- Yachting World

- Digital Edition

First look: Rapido 50 folding trimaran

- June 9, 2021

The recently launched Rapido 50 will share many of the same characteristics of her predecessors as a performance folding trimaran that should turn heads

When launched in 2016 the Morelli and Melvin-designed Rapido 60 quickly established this brand as a new breed of ultra-fast, yet practical, performance cruising/racing trimaran

The Vietnam-based builder has two further models in development, at 40ft and 50ft. Both are folding multihull designs, which enables them to slip into a regular monohull marina berth and reduces storage costs when ashore.

Construction of the Morelli and Melvin design is of infused carbon foam sandwich, with beams, daggerboards and rudder made of pre-preg carbon. The central hull is configured for single-level living, with the cockpit and deckhouse both on the same level, although the Rapido 50 has a higher helm station to give a clear view over the coachroof.

Polars for this model show it being capable of well over 20 knots of boat speed across a wide range of reaching wind angles, and as much as 18 knots beam reaching in just 14 knots of breeze. The first Rapido 50 was built for delivery to an owner in Palma, Mallorca.

Article continues below…

Sailing La Vagabonde explain their multihull criteria

Over the last seven years Riley Whitelum and Elayna Carausu have advanced from novice sailors to logging more ocean miles…

The inside story of Greta Thunberg’s upwind Atlantic crossing on La Vagabonde

The sky flashed a blinding white light and a spark came down just a few hundred metres to port. We…

Rapido is also working on a 40-footer with curved C-foils and T-foil rudders. As well as offering a performance boost, without the control issues of a fully foiling boat, these allow the interior to be opened up as there’s no need for a daggerboard in the central hull.

The result looks to be a very enticing high performance yacht with a civilised two-cabin interior and acres of deck space.

Base prices are ex works, ex sails and electronics, and with aluminium spars.

Rapido 50 specification

LOA: 15.24m / 50ft 9in LWL: 14.96m / 49ft 1in Max beam: 10.38m / 34ft 1in Folded beam: 5.5m / 18ft 1in Draught: 0.67-3.52m / 2ft 2in to 11ft 7in Displacement (light): 8,200kg / 14,400lb Base Price: US$1.25m ex VAT

If you enjoyed this….

Yachting World is the world’s leading magazine for bluewater cruisers and offshore sailors. Every month we have inspirational adventures and practical features to help you realise your sailing dreams. Build your knowledge with a subscription delivered to your door. See our latest offers and save at least 30% off the cover price.

- ENQUIRE NOW

Specifications

(For more photos of the Rapido 50, visit our photo gallery .

General Details

- Length overall (LOA): 15.24m (50 ft)

- Length of waterline (LWL): 15.2m (49.9 ft)

- Beam overall (BOA): 10.24m (33.6 ft)

- BOA (folded): 5.8m (19.0 ft)

- BOA (float to float CL): 9.29m (30.5 ft)

- Average light displacement (subject to final options): 8,550kgs (18,850 lbs)

- Freeboard: 1.67m (5.5 ft)

- Daggerboard up: 0.67m (2.2 ft)

- Daggerboard down: 3.52m (11.5 ft)

- Mast Height above DWL: 24.98m (82 ft)

- Headroom in cockpit area (no ceiling liner): 2.01m

- Headroom in saloon (ceiling liner): 2.0m

- Headroom in forward cabin and head area (ceiling liner): 1.91m

- Storage volume of floats (at greatest dim.): (L) 4.6m x (W) 1.1m x (H) 1.5m

- Storage volume under cockpit (at greatest dim.): (L) 1.7m x (W) 2.4m x (H) 1.0m

- Download the Rapido 50 General Specifications (10 January 2022)

- SA Main: 97m2 (1,044sqf)

- SA Solent: 57.5m2 (619sqf)

- SA Staysail: 27.9m2 (300sqf)

- SA Reacher: 150m2 (1,615sqf)

- SA Asym Spin: 230m2 (2,476sqf)

General Information

360 degree virtual tour.

Click here to watch 360 degree tour of the Rapido 50.

The Rapido 50 – The World’s Ultimate Folding Cruising Trimarans

Every exceptional product needs a source of inspiration. For the all-new Rapido 50, that source has been the Rapido 60 which has proven herself to be an exceptional trimaran for:

- Podium performances

- Fast passage-making

- Classic cruising

- Couples; and

Critically, the Rapido 60's DNA can be found throughout the Rapido 50. But where the Rapido 50 sharply differentiates herself is that she has the ability to fold the floats to slip into single berths at marinas.

Video above: Multihulls World magazine has announced that the Rapido 50 has won the Multihull of the Year Award for 2022 in the 45'-55' category. The award was announced at the Multihull Show at La Grande Motte on 20 April 2022.

Advantages of the Rapido 50’s folding system

Folding floats :

- Access to single marina berths

- Access to all marinas

- Reduced marina, hard stand and shipping costs

- Keeps floats in upright position (no barnacles or algae on sides)

- Maintains stability of trimaran in folding position and during folding

Folding mechanism :

- High tech design by world-acclaimed multihull designers, Morrelli & Melvin

- Patented Design (concept by Paul Koch, Australia Patent Application No. 2019902014)

Summary of Rapido 50

The Rapido 50 sets a new standard in the market place. Upon its launch in October 2020, it will generate an enormous amount of interest and attention. Its benefits include it being:

- Easier and safer to handle with self-tacking jib, roller furler head sails and spreaderless mast

- CE A Certification for safer ocean crossings

- Better weight distribution with heavy items (eg engine) in the middle of the boat

- Functional interior finished to Rapido 60 standards

- High tech, infused carbon foam sandwich construction with beams, daggerboards, ruddercase and blade made from prepreg carbon and cured in autoclave

- Folding floats (reduced fees for marina, hard stand and shipping)

Download these pdf files

- Rapido 50 Interior Arrangement (24 July 2018)

- Rapido 50 Sail Plan (29 August 2019)

- Rapdio 50 General Specifications (5 November 2020)

- Rapido 50 General Arrangement , click here (24 July 2018).

Further details – Rapido 50

- Email Paul Koch

- Contact your nearest Rapido Trimarans' Dealer

FAST AND POWERFUL

Trimarans are safe, powerful and fast as demonstrated by the fact that they consistently win races and hold the solo speed record for circumnavigating the world.

Safety at sea is the No. 1 priority and this thinking is reflected throughout the design and construction of the Rapido.

The Rapido has some truly amazing living spaces which provide more open, private and intimate areas than monohulls or catamarans.

stable and comfortable

Trimarans are comfortable on all points of sail.

The combination of safety, performance and comfort put the Rapido in a league of its own. The enormous trampoline nets add fun and excitement as you watch the blue water rush underneath you – or as you lounge on the nets while gently floating over a reef. You will be instantly hooked.

look inside the 50

50 in action.

See more Rapido Trimarans videos (You Tube)

View all Rapido 50 photos

– in the media

Below is a list of articles which have appeared in various publications regarding Rapido Trimarans.

- C-foils on a fast cruising trimaran? This looks rapid!, Rapido 40 tour, Yachting World magazine video by Toby Hodges, 8 September 2023

- Rapido 40: The Alternative Trimaran , by François-Xavier de Crécy with photos by Ludovic Fruchaud, LE MONDE DU MULTICOQUE #24 by Voile Magazine. July, 2024.

- The Rapido 40 is a 20 knot cruising tri , George Day, Cruising Compass, 24 May, 2023

- Boat Review of Rapido 40, Zuzana Prochazka, Sail Magazine, 4 May 2023

- Rapido 40: ultra fast cruising in complete safety on three hulls , Maxime Leriche , SailboatNews.com, 25 April 2023

- Boat anomaly: Rapido 40 Trimaran , No Frills Sailing, 19 April 2023

- Rapido 40 – Fast, foldable and worry free!, Multihulls World magazine, No. 189, May-July 2023

- Shipyard Focus: Rapido Trimarans , by Kevin Green, Multihulls World, August / September 2022.

- Rapido, changing the game , by Zuzana Prochazka, Sail Magazine, 23 March, 2022

- Rapido 40: A livable sailboat for cruising on 3 hulls , Briag Merlet, Sailboat News, 23 February 2022.

- Rapido, changing the game , (takes a detailed look at the cutting edge design and technology of Morrelli & Melvin) by Zuzana Prochazka, Multihull Sailor, December 2021

- Boat Review: Rapido 50 , Kevin Green, Boating New Zealand, November 2021

- Harnessing Speed , by Kevin Green, Boating New Zealand, November 2021

- Rapido 60 Trimaran Boat Review: A Bold Gamechanger For Performance Bluewater Cruising , by Zuzana Prochazka, Yacht World, 23 September, 2021.

- Harnessing the wind , by Kevin Green, Multihulls World, September / October 2021 issue, 6 page spread on Rapido Trimarans.

- Sailing La Vagabonde choose Rapido 60 to sail world’s oceans , video announcement by SLV to their 1.59 million subscribers, You Tube, 8 June 2021

- The Ultimate Racer-Cruiser: Clients on Romanza are turning heads on the racetrack when they're not cruising at high speed , North Sails, 19 April, 2021

- Making Short-handed Short Work – Onboard Rapido 60 , Anna Merchant, Sail-World, 11 February 2021

- Rapido 50 News from the Shipyards , Multihulls World, 2 February 2021

- Buyers' Guide 2021, Rapido 50 , Multihulls World, 18 December 2020

- “New breed” Rapido 40 & 50 , Yachting World magazine, November 2020

- Cruising Helmsman reviews Rapido 60 , October 2020

- Romanza takes top spot in Yates Cup , SEA Yachting magazine, September 2020

- Rapido Trimarans relocates production arm into Vietnam , SEA Yachting magazine, Nov/Dec 2019.

- Rapido Trimarans, On the March, Seahorse Magazine , October 2019.

- (French) Rapido 40, un trimaran repliable de 12 m , Bateaux.com, 29 August 2019.

- Rapido 60 – The most exciting production multihull in the world? (or click here for selection of quotes), Multihulls Magazine, Summer (July) 2019.

- Rapido , Cruising Yacht Club of South Australia, June 2019 (pp23-24)

- Ineffable’s Steve Bourne: I’m a nutter for sailing , Daily Herald, 26 February 2019.

- Rapido 60′ the fastest production multihull in the world? , International Multihulls World, December 2017

- RAPIDO 60’ : Le multicoque de série habitable le plus rapide du monde? , Multihulls World, 23 November 2017

- Finding Mrs Right , Boating New Zealand, August 2016

- Blue Water Cruising Trimaran , Australian Multihulls World, August 2016

- Rapido 60 , Cruising World, 25 August, 2016

- Rapido 60 , by Emma Bamford, Sailing Today.

Professional BoatBuilder Magazine

Folding multihulls.

By John Marples , Jan 28, 2023

Folding multihulls and their beam-reduction strategies.

A Farrier 33R trimaran with amas folded and secured on a road-legal trailer exem- plifies the advantages of adjustable- beam multihulls, which are easy to trans- port and store out of the water.

“I’ll be surprised if you can find space in the harbor for that thing,” I heard him say as my new 37 ‘ (11.3m) trimaran was about to be launched. I hadn’t given it much thought, but now this legitimate question was raised, and where to moor was the next issue at hand. Space, particularly width of a slip, becomes the limiting requirement. But then, space also is one of the attractive features of multihulls—deck space to move around on, free from the confines of the cockpit.

Step aboard any multihull and it is obvious how much real estate they offer. Even small models seem expansive. The beam of the typical catamaran is half its length, and trimarans are even wider, sometimes as wide as they are long. Aside from increasing space, beam also boosts stability without adding ballast. The early Pacific Islanders created these form-stable craft for fishing and interisland commerce and voyaging where natural island harbors were few, so the boats had to be light enough for crew to carry them up the beach. Today’s modern multihulls are still lighter than contemporary monohulls, but the larger ones preclude the option of dry sailing them from the beach. They require more marina space than monohulls, and the limited number of slips to accommodate them can be a problem. As someone once put to me, “Multihulls have a poor ‘stacking factor.’”

With catamarans and trimarans becoming more popular, they demand mooring solutions. Some marinas offer shallow-water slips to multihulls, typically at the inboard ends of docks, next to the seawall, because multihulls either have shallow keels or retractable boards. Some marinas also designate the end ties as multihull slips in areas not used for transients. Even though these boats protrude farther into the channel than monohulls, the extra space their beam occupies is relatively small. With multihulls crowding waiting lists for marina slips, builders were prompted to consider folding systems to “improve their stacking factor.”

Without ballast, smaller multihulls up to about 30 ‘ (9.1m) can be dry-stored on a trailer, and most launch ramps easily accommodate over-width boats. If the boat’s beam can be reduced to the legal highway width of 8.5 ‘ (2.6m), the owner can store the boat at home. Today, folding trimarans and catamarans are common sights on trailers in storage yards and backyards. Various folding systems have evolved to support this need, especially for the backyard builder. Some beam-reduction systems allow the boats to be folded and stored in the water in conventional-size marina slips, while other systems facilitate efficient storage or provide street-legal trailering.

Folding Systems

Basic folding systems are separated into several categories:

- take-apart akas, the simplest beam-reduction method

- telescoping akas (sliding beams)

- simple horizontal hinge

- complex horizontal hinge systems

- vertical hinges (swing wing)

- complex swing wing

The following overview of folding systems illustrates how these mechanisms work. It is not intended to be an exhaustive listing of available folding designs. I’ll address two-hull boats (catamarans and proas) first, followed by trimarans. Each type has its challenges and advantages. All are separated into two more categories: transportable boats and trailerable boats. The characteristic distinguishing between them is the time and effort required to launch, starting from an on-the-trailer folded condition. Trailerable implies the possibility of daily launching, requiring less than an hour from trailering to sailing. Transportable denotes a road-legal trailer package but with a longer assembly time to sail away. It might even take more than one trailer load, and considerable assembly time. Legal width in this category could extend to 10 ‘ (3m) wide if OVERSIZE LOAD signs are used (consult local laws). Transportable boats usually require seasonal transport with storage in the water during sailing season and dry storage in the winter. Both categories benefit from the ability to “go to weather at 65 mph” to reach any suitable launching site, even hundreds of miles from home. This opens the possible sailing venue to any water body with a launch ramp and road access, and some trailerable and transportable boats can be delivered anywhere in the world in standard shipping containers.

Catamarans and Proas

The WindRider 17′ trima- ran’s telescoping tubular akas are secured with pins

Hobie Cats and other beach cats are familiar sights around lakes, beaches, and harbors. They are usually built to 8 ‘ (2.4m) beam and do not need folding systems. The 19 ‘ (5.8m) Tornado class catamaran at 10 ‘ wide uses a side tilt-up trailer to reduce beam. Larger catamarans needing folding systems have greater challenges than trimarans of the same length, for a few reasons: The hulls are normally bigger (and heavier) than amas for the same length trimaran; the mast is stepped on the center of an aka, midway between the hulls, which means the aka must be extra strong; and there is no easy means of supporting the hulls while the beam is being expanded to the sailing position, requiring that the trailer have an expanding-beam function. As a result, folding systems are less common on cats and are usually of three types:

- folding akas along the centerline or to a center pod

- telescoping akas

- take-apart akas

On this Wharram cat, the akas are securely lashed into “deck alleys.”

Designers have used telescoping akas, but production boats generally avoid the associated complexity and cost. The mechanically straightforward take-apart feature has successfully been used by many boats, like the 27 ‘ (8.2m) Stiletto Cat and others. Generally, the assembly of these boats takes some time and muscle, which relegates them to the transportable category. Stiletto Cat advertising suggests a four-hour setup time, but in reality, it is much longer. All the James Wharram–designed catamarans up to 63 ‘ (19.2m) are held together with rope lashings and can be dismantled for transport. The required time and effort are generally proportional to the length of the boat.

Note that the Gougeon 32 ‘ (9.7m) sailing catamaran is unique, at 8 ‘ wide, without folding capability but with a water ballast system to make up for the lack of form stability.

The large main hull of a typical smaller trimaran offers a larger interior space than a comparably sized catama ran, a deep footwell in the cockpit for comfortable seating, and a folding system for trailering with the amas connected to a well-supported main hull. In addition, the mast is stepped on the main hull, with the headstay attached to the bow, not to the akas.

Trailerable trimarans come in all sizes to about 32 ‘ long, with transportable designs somewhat longer. The latter types tend to have larger interior spaces and less complex connectives. To a certain extent, manufacturers were willing to add cost to the folding system to reduce setup time. Folding capability on or off the water also adds to the design challenges.

Take-Apart Aka Systems

This is the least expensive method and easiest to achieve for the home builder or the manufacturer. The akas may be built-up wood box beams or tubular metal. Each beam is secured to the hulls by through-bolts, bolted straps, plug-in sockets, or lashings. Tubular aluminum beams are the lightest but most expensive. Regardless of attachment method, the hulls must be supported in their respective positions for the akas to be installed. In small vessels, this can be an abbreviated procedure, but larger vessels will require a special trailer to hold the disconnected amas while on the road.

The Chesapeake Light Craft 15′ single outrigger canoe akas lash into saddles on both hulls.

Telescoping Aka Systems

The telescoping option is limited to boats where the total stack-up width and length dimensions of the hulls and fully retracted akas do not exceed the legal road limits. The WindRider 17 is a good example. The boat is supported on “high bars” on the trailer, leaving the amas free to be moved in or out. The simplicity of the akas and trailer-support system reduces cost and launching time.

In larger vessels, this system has been applied to reduce width for storage in marina slips. For these boats, the sliding system is large and complex, usually requiring some sort of power to make the telescope slide. Because the sliding mechanism requires a small clearance between the sliding members, the akas will move slightly during sailing, which is difficult to avoid.

The 1970s-vintage Telstar 26 features a simple hinge-down system with a bolted con- nection on deck and a bolted strut below.

Simple Horizontal Hinge Systems

Early trailerable trimaran designs often incorporated a simple hinged beam-reduction system to fold both sides down. Boats to about 25 ‘ (7.6m) with a 16 ‘ (4.9m) beam could be made to fold to 8 ‘ . At the ama end, lifting the hull, sometimes with attached wing deck, could require substantial muscle or a mechanical lift. Even for smaller boats this task may be beyond one person’s capability. Normally, bolts and plates between the members secure the hull for sailing. On the Searunner 25 and Constant Camber 26 (7.9m), double-hinged tubes are bolted to tangs on the main hull.

The Searunner 25 trimaran has a hinge mechanism on its metal-tube A-frame akas that secures with bolts at both ends.

Commonly, simple hinge systems require that the main hull be positioned rather high on the trailer so the amas clear the trailer wheels beneath. A disadvantage is that the trailer must be submerged more deeply than usual for the boat to float off. Compared to the Telstar system, the Searunner 25 offered some improvement by positioning the hinge point at the top of the cabinside, raising the folded ama slightly.

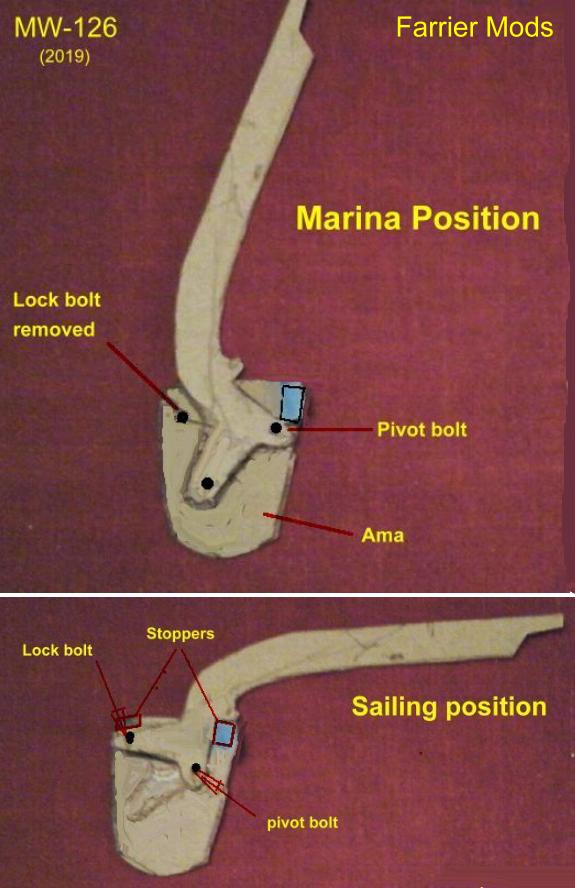

Complex Aka Hinge Systems

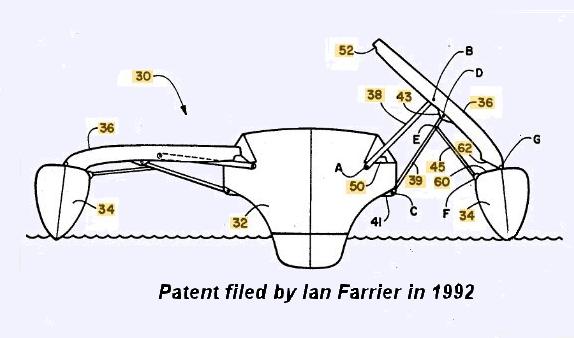

A complex system for folding multihulls, much like a garage door lift linkage, was developed and patented by Ian Farrier for his trailerable trimaran designs. It allows one person to fold or unfold the boat while it’s afloat. Before launching, the mast is stepped and secured with lower stays. Note that folded storage in the water for long periods is not practical because the immersed ama’s topsides will gather marine fouling. In addition, the arrangement of the support linkage arms has a very shallow angle with the aka, causing them to be highly stressed, which adds significant weight and cost.

Unfolding it requires help from friends.

A complex folding system I developed has only four attachment bolts and a wide-angle strut brace. It is very light but requires folding prior to launching. It relies on a simple roller dolly on a beam attached to the trailer to support the ama during folding and unfolding.

Swing-Wing Systems

In-water storage of folding trimarans is generally limited to swing-wing designs, where the hulls all float on their respective waterlines, either folded or unfolded. Many variations have been used in production boats, and among the most successful is the Quorning-designed Dragonfly. It has hinged arms supported by a “waterstay”— a diagonal cable under the arm to counteract cantilever aka loads. The outer end of the arm, on the ama deck, pivots on a single pin. The waterstay becomes slack when the boat is folded, leaving only the hinge to support the ama in the folded configuration. I’ve seen one folded boat that was damaged while moored at the dock in strong harbor waves when the ama climbed onto the dock. Swing-wing designs stored in the water must provide strong vertical support for the ama in the folded condition

A swing-wing aka system on the Borg Quorning–designed Dragonfly 32 is further supported by a waterstay when rigged for sailing. The akas can be adjusted in and out while in the water and for storage at the dock.

The main challenge of the swing-wing system is to get all the pivot axes parallel because they must rotate about 90° without binding. If there is any depth to the structure, this accuracy is critical, as the pins or pivot axles could be quite long, so even a small inaccuracy will make the system difficult to assemble, let alone pivot smoothly.

Folding Multihulls with Flat Swing-Wing Akas

The most basic swing-wing system is the flat aka configuration developed by Jim Brown. He avoided the need for perfect parallel alignment of all hinge axes because the beams are not very thick, and the pivot-pin holes can have additional clearance. For the swing system to operate without binding, spacing of the pivot points must be identical on all the swing arms. The system’s downside is strength, because the aka must support all the heeling loads in a relatively narrow beam. For some boats, a waterstay may need to be added to increase cantilever strength and reduce deflections when sailing.

The Seaclipper 16 flat swing- wing akas are made from common dimensional lumber and pivot using steel bolts.

A logical improvement in strength for swing arms is to add a truss, with triangulated strength that will easily bear all the heeling loads from the ama. Here again, it is essential that pivot axes be in perfect alignment to avoid binding. To my eye, open trusses in sleek yachts are never beautiful, but they offer higher strength for lower weight.

Complex Swing-Wing Systems

If the akas are not flat along their full length, it is more difficult to achieve a smoothly pivoting system. My latest boat, Syzygy (pronounced, sis-a-gee), is a case in point. Flat akas offer little variation in styling—flat is flat. To add underwing clearance and more attractive aesthetics, many designers favor the arched aka. This configuration allows the aka to approach the ama hull from above and connect through the deck for more usable immersion of the ama buoyancy, and to keep the aka above the wavetops.

This system has arched akas with an upward angle (dihedral) as they extend from the main hull and descend with a smooth curve onto the ama deck. The pivot axis must also be inclined, normal to the surface, to allow it to pivot. To make life simple, the vertical centerline of the ama is inclined inboard at the top by the same amount, which aligns all the pivot axes with the ama vertical centerline. If the beam is level fore-and-aft, when the ama is folded inboard, it is positioned rather low, due to the arch. To compensate, the akas must be given a negative angle of attack to make the folded ama arrive in the same position as a simple flat aka system. It’s a good challenge for any boatbuilder to get it right and a good use of a digital level. The angles in Syzygy were 8° dihedral, and a nega tive 5° angle of attack. The aka pivot surfaces must be perfectly parallel on both ends—at the inboard aka pivots and the ama deck pivot tables.

Jan Gougeon designed and built strings, a 40′ swing-wing catamaran with carbon- tubular-truss swing akas built over foam mandrels.

A late iteration of the Telstar 26 became the Telstar 28 with a vertical-axis swing-wing system. This production boat is no longer manufactured but was unique for its faired wing and attempt to hide the folding system from view. It also featured an electric linear drive to fold/unfold the heavy akas.

For transporting folding multihulls on the highway, road trailers must have some specific attributes to properly support the hulls. Most models use transverse cradle supports under the hull at major interior bulkhead positions. It is important to install bow guides on the trailer to get the hull to settle in exactly the right place when retrieved from the water. Rollers beneath the hull are not recommended, as they tend to distort it and potentially cause damage. The amas require enough support so the folding mechanism is not carrying the load when being towed.

For swing-wing boats, there is a significant change in the center of gravity between folded to unfolded configurations. Normally, the amas swing back when folded and swing forward for the sailing position. If the trailer has the proper tongue weight for towing on the hitch with the boat folded, the weight will increase when unfolded. For trailers with telescoping tongues, tongue design must accomodate that weight; otherwise, the extended tongue may bend severely during launching or retrieval.

Homebuilt wooden trailers are popular for these specialized boats, and some designers provide plans for them. Without much metal in them, they will probably float, which sometimes leads to difficulty at launching. Adding some steel channel to the bunks can solve that. However, floating is not an undesirable feature if a trailer floats level but is submerged enough to maneuver the hull into the bunks, and the hull settles into the right place automatically. Floating trailers also never run off the end of the ramp.

Conclusions

There’s truth in the humorous claim that “the new family yacht has to look good behind your SUV.” But while many of the latest small boats are daysailers, folding multihulls have expanded the trailerable and transportable boat size to include those with weekend cruising capability, up to about 32 ‘ . As we’ve seen, those essential folding or retraction mechanisms are not simple and must be carefully designed and engineered, even by the home builder. But for owners of these boats, seasonal storage and slip availability are no longer problems. And the overall reduction in total cost can bring owning a boat within reach for many more people. What’s not to like about that?

About the Author: John Marples has designed, built, and rigged many sail- ing vessels. His portfolio includes doz- ens of wood-epoxy composite sailing and power multihulls to 110′ (33.5m). He operates Marples Marine , a multihull design and engineering firm in Penobscot, Maine

Dieter Loibner | Professional BoatBuilder Magazine

Nomenclature

Multihull designers have developed some useful, specific names for components, mostly derived from the Pacific Islander language.

Aka (ah-kah) refers to the crossbeam structure of any multihull. Designers used to call them “cross-beams,” but writing that on hand-drawn plans took up too much space and time, so this shorter Polynesian name became the standard.

Ama (ah-mah) is the Polynesian name for the outer hull of a trimaran or proa. They were formerly named “floats” or “outer hulls” (never pontoons), but again, ama is shorter.

Vaka (vah-kah) is the Polynesian name for the main (largest) hull of a trimaran or proa. Since it can be confused with the other names and is not very descriptive, most designers have opted for the term main hull.

Waterstay is a diagonal stay, metal or synthetic rope, below the aka, between the main hull near the waterline and aka near its outboard end. This stay counteracts the upward load from ama buoyancy when the ama is immersed.

—John Marples

The Crossbeam (Aka) Structure

T he essential function of any crossbeam (aka) system on a multihull is to structurally connect the hulls in a way that resists all the forces generated when sailing. Heeling forces from lift on the sails must be transferred to the leeward hull by the aka structure. The forces on the akas are complex, composed of cantilever bending due to heeling loads, twisting of the structural platform, and horizontal bending caused by drag from the ama’s forward motion through the water. The heeling force, resisted by the buoyancy of the ama, pushes up, causing cantilever bending loads in the akas similar to the forces on an airplane wing. Torsion is created when the sails’ lift pushes the leeward ama bow down, while the shrouds supporting the mast pull the weather-side ama stern up. Drag from the leeward ama tries to bend the akas toward the stern, and forces from the windward shroud tend to pull the aka forward as well as up. These forces all act together at the attachment points on the hulls. In most cases, torsion is resisted by the tubular hull and cabin structure itself. Heeling is countered by the cantilever strength of the aka beams and is sometimes strengthened by diagonal waterstay cables beneath. Drag forces can be resolved by the fore-and-aft strength of the akas or by adding diagonal cables between the akas. Each folding system must accommodate these loads through all the pivoting components in the structure.

Of key interest in aka design are the loads imposed on the ama hulls by the seaway when sailing to windward. These hulls are subject to significant loads on the outboard sides. The windward ama is pummeled by wavetops, and the leeward ama is pushed sideways due to leeway. Since the aka system is characteristically attached through the ama deck, these forces are trying to rotate the ama keel inboard, toward the main hull, in either case. The same is true for catamarans, concerning the aka loads where they emerge at the hull inboard sides. These loads can be calculated to estimate the strength required for any configuration and should be part of the design’s stress analysis. If centerboards or daggerboards are located in the amas, those rotating forces are significantly increased.

Of further interest in swing-wing designs is the clearance between pins and brackets in vertical pivot mechanisms. When sailing, the forces at the hinge pins can change from positive to negative repetitively, creating noise and wear. The wear will eventually elongate the holes, reduce pin diameter, and become a maintenance problem. Designs like the flat wing can be tightened to eliminate movement, which will eliminate wear. Amas with waterstays tend to put the akas in compression and stop the vertical deflection that would be normally carried through the hinge pins. In that case, the pins would be loaded in only one direction and not be subject to cyclic ± loads. —J.M.

Read more Construction , Design articles

- SNAME Powerboat Symposium Is Back

The Society of Naval Architects and Marine Engineers (SNAME) Technical and Research Program, in cooperation with the Hampton Roads, Virginia Section of SNAME, will host the Sixth Annual Powerboat Symposium… Read more »

- Candela’s Faith in Foiling Ferries

In the rarefied world of fully foiling electric boats with carbon hulls and appendages, sensor-based digital ride control systems, and hefty price tags, Candela grabbed the spotlight by delivering on… Read more »

- Australia II Wing Keel Controversy – Part 2

A tank-testing laboratory team in The Netherlands convinced Australian challengers to rely on performance-prediction data and analysis that helped create the 12-Meter that made America ’s Cup history.

Recent Posts

- Australia II Wing Keel Controversy – Part 1

- Learn Electrical Systems from Nigel Calder

- Companies (83)

- Construction (105)

- Design (160)

- Drawing Board (10)

- Education (25)

- Environment (16)

- Events (21)

- Materials (49)

- Obituary (17)

- People/Profiles (48)

- Products (16)

- Propulsion Systems (32)

- Racing (16)

- Repair (37)

- Rovings (315)

- Short Cuts (3)

- Sponsored Partner News (13)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

Farrier International

a Division of Daedalus

The New F-33

The 2015 F-33 is a new design by Ian Farrier, having evolved from the F-32 , and replaces the original 2004 F-33 . It is available in several formats, the F-33 , F-33X (with wider center hull), or the more race orientated F-33R and F-33RX, plus all carbon versions, the F-33RC and F-33RXC . Both aft cabin and aft cockpit versions are also currently available.

The new F-33 is a truly modern ‘state of the art’ design, and incorporates the latest third generation Farrier Folding System ™. The third generation beams have no intrusion into the main cabin, and eliminate the awkward beam pockets in the cabin sides. Floats are as large as they can be for such a folding trimaran, with extra buoyancy having been designed in forward and low down for the maximum sail carrying power.

The standard F-33 offers more room than any other equivalent legally trailerable folding trimaran, due to efficient design, plus heavy and space robbing interior liners are not used , which also makes the F-33 the lightest available production boat of its type. The extra wide maxi F-33X is even larger again, and is easily the roomiest and most seaworthy folding trimaran in its class.

The new F-33 series has one major advantage over the original F-33, this being the availability of the narrower 2.6m (8′ 6″) F-33 version which is the largest legally trailerable trimaran available, with no permit required for US roads. The wider F-33X will require a permit to be trailered, but it has much more room and a higher load carrying capacity.

The new F-33 series has been designed with a limited ocean going capability in mind, and best of all they are true Farrier designs, so reliability is ensured.

A ‘kick back’ centerboard option is available for the new F-33 design series. This will give a ‘roomier feel’ to the main cabin, and a much larger cabin table (can easily seat 6) is now possible. The settee seatbacks can also be dropped in between settees to form a very spacious main cabin double.

The other major advantage is the ability for the board to ‘kick back’ should one run aground, and this can be a very useful safety feature in shallower waters. Board is a higher aspect foil than the standard daggerboard, so it will be slightly more effective. This will help make up for the extra slot drag associated with a centerboard case, and overall performance should be similar.

Note that ‘kick up’ centerboards are more complicated than a daggerboard, so more maintenance may be required. However, the configuration used has been very well developed and tested, and should be virtually trouble free.

The current F-33X interior quality and room can be seen in the following photos:

THIRD GENERATION FARRIER BEAMS AND FOLDING SYSTEM:

The latest F-33 beams have been designed to trap and deflect any spray downwards to eliminate or reduce spray at high speeds, while the beam folding strut anchors are internal which eliminates multiple metal brackets and bolts. This reduces windage, weight and complexity, while folding struts are now set higher, keeping them further away from wave tops. The above drawing also clearly shows the difference between the F-33 and F-33X .

Beams are more streamlined while also being slimmer and higher at outer ends for less drag. The inner beam end to main hull connections are now fully external, for easier setup and maintenance, and this also gives a lower trailering height with less windage on the road for more economical towing.

Models Defined:

F-33 – the standard version, legally trailerable in the USA without permit

F-33X – a wider, roomier maxi version, that will require a permit for trailering, the ‘X’ standing for extra room. The best choice for ocean work with a greater load carrying capacity, and a wider overall beam.

F-33R & F-33RX – more sporty racing versions for experienced sailors, with a taller rig, the ‘R’ standing for Race. Add ‘C’ at end for the all carbon version

F-33SR & F-33SRX – new highly powered super racing versions for experienced sailors only, with the very tall SR rig, the ‘SR’ standing for Super Race. Has a 50′ (15.24m) carbon mast, and all carbon construction is optional. Profile drawing below.

F-33 Specifications L.O.A………………………………. 33′ (10.06m) B.O.A………………………………. 23′ 2″ (7.05m) …. F-33X – 23′ 10″ (7.25m) L.W.L………………………………. 32′ 4″ (9.85m) F-33 Folded beam………………. 8′ 6″ (2.58m) F-33X Folded beam……………. 9′ 6″ (2.9m) Approx. bare weight …………… 2800 – 3700lbs (1270 – 1680kg) depending on model Load Carrying Capacity ……… 2600lbs to 3000lbs (1180 – 1360kg) depending on model & weight F-33 rotating mast ……………….44′ 7″ (13.6m) aluminum or carbon mast F-33 sail area (main & jib)…… 654sq.ft (60.5sq.m.) F-33R rotating mast …………….47′ 3″ (14.4m) – carbon mast F-33R sail area……………………702sq.ft (64.9sq.m.) Stability …………………………….56,900ft.lbs …. F-33X – 58,400ft.lbs Draft (board up)…………………. 1′ 5″ (0.42m) Draft (d/board down)………….. 6′ 4″ (1.93m) Draft (centerboard down)…….. 6′ 2″ (1.88m) Aft Cabin Cockpit length………4′ 10″ (1.46m) Aft Cockpit length……………….7′ 7″ (2.3m) Interior Headroom ……………….6′ 2 to 6′ 4″ (1.88 – 1.93m) depending on interior layout Auxiliary…………………………… Outboard or Inboard optional Bunks can be a minimum of 6′ 6″ (2m) long or longer if required. All specifications may be subject to change

As with the original F-33, the new F-33 is expected to have a very high resale value, due to the high quality construction, and the design reputation. The last original F-33 sold did so within 10 days of going on the market, and the price paid for what was a 7 year old boat was near what it cost new. Such value means the F-33 will be a very low cost boat to own as was the case with the original F-27, which has been the resale value leader for many years.

The New F-33SR

A new addition to the F-33 range is the F-33SR or F-33SRX. These are ultra high performance versions of the F-33 and will replace the F-32SR, but with more interior room.

There will be both glass and carbon options, the all carbon version being called the F-33SRC or F-33SRXC, and lifting foils will be optional.

More Interior Options:

Copyright Reserved © 2015 by Farrier Marine (NZ) Ltd.

- 0 No item in your cart

- SUBSCRIPTION

- Classified Ads

- Technical Specifications

- Destinations

- Address book

- All the magazines

Corsair 36: A big folding trimaran from the ‘global village’

The design of the central hull offers both interior volume and good performance under sail! Bravo...

Practical info

- Builder : CORSAIR MARINE INTL

- Technical specifications

- Finance your Corsair 36/37

- Articles about the Corsair 36/37

- Available in issue # 105

Boat Test price $5.00 Inc. tax

Add several tests to your cart

and get an extra discount!

Corsair was created by a New Zealand architect in California, and has built more than 1,200 folding trimarans between 1984 and 2008, which makes it the leader in this segment, along with the Danish Dragonfly. We have just tested the biggest of these trimarans, the Corsair 36...

The 36’ has now been replaced by the Corsair 37, a re-styled version of the same boat. Taking into account the small number of examples present in Europe, we leapt at the chance to test one, whilst waiting to present the 37’ carbon (RS) development.

Aluminium rotating mast, carbon bowsprit and nice Pentex sails by Calvert Sails: the Corsair 36 offers simple but high-performance choices!

The split with the founding architect

In 2000, Ian Farrier left the Chula Vista company that he had created and of which he was the vice-president and the emblematic architect. The disagreement with Paul Koch, the new strong man at Corsair (an Australian who built the Farrier Ostac), led the designer to return to his New Zealand offices, from where he re-launched his own range (F82, 32’, 36’ and 39’), intended for individual (up-market) construction, and Australian and Phillipine (Melvest Yard) production.

A really liveable trimaran which allows you to envisage offshore cruising...

The 36’- 37’: the flagship of a turbulent range

The 36’s characteristics show clearly that it belongs to the Farrier line, and it is obvious that despite the difficulties, the Corsair research and...

To read in full, Buy the boat test

Tags :

- trimaran ,

- Boat review

What readers think

Post a comment

No comments to show.

Share this article

Follow us on, vous avez ajouté " " à vos favoris., vous avez supprimé " " de vos favoris., in order to add this article to your favorites, please sign in..

16 Best Trimarans For Sailing Around The World (And a Few For Daysailing)

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

Trimarans are growing in popularity worldwide, due to their light construction and high stability these multihulls are even faster than catamarans. Trimarans are still one of the lesser-known boat types so in this article ill be checking out some of the most popular models.

The best trimarans include:

- The Neel 43

- The Neel 47

- Dragonfly 28

- The Pulse 600

- Corsair 37

These tris are built with your safety in mind while also packing powerful speed and a wide array of comfort features to optimize your sailing experience , some are even foldable making them possible to load on a trailer and transport to the sailing destination of your choosing.

In this article, I have created a list of the 16 best trimarans in the market and their unique features. You’ll also learn the best options for different purposes such as circumnavigation, weekend sailing, racing, and more.

Table of Contents

What Is a Trimaran?

A trimaran is a multi hulled sailboat with three individual hulls; the main hull ( vaka ) and a pair of outrigger hulls ( amas ). These smaller outrigger hulls are attached to the main hull using beams.

While trimarans have a rich history dating back nearly four millennia, these types of sailboats have only gained popularity in the late 1900s and early 2000s.

Trimarans are primarily used as personal boats for sailing enthusiasts or racing. These sailboats draw their versatility from their lightweight design, making them faster and easier to handle at sea when compared to single-hulled boats (monohulls). Additionally, the three hulls also contribute to better stability, making it very hard to capsize (although more likely than a cat according to this study)

Trimarans come in various sizes, and some can be as small as 19 feet (5.8 meters) in length, while others go up to 60 feet (18meters). They’re also used for different purposes. Most trimarans are used for racing and recreational purposes, although some units are still used as ferries.

As with all things, to find out which is the best we need to understand what it will be used for. There is a big difference in requirements between a boat used for day sailing compared to offshore around the world sailing.

The list below highlights the best trimarans for different purposes.

Best Trimarans For Cruising, Liveaboard and Sailing Around The World

The Neel 43 is a French trimaran best suited for cruising. Its key features include:

- Easy maneuverability on the open sea by only a small number of crew members

This unit is also built for comfort, ideal for more extended travels. This 43-feet (13-meter) trimaran is also made with recyclable and bio-sourced materials, highlighting the manufacturer’s commitment to environmental consciousness.

This trimaran has a base price of €329,000 excluding VAT. This translates to approximately $370,138.

2.Neel 47 Possibly The Best

Named the best full-size multihull for 2020, the Neel 47 is a strong contender for one of the best trimarans in the market. This 47-foot (14.3-meter) long trimaran features optimized exterior and interior ergonomics for a unique design and look.

Still on design, the Neel 47 is ideal for couples looking to take a weekend off or spend some time as liveaboard. It has a spacious owner’s cabin and two bedrooms. It also features a spacious living room and kitchen and is optimized to ensure comfort for a couple.

The Neel 47 also has two basic guest cabins so your friends or children can tag along on your sailing adventure. Accordingly, this unit is ideal for those looking to explore the sea for the sheer joy of sailing.

The Neel 47 comes at a 571,139 euro ( $643,600 ) price tag, excluding VAT.

3. Rapido 60 The Fast and Comfortable Circumnavigator

The Rapido 60 offers a blend of performance, safety, and luxury, making it one of the best options for bluewater sailing. Measuring 59.3 feet (18 meters) in length, the Rapido 60 is an imposing unit. It’s made from lightweight sandwiches and carbon materials that provide speed and strength, allowing it to stand up to strong ocean currents.

The Rapido 60 also has spacious living spaces and is built for comfort at all points of the sail. Its design also optimizes safety. While it’s an ideal option for circumnavigating, it’s also an excellent choice for racing due to its speed.

This is also the same boat that The Youtube channel La Vagabond just purchased.

The Rapido 60 retails at $1,400,000 .

4. Rapido 40

The Rapido 40 measures 39.4 feet (12 meters) in length and is ideal for cruising around the world. The Rapido 40 features twin “C” foils, which provide added lift, enhancing its speed and performance whether you are sailing downwind or upwind.

Because it has C foils, this trimaran doesn’t have a central daggerboard, increasing interior space. Accordingly, it’s an excellent option for couples looking to cruise and enjoy great performances .

The Rapido 40 is made from high-tech all-carbon materials for a lightweight yet sturdy design. This material is also used for the countertops and furniture, and the cork flooring adds a touch of style.

This trimaran retails for $595,000 , making it a cheaper option than the Rapido 60.

5. Dragonfly 40

The Dragonfly 40 measures 40 feet (12 meters) in length. It features high-comfort standards, making it one of the best trimarans in the market for taking your family for a cruise. Because of its larger size, it has a better capacity, being capable of accommodating six to eight people, so you can bring your family and friends along.

It’s easy to navigate and extremely safe. With a maximum speed of 24 knots (44.5 km/h), this trimaran also provides fast speeds to make your cruise even more exhilarating.

The Dragonfly 40 retails from €509,000 exclusive of VAT, which rounds up to $572,000 .

6. Dragonfly 32

The Dragonfly 32 is a high-performance cruiser. Like the Dragonfly 28, this unit features a contemporary design for racing. This trimaran can accommodate five to seven crew members.

Although slightly longer than the Dragonfly 28 with its 32-foot (9.8-meter) length, the Dragonfly 32 has a max speed of 23+ knots (42.6+ km/h), making it one of the fastest trimarans for racing. This unit also has comfortable accommodation, which makes it an ideal option for a weekend cruise with family and friends.

The Dragonfly 32 has a base price of $350,000 .

7. Corsair 37

Thanks to a variable draft with a retractable rudder, the Corsair 37 is an ideal choice for shallow water exploration. This 37-foot (11.3-meter) long trimaran features advanced foam-cored construction designed for safety, making it virtually unsinkable.

The carbon hulls minimize weight, this makes for a lightweight ocean exploration sailboat with blistering speeds. One of its selling points is that this trimaran has previously been used for Arctic expeditions, possibly marking it as one of the better options for circumnavigation and offshore sailing in the northern waters.

This trimaran has a base price of $189,000 but can go up to $204,125 .

Best Trimarans For Day/Weekend Sailing

8. dragonfly 28.

The Dragonfly 28 is a 28-feet (8.75-meter) long sailboat that can accommodate up to five people. It comes in two versions:

- Touring version: This version is ideal for families.

- Performance version: This is built to provide optimal performance for the sports enthusiast within you.

It clocks a maximum speed of 22+ knots (22+ km/h) and is beam-folded. It’s an excellent option if you want a high-performance, comfortable yet smaller unit for your day or weekend cruise.

The Dragonfly 28 starts at €188,280 inclusive of VAT, which comes to around $211,600.

9. Dragonfly 25

Like other trimarans under the Dragonfly brand, this 25-foot (7.62-meter) trimaran is great for both racing and short term cruising. However, this high-performance boat delivers easy handling, making it perfect for couples looking to take a ride out over the weekend and seasoned sailors looking for an exhilarating racing adventure.

The Touring version features a lightweight build and offers comfort and accommodation to keep you, and the few guests you can fit, comfortable during the ride. This trimaran also has a Sport version, which is optimized for racing.

The Dragonfly 25 retails from EUR 86,800 .

10. Pulse 600

The Pulse 600 trimaran is a compact sailboat. It’s made from lightweight, carbon-reinforced construction and vacuum-formed materials for optimal speed. This trimaran is an ideal option if you are looking for speed.

It also features ample deck space, greater stability, and volume than most trimarans of similar size and build.

This trimaran measures 19.8 feet (6 meters) in length and can be sailed single-handedly by one person with minimal effort. The Pulse 600 has a base price of $38,800 , which places it in the lower price range.

The F-22 is one of the smaller trimarans in the market. Developed in New Zealand, the F-22 is a folding trimaran built for speed. The hulls are made from narrow fiberglass tied together using fiberglass beams and aluminum, minimizing bulk while optimizing speed.

The F-22 is roomy and is not as pricey as other models in the market. This trimaran has two main versions:

12. 2019 Weta Trimaran

The 2019 Weta trimaran is a 14.5-foot (4.4-meter) trimaran featuring a carbon frame, centerboard, rudder foil, and rudder shock. The hull is made from fiberglass and foam. The Weta is built for strength and speed based on these lightweight materials.

The 2019 Weta trimaran is easy to sail and is worth considering whether you want to take a quiet sail, race with your friends, or take kids to a sailing lesson. It has a simple design and is easy to set up independently. Thanks to its collapsible design, this trimaran is easily stored away with minimal space demands.

13. WindRider 17

The 17.4-foot (5.3-meter) WindRider 17 is one of the more versatile trimarans in the market. It packs high performance for a low cost. This trimaran has a light rotating mast to boost performance, and a full-battened mainsail optimizes visibility.

This sailboat is made from rotomolded polyethylene, which is more durable than fiberglass and demands less maintenance.

The WindRider 17 has a comfortable interior and can fit six adults. This is an ideal choice for social sailing for a couple or a family and friends. It’s easy to ride, and a shallow draft allows easy maneuverability.

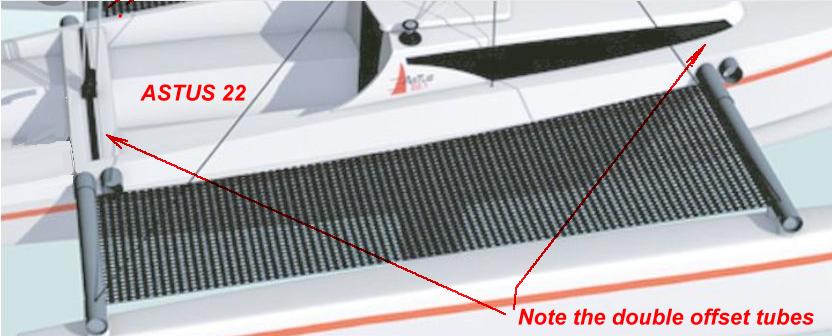

14. Astus 22.5

If you’re looking for something small but still comfortable, this 22.5-foot trimaran is for you. Built for speed and maneuverability, the Astus 22.5 has optional foils to optimize speed. The modern design, coupled with the spacious interior, can fit up to four beds. Accordingly, this trimaran is suited for family outings.

This trimaran also has a foldable design, collapsing to only 16 feet (4.9 meters) for easy storage.

15. Multi 23 Trimaran

The Multi 23 trimaran has a contemporary design, featuring a vinyl ester and PVC foam core construction. The section below the waterline is made of solid glass for a sturdy base.

The beams are made of lightweight carbon, and the trimaran features a 33-foot (10-meter) aluminum rotating wing mast for optimal harnessing of the wind. While ideal for weekend excursions with family, once rigged with the asymmetrical spinnaker will get your heart pumping.

This trimaran packs high performance at a lower cost than most other options in the market. It’s a good choice if you are looking for a high-performing unit without spending an arm and a leg.

16. Challenger Class Trimaran

The Challenger Trimaran 15 is the best choice for persons with disabilities. It’s designed to provide disabled sailors an opportunity to explore their passion for sailing without worrying about aspects like safety or operation.

A man named Geoff Hold circumnavigated the British Isles in 2007, becoming the first disabled person to achieve this feat. He had quadriplegia.

Living up to its name, the Challenger can withstand harsh weather conditions while blending performance with speed.

Final Thoughts

Admittedly, no trimaran is best for everyone. But whether you are looking to race with your friends, take your loved ones or friends for a cruise over the weekend, or circumnavigate the ocean, you can rest assured that these lightweight trimarans will deliver speed, safety, and comfort to make it worth your while.

These brands are innovatively designed and feature intricate safety mechanisms that make them virtually unsinkable. Give them a shot and begin your ocean adventure.

- Basco Boating: A Comprehensive Guide & Introduction to Trimaran Yachts

- TheBoatAPP: New Trumarans: Which are the Best Ones

- Corsair Marine: Corsair 37

- Dragonfly: Dragonfly 28

- Rapido Trimarans: Rapido 60

- Neel Trimarans: Neel 43

- Yachting World: World’s Collect Yachts: Maxi Trimaran MACIF

- Yachting Monthly: Dragonfly 28 Performance

- Rapido Trimarans: Rapido 40

- Dragonfly: Dragon 32

- Dragonfly: Dragonfly 40

- Yachting World: Dragonfly 40 yacht tour: This cruising trimaran can do 24 knots

- Dragonfly: Dragonfly 25

- NauticExpo: Dragonfly 25

- Yachtworld: Corsair 37 boats for sale

- Cruising World: Neel 47 Trimaran: Best Full-Size Multihull0

- Neel Trimaran: Neel 47

- Multihull Solutions: NEEL 47 Boat Review | Cruising World

- Yacht World: 2022 Neel 47 for sale

- Farrier International: F-22

- Weta Marine: The Boat

- WindRider: WindRider 17 Trimaran Sailboat

- Astus Boats: Astus 22.5

- Boat-specs: Multi 23

- National Maritime Museum Cornwall: Challenger Trimaran #1 – BC26

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

Folding System

Legendary ability, unbeatable reliability.

Folding and unfolding a Corsair trimaran takes only a minute. With just 4 bolts to remove, it is easily managed by one person, and is normally done while afloat. Simply raise (to fold) or press down (to unfold) the inboard end of one cross beam – meaning it can be done from the safety of the cockpit. Only a little force is needed due to the folding system’s carefully balanced geometry and the floats movement being mostly horizontal.

The solid aluminium folding struts have absolute control over the folding motion and prevent flexing or racking. A stainless steel bolt on the inboard end of each beam secures the floats for sailing. Crucially, wingnets remain attached during the folding process – their frictionless fixing allows them to tension themselves appropriately through the folding process. The system is so simple, the trimaran can even be folded while motoring.

Step 1: Remove Beam Bolts

Remove all four beam bolts, using a spanner or the provided speed wrench. As these are installed firm but not overly tight, this is a simple task requiring minimal physical effort.

Step 2: Loosen Shroud Tension

If required, ease out some length on the cap shrouds. This is made easy by the use of dyneema shrouds and synthetic lashing. Note: smaller trimaran models such as the Corsair 760 do not require this step as tension is maintained in both folded and unfolded positions.

Step 3: Fold

By pulling up on the inboard beam straps the beam will begin to lift as the boat floats gradually make their way inboard. As the floats are supported, there is very little weight on the beam allowing this process to be easily performed by one person.

If you’d like more details on how to fold a specific Corsair trimaran model, detailed instructions can be found in the Corsair Trimaran Sailing Manual

IT'S THAT EASY

Corsair trimarans fold on water, off water and with effortless ease . Most models fold within the width of similar-lengthed monohulls! This allows a level of versatility unachievable in a conventional trimaran due to the huge beam required for high performance sailing.

60 Seconds or Less

Single-handed folding takes only one to two minutes, and less than 60 seconds with a couple. It can be done by manually moving an inner beam end. Little force is required as the float’s movement is mostly horizontal. The wingnets fold or tension themselves automatically, and there is no need to undo or re-lace these. Folding a Corsair trimaran can be done in smooth water, rough water, or even while motoring. There are no restrictions of any kind.

- Folding Corsair Trimarans: Legendary Ability, Unbeatable Reliability

- 5 Reasons Why The Corsair 760 Trimaran Won Multihull Of The Year

- Corsair Range Brochure

- Corsair Community

- Find A Dealer

Tel +84 28 3873 3630

Sales Enquiry:

Customer Service Enquiry:

© 2024 Corsair Marine International. Alls rights reserved.

Privacy Policy

Lunada Design

Creative boats for home builders, category archives: folding trimarans, back bay sit on top kayak, a modular system approach to sot kayak sailing, paddling and mirage drive propulsion.

Sit-On-Top (SOT) kayaks are easy boats on which to learn to paddle. They have none of the “get in the coffin and you are about to drown” psychological identity that one finds in the Sit-Inside boats and they’re amazingly adaptable to a wide range of paddling activities. It also doesn’t hurt that they are pretty straightforward boats to rotomold, which makes them very cheap to produce in large numbers.

I didn’t envision just one boat for this niche in the home-built kayak market. Instead, it came to me that there would need to be at least three models that could address the wide-ranging styles of boating interests in this area of the kayak world. The result was a couple of very clean, SOT models at 14’ and 16’ called the Corona and the Back Bay, respectively. The third model was going to be called the Wahoo, as it was specifically designed for the folks who spend a lot of time fishing with their SOT’s. I’ll get to the Wahoo in the next article.

As a canoe and kayak sailor and a guy who had just been out for a test drive on the Hobie Adventure Island, which is based on their 16’ SOT Adventure model, I wanted to offer my own take on what makes for a truly fun and stylish, sailing SOT kayak. The result was that a fully integrated system of component parts was designed for the basic Back Bay. This modular approach allows the Back Bay to go sailing by simply adding a system of light-weight, easily built elements that quickly convert the SOT to a single aka sailing boat called the Scorpion, OR, to a double aka sailing boat with slightly larger ama volume, called the Doubloon. Of the two configurations, the Doubloon is most like the well-known and highly respected, Hobie Adventure Island.

The Corona and the Back Bay are virtually identical models, save for their respective lengths. For the purposes of this article, I’ll focus on the Back Bay version and all the potential add-on systems I’ve incorporated in the design.

THE BACK BAY SOT KAYAK

Specifications: Length overall – 16′ Beam overall main hull – 28″ Depth of hull max – 12” Weight – 48 lbs. or less Displacement – 335 lbs.

This boat is built in the S&G style of construction in 4mm marine ply with 6 oz. plain weave fiberglass set in epoxy on the inside and outside of the hull for full laminate sandwich strength. The build process uses external cradles as building supports, ensuring that the hull goes together with minimum hassle when handling the rather slender and longish hull panels. The boat is bulkheaded internally at three key points. These bulkheads create not only integrated strength in the design, but they also cleanly separate the hull cavity into four unique volumes for gear storage and watertight flotation.

The Back Bay can be configured with a large, open tankwell set aft of the cockpit, or built with a watertight, aft hatch cover for internal storage in a conventional kayak style.

Specifications: Beam overall – 10′ Weight (est.) – 90 lbs. Sail Area – 56 sq. ft. Displacement – 350 lbs. Draft (board down) – 28″

The Scorpion variant is a Sit-On-Top design for fun sailing, paddling, or Mirage peddling… or all three, as the builder desires. There will be a design for a leeboard mount included in the plans for those who are going to build the boat for sailing. Having the aka gull wing form set well forward permits a full paddle swing arc. The aka beam connectives to the amas is split into a pair of mounting elements. I did this to make for a stronger, single beam mounting struture. With a single beam design, there is a tendency for the am to want to rotate around the beam, making for a very stressed component that could lead to early failure. By splitting the beam and spreading the mounting points, I have given the structure more resistance to this rotational force, making for a more rigid boat in use. This setup will allow the owner to power sail in light air with both the paddle and the sail providing thrust. With the leeboard swung down for sailing, the owner can do some “power sailing” and utilize the Mirage drive, as well as the sail, in light conditions. The Mirage is capable of boosting boat speed enough that it creates apparent wind over the sail, adding power where there really isn’t enough for sailing alone.

The amas are positioned to optimize capsize resistance when sailing off the wind. The amas do not touch the surface of the water at rest in stable trim and provide only minimal wetted surface drag when underway by paddle or peddle. As soon as the sail is loaded by the breeze, though, the ama on the lee side begins to immerse, firming-up the boat and resisting the heeling moments being generated.

The aft deck can be configured as a watertight hatch with full access to the aft sections of the hull, OR a large, diving tank well with self-draining ports. The cockpit is fitted with self-drain ports under the seat as well as forward, in addition to the daggerboard slot. There is a watertight deck plate just forward of the seat, between the knees of the sailor/paddler to provide secure storage for critical items that may be needed on a routine basis. The foredeck has a watertight hatch cover for bow storage needs.

The rig is a fully battened Dacron sail with two reef points and a multi-section, self-supporting mast which steps into a sealed mast socket in the hull. The mast and boom sections can be aluminum or carbon, as budget permits. The sail choice is open for the customer as long as it can be balanced with the fixed positions for the mast and dagger board. The Cunningham is run to the deck of the gull wing aka to keep the rig on the boat in the event of a capsize.

With 56-sq. ft. of sail on a 90-pound boat, this will be a decently speedy boat without being in over its head all the time in a stiff breeze. I suggest two reef points in the sail to allow for sailing in a wide variety of conditions.

This will be a wet boat at speed, yet there are no worries at all for flooding and sinking, save for a truly nasty trip over a reef that shreds the entire underside of the craft. The bow, cockpit and aft hull volumes are all independent, sealed compartments, as are the ama volumes.

Reentry from a swimming session will be easy with a simple, sling, or rope ladder much like those used by rock climbers, called etriers.

The boat is constructed in a multichine, marine plywood style with epoxy glass laminates inside and out in a stitch and glue style. Stainless T-Nuts are embedded in the hull deck surface from below to provide a secure set of mounting points for the aka wing. The amas are held in place on the aka tips by large bungees and a notched lock system. This system provides for quick setups on the beach.

You just fit the aka to the foredeck, insert four, 1/4″ threaded stainless screws with comfortable, knobbed grips and screw down the aka wing. The amas slip onto the ends of the aka and you lift the pair of 3/8″ bungees up and over two raised hooks on the aka ends to secure the ama in place. Simple, easily maintained and near foolproof in operation.

DOUBLOON SAILING SOT

The Doubloon is the second variation on the central SOT theme of this group of boats. In this design, I am looking to provide a more expansive utility application for the base, Back Bay SOT version. The Doubloon is essentially a solo craft and it carries the same, 56 sq. ft. sail, but the overall potential of the boat is expanded through the use of dual akas and full trampolines on both sides of the Back Bay hull. The rendering of the Doubloon shows a daggerboard inserted down through the Mirage Drive trunk, but in use, I would prefer to have the board mounted outside the Back Bay hull as a leeboard. Plans will be supplied with the leeboard solution.

The akas on the Doubloon are spaced to allow for a full paddle stroke with the boat setup as a trimaran. There are two sections of tubing that span the opening fore and aft between the akas from which the tramp is mounted. The trampolines are designed to roll-up on the outer tube section, much like a window shade and they are deployed by an endless loop of light halyard line. With the tramps fully deployed, the inner tube section lifts up and over a holding pin in the aka and the sailor applies as much tension to the tramp as he feels he needs by hauling-in the endless loop line and cleating it off. If a paddling session is desired, he simply pops the jam cleat and pulls the line to roll-up the tramp on the outer tube section. This procedure applies for both port and starboard tramps.

Like the Scorpion, the Doubloon can be built to utilize a Mirage drive in the center well and the need to roll-up the tramps for paddling is essentially negated, (though it is nice to have the option once in awhile as Mirage drives can be difficult to maneuver in tight places)

The aka beams are held to the deck of the Back Bay hull with the same, threaded knob strategy for quick setup and takedown times. Similarly, the amas are held to the aka ends with hefty bungee cords for the simplicity of use. There’s another, rather invisible, benefit to using the bungee cords for ama mounting. Because they are being held in place through a fairly dynamic hold-down system, the amas can move about, ever so slightly, while underway. This allows the amas to have some structural “give” and the result is that the banging and thrashing that is typically experienced by the ama, is somewhat dissipated through the flex of the joining system.

All in all, I think the Back Bay SOT should be a really fun boat to own for warm water/warm weather boating adventures. It has the capacity to carry enough gear for several days out on the water. When rigged with a sailing system of your choice, it can also cover some pretty good distances if the winds are favorable. Plans for this boat and all its variations will be available from this site and Duckworks Magazine.

Chris Ostlind

Lunada design Chris@Wedgesail.com.

Log in or Sign up

You are using an out of date browser. It may not display this or other websites correctly. You should upgrade or use an alternative browser .

Trimaran folding system attachment

Discussion in ' Multihulls ' started by Will001 , May 13, 2019 .

Will001 Junior Member

Hi, i just joined the forum, hoping you guys could help me out. I recently bought a custom (home built) 21 foot trimaran based on a Mystere 6.0 catamaran (very similar to a tornado i believe). 9.5m mast, 5.2m beam. The main hull and folding mech is about 7yrs old. It's in need of a fair bit of tlc, but one thing which concerns me is the folding mechanism attachment to the main hull. It looks like the main forward attachment points are not in great condition. The lower side is compressing the hull laminate and the top is separating from the hull with some minor cracking. It is thru bolted to aluminium backing plates on the inside of the hull. There are small struts bolted onto the lower backing plate to transfer load to the opposite side of the hull. The upper backing plate is unsupported.. Is this a normal way to distribute load in a folding trimaran? I was thinking about replacing the internal struts and backing plates with a single rigid beam which both upper and lower bolts are attached to? The hull is made from polycore, a polypropylene honeycomb, with epoxy/glass inside and out.

trip the light fandango Senior Member

Yes it is strange, it is like the work was done reasonably well but missed 50% of the point of having the internal brace, very odd, probably just wanted to use it, sick of working on it.. Be careful with your stainless/ aluminium, delrin washers and marine grease/lanolin help.

W17 designer Senior Member

Seems that Fandango has understood your arrangement better than I Would you have a photo looking from forward back on to the folding system with the ama out? Then we can determine how the loads are applied. For sure, you cannot securely attach something bolted through a honeycomb without making the core solid at that point. If this is a Farrier-style linkage, the inner upper aka will be working mostly in tension or compression and the deck can be designed to take this with some form of beam at the connection point. Under the most critical condition, the lower arm will try to pull ou t from the shell on the leeward (in the water) side, based on the maximum buoyancy* that the ama has, while that same lower arm on the windward side, will press into the shell based on a maximum load of the weight of the ama plus all the crew weight that you may add on that ama. While the sail load will help to support this (via the tight windward shroud), its best to calculate the strength needed by the arms and their connections from the full max. loading I've noted. Outboard of the linkage, the aka will act in bending as a cantilever .. again based on the maximum loads indicated above. The lower link will generally need a solid cross connection through the main hull, from side to side ... again with any core material replaced with something solid. Even for a small boat like this, I would add extra strength with a safety factor of around 2, with more for a larger boat. *As noted in this article, I design using 100% of the total ama buoyancy on the forward beam with about 75% generally being ok for the rear one. https://smalltridesign.com/Trimaran-Articles/design/crossbeam.html Hope this helps, but a photo or sketch will help if not. mike www.smalltridesign.com

SolGato Senior Member

I think the rigid beam mod would be wise. I’d also increase the surface area of the outer plate to the hull to help spread the load over that area which has probably been weakened. On the Farrier boats the connection points for the folding system have a lot of shape built into them for strength. They don’t just connect to a flat surface, the hull has been molded to accommodate the mounting so as to not create a stress point.

Thanks for the replies guys. trip the light fandango said: ↑ Yes it is strange, it is like the work was done reasonably well but missed 50% of the point of having the internal brace, very odd, probably just wanted to use it, sick of working on it.. Be careful with your stainless/ aluminium, delrin washers and marine grease/lanolin help. Click to expand...

A word of caution if you decide to add bunks to your trailer to support the amas- Your center hull supports should do all the work and the outers only helping to keep the boat upright when loading, otherwise you risk damaging the outer hull skins if the outer bunks are supporting any of the boats weight. The folding mechanism isn’t really designed for this when folded and unless your Amas were laid up with reinforcements along the inside outer skins, you risk damaging them, especially if you have a flexible bunk board, or if you lose a tie down or main hull bunk board while towing. And I agree part of the distortion is probably due to using those connecting points at tie down points. You might want to come up with a removable fixture that can be placed in the slots that the beams unfold into that can be used for tie down instead.

Although trailers are often responsible for damage to main hull bottoms when rollers are used instead of bunk boards, I rather doubt this is the case for the amas, unless they are suspended loose and are free to jump around on bumps. The folding arms should be more than amply strong enough to carry dry ama weight in any position. But amas should be lashed to avoid shock loads from jumping around loose while on the road. Heavy duty shockcords are better than chains IMHO if attached to your folding arm brackets when on the trailer as the main hull should have its own separate lashing straps. My first concern would be to check to see that the honeycomb was removed in way of any bolted attachment, as otherwise loads (both sailing and trailing) could have damaged that area and permit movement that should not be there. As I pointed out in my earlier post, the forward beam takes a high proportion of the load at sea, so this might explain why the forward one is more in need of repair than the aft one. It's good to consider all the load options to figure out the real cause of the problem as then you can personally find the best solution. Good luck with this.