coated, to see if it is the coating that induces separation-bubbles, or if it is AoA exceeding functional angle, for that surface & foil,, while the boundary-layer is in specifically turbulent flow, as opposed to the ideal laminar, as aviation’s results indicate…

just an amateur student of naval-architecture & aircraft-design ( Daniel P. Raymer’s “Conceptual Aircraft Design” is *brilliant*, btw ), who happens to study this stuff autistically, as that is the only way to make my designs become absolutely-competent, is all…

I got a pearson and the rudder broke. Can I just replace with a outboard rudder mount it off set for room for outboard need info.

You could but it will not work very well. How badly it would perform is difficult to say. It might be just poor or disastrous. Things really need to be balanced on sail boats.

Polished rudders stall at low angles of attack and ask any hobie cat racer.

Pi is NOT 3.146

3.1416 maybe

Yup, 3.1416. Typo.

Before 2005 , when I fully retired and went cruising 10 months per year, I changed auto pilots, the hydraulics of which reduced the maximum rudder angle. “Someday” had always been difficult to steer in marinas, so I added 30% more rudder area to the Gulfstar 41′ by deepening and following the existing angles. (the pivot was unchanged, as all added area was aft of that.) It increased rudder effort noticeably, but not excessively, improved motor maneauvering and allowed being able to hold a close line better. Noticeably, it caused a lot more stalling of the rudder whenever it was turned very much. A recent tangle with a Guatemala fish net damaged the extension, which I had intended to be sacrificial. I cleaned up the separation somewhat, but have not replaced the extension. The boat again now requires more steering correction when heading at all upwind, but the rudder does not stall as easily.

This is not a scientific study, just my personal non-scientific observations. The added rudder area was quite low, and the fairing quality was…well! modest.

I’ve seen data suggesting ~ 400 grit is best, and I’ve seen data suggesting polished is best. They were both smart, respected guys that I would not second guess. My conclusion is that other factors, such as the specific foil profile and the type of coating, are involved. Let’s just agree that many layers of rolled bottom paint with a few lumps and chips is sub-optimal! We’re talking about cruising boats.

Thanks for great article. I’m convinced enough to go sand my bottom paint off the lifting rudder of my Dragonfly Tri.

Absolutely! No lifting rudder should have bottom paint. My Farrier rudder was sanded fair and painted with gloss white.

Dagger boards and center boards that retract still need antifouling, since they do not lift clear of the water, but because they are in a confined space with little oxygen or water flow, fouling is very limited. Because the space is tight and paint build-up can cause jamming, sand well and limit the number of coats. For my center board I go with two coats on the leading edge (exposed even when lifted) and one coat on the rest.

I do remember a comment directed to cruisers a few years back suggesting that a faster cruiser would be more likely to get out of the way of dirty weather, especially with modern forecasting. I reckoned that this concept would gain traction, but I haven’t seen it. Can anyone weigh in on this opinion?

I would agree ONLY for coastal crusing when a safe harbor is always no more than a day away. OR ocean racing where speed matters and the boat is kept light. We all know weather reports past 24hours are a guide not a guarantee. Once a storm is bearing down NO boat even a fast one is going it out run a storm. Also we sail on boats that need wind and it’s always a balance between a course between high pressure systems (doldrums) and low pressure systems (high likelyhood of a storm) so because we seek wind sometimes we get more then we want. Try and avoid that and you risk venturing too far into the high pressure system and NO wind. So yes weather forecasts can give you a 1-2 day weather window and a fast boat that can get the hell out of dodge and put a few miles between itself and the oncoming weather could avoid a storm. BUT we are usually not talking about a world ocean race boat vs an old full keel tank. We are talking a faster but still rather slow loaded down cruising boat. It may be only the difference of 7knot average vs 9 knots average. Even a faster cruiser/racer is not a stripped down Volvo series racer. And even those super fast ocean racers pushing the edge of technology get caught in storms and frankly I would not want to use one of those boats as my floating home on the water. They are a thrilling ride but far from comfortable. And they STILL can’t sail fast enough to out run a storm and guarantee you you will never have to sail in big waves and high winds. There is not a cruising SAIL boat that is as fast as a center console fishing boat with 1200hp in outboards on the back and guess what when a squall is coming even they get caught and can’t out run it. And no it’s not a hurricane and it won’t last long but it’s enough when it hits you if your on a light boat over canvased because trying to outrun the oncoming squall it’s enough to get scary. And then there is comfort. Even when there is no storm near you the swell from a storm hundreds of miles away can make for a uncomfortable ride in a boat designed to go fast vs a heavy displacement boat that just pushes threw waves and Has the tonnage not to get knock around. So much of this article screams weekend coastal sailing as even a week on anchor all that work to smooth your rudder will be canceled out by bottom growth todays antifoul paints don’t work as good as the older but far more toxic formulas so even the most meticulously cleaned cruising boat picks up growth ya you can dive and clean it regularly but I often it’s like Sisyphus pushing that rock up the hill. And besides if your sailing on a fullkeel with a keel hung rudder most of this is mute. yes a clean smooth bottom makes a difference on any boat but it’s the full keel and its tendency to track straight the over all weight and momentom of the boat it’s not fast and never will be but they can maintain their hull speed and track a comfortable ride threw chop and be unaffected by the swell. I’ll take a old full keel boat with a protected rudder I know is very unlikely to ever hit something to bend it or loose my rudder ever over a spade rudder or even worse duel rudders both hung exposed with a long but thin bolted on keel that if you hit a coral head means a haul out to inspect it as it more then likely cause a lot of expensive damage. And if not fixed right could lead to a future disaster (Cheeki Rafiki).

As interesting as the article reads, I wonder how it helps a prospective buyer of a used boat. Pictures will not do, and neither will taking several boats out of the water to examine them; it’s too expensive. It would be more helpful to indicate which boat manufacturers have the type of rudder the author recommends. After all, the buyer usually cannot be expected to change a rudder prior to buying it; it is also expensive. By the way, these types of very sophisticated articles are seen when it comes to hulls, keels, or rigging but without identifying the boats that carry the wrong equipment. If a specific rudder or keel configuration is not the proper one for efficient sailing, the author ought to state which boats carry the proper ones so that the buyer will concentrate on the whole (the boat) rather than the part.

I was describing the opportunity to improve the existing rudder. As I think back, I have modified the rudder of every boat I have owned in order to improve efficiency. The first two got small changes in balance and improved trailing edge sharpness. On the third I tightened the the hull clearance and changed the section. On my current boat I adding an anti-ventilation fence to improve high speed handling. https://4.bp.blogspot.com/-2ZGPzKdj_tE/WyF9G2mHtLI/AAAAAAAAOwE/r6zgQEr4vkcDB4ciMLcgboFdazDAseDBgCLcBGAs/s1600/ian%2Brudder%2Bfence.jpg None of these tasks was overly difficult, and none was undertaken until I had sailed the boat for a season and learned what balance she liked and noted her habits.

For me, I buy a boat based on reputation, a test sail, and in most cases, a survey. As you imply, it is the whole boat you are buying. Does it have good bones? Do you feel happy at the helm? Then comes the fine tuning. I’ve been told that I sell a boat when I run out of things to tweak.

wow, so now case reports/medical reports/evidence don’t count as “evidence”, but certain remedies, even if they are cited in medical journals but do not work in the real world, count as evidence to you?? Maybe we need to redefine evidence based on your philosophies.Anyway, i’ve wasted enough time here. goodbye.

Weight 2.5 tonnes

Do you have any articles on the ideal cross section shape for an outboard rudder mounted 50mm from the transom vertically The yacht is a 26 ft trailer sailer weight 2.5 tonnes

The most common choice would be NACA 0012. http://airfoiltools.com/airfoil/details?airfoil=n0012-il

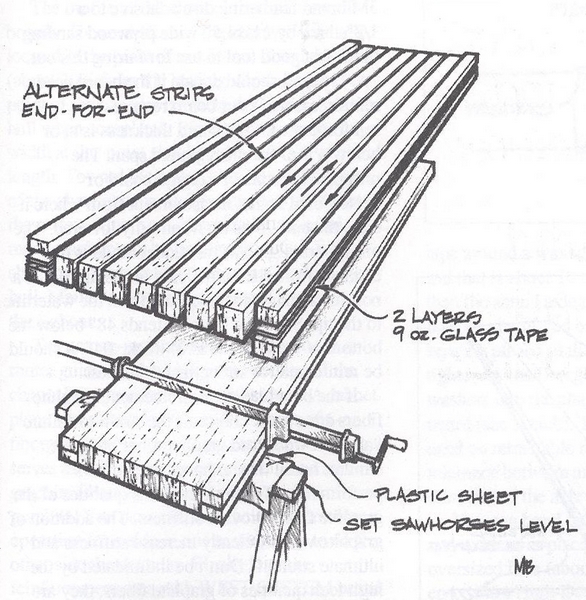

There are many ways to build a rudder, including laminated solid rot-resistant wood and fiber glass covered foam with a metal armature core. For the DIY, laminated wood is probably the most practical.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Tartan 30 | Boat Review

Fuel Contamination? The Baltimore Francis Key Bridge Collapse

Safety At Sea For You & Your Family – The Joe...

What’s The Best Vinyl Window Cleaner for Your Boat?

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Small Craft Advisor

Build Your Own Kick Up Rudder

William mantis offers up plans for a creative and effective diy rudder.

by Bill Mantis

I built a rudder for my 8.5’ x 4.5’ sailboat—named City Slicker 2. 0—the same time I built the boat itself, two years ago . Since I was in a hurry to get it done, I didn’t bother designing a kick-up rudder, figuring I could make the modification at a later date. But then I lost it. I lost my rudder. How does one lose a rudder? I can’t explain how it happened. I only know I had it when I came ashore one day, and didn’t have it the next time I tried to launch. Fortunately, I’d been designing a kick up rudder before suffering the loss, and I had the necessary epoxy and lumber on hand. Only the material for the rudder blade and new pintles had to be ordered. As a result, I lost only one week of the sailing season.

Continue reading this post for free, courtesy of Joshua Colvin.

How to Build a Sailboat Rudder From Scratch

Introduction: How to Build a Sailboat Rudder From Scratch

This particular rudder is built off of the original rudder for a ~20' Bayliner Buccaneer sailboat. The original had cracked and rotted pretty badly. The owner of the sailboat cut the top of the rudder off and made a wooden 'boot' to cap the rudder. However, it wasn't water sealed with fiberglass, and over time more and more moisture got in until it became so flimsy that it wasn't reliable. While this instructable is specifically for this Bayliner sailboat with a tiller-style rudder, the instructions should be general enough for you to modify it to work for many sailboats. With that said, there are many many nuances to fiberglass/composite marine construction, so this type of build will require more research beyond what is covered here.

Step 1: Previous Rudder

In these photos you can see the extent of the damage. The rudder was foam-core/fiberglass sandwich. Think of it as a Big Mac; the three buns of the Big Mac were layers of fiberglass, and the meat was the foam (the yellow stuff). The only difference was that the buns would have all been connected and fully enclose the meat. First, I cut apart the rudder along its perimeter with an oscillating saw, so that I could use the pieces as templates for the build. In the fifth image you are seeing a piece of balsa (I think) at the edge of the rudder where the mounting hardware was located so as to provide compressive stability for the tightened hardware. In the last image, if you look at the top of the image you can see where the previous owner had chopped off the top of the rudder. There was a rudimentary wooden cap on that, so you can see how easy it would have been for water to get in.

Step 2: Rebuild

Because of the difficulty of rebuilding the rudder the same way, I chose to use two sheets of 3/4" solid plywood. While this increased the overall weight of the rudder, it ensured maximum strength and stability. There is a good reason that I chose to do it in two pieces: I wanted to be able to sand the exterior faces of the rudder in order to get a tapered surface, and by doing it in two pieces allowed me to have the piece be level on one side. In the first image below, you can see the old pieces of the rudder all stripped of foam next to the new plywood pieces. In the background you can see the middle fiberglass 'bun' of the whole kit 'n caboodle. I scraped away all of the foam because I had originally wanted to save the exterior pieces and reuse them, but the Big Mac style construction made it more difficult to reuse them. Simply place the old pieces on your sheet of plywood, trace, then cut out with a jigsaw. If for some reason, you only have one template to work with, and you are using two pieces of ply that will later get glued together, be sure to flip the template over before tracing, so you have mirrored pieces. The customer asked for a little more material at the top of the rudder, as you will see in the last images of the Instructable. It ended up making it look a little strange, however.

Step 3: Sanding

Unfortunately, I only took one image of the sanding process, shown below. As I mentioned, it is good to sand the two pieces separately, although this picture is of the two already glued together. A handy trick is to imagine your surface and the lines of ply as the lines on a topography map. The curved edge of the rudder closest to us in the image is the narrowest edge, from the little notch all the way down the side to the very bottom of the rudder. This is because it is the edge of the rudder that points forward when it is on the boat. I started by using a disc sander, but it was too slow, so I switched to a grinder. The grinder worked well, but it was a bit too fast, so if you decide to use one, be very judicious in your use of it, otherwise you will end up with big divots.

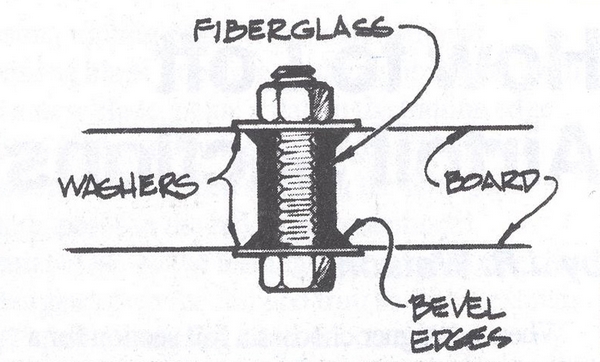

Step 4: Fiberglass Layup

As I already alluded, there are many many variations to fiberglass construction. For this project I used chopped strand mat (which you can see in the first image), and a woven fiberglass cloth on top of that, with vinylester resin. Later on in the project I switched to West Systems Epoxy 105 and 205, because it was on hand. This type of layup requires you to use both the mat and the cloth in one process. The general idea is that you cut your mat to about the same size as your rudder, pour your resin on top, spread it and around, then immediately lay on the cloth (that you have also already cut to size), and the resin underneath should be enough to saturate the cloth. Often, however, it wasn't, and I had to mix more up really quick and pour it on top of the cloth to get it fully saturated. This is where you will need to conduct more research on mixing ratios of resin, temperature, amount per surface area, etc. Generally, I was able to get about 30 minutes of working time out of each batch. In the back is a finned roller that you use after you mix and start pouring the resin to remove the air bubbles from under the chopped strand mat and to spread the resin around. After a while the roller gets all gummed up, and I ended up using just my gloved hand to push out the bubbles, and I found that a simple plastic spreader worked best for spreading. Don't worry about the stuff that hangs over the sides. Originally I wanted to have it fold over and seal the edges at the same time, but this was near impossible, as we will see soon, and I just let it hang and harden from any of the spilled over resin. I dealt with it later with a lot of sanding.

Step 5: First Layer and Sanding

The order I used was as follows: Glass one side of the rudder, let cure. Cut off excess edge stuff and rough sand/grind. Glass other side of rudder, let cure. Cut off excess, sand until flush. Glass edges based upon which were generally 'up' when clamped in a mostly horizontal way (images 4 and 5). Glass the remaining edges. Sand the nasty edges until flush. The first image is after the glass on the faces have cured, showing the excess. The third image was after sanding the excess from the faces. The following images were taken doing first layers of the edges, after the faces.

Step 6: Additional Layers and Difficult Spots

I don't remember exactly how many layers went on total, because after sanding where necessary, sometimes more wood gets exposed, and all that's required is a simple patch. The first image is after fully sanded face and edge layers. There are some really difficult spots that you need to pay attention to. Generally, corners are the spots you need to look out for. It's like trying to wrap a piece of paper over a 3D form without letting any edges lift. They will tend to lift up one end of your saturated cloth and allow air to get right in there, which means you'll have to sand that air bubble out and re-do it later. The very bottom tip of the rudder was one of them. Although the second picture is after I had drilled the holes for the hardware, it's useful to see the method for tackling those difficult spots. Visibile at the tip of the rudder is a bit of blue painter's tape. For that spot and others, which I will mention later, I basically taped the heck out of it, making a small well, and poured in enough resin to cover it. You can also see in this picture, how it has started to get thick/bulky. That's normal as layers build, you just need to sand it down flush later. Sometimes the tape gets sealed in there, so I just left it in.

Step 7: Notes of Caution

If, after a good amount of sanding, your rudder has patches of white at the surface and you can feel a clothy texture when you run your fingers over them, it means the cloth did not get fully saturated and means the surface is not fully sealed. When this happens, it is sufficient to mix up a new batch of epoxy/resin, and spread it over the surface(s) without the need for another layer of cloth. The entire surface is sealed when all of it feels smooth/looks glossy and hard, although some spots may still be bumpy. After you think you've sealed the whole rudder and you go to sand it smooth, you may uncover more white patches or air bubbles. It's extremely frustrating to think you're almost done and find another one of those, but it pays off to patch them properly. If there are some air bubbles or pockets that just don't seem to patch up and keeps reappearing after you sand this product is really helpful: http://www.marinetex.com/marinetexepoxyputty.html. It's a putty-like marine epoxy, so it serves the same purpose as regular epoxy, but it is much more workable and can be packed into a hole to completely seal it. The is the best product for repairs of deep scratches or small punctures in a fiberglass surface. The notch at the top of the first image was one spot that I taped significantly in order seal every spot with epoxy. This is the point where I switched to epoxy from resin, as I had run out. The purple is the natural color of the epoxy after it hardens.

Step 8: Hardware Holes

This step is extremely important and tricky. If, by chance, you have the previous hardware which mounts the rudder to the transom of the boat, great. Use them as guides as you don't want to make your rudder thicker than the original and not fit into the hardware. If you don't have previous hardware and your boat needs a very specific bracket, go buy it early so you can make sure to construct your rudder to fit into those, otherwise, just buy some to suit. Use this tutorial to help you get the holes right: http://www.boat-project.com/tutorials/drill.htm. Basically, you need to drill your holes bigger (1.5x, I think. The tutorial with specify this.) than the hardware needs. You then fill the hole with epoxy and let cure. Then you drill your holes again with a bit sized for your hardware. After painting, get some sealant (specified in the tutorial) and coat the bolts, holes and the inside face of the bracket immediately before placing them on the rudder. It's really important to drill your holes square through the rudder. If you don't, you'll find when putting the bolts through, that they won't meet with the bracket holes. If you're slightly off (like I was), you can just enlarge the hole at the problem end. If you're really off, you'll have to sand the paint away, drill the new hole, fill with epoxy again, re drill, then paint.

Step 9: Painting

Painting a boat or any underwater surface is another realm that has a large amount of nuance, specificity, and also varying opinions. It is still a bit unclear to me, but the most ideal situation is to find a marine paint that actually bonds with your fiberglass/epoxy surface. Interlux makes really good products and they have tutorials on which paints to buy and how to apply them: http://www.yachtpaint.com/usa/diy/default.aspx. Before painting, you must 'cut' the surface (a light sanding), so there is surface for the paint to bond to, and you will need to remove any oils or chemicals that are on the surface with acetone or a similar product. The paint will usually specify a total thickness of paint required to be considered sealed, and will allow you to calculate the number of coats from the average thickness per coat. Next use a top-side paint (I think we used an auto-body paint) to cover the surfaces above the waterline to make it look nice. Lastly, apply a bottom paint (also called anti-fouling paint) below the waterline of the rudder. Bottom paints, especially, vary greatly by geographical location, type of water, EPA legal restrictions, etc. Their purpose is to prevent organisms from attaching to the submerged surfaces, so naturally, they will contain certain chemicals and/or metals. Copper is a common ingredient in anti-fouling paint, as it slowly leeches from the paint, preventing any organisms from attaching permanently.

Step 10: The End!

Attach the hardware and tiller, and you're ready to put it on the boat!!! (That's my pops holding the rudder.)

Recommendations

Remake It - Autodesk Design & Make - Student Contest

Making Time Contest

Books and Bookshelves Contest

Learn the Basics of Dinghy Sailing: A Beginner’s Guide

Alex Morgan

Sailing a dinghy can be an adventurous and rewarding experience, allowing you to navigate the water and harness the power of the wind. Whether you’re a beginner or looking to improve your sailing skills, understanding the fundamentals of sailing a dinghy is essential. In this guide, we will delve into the different aspects of sailing a dinghy to help you get started and sail with confidence.

Sailing dinghies are small sailboats that are designed to be sailed by one or two people. They are versatile and can be used for leisure sailing, racing, or even as a training vessel. Dinghies come in a variety of shapes and sizes, each with its own unique characteristics and sailing capabilities.

Before setting sail, it’s important to choose the right dinghy that matches your skill level, sailing goals, and local weather conditions. Factors to consider include the type of dinghy, hull design, size, and rigging options.

To ensure a safe and enjoyable sailing experience, it’s crucial to have the right equipment on board. This includes sailing gear such as life jackets, wetsuits, and appropriate footwear, as well as safety equipment like a whistle, signaling devices, and a first aid kit.

To effectively sail a dinghy, it’s important to familiarize yourself with its various components. These include the hull, rigging and sails, centerboard or daggerboard, and tiller and rudder. Understanding how these parts work together will help you maneuver the dinghy more efficiently.

Mastering basic sailing techniques is essential for any aspiring dinghy sailor. This involves understanding wind and weather conditions, launching and landing the dinghy, steering and maneuvering, and becoming familiar with different points of sail.

Once you have a solid foundation in basic sailing, you can explore more advanced techniques. These include tacking and gybing, sailing upwind, using sail controls to optimize performance, and adjusting your technique according to different wind conditions.

Safety should always be a top priority while sailing a dinghy. We’ll cover basic safety rules, collision avoidance, right of way rules, and how to respect the environment while out on the water.

Sailing a dinghy is a skill that can be continually improved upon with practice and experience. As you gain more confidence, consider taking lessons, joining a sailing club, or participating in races to further enhance your skills and enjoyment of this exhilarating sport.

Key takeaway:

- Choosing the right dinghy is crucial: Consider factors such as size, stability, and intended use when selecting a dinghy for sailing.

- Master the basic sailing techniques: Understanding wind, launching and landing the dinghy, steering and maneuvering, and knowing the points of sail are essential for successful dinghy sailing.

- Prioritize safety and etiquette: Follow basic safety rules, learn collision avoidance and right of way rules, and respect the environment while sailing a dinghy.

Choosing the Right Dinghy

When it comes to choosing the right dinghy , there are crucial factors to consider. From the size and weight to the sailing conditions you’ll be facing, this section dives into the key elements that will help you make an informed decision. So, before you set sail, let’s explore the essential aspects that can make or break your dinghy sailing experience. Get ready to navigate the waters in style and with confidence!

Factors to Consider

When choosing a dinghy for sailing, there are several factors to consider. You should think about the size and weight of the dinghy. A smaller, lighter dinghy is easier to maneuver and launch, which makes it perfect for beginners or sailors who will be sailing solo.

It’s important to assess your skill level as a sailor. If you are a beginner, you should opt for a dinghy that is stable and forgiving . On the other hand, more experienced sailors may prefer a high-performance dinghy that offers a thrilling sailing experience.

Next, consider the intended use of the dinghy. Will you be using it for racing or cruising? It’s crucial to choose a dinghy that is specifically designed for your intended purpose.

Of course, cost is another important factor to take into account. Dinghies come in a range of prices, so you should choose one that fits within your budget. Remember to factor in the cost of any additional equipment and maintenance.

Another consideration is the availability of spare parts and accessories for the dinghy. It’s advisable to choose a reputable manufacturer that offers a wide range of support and resources.

Think about where and how you will store and transport the dinghy. Assess whether you have enough space at home or if you will need to rely on a boatyard or marina for storage.

A pro tip is to try out different dinghies before making a final decision. This hands-on experience will help you determine which dinghy feels the most comfortable and suits your sailing style.

Essential Equipment for Dinghy Sailing

When it comes to sailing a dinghy, having the right equipment is essential . In this section, we’ll explore the must-have gear for an enjoyable and safe sailing experience. From top-of-the-line sailing gear to crucial safety equipment, we’ll cover everything you need to know to be fully prepared on the water. So, get ready to gear up and sail with confidence in your trusty dinghy !

Sailing Gear

When it comes to sailing gear, every sailor should have these essential items:

Having the right sailing gear is essential for comfort, safety, and enjoyment while on the water. Invest in quality gear and always check its condition before setting sail.

Safety Equipment

When sailing, prioritize safety. Here are essential safety equipment items to consider for dinghy sailing:

- Life Jacket: All sailors must have a properly fitting and Coast Guard-approved life jacket. Wear it at all times while on the water.

- Personal Flotation Device (PFD): Similar to a life jacket, a PFD provides extra buoyancy and is a lightweight option.

- Whistle or Horn: Use these signaling devices for emergencies or to communicate with others on the water.

- Throwable Flotation Device: A buoyant object thrown to someone in distress to assist with their flotation until help arrives.

- First Aid Kit: Keep a well-stocked first aid kit onboard for injuries or medical emergencies while sailing.

- Anchor: Essential for stopping the boat’s drift in case of engine failure or strong currents.

- Fire Extinguisher: Have a fire extinguisher onboard to handle potential fires caused by fuel or electrical problems.

Remember, safety equipment is effective with proper use and regular maintenance. Regularly inspect and replace damaged or expired safety equipment. Familiarize yourself with each item’s use and ensure everyone onboard knows the location and operation of the safety equipment.

Understanding the Parts of a Dinghy

Get ready to set sail as we dive into understanding the different parts of a dinghy. We’ll be exploring the hull , rigging and sails , centreboard or daggerboard , and the tiller and rudder . Each sub-section sheds light on a crucial component of a dinghy, taking you one step closer to mastering the art of sailing. So grab your life jacket and join us on this nautical adventure!

The hull, an integral part of a sailing dinghy, provides both buoyancy and stability . Constructed from materials such as fiberglass , its purpose is to withstand the forces of wind and water.

The performance of a dinghy is greatly influenced by the shape of its hull. For novices or when sailing in calm waters, a flat-bottomed hull offers exceptional stability. Conversely, a V-shaped hull is more adept at slicing through waves, enhancing speed and maneuverability.

To facilitate orientation and communication, a dinghy’s hull is divided into distinct sections: the bow (front), stern (rear), port (left), and starboard (right). These sections help sailors easily identify different areas of the boat and provide precise instructions.

Maintaining the hull’s condition necessitates regular cleaning and inspection. This practice ensures the early detection of any cracks or damage that may compromise the hull’s integrity. Proper storage and transportation are equally vital to prevent unnecessary stress or wear.

When selecting a dinghy, it is crucial to consider both the hull design and the appropriate material that aligns with your specific needs. Whether your purpose is leisurely sailing or competitive racing, seeking guidance from experts or experienced sailors can aid you in making the right hull choice.

Rigging and Sails

The rigging and sails on a dinghy are crucial for supporting and controlling the sails.

The mast , boom , and standing rigging all play a part in this process.

The mast , which is a tall pole, holds up the sails and can be securely attached to the hull of the dinghy.

The boom , on the other hand, is a horizontal pole that extends from the mast and holds the foot of the mainsail.

The standing rigging consists of wires or cables that provide support to the mast and keep it upright.

This includes the forestay , backstay , and shrouds .

The forestay helps in supporting the mast and controlling its movement, while the backstay provides additional support and stability.

The shrouds prevent the mast from leaning too much to one side.

One particular day, John found himself sailing in his dinghy when he suddenly encountered a fierce storm.

The powerful wind and massive waves made it incredibly challenging to control the sails.

It was in this difficult situation that John truly recognized the significance of well-rigged sails.

The proper tension and positioning of the rigging allowed him to swiftly adjust the sails, enabling him to navigate through the turbulent waters.

Thanks to the robust rigging and well-maintained sails, John safely guided his dinghy back to shore.

This experience served as a constant reminder of the crucial role that rigging and sails play in enhancing the performance and safety of a dinghy.

Centreboard or Daggerboard

The centreboard or daggerboard is an essential component of a dinghy, and it plays a crucial role in enhancing its sailing performance. Understanding its significance and how to utilize it effectively can greatly enhance your sailing skills and maneuverability. Here are some key points to consider about the centreboard or daggerboard:

– The centreboard or daggerboard is positioned in the center of the hull and functions as a retractable fin-like structure.

– Its primary function is to prevent the boat from drifting sideways while sailing upwind.

– Depending on the wind conditions and sailing direction, the centreboard or daggerboard can be raised or lowered accordingly.

– By retracting the centreboard or daggerboard , the dinghy can sail in shallow waters without the risk of grounding.

– The size and shape of the centreboard or daggerboard have a significant impact on the boat’s stability and its ability to point into the wind.

– Smaller dinghies typically have centreboards , while high-performance racing boats commonly use daggerboards .

– When sailing upwind, it is advisable to fully lower the centreboard or daggerboard to maximize resistance and minimize leeway.

– Regularly inspecting the centreboard or daggerboard for any damage or signs of wear is essential, as it may affect the boat’s overall performance.

– Having a proper understanding of how to use and adjust the centreboard or daggerboard will contribute to optimizing your dinghy sailing experience.

Considering these aspects and incorporating the centreboard or daggerboard effectively will ensure that you make the most out of this crucial sailing component.

Tiller and Rudder

The tiller and rudder are necessary parts of a sailing dinghy that assist in steering and maneuvering the boat efficiently.

Both the tiller and rudder collaborate to provide control and stability to the sailing dinghy. They enable the helmsman to navigate the boat smoothly, making precise turns and adjustments based on wind and water conditions.

It’s crucial for the helmsman to understand how the tiller and rudder function and how their movements impact the boat’s direction. Mastery of the tiller and rudder requires practice, as different sailing techniques, like tacking and gybing, demand precise control over these components.

Always maintain a firm grip on the tiller while sailing and remain cautious of any obstacles in the water. Proper utilization of the tiller and rudder ensures a safe and enjoyable sailing experience.

Basic Sailing Techniques

Get ready to set sail! In this section, we’ll dive into the basic sailing techniques that will turn you into a skilled dinghy sailor. From understanding wind and weather conditions to mastering the art of launching and landing the dinghy, we’ll cover it all. Get ready to learn about steering and maneuvering techniques, as well as the crucial concept of points of sail. By the end, you’ll have the knowledge and skills you need to confidently navigate the waters with your dinghy.

Getting Familiar with Wind and Weather Conditions

When getting familiar with wind and weather conditions for dinghy sailing, it is important to consider the following key factors.

You need to determine the wind direction in order to make the right maneuvers and select the appropriate course. Assessing the wind speed, which is measured in knots , is crucial. Light winds typically range between 5-10 knots , while stronger winds can exceed 20 knots .

It is also essential to stay informed about the weather conditions, including any changes in wind speed, gusts, or the possibility of storms. Observing cloud formations can provide valuable indications of approaching storms or strong winds.

It is important to take note of the sea state, as choppy or rough seas require extra caution. Considering the temperature is necessary for both comfort and ensuring appropriate clothing or sun protection.

Seeking advice from experienced sailors or locals can provide valuable insights on wind patterns or any peculiar weather conditions. It is crucial to be adaptable and prioritize safety by adjusting your plans based on the changing weather conditions.

Launching and Landing the Dinghy

Prepare the dinghy by securing all equipment and adjusting the rigging. Check the wind direction and current conditions to choose the best spot to launch. Lower the dinghy carefully into the water, making sure it floats freely.

Climb into the dinghy while holding onto the dock or shore. Release the dinghy and use a paddle or oar to push away if needed. Paddle or row to navigate away from obstacles and into open water.

Once a safe distance from shore, raise the sails if applicable, following proper procedures. Adjust the sails and tiller as necessary to control the direction and speed of the dinghy.

When returning to shore, steer the dinghy towards the desired landing spot, considering currents and obstacles. Gradually slow down the dinghy by adjusting the sails and tiller for a smooth approach.

If necessary, lower the sails and use oars or a paddle to maneuver into a suitable landing location. Guide the dinghy towards the shore, being mindful of other boats and people.

Once close enough to the shore, step out of the dinghy onto solid ground. Secure the dinghy to a dock, anchor, or other object to prevent drifting away.

Last summer, I went sailing with friends in a beautiful coastal area. We explored clear waters and enjoyed a warm breeze. One day, we anchored the dinghy near a secluded beach for a swim.

Upon returning, we faced challenges with launching and landing the dinghy due to the wind making it difficult to get back in. With careful maneuvering, we successfully landed the dinghy on the beach. This small victory added to the excitement of our sailing trip.

Launching and landing the dinghy require attention to detail and adaptation to changing conditions. Following safety precautions and being prepared ensures a smooth and enjoyable sailing experience.

Steering and Maneuvering

Steering and maneuvering a dinghy requires specific steps:

1. Hold the tiller firmly with both hands.

2. Push the tiller away from you to execute a left turn.

3. Pull the tiller towards you to execute a right turn.

4. Shift your weight to maintain balance in the boat and facilitate smooth turns.

5. Utilize gentle tiller movements to avoid excessive steering.

To ensure effective steering and maneuvering, it is important to practice and coordinate your actions. Be mindful of the wind direction and make adjustments to your steering accordingly. Take into consideration that the size and weight of the boat can influence its responsiveness to your commands.

Throughout history, dinghies have served a variety of purposes, ranging from transportation to recreational activities. The term “dinghy” stems from the Bengali word “dingi,” which refers to a small boat used for fishing and coastal transportation. These boats have played a significant role in maritime history, particularly in areas with shallow water or limited dock access. Over time, dinghies have evolved into versatile and maneuverable vessels, popular for sailing, racing, and rescue operations. Today, dinghy sailing is not only a recreational pastime but also a competitive sport enjoyed worldwide. To achieve success in sailing a dinghy, it is imperative to master the techniques of steering and maneuvering.

Understanding Points of Sail

The concept of points of sail is key for understanding sailing techniques. Points of sail are the angles at which a boat can sail in relation to the wind. The main points of sail are upwind or close-hauled, reaching, and downwind. Upwind or close-hauled means sailing as close to the wind as possible, with the wind coming from the front. Reaching is when the boat is sailing at an angle to the wind, either on a broad reach or a beam reach. Downwind means sailing with the wind coming from behind the boat, either on a broad reach, running, or dead downwind. Each point of sail requires different sail trim and steering techniques to optimize boat speed and efficiency. When sailing upwind or close-hauled, it’s important to trim the sails in tightly to create a close-hauled sail shape and ensure the boat can sail as close to the wind as possible. When reaching , the sails can be eased out slightly, and the boat can pick up more speed by being slightly off the wind. When sailing downwind , the sails are eased out even more, catching as much wind as possible to propel the boat forward. Understanding points of sail allows sailors to navigate different course directions effectively and make the most of available wind conditions.

Advanced Sailing Techniques

Ready to take your dinghy sailing skills to the next level? In this section, we’ll dive into the exciting world of advanced sailing techniques . From mastering the art of tacking and gybing to fine-tuning your sail controls , we’ll cover it all. Learn how to sail upwind like a pro and navigate through various wind conditions with confidence. Get ready to enhance your sailing prowess and sail with style !

Tacking and Gybing

Tacking and Gybing are important sailing maneuvers for changing direction efficiently.

Tacking is turning the bow of the dinghy through the wind to change its sailing direction. The sailor brings the bow into the wind by turning the tiller towards the wind. As the dinghy passes through the wind, the sail switches sides. Then, the sailor adjusts the sails and steers the dinghy on the new tack. Tacking is used when sailing upwind or changing the boat’s direction.

Gybing is changing the dinghy’s direction while sailing downwind. During a gybe , the stern of the dinghy passes through the wind, causing the sails to switch sides. To gybe , the sailor turns the tiller away from the wind, steering the dinghy downwind. It is crucial to control the movement of the mainsail during a gybe to prevent an accidental gybe, which can result in a sudden shift of the boom and potential injury. Gybing is used to change the direction of the dinghy when sailing with the wind.

Sailing Upwind

Sailing upwind requires specific skills and techniques to navigate against the wind. When sailing upwind, it is important to consider the following key points:

1. Angle of Attack: To optimize forward momentum, adjust the sail angle by pointing the bow slightly off the wind, around 30-45 degrees. This will ensure the best performance while sailing upwind.

2. Trim the Sails: Properly adjusting the sails is crucial for maintaining tension and shape. Make sure to tighten the leech, which is the back edge of the sail, to prevent fluttering. It is also important to ensure that the sails are not over or under trimmed.

3. Weight Distribution: When sailing upwind, position your body weight towards the front of the boat. This will counterbalance the wind pressure and help keep the boat upright, ultimately reducing drag.

4. Use Your Centerboard: To minimize sideways drifting caused by the wind, deploy the centerboard or daggerboard. Adjust the depth of the board based on the prevailing conditions in order to maintain stability and control.

5. Tacking Technique: To maintain momentum when changing direction, use a proper tacking technique. This involves turning the bow through the wind while coordinating the movements of the sail and crew.

Remember, sailing upwind can be challenging, especially in strong winds. Regular practice and gaining experience will enhance your proficiency in handling different wind conditions. Keep refining your skills by experimenting with sail controls and techniques in order to fully master the art of sailing upwind.

Using Sail Controls

Using sail controls is crucial for maneuvering a dinghy and maximizing its performance. Here are the necessary steps to properly utilize the sail controls:

- Adjust the mainsheet: Utilize this control to alter the angle of the mainsail in relation to the wind. Tighten the mainsail to increase power or loosen it to decrease power.

- Operate the boom vang: This control allows you to adjust the tension of the boom, preventing it from rising. Alter it accordingly to control the shape of the mainsail and stabilize the boom.

- Tweak the cunningham: This control enables you to adjust the tension of the luff of the mainsail. Utilize it to flatten the sail and decrease power in stronger winds.

- Manage the outhaul: This control influences the depth of the sail along the foot. Tighten it to flatten the sail or loosen it for more power.

- Utilize the jib sheets: These controls regulate the angle of the jib relative to the wind. Pull them in to trim the jib for enhanced power or let them out to reduce power.

- Engage the jib halyard: This control allows you to adjust the height of the jib. Raise it to increase the power of the sail or lower it to decrease power.

- Operate the jib fairleads: These controls determine the position of the jib sheets. Adjust them to achieve the proper sail shape and optimize performance.

By effectively utilizing these sail controls, you can enhance the performance of your dinghy and maximize your sailing experience.

Sailing in Different Wind Conditions

To effectively sail in different wind conditions, follow these steps:

- Assess the wind direction and strength before setting sail.

- Adjust the sail trim according to the wind direction. Trim the sails tight when facing a headwind and let them out when facing a tailwind .

- Stay alert for wind shifts and gusts. Watch for changes in the water’s surface and the movements of other boats.

- When sailing upwind, trim the sails tightly and steer close to the wind.

- When sailing downwind, use the sails to maximize speed and maintain control.

- Manage the boat’s heel angle by adjusting the sails and the distribution of body weight.

- Understand the concepts of “ tacking ” and “ gybing .” Tack to change direction by turning the boat into the wind, and gybe to turn away from the wind.

- Be prepared for varying wind strengths by adjusting the sail area. Decrease the area in stronger winds and increase it in lighter winds.

By following these steps, you can confidently sail in different wind conditions and adapt your strategy to optimize speed and control.

Sailing Safety and Etiquette

Navigating the open waters on a dinghy can be an exhilarating adventure , but it’s crucial to prioritize safety and respect for fellow sailors and the environment. In this section, we’ll explore the essential guidelines and rules that encompass sailing safety and etiquette . From basic safety rules to collision avoidance and right of way protocols , we’ll ensure you have the knowledge to sail with confidence. Plus, we’ll delve into the importance of respecting the environment, preserving the beauty of our precious marine ecosystems .

Basic Safety Rules

When sailing a dinghy, prioritize safety. Remember these basic safety rules:

- Wear a life jacket or personal flotation device (PFD) at all times.

- Check the weather forecast before sailing and avoid stormy or windy conditions.

- Maintain the dinghy properly, ensuring no loose fittings or leaks.

- Inform someone onshore of your sailing plans, including route and estimated return time.

- Stay alert and watch out for other boats, obstructions, and swimmers.

- Follow buoys and navigational markers to avoid dangerous areas.

- Understand and adhere to right-of-way rules to avoid boat collisions.

- Avoid areas with strong currents, undertows, or rough surf.

- If capsized, stay with the dinghy and try to climb back in. If unable, signal for help.

Pro-tip: Take a sailing safety course for more knowledge on safety procedures, navigation rules, and emergency protocols relevant to dinghy sailing. Preparedness and knowledge are crucial before venturing onto the water.

Collision Avoidance

Collision Avoidance is crucial for the safety of sailors and their boats. Here are some key points:

1. Awareness: Sailors must constantly be aware of their surroundings, including other boats, obstacles, and navigational markers.

2. Right of Way: Understanding the right of way rules defined by the International Regulations for Preventing Collisions at Sea (COLREGS) is crucial. For example, a boat on starboard tack has right of way over a boat on port tack.

3. Communication: Using appropriate signals, such as horn blasts or hand signals, helps communicate intentions to other sailors, especially in busy areas.

4. Predicting Actions: Sailors should anticipate the actions of other boats by observing their course, speed, and relevant signals to avoid potential collisions.

5. Maneuvering: When approaching another boat, it’s important to maintain a safe distance and adjust speed and heading if necessary to avoid a collision. This requires good boat handling skills.

In a true story, two dinghies were sailing closely during a regatta. Both sailors followed the right of way rules and effectively communicated their intentions. As they approached a narrow mark, a collision seemed imminent. One sailor quickly altered course, narrowly avoiding a collision. This incident emphasized the importance of situational awareness, quick thinking, and skilled maneuvering in collision avoidance.

Right of Way Rules

Understanding and following the Right of Way Rules is crucial for safety when sailing a dinghy. These rules prioritize certain situations to avoid collisions and accidents.

1. Sailboats have priority over powered vessels. If you encounter a motorboat while sailing, the motorboat should yield and avoid interfering with your course.

2. When two sailboats approach each other on opposite tacks , the boat on the starboard tack has priority. The boat on the port tack must keep clear and change course to avoid a collision.

3. If two sailboats are on the same tack , the leeward boat should keep clear. The leeward boat is the one positioned downwind and behind the other boat. It is the responsibility of the leeward boat to adjust their course and avoid potential collisions.

4. If two sailboats are on the same tack and overlapped , the windward boat must keep clear. The windward boat is the one positioned upwind and in front of the other boat. It is their responsibility to maintain a safe distance and avoid hindering the progress of the other boat.

Remember, these Right of Way Rules are essential for safety on the water. Understanding and following them will help prevent accidents and create a harmonious sailing environment.

Respecting the Environment

Respecting the environment is crucial when sailing a dinghy. It is important to follow these guidelines to minimize your impact on the ecosystem while enjoying the sport.

1. Dispose of waste properly: Avoid throwing trash or waste overboard. Make sure to carry a designated trash bag and dispose of it responsibly on land.

2. Avoid damaging marine life: It is essential to be mindful of your surroundings and to avoid hitting or disturbing marine animals, such as dolphins, turtles, or birds. Always keep a safe distance and never harm wildlife.

3. Use eco-friendly cleaning products: When it comes to cleaning your dinghy, choose biodegradable and environmentally friendly cleaning products. This practice helps to prevent harmful chemicals from polluting the water.

4. Respect marine protected areas: Take the time to learn about designated marine protected areas and follow their rules and regulations. By avoiding entering restricted zones, you contribute to the preservation of fragile ecosystems.

5. Minimize noise pollution: Keep noise levels low to avoid disturbing marine life and other sailors. It is recommended to avoid loud music, shouting, or unnecessary engine revving.

6. Reduce your carbon footprint: Whenever possible, choose sustainable transportation methods. Consider carpooling, using public transportation, or sailing to your destination in order to reduce carbon emissions.

Pro-tip: Always remember that the environment is a shared resource. Leaving it as pristine as you found it not only contributes to the preservation of marine ecosystems but also promotes sustainable sailing practices.

Some Facts About How To Sail A Dinghy:

- ✅ Balance is an essential control in sailing a dinghy. (Source: Our Team)

- ✅ Sail setting is crucial and involves adjusting the mainsheet to achieve optimal positioning. (Source: Our Team)

- ✅ Boat trim is necessary to keep the dinghy level from front to back, preventing submersion of the bow. (Source: Our Team)

- ✅ The centreboard is used to correct sideways drift, with different positions required depending on the point of sail. (Source: Our Team)

- ✅ Choosing the most appropriate course and compensating for factors like tide and leeway are important in sailing a dinghy efficiently. (Source: Our Team)

Frequently Asked Questions

How do i maintain side to side balance while sailing a dinghy.

To maintain side to side balance while sailing a dinghy, you can lean out or in depending on the wind conditions. Leaning out helps counterbalance the force of the wind and keeps the boat level. Adjusting the mainsheet is also crucial for sail setting to ensure it is not too loose or too tight. The luff of the sail should just stop flapping for optimal positioning.

What is a zigzag course and when should I use it?

A zigzag course, also known as beating or tacking, is used when sailing upwind. It involves sailing in a diagonal pattern, alternating between a close-hauled course and a reaching course. This allows the boat to make progress against the wind direction and reach a desired destination. Use a zigzag course when the wind blows directly towards you or at an angle.

How do I maintain fore and aft boat pitch?

To maintain fore and aft boat pitch, also known as boat trim, you need to keep the boat level from front to back. Different positions are required depending on the point of sail. When the wind is blowing from behind, sitting well back in the boat is necessary to prevent the bow from submerging. Proper boat trim helps prevent the boat from dragging in the water.

What is “Neue Funktionen testen” in the sailing context?

“Neue Funktionen testen” refers to testing new features or updates being developed for sailing equipment or technology. This allows sailors to try out and provide feedback on these new features to improve their sailing experience, such as high-speed sails or advanced navigation systems.

What should I do if the wind dies while sailing a dinghy?

If the wind dies while sailing a dinghy, you can resort to alternative techniques to maintain your course made good. This may include using a paddling technique with oars or a paddle, or even manually towing the boat to a desired destination. It is also important to keep calm and patient, as the wind may pick up again.

How does YouTube work in relation to sailing?

YouTube is an online platform that allows users to upload, share, and view videos, including sailing-related content. Sailors can use YouTube to access a wide range of resources, including tutorials, tips from experienced sailors, and coverage of sailing events. YouTube’s recommendation algorithms also help users discover relevant sailing videos based on their interests and viewing history.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

Using the rudder

Changing direction on a dinghy or yacht bears little resemblance to steering a car. The rudder is likely to be the primary control when you want to change direction, but it must be used with secondary controls, such as the sail trim, and the boat has to be balanced.

STEERING A DINGHY

A dinghy rudder assembly has four main parts: the rudder blade, rudder stock, tiller, and tiller extension. The blade is attached by hinges to the stock, which is in turn attached to the transom of the dinghy. The tiller is attached to the stock and enables you to turn the blade from side to side. The tiller extension lets you steer while sitting on the sides of the boat. Turning the blade causes it to act like a brake as turbulent water builds up in front of it. Most of the time, only small rudder movements are needed to change direction, and the faster the boat moves, the more sensitive the rudder becomes.

BALANCED RUDDER

If sailing a straight course, balance the boat and sails so the rudder feels neutral (see opposite). Rectify any excess weather helm (see p.69) by lowering the rudder blade fully.

STEERiNG TOWARD THE WiND

To steer into the wind, push the tiller away only slightly. You can help the boat to turn by pulling in the mainsail and letting the boat heel to leeward.

Boat turns to leeward

steering away from the wind

To turn to leeward, pull the tiller very slightly so that the rudder does not act as a brake. To help the turn, let out the mainsail and let the boat heel to windward.

gently does it

The rudder blade is vertical when sailing, but it can be lifted for bringing the dinghy ashore. The rudder stock holds the blade in place and allows it to swivel from the up position to fully down. Tiller

Tiller extension

Rudder stock

Rudder blade

STEERING A YACHT

Most larger yachts use a wheel connected to the rudder by cables to control steering. Unlike a dinghy rudder, the blade is sited beneath the hull and often sits behind a fixed fin called a skeg. This helps direct water flow over the rudder blade, helping to keep the yacht balanced when the blade is turned.

The response of a rudder depends on the speed of water flow over the blade. At slow speeds, a yacht may lose steerage; if it stops altogether, the rudder will have no effect at all. When motoring, the phenomenon known as "prop walk" (see Maneuvering under power, pp.192—193) can have a major effect on the rudder when going astern.

NEUTRAL RUDDER

Sailing straight ahead in very light winds, the wheel can be centered. If the boat is heeling, it will tend to head into the wind and you need to steer slightly away from it.

Turning the wheel to the right turns the boat to starboard, which here is toward the wind. Pulling in the mainsheet will encourage the boat to turn.

STEERiNG AWAY FROM THE WiND

Turning the wheel to the left turns the boat to port, which here is away from the wind. If the boat is heeling, let out the mainsail to allow the boat to turn.

Continue reading here: Sail trim

Was this article helpful?

Recommended Programs

Myboatplans 518 Boat Plans

Related Posts

- Basic maneuvers - Sailing Techniques

- Rigging a singlehanded dinghy

- Rudders - Catamarans Guide

- Dropping the mainsail - Sailing Techniques

- Auxiliary rudder systems - Wind Steering Systems

- Keel and Rudder Design Ftv

Readers' Questions

How a tiller should be attached to rudder of sailing dinghy?