Better Sailing

How to Repair Sails On Your Sailboat

Even if you try to avoid any sail damage to your sailboat, there will be a time, unfortunately, when they get damaged at sea. So, what happens in the event of sail damage? Of course, the fact is that you’ll have to repair them while at sea and then quickly do a damage assessment. For that, you will probably need someone to lend you a hand and a flat surface to place the sail open. But before we get to the details on how to DIY repair a sail tear on your sailboat remember to be prepared for any unexpected scenario. In other words, having the right tools and supplies onboard gives you a huge advantage in dealing with the problem. Some of the basic tools include a waxed twine, a selection of sail needles, sharp scissors, spare webbing, and a sticky-back Dacron. Let’s move on and see the details!

Stitching your Sails

It is of great importance for a sailor to be able to stitch a sail by hand. If you know how to do this, it’s really practical in case of a chafe or of any other torn seams. The process is really simple. Firstly, make one pass to stitch on one set of diagonals as well as to the opposite direction and then fill in the other set. This can be applied in case you are following an existing zigzag stitch. Moreover, the sailor’s palm will facilitate you in order to force the needle through the fabric, and pliers will help you pull the needle through it. Remember to melt the ends of each knot with a lighter to prevent any loosening, as well as try to make tight stitches to ensure a strong repair. Buy a Sail Repair Kit From Amazon

Patch Repairs

For repairs that are not on a seam, a patch fix is necessary. You can use a Dacron patch for almost everything except spinnakers. Dacron can even stick to many laminate sails on the film side, but not on some resin-based and silicone-covered sails. In addition, dacron tapes come in different forms of thickness rolls and you can also buy larger sheets. Naturally, sails are not flat and they’re made up of panels that create depth. However, due to its design, when the surface you lay it on is flat it might pose you a problem. So do some temporary tucks and folds in the cloth, but away from the rip, and try to keep it flat. So, be patient and follow the below-mentioned procedure:

- The space you’re going to “work” is essential. Find a dry and safe place with a flat surface like below the saloon table or even on a chopping board.

- Always clean your fabric of salt with a freshwater rinse. Then allow a few moments for the fabric to dry. Continue by removing any residues with rubbing alcohol. This tip facilitates the drying process, as the alcohol evaporates.

- Most of the time, some sails (mostly white), tear in lines. For that reason, they shouldn’t be pulled too close together or overlap each other. Otherwise, their shape will change, and thus loading will be created. In case the tear has gone off in different directions repair the longest first.

>>Also Read: Best Sail Repair Tape

Seam Repairs

In order to make sure that no seams are starting to appear, try to check your sails daily. It’s not particularly hard for a seam to be unstitched, right in the middle of your voyage. So, if you see any loose stitching, put the sail down immediately, if possible, in order to get it fixed. Stitching a seam back together is a task that requires some time and attention. However, it’s much easier than dealing with ripped fabric. When you stitch seam you just work your way methodically back through all the holes. Try finding a comfy place on deck to work because it might be difficult to move a large sail down below. And remember that “a stitch in time saves nine”!

Patch and Glue

Sail damage can be also caused by a tear to the sun protection on roller-furling headsails. If that happens don’t put new holes in your sail in order to stitch up the tear. This will be really time consuming. Use instead some sticky-back which definitely is an efficient and fast solution. Although you have to take the sail down and put it back up to do that, sticky-back is the answer to this problem.

The first step is to cut the corners of the patch round in order to keep them from peeling off the sail. Then clean the whole area from the repair with acetone, and once the patch is ready, rub from the center to the edge with a scissor handle in order to make sure that it’s totally adhered. Furthermore, sticky-back patches work efficiently for small holes in the actual fabric of the sail. If any holes appear in the fabric then use patches on both sides of the sail, an inch or two larger than the rip in all directions. Keep in mind to slightly counterbalance the two patches so that the load won’t spread out around the repair. Also, take with you ripstop sticky-back to match the colors on any downwind sails, as well as small, pre-cut round patches, which can be practical for small holes in nylon sails.

A lot of spinnakers are no longer stitched and are put together just with tape, so if you need to make a repair it’s a particularly easy task. For most repairs a sticky back spinnaker repair tape is fine. Try not to change the panel’s shape and don’t use too much cloth for the patch. This way you’ll avoid generating unnecessary loads and stress lines. Instead, use the same amount of cloth for the patch so it moves and stretches simultaneously. Also, in case that a tear passes through the panels, repair one panel at a time and not all together. This way each panel is going to move and stretch as it was designed to.

One of the things that need occasional repairs on your sails is fabric. Fabric is one of the most vulnerable parts of your sails. Most of the time, when a sailboat uses its slab reefing it will subsequently wear out the webbing attachments to the tack rings. Therefore a failure of the webbing connection to the mainsail luff slides will be caused. As I’ve mentioned before, the most practical and easy solution to this is to be equipped with twine, a webbing, a needle, and a sailor’s palm . In case you don’t have the correct size of webbing, then Spectra cord can attach a slide fairly well.

These repairs are permanent and won’t take you more than an hour. Another sail damage for many sailboats with full-length battens might be caused by the connection point between the batten and the luff track on the mast. The best thing to do if that happens is to apply West System epoxy along with 3M adhesive sealant 5200 fast cure . This will untie your hands and is also an easy task to perform.

Common Damage Areas

- Spinnakers : Anything sharp can damage the spinnakers. Especially near the boom, so check that everything is taped up. Also, spinnakers tend to get caught between the shrouds and above the spreaders so consider closing off this gap with a bungee.

- Spreader and Rig Chafe : When you’re sailing downwind the mainsail spends a lot of time relaxing on the rig. Keep in mind to fill your spreaders with pipe insulation. Moreover, consider having extra reinforcement patches for the spreaders on the batten pockets and at each reef point.

- Spreader Ends : Always reinforce the sail and put smooth cages around protrusions. In addition, wrap foam around your spreader caps on long voyages.

- Bottom of the Headsail : Try to lower the halyard enough in order to reach the damaged section. Then reinforce with a sail repair tape . In case the conditions don’t favor you to do so, keep a wrap in the sail to take the pressure off the damage.

Summary – How to Repair the Sails

All this is much easier if your sails aren’t damaged in the first place. But, I know for a fact that sometimes you can’t prevent it from happening. In any case, always be alert to what is going on with the rags. Moreover, always carry a sail repair kit (link to Amazon) on board especially for long-distance cruising. Before leaving for any long trip have also a sailmaker service to check your sails for any weak points. Last but not least, in case that your sails are damaged at sea reinforce any loose stitching immediately and tape both sides of repairs to ensure extra strength.

Peter is the editor of Better Sailing. He has sailed for countless hours and has maintained his own boats and sailboats for years. After years of trial and error, he decided to start this website to share the knowledge.

Related Posts

How Does a Boat Sail Upwind? Unveiling the Mechanics of Against the Wind Sailing

How Does Sailing Work? The Physics of Sailing

Best Non Skid Boat Deck Paints

How to Restore Teak on a Boat

- Buyer's Guide

- Destinations

- Maintenance

- Sailing Info

Hit enter to search or ESC to close.

The Worldwide Leader in Sailmaking

- Sail Care & Repair

- Sailing Gear

- Sail Finder

- Custom Sails

- One Design Sails

- Flying Sails

- New Sail Quote

- 3Di Technology

- Helix Technology

- Sail Design

- NPL RENEW Sustainable Sailcloth

- Sailcloth & Material Guide

- Polo Shirts

- Sweaters & Cardigans

- Sweatshirts & Hoodies

- Accessories

- Mid Season Sale

- Mid & Baselayers

- Deckwear & Footwear

- Luggage & Accessories

- Spring Summer '24

- Sailor Jackets

- Maserati X North Sails

- NS x Slowear

- Sailor Jacket

- Sustainability

- North Sails Blog

- Sail Like A Girl

- Icon Sailor Jacket

- Our Locations

- North SUP Boards

- North Foils

- North Kiteboarding

- North Windsurfing

SAIL FINDER

SAILING GEAR

COLLECTIONS & COLLAB

WE ARE NORTH SAILS

ACTION SPORTS

Popular Search Terms

Collections

Sorry, no results for ""

THE WORLD'S BEST SERVICE

SAIL CARE & REPAIR

On Your Team, At Your Service

WE'RE HERE FOR YOU

North certified service.

Sails are a major investment, and North Certified Service experts are committed to helping you maximize their performance and lifespan. Our global network of service lofts puts North Sails service and support within easy reach no matter where you are. Every sail serviced in a North loft undergoes a thorough inspection designed to identify maintenance issues early, so they do not become major problems later on. Find your closest loft and get in touch today.

WHAT TO EXPECT?

Our expertise, customized.

With the most experienced team in sailmaking, North Sails is positioned to deliver expert repairs, maintenance, and upgrades in a timely manner. We wrote the North Manufacturing Blue Book, the industry benchmark for quality control, and we adhere to its strict standards for each and every sail that’s repaired in a North loft. Whether you need an emergency repair or annual washing and storage, our North Certified Service team will keep your sails looking their best.

BLUE BOOK STANDARDS

The Blue Book is the most comprehensive documentation of sail construction standards ever written. Our manufacturing and service sites around the globe depend on the Blue Book to build and repair a consistently excellent product. It is our clients’ guarantee of superior quality, durability, and performance in every North sail.

LOCAL LOFTS, GLOBAL SUPPORT

Your local service team is ready to provide you with our signature Certified Service. Get in touch with your local team today to schedule an appointment. You can drop off your sails at any North Sails loft or ship directly to us. Thanks for helping us help you keep your sails in top condition!

NORTH SAILS CERTIFIED SERVICE

REGATTA REPAIR

North Sails Certified Service Experts will repair your sails overnight. Our Service van is on-site at select events, offering regatta venue pick-up and drop-off. Tears happen, but they shouldn’t leave you without a key piece of race inventory.

ANNUAL INSPECTION

An annual inspection of your inventory will aid in extending sail life and maintaining peak performance. Every sail that is serviced by North undergoes a thorough inspection designed to identify maintenance issues early, so they do not become major problems later on.

ONE YEAR FREE SAIL CARE

North Sails proudly offers one year of sail care and repair free with the purchase of a new Cruising, Racing, or One Design sail. This program is honored anywhere in our worldwide network of sales and service locations.

TERMS & CONDITIONS

SAIL CARE TIPS

Time for a tune up.

During our comprehensive inspection, the North Sails team will also check if any adjustments could help your sail perform its best. Regardless of what your sail needs, we've got you covered. Your local loft will keep your sails looking best all season long. Get in touch for a pre-season race upgrade or before you dock off for your next cruising adventure.

OUR SERVICES

Sail repair, sail inspection, race upgrades, seasonal sail care, sail washing, get in touch, schedule your service, one year free sail care: terms & conditions.

Valid for one year (12 months) from the ship date. Valid on all boats with a luff length up to 22 meters. Includes all One Design sails. You will automatically be registered for one year (12 months) of free sail care when your new sail is shipped. Normal wear and tear is covered. Includes end of season consultation and sail check by North Sails Certified Service team. Clients are responsible for the transportation of sails to the local North loft.

One Year Free Sail Care does not apply to the following: Overnight Regatta Repair, North downwind sails used for racing, sail washing, shipping or delivery, aftermarket upgrades or retrofitting performance reshaping. If damage to your sail approaches or exceeds its current value, the sail may be deemed not repairable.

- Refresh page

Sail Repair What to Do and How to Do It

Most sailors approach sail repair with the same confident enthusiasm with which they might attempt brain surgery. This sense of foreboding often benefits die saibnaker (who, as a result, gets a lot of business), but not the offshore cruiser whose self-sufficiency in every aspect of maintaining his/her vessel and its attendant gear is vitally important.

There's a mystique surrounding sails — perhaps since their operating principle (turned 90 degrees) consists of the same magic that keeps airplanes in the sky. However, fixing sails really is straightforward — trust me.

The first step in sail repair is assessment: ascertaining just what needs fixing — and in some cases if the sail is worth putting time and materials into.

The initial clue regarding a sail's condition is its age. Dacron sailcloth will last approximately 8-10 years (longer if a sail's use is seasonal or infrequent). The amount of abuse and exposure to light a sail endures determines its useful life. Dacron has two major enemies: ultraviolet deterioration and chafe. The mo« effective maintenance routine for dacron is to cover it when it's not in use and to protect it from wear against spreaders, spars, running and standing rigging, pulpits, cotter keys, saikrack fittings, and hardware integral to the sail itself. A less obvious form of chafe is dirt and salt in the weave of the cloth — keeping a sail clean extends its life. Remember, flogging a sail may resuk in severe wear and tear, not to mention a resounding racket that assures unwanted attention on the helmsperson or sheet trimmer.

The assessment procedure is a thorough inspection which both local and coastal cruisers should do annually and offshore cruisers should conduct prior to each passage. The process begins with laying the sail out full on a clean, fiat surface. Location-wise, a sail loft floor is the obvious first choice. However, I've used domestic and foreign airplane hangars, runways, gymnasiums, bams, ballrooms, tennis courts, parking lots, pool halls, tropical resort lawns and golf courses to name a few. Be creative and improvise — you'll probably have to during the rest of the repair process!

. ' •■■vi|f'-'.-l ■• .1 '". c ''I 'i^V-iii -

,.. a flogging Mil, ma? resttfc ' in severe wear ana tear, not to mention a-j re so un di n g racket.. i •• '::' fe ■

When spreading the sail, make sure reinforcing patches at head, tack and clew, batten pockets and reef points are "up" for viewing. Remove sheets, battens and shackles. The sail is now ready for inspection.

.Use the following "laundry list" to assess your sail. Be sure to take careful notes and mark the sail with pencil so you can find the areas that need attention later.

1. Look for broken stitches in the head reinforcing patch.

2. Examine the headboard or head ring for elongation or deterioration.

3. Check the sailcloth, luff tape and/or boltrope around the headboard for wear.

4. Make sure slides in or around the headboard are secured well and that their method of attachment isn't chafing the headboard, sailcloth, or bail of the slide.

There was an English sailor who neglected the above item and, as a result, provided gainful sail repair employment for me while I was waylaid in Nassau. The slide at the head — where loading is the greatest — chafed through its seizing and departed from his mainsail after a transAtlantic passage. While cruising in the Bahamas, a gale in the "Tongue of the Ocean" blew up and the mainsail slide two feet down the luff from the headboard (not meant to take the load without a slide in the headboard above it) tore out. So did die grommet it was secured to. Almost immediately, moat of the slides and grommets below it yanked out and the boltrope was liberated from the mainsails leading edge as well. Had this mainsail been properly made with two slides at the head, handsewn rinp instead of grommets along the luff for the luff slides to be secured to, and a boltrope handsewn around the head and along the leech the length of the head reinforcing patch (see illus. 1) this probably wouldn't have happened. That's a construction story, not a repair story, however. Back to our list.

5. Check for chafe and broken stitches in the luff tape and boltrope both between and under each luff slide, working your way down the luff towards the tack.

6. Make sure each slide on the luff is in good condition, is seized securely to its ring or grommet, and that the seizing is not wearing the sail or slide.

C. Mainsail headboard with internal boltrope (production standard).

D. "Quick and dirty" headboard installation — no boltrope

E. Head of baaenless mainsail — note head ring instead of headboard.

IBus: 1: Construction options for the heads of mainsails.

7. Check that each grommet or handaewn ring on the luff which the slide is seized to is not corroded or pulling out.

8. Examine the reef reinforcing patch for broken stitches.

9. Make sure the reef tack ring isn't corroded, elongated or coming out of the tack reinforcing patch.

10. Examine the bokrope or luff tape for chafe where the reefing tackle might abrade when it's engaged.

11 Observe the tack reinforcing patch for broken stitches.

12. Make sure the tack ring is in good condition and securely in place.

13. Note if there is chafe on the ckxh, boltrope or leather around the tack ring.

14. Proceed along the foot looking for broken stitches and chafe in the dacron tape or boltrope.

15. If there are slides on the foot of the sail, make sure they are in good condition and properly fastened to the sail.

16. Make sure grommets or rings along the foot which slides are attached to aren't corroded or pulling out.

17. Monitor clew patch for broken stitches.

18. Note chafe in the sailcloth, boltrope or leathers around the dew ring.

19. Make certain clew ring is in good condition and securely in place.

20. Observe the entire leech, noting broken stitches in the leech hem.

21. See if the leech line inside the leech hem is chafing through the hem.

22. Ensure that the leech line cleat is in operable condition.

23. Check to see if the leech line works (i.e. tightens the leech when pulled).

24. Examine stitches in the reef reinforcing patches on the leech.

25. Survey the condition of the sailcloth around reinforcing patches.

The importance of the above item became all too clear to me while aboard a schooner in the Bahamas. A controlled jibe shockingly resulted in the sail splitting from leech to luff. It was blowing hard and we were reefed. The tear began in the sailcloth directly above the reef reinforcing patch and continued lightning-bolt style, 4-6" up to the seam above the reinforcing patch and shot across the entire width of the sail in seconds.

Almost immediately, most of the slides • and grommets below it yanked out and the boltrope was liberated from the mainsail's leading edge as well. -r'.

Had we observed the weakened sailcloth surrounding the reef reinforcing patch and added a larger "cover patch" over the original reinforcing, this disabling circumstance could have been avoided. Repairing the sail was no minor feat and required usurping loft space, time and took from the British America's Cup Lionhart syndicate's boatyard complex. I still consider this a diplomatic miracle. The logistics of coming an<l going with a 500 square foot mainsail in pieces by overloaded dinghy to avoid being in the loft when the syndicate needed it is a story in itself — but back to sail assessment...

26. Look for chafe around the reef ring that might be caused by reefing tackle.

27. Observe condition of the reef ring.

28. Carefully monitor batten pockets for chafe or holes on both sides of the sail.

29. Having arrived back at the head, walk or crawl along each seam looking for broken stitches.

30. Check each panel for tears.

31. Make sure the stitches that hold reef point reinforcements in place are in good order.

32. Make sure reef point rings or grommets aren't corroded or pulling out.

33. Congratulate yourself! You've just completed a thorough inspection of your sail; it's not often in life that we confront thinjp far bigger than ourselves.

A. Outer square is the seui-to line with strike-ups. Inner square is the cut line (the tear will be cut out of the sad doth along the cut-lines)

B. The patch in place may be sewn by hand (as shown) or zig-zag machine.

Illustration 2: T.V. screen patch.

Htadsai! inspection is a similar process: examine comers, edges, and body of the sail for broken stitches, chafe, or tears and go over hardware (hanks, grommets or nn^) for wear. In both cases, once problems are determined, repairs and/or reinforcements may be made. Now that we've covered assessing the condition of the sail, let's take a look at dealing with the weaknesses we've uncovered.

Holes in the body of the sail may be repaired using the "TV screen" patch.

Broken stitches can be repaired with dacron twine or thread either by hand or using a zigzag machine. The best, although not the fastest or most practical, method is to follow the old needle holes. The proper handsewing stitch will be discussed in another installment of "Confession»,'' but it's shown in the handsewn T.V. screen" patch illustration (see illus. 2). V-69 dacron thread with a 110 needle or V-346 or 3-ply dacron waxed twine with a #16 or #18 needle are appropriate for restitching. with machine or by hand respectively. Begin by sewing on top of 2-3" of the remaining

"good" stitches. Continue over the broken stitches and finish 2-3" into the "good" stitches on the other side of the worn area.

Holes in the body of the sail may be repaired using the 'T.V. screen" patch. Measure the six of the hole or tear and cut out a piece of dacron of the same weight as the sail. The patch should be square or rectangular in shape and 1-1 1/2" larger than the hole or tear on all four sides. Tne larger the hole, the more important* V becomes that the weave of the patch line up with the weave of the sailcloth underneath it. In this case, youU want to match the "grain" of the patch with the sail before cutting the patch to size. It's best to cut dacron with a "hot" gun or knife which both cuts and seals at once, preventing cloth from unraveling at its raw edges.

Once the patch is made and the sail is lying flat, hold the patch in place with pushpins and carefully draw around it. A sailmaker has two aids to sewing navigation — the "sew-to" line and "strike-ups." The sew-to line is the one that the patch will be sewn along — the one drawn around the patch while it is pushpinned in place. Strike-up* are short marks (1/4-1/2") made perpendicular to the sew-to line to ensure that the patch is sewn in evenly. By matching the strike-ups as one sews along the sew-co line it's assured that the patch will be stitched in the desired location. But, we're a little ahead of ourselves.

Once sew-to lines and strike-ups are drawn around the patch, remove the pushpins and patch from the sail. Neatly cut (preferably with a hot gun or hot knife) a rectangular or square hole 1-1 1/2" inside and parallel to the sew-to line. The patch can be sewn to the sail by machine or hand. When this is complete, the sail is sewn to the patch (see illus. 2). The result is a neat patch resembling a T.V. screen. I've often wondered what sailmakers pre-1940's called this type of repair. By the way, the rule about repairing holes is: if you can't stick a pencil through it, don't fix it.

If ultraviolet rot is the cause of holes or tears, you'd better order a new sail.

If a seam has come apart, use pushpins to align panels as closely as possible to their original position. Draw a sew-to line and strike-ups (you can use the original ones it they're still visible) and stitch the seam back together by hand or machine.

Chafe is usually the culprit in the above cases of broken stitches, tears, or opened seams — so find the cause of it. Use rigging

Continue reading here: Rig Maintenance

Was this article helpful?

Recommended Programs

Myboatplans 518 Boat Plans

Related Posts

- Sail Selection - Offshore Cruising Guide

- Heading up and bearing away

- Storm Jib - Sail Technology

- Skin Problems Coral Cuts - Offshore Cruising Guide

- Boat Preparation And Spare Parts List

- Boat Selection - Offshore Cruising Guide

Readers' Questions

How to fix a deteriorated head sail?

Inspect the sail thoroughly for any rips, tears, or holes. If you find any, you will need to patch them with a sail repair kit or a professional sailmaker. If the sail is severely deteriorated, you may need to replace it. Consider the cost and benefits of replacement compared to repairing the sail. If the sail is not severely deteriorated, you can try to clean the sail by washing it with mild soap and water. Rinse the sail thoroughly and allow it to dry. Once the sail is dry, inspect it for signs of UV damage. If the sail has been exposed to the sun for an extended period of time, it may have faded or yellowed. If this is the case, you can use UV protection sprays to help slow the degradation of the sail. If you decide to repair the sail instead of replacing it, use a needle and thread to stitch repairs to the sail. Make sure to use a strong thread that is the same color as the sail material. If you are still having difficulty keeping your sail in good condition, consider using a sail cover when not in use to help protect it from UV damage and dirt.

- No results were found.

Schedule Your Boat Maintenance Today

At SkipperBud’s, we are dedicated to providing exceptional service to our boat owners and have been for over 60 years. Our service department is staffed year-round and continues to deliver top-notch service on boats of any size.

Boat Services:

Whether you're looking for routine maintenance or a specialty repair, we have the expertise and skills to meet all your boat service needs.

Keep your boat running smoothly with our comprehensive maintenance services. We'll ensure your boat is in top condition, from engine checks to fuel system inspections.

Prepare your boat for the colder months with our professional winterization services. We'll protect your boat from freezing temperatures and potential damage, giving you peace of mind during the off-season.

Accidents happen, but our skilled technicians are here to fix any fiberglass damage. We'll restore your boat's appearance and structural integrity from small scratches to major repair

Enhance the beauty and functionality of your boat with our underwater lighting installations. Create a stunning ambiance and improve visibility during nighttime cruising.

Protect your boat from harsh weather conditions and UV rays with our boat shrink-wrap services. Our high-quality materials will keep your boat safe and secure during storage or transportation.

If your boat's hull has suffered damage, we have the expertise to restore it. Our professionals will assess the extent of the damage and provide effective solutions to get your boat back on the water.

When your boat's engine needs attention, our experienced technicians are ready to diagnose and repair any issues. We'll ensure your engine operates at peak performance.

Give your boat a fresh new look with our body paint services. Whether you need a touch-up or a full re-painting, our skilled painters will make your boat stand out on the water.

From wiring repairs to electrical system installations, our technicians have the knowledge and expertise to handle all your boat's electrical needs.

Enjoy a superior onboard entertainment experience with our AV installations. We'll set up high-quality audio and visual systems tailored to your boat's specifications.

If your boat's woodwork needs attention, our craftsmen can restore or replace damaged components, ensuring your boat maintains its classic beauty.

Enhance your boat's functionality with our platform installations. From swim platforms to fishing decks, we'll customize solutions to suit your boating lifestyle.

Ask a Question or Request a Service Appointment

- Boat Accessories

- Where to Buy

Special until April 30th: 30% off Solvent & Cleaner for the month of April. Use Code APR24 at checkout. *restrictions apply

Free ground shipping in the Continental US for any orders over $150!

Sailboat Deck Repair Guide...

Sailboat deck repair guide.

A sailboat is only as good as two things: the people sailing it, and the materials keeping it afloat. And though you may be an expert navigator and sailor, sometimes, the latter can disappoint you. That’s when it’s time to dust off the work gloves and consider handling some light repairs yourself. But how can you do a sailboat deck repair your own—and is it worth the extra time and labor? Here are a few tips for handling your sailboat deck and keeping it in tip-top shape.

Know Your Sailboat Deck—And How to Repair It

It starts with a basic understanding of your sailboat deck. According to Sail Magazine , many “decks are cored with end-grain balsa or plywood with a fiberglass laminate on each side.” If this is the case for you, you might notice that moisture can work its way into the core of the deck, which tends to rot the quality of the wood over time.

When the plywood core of the deck goes bad, it will generally be better to replace this plywood rather than work around the issues. However, try to get a second opinion before you start tearing out old decking. For example, you might be able to use:

Liquid LifeSeal® Sealant 5.2 fl. oz. Clear

Stainless Steel Cleaner 16 fl. oz.

Related blogs, thanksgiving trivia.

Thanksgiving is one of America’s oldest and most loved holidays. Even though the story is steeped in a dark history […]

Detailing Your Boat

There’s nothing better than hitting the water in a beautiful boat. A warm summer day with the sun shining, there’s […]

How To Properly Clean Your Boat Trailer

We all know that cleaning your boat is important to not only keep it looking great, but to also ensure […]

All products proudly made in the usa

We are proud to be the largest facility of its kind on the Gulf Coast. With over 20,000 square feet of repair space located in Kemah, TX, we are equipped to handle many major jobs and large vessels that other facilities simply cannot. We specialize in the repair, refurbishment, and customization of performance, fishing, and sailing watercraft. Our experts in fiberglass, Kevlar, carbon, polyester, epoxy, and paint can handle jobs of virtually any size and scope to meet your specifications. Our 80’ x 25’ indoor paint booth allows us to paint anytime in any weather. All of our mechanics are factory certified and trained in Mercury, Mercury Racing, Yamaha, and Volvo-Penta gas engines. Whether you need an oil change, re-flash, or a re-build, our mechanics are qualified. Bring us your high performance racing engine, onboard generator, or A/C unit, and get back out on the water!

Our services

Outboard/inboard engine repair.

Whether its preventative maintenance your looking for or your having engine troubles our team can make sure you get back on the water quickly.

New and Used Boat Sales

We want the best for our customers and that is why we have selectively chosen to provide the Gulf Coast with Pathfinder and Maverick boats. Come by and see our inventory today.

Parts Department

With over 30 years of experience and the largest inventory of Mercury, Yamaha, and Volvo-Penta parts in Clear Lake our parts department is sure to have the part you are looking for.

Paint and Fiberglass

Our paint and fiberglass shops are equipped to handle any job. Our paint shop is unmatched on the Gulf Coast. Whether it be a cosmetic repair or custom fit parts we can tackle any project our customers throw at us.

Insurance Claims

We work with all major insurance companies to make sure you are treated fairly and your boat is repaired better then before your accident.

And Much More...

With the largest marine repair facility on the Gulf Coast we have got your power boats and sail boats covered. Our 25,000 sq ft facility contains a parts department, Engine Shop, Welding shop, Paint Booth, Fiberglass Shop.

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

What You Can Learn on a Quick Test Sail

Cabo Rico’s Classic Cutter

Bob Perrys Salty Tayana 37-Footer Boat Review

Tartan 30: An Affordable Classic

Preparing Yourself for Solo Sailing

Your New Feature-Packed VHF Radio

Preparing A Boat to Sail Solo

Solar Panels: Go Rigid If You have the Space…

Shoe Goo II Excels for Quick Sail Repairs

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

Worship Your Universal M-Series Diesel With the Marinized Kubota Block

Taking Care of Your 12-Volt Lead-Acid Battery Bank

Hassle-free Pumpouts

What Your Boat and the Baltimore Super Container Ship May Have…

Battle of the Teak Cleaners — Snappy Teak-Nu vs. Star Brite

New Seacocks for the Offshore Sailor

Bottom Paint Care

Quick and Safe Sail Cleaning

Are E-bikes Worth the Extra Weight and Cost?

How to Handle the Head

The Day Sailor’s First-Aid Kit

How to Select Crew for a Passage or Delivery

Re-sealing the Seams on Waterproof Fabrics

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Boat Maintenance

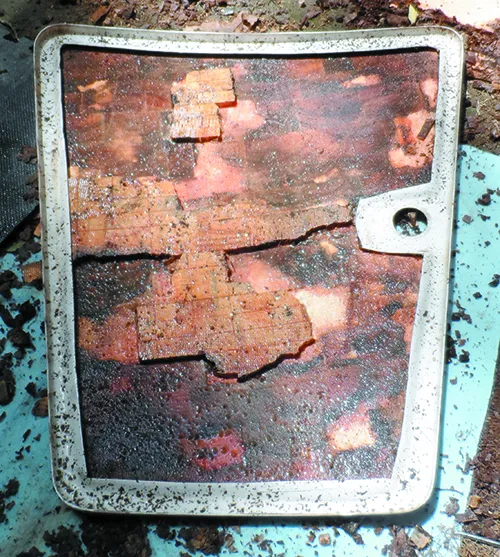

Step-by-Step Deck Core Repair

Last month we looked at the effectiveness of injecting resin to repair damaged core sections (see “ Can Glue Injection Fix Rotten Core ,” PS July 2018. This month we’ll review the more robust repair option—replacing the bad core.

The factory skimped on resin when laying up the internal skin of the anchor locker hatch on our Corsair F-24 test boat. The goal was to save weight, but the result was hundreds of pinholes, which over the course of thousands of warming and cooling cycles, sucked in a substantial volume of humid anchor locker air. The core became damp, bacteria moved in, and the balsa decayed to the consistency of garden mulch. Small wonder the hatch bent noticeably under foot.

Fortunately, the skins had not yet cracked. The other positive was that the hatch could be taken home for renovation, and that makes any job easier.

When repairing deck core, work can proceed from either the interior side or exterior side. Working from the exterior means your repair will need to match surrounding skin, whereas interior work is usually hidden from view.

For deck repairs, working from the outside means that gravity is on your side. The old core doesn’t land on your face as you remove it, and bonding in new core material is straightforward.

Working from the inside requires removing interior liners and modifying your laminating technique. Larger jobs tend to favor working from above, while small jobs go faster from inside. It all depends on geometry. In our case, we just flipped the cover over.

We cut away the skin using delicate, shallow cuts with an angle grinder. A vibrating multi-tool with a carbide blade is handy for small areas. The skin was then peeled back using a dry wall knife and a pair of pliers.

If it is undamaged and you are working from the top side, save this for later reinstallation. It will preserve the non-skid pattern and smooth curvature in the corners. Even when you are careful, thin skins are often destroyed during removal process, which means you’ll have to laminate a new one—something to consider when deciding which side to work from.

Whichever method you choose, be sure to wear gloves while laminating. Change the gloves every 10 minutes or whenever they begin to get sticky; if glass fibers are sticking to your fingers, you need new gloves. Likewise, have a stack of disposable brushes and polyethylene spreaders available.

Cleaning Out Old Core

Some of the old core will fall out, bringing comfort that you are doing the right thing. Some will come out with a scraper. We’ve found a wire cup brush, in either a cordless drill or angle grinder, makes fast work, with less risk of cutting into the second skin than with vigorous use of a scraper or chisel.

You don’t need to remove undamaged core; when it gets really difficult to remove, you’re probably done. We left some core, after determining that it was like new and that we couldn’t remove it without damaging the skin. Allow the panel to dry.

1. A cutting wheel was used to trim the outer laminate to access the core.

Bonding New Core

You can use either polyester or epoxy resin (see Inside PS blog post “ Epoxy Versus Polyester Resin ”). If you’ve worked with neither before, practice on some sample laminates.

Some sections could be solid glass instead of core. Lay those areas up with cloth or possibly Coosa Bluewater 26 (see “ The Multipurpose Core ,” PS February 2020). For cored areas, coat the sections of replacement core with resin thickened with colloidal silica to a peanut butter consistency. Press into place with a grooved laminating roller.

Use lightweight cores for overhead panels. Plywood is not recommended. Marine core is typically scored with kerfs and attached to a scrim backing so that it can follow curves. If the curve is concave, the kerfs will open the blind side, so be certain to apply enough thickened resin to fill these kerfs as they open.

There is no reason to apply core in large sections, since it is scored anyway. Small sections, generally not much bigger than 6 inches square, are easier to manipulate. Cut smaller pieces to fill the larger gaps, and then spread thickened resin over the entire area using a flexible spatula, forcing it into the remaining hair line cracks. Allow to cure.

Use 60-80 grit on an orbital sander (or a disk grinder with a very light touch) to sand the new core smooth. Even if you matched the original core thickness, there will be irregularities resulting from bumps of old resin and angles from the core.

Laminate a replacement skin, matching the original schedule. Several layers of 17-ounce biaxial cloth with ¾-ounce mat attached (1708), followed by a single layer of 6-ounce finish cloth is common on cruising boats. Smaller boats may use only a few layers of 6-ounce finish cloth. Bevel the core edges to a 10:1 taper.

From the Inside

If you are working from the inside on an overhead panel, lay the cloth on a plastic disposable work surface and pre-saturate the fiberglass cloth, using a squeegee and roller, before placing on the ceiling. Some like to do this on a bench outside the boat and carry the sections in on waxed paper.

Don’t attempt to saturate the cloth directly on the surface; the resin will drip all over you and the glass will keep falling off.

Rub the pre-wetted laminate down firmly with gloved hands and a roller until it begins to cure. If applying more than a few layers overhead, allow the initial layers to gel. This prevents the whole mess from falling off in a sticky pile. Allow to cure.

Use vinegar to wipe surrounding areas that were not covered with drop cloths, being careful not to get any on the bond areas.

From the Outside

If you are reusing the old deck skin, carefully grind the core to fit the original skin, test fitting frequently. You will add thickened resin to bond and fill low areas, but there can’t be any high spots and it is best if the fit is very close.

Unlike a new skin, you won’t be able to roll it in for a perfect bond. This is why we dislike this method other than for very small sections. Press the skin in place, weight it down it with sand bags, and hope for the best.

Finishing and Cleanup

If you are working from the inside, all that remains is to grind it reasonably smooth and replace the liner or paint to match. If you worked from the outside, bevel the joints 10:1 with a hand grinder, add fiberglass tape to match the original thickness, and finish with gel coat or paint.

Clean your tools with vinegar. As long as the cure is not too far alone, vinegar stops the chemical reaction and eliminates the stickiness, allowing clean-up with soap, water, and a brush.

PS Technical Editor Drew Frye is the author of “ Circumnavigating the Delmarva—a Guide for the Shoal Draft Sailor ,” available for Kindle through Amazon.

RELATED ARTICLES MORE FROM AUTHOR

Injectadeck has very specific instructions, it looks like they used it like Git’Rot’ against wet wood? That was not a proper demonstration of the process of injectadeck. I have been using it for three years on several boats. The aforementioned product doesn’t work at all nothing can soak into wet wood or stick to its slime. Injectadeck adheres fiberglass layers together very well, displaces water, hardens in a void.

(Inject-a-Deck was reviewed in “Can Glue Injection Fix a Rotten Core,” July 2020)

Inject-a-Deck can work. There is no question it can firm up a mushy deck and that it is much easier to use than other methods. But we tested it a number of times, in several ways (wet and dry) and concluded that other products were stronger and better suited limited repairs and areas where great strength was required. In fact, we warmed up to the idea that injecting epoxy and Git-Rot is probably not the best method for larger areas of extensive damamge or rot, that the repair materials does not need to be strong like epoxy, only as strong as the original core, and that foaming products, including the original Gorilla Glue, have considerable advantages.

The best repair method is core replacement, but even that method must be approached circumspectly. We recently reviewed a “professional” repair to a PS test boat and found that the contractor had made critical errors, resulting in a repair that was far weaker than what he started with. He hid his tracks well enough that any surveyor could miss the hidden damamge. The result was a sudden failure of the core repair underway. * He reused the original skins by gluing and fairing the edges together, without scarfing in reinforcing lamination. Invisible joints that were very weak. * Cut through critical carbon fiber reinforcements buried within the laminate and did not replaced them. You never know what is inside the deck, and it apparently did not concern him when he got black sawdust, or when he pealed the deck up and saw the carbon plate.

So injecting foam, such as Inject-a-Deck can fall within the “do no harm” philosophy. You won’t hurt anything. It would have been much better, in this case, if the contractor had just injected foam, rather than cut through good laminate he was not committed to properly replacing. Sometimes you don’t know what you are getting into.

Bacteria do not cause core decay. The statement: “The core became damp, bacteria moved in, and the balsa decayed to the consistency of garden mulch.” is misleading because 1) the damage is caused by fungi, not bacteria, and 2) the fungal spores have inhabited the balsa ever since it was changed from being a tree to being small blocks. The spores are patiently waiting for the substrate to become damp to the degree that they can become active.

Good point on the fungi, although that is only true to a point. Rot results from a mixed community of bacteria and fungi, the fungi being more active in the presence of oxygen and during the initiation of rot, and the bacteria becoming more prevalent and active in anaerobic conditions (prevalent in cores) and as the core gradually becomes mulch. But yes, most of the damage is caused by fungi. I took too much literary license, and I knew better. In the end… wood rots. The distinction is mostly relevant when choosing a rot-preventative.

A good read. I’ve done everything from below with Vinylester resin. Of course, you need an excellent full facemask with the right cartridges. Good to know about the “professional” repair mentioned in the above comment. I’ve been “peg boarding” from the inside to dry out the core which did dry quite well with heat lamps (and a temperature gun to not get over 110 degrees). However, if the fiberglass flexed when pushing the drill to drill the hole, I just peeled that area and replaced the core. This winter I will work on the doghouse and this method of looking for some flex won’t work since the interior doghouse glass is thicker. Not sure what I will do.

The softening temperature of vinyl cores is about 190F and epoxy, gelcoat, and vinylester are are a bit higher than that. I would think 150F would be a safe temperature for drying core. I’m sure decks pass 110F in the sun all the time!

Drew I agree, and it’s good to know what you just wrote. And to your point on a hot sunny day in late August here in RI, in the afternoon, the deck was 116F on my temp. gun. The boat I’m working on came from Lake Lanier, Georgia, I’m sure it hit 110 air temp…

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

Beneteau 423: What You Should Know | Boat Review

Buying A Sailboat Is Scary! Yacht Broker Interview

The Great Loop – The Basics

Bottom Paint Showdown – Six Paints, One Winner!

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

- Service and Repair

Linthicum Sailmakers Serving Sailors in NJ, NY, PA, MD, & DE

Request A Quote Today

Linthicum Sailmakers, a family owned business, has been providing high quality sails and related services since 1966. At Linthicum Sailmakers we are not only committed to the craft, but also to making your sailing smoother and more enjoyable. We pride ourselves in serving you. That's why we keep the Linthicum Promise, a strong commitment to our customers to do what we say we are going to do, when we say we are going to do it.

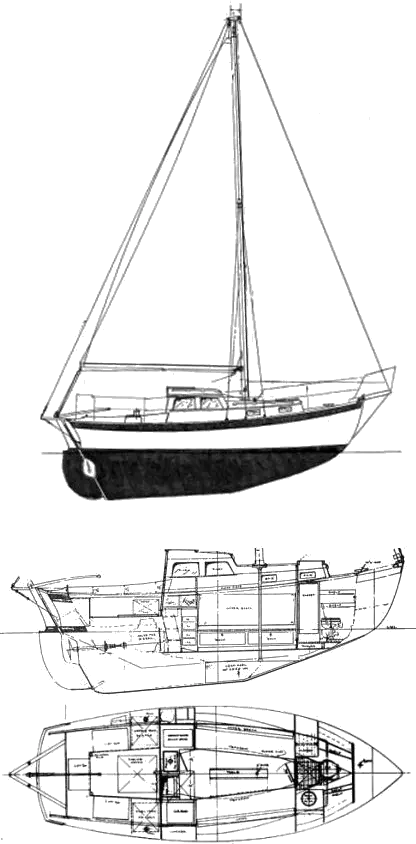

Linthicum's experience is extensive. Brad started with Sunfish sails in his basement in 1966. Since then he has made thousands of sails for boats from dinghies to ocean going cruisers. Need a Gaff sail? Battened sail? Multi-hull sail? Spinnaker? The company has an extensive database of rig dimensions and sail plans for thousands of boats. In addition, we now employ the latest in computer design and cutting technology. You will definitely find the right sail for your boat at Linthicum Sailmakers because we make the sail according to the boat dimensions and your requirements. Because each sail is hand crafted right here in our Somerdale, NJ loft, you can even stop by and check on its progress.

In addition to sail making, We offers expert sail repair, sail modification, cleaning, canvas work, rigging, and cushion cleaning. Linthicum Sailmakers is conveniently located near the Route 30 (White Horse Pike) exit of 295.

We'd be delighted to provide a quote on new sails in a timely manner. Please call us or fill out our easy contact form and indicate you'd like a quote.

Linthicum Sailmakers Inc. 607 Grace St. Somerdale, NJ 08083

Phone: 856-783-4288

Email: [email protected]

Hours: It's best to call.

Winter drop off and pickup hours are 9:30 to 1:30 weekdays.

We are also available evenings and weekends by appointment.

Serving the sailing community since 1966

Winter is here! It's a perfect time to beat the spring rush! Bring your sails, canvas and rigging needs in now so you'll be ready for spring splash!

Services include:

Sail Inspection and Repair

Sail Cleaning

New Sail Construction

Canvas Cleaning and Repair Including Window Replacement Rigging Fabrication

Call Today for Details and Free Estimates!

The Linthicum Promise

We do what we say we are going to do.

We do it when we say we are going to do it.

Rely on Linthicum Sailmakers.

Web View Mobile View

Wednesday Showroom Hours: 8:00 AM - 6:00 PM Service and Parts: 8:00 AM - 5:00 PM

Change My Store

- No results were found.

First-Rate Boat Repair and Boat Service Keeping You on the Water

Service and maintenance.

Routine maintenance is a requirement for factory warranties and key to making sure your boat is always ready. Learn more about the maintenance services MarineMax provides.

MarineMax Marinas

MarineMax is ecstatic to provide marinas in some of our locations that other a wide range of amenities. Check out your local marina today!

MarineMax Financing

Let our experts provide you with short-term and long-term, hassle-free financing packages to help you fund your boating dream.

MarineMax Boat Insurance

MarineMax is here to help navigate you to the right coverage options for your boat. Protect your investment with premium, competitively priced insurance options. Find out what coverage option fits your vessel.

Boat Parts and Boat Accessories

MarineMax has a full inventory of parts and accessories to repair and maintain your boat. Visit us in-store or online to learn about our wide selection.

Download the MarineMax App for iPhone and Android

Boating made easier! The new MarineMax app has one goal: to help you indulge your passion for boating.

MarineMax Experience

The best service network in the country.

Our customer commitment extends beyond creating a lifetime of memories on the water. We’re there to help with service, routine maintenance, engine upgrades, storage options and more. From providing world-class service with factory-certified technicians to finding marina slips and dry storage locations, your MarineMax team will always be there.

Closer Store Found

Based on your zipcode, [NewStoreName] should be your MarineMax store. We will update your store.

Before you Go...

Additional Services

Boat repair & maintenance services, maintenance & repair services.

Onyx services are designed to make your experience on the water the best it can be. We understand that boat maintenance can become time-consuming and a hassle at times. Our goal is to provide a fast, carefree, and professional service. Count on our certified repair team to ensure you invest all your free time enjoying your yacht, NOT working on it.

Onyx services are designed to make your experience on the water the best it can be.

We understand that boat maintenance can become time-consuming and a hassle at times. Our goal is to provide a fast, carefree, and professional service. Count on our certified repair team to ensure you invest all your free time enjoying your yacht, NOT working on it.

Request a Quote

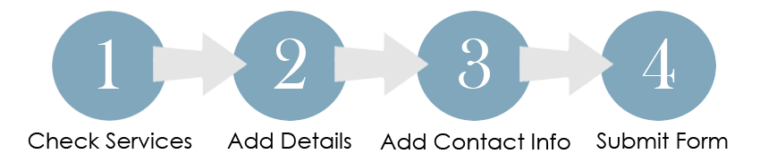

How it Works!

An Onyx specialist will contact you within an hour after submitting a request. For time-sensitive issues or, if preferred, please call

An Onyx specialist will contact you within an hour after submitting a request.

For time-sensitive issues or, if preferred,

please call (786) 505-4259 .

- (786) 505-4259

Yacht Repair & Prevention

Yacht painting, yacht detailing, cosmetic yacht repair, your services.

You may add specific requests and instructions using the text box below.

Contact Information

Onyx yacht painting, onyx yacht painting ____________________.

Protecting your investment in your yacht is a necessary part of owning a luxury vessel. Harsh saltwater conditions require a regular painting and coating treatment to keep your boat sailing on clear waters.

Painting/Maintenance options for your vessel include:

- Marine Paint (single or two-part)

- Gel Coating, Ceramic Coating, Bottom Painting, Varnishing and Carpentry

Prop Speed Painting

Painting and Coating will breathe new life into your vessel. It will prevent damage to the hull and arrest the growth of marine organisms that attach to fiberglass and metal. Barnacles, algae, seaweed and other marine organisms accumulate on hulls and eventually lead to surface drag, lower performance, decreased speeds, higher fuel costs and even damage to propellors and other underwater mechanics.

Our painting and coating solutions include modified epoxies, ablative, thin-film, soft and vinyl. Here is a rundown on the most popular options:

Marine Painting

When determining what paint/coating system is best for your vessel, the decision will come down to three elements: time, level of finish, and budget.

Traditional one-part paint (alkyd enamel) applies right from the dispenser and evaporates quickly. It has good weatherproofing qualities, and the base can be modified for gloss, hardness, or longevity by using various additives.

The two-part polyurethanes are formed by mixing components. That mix triggers a chemical reaction that forms the cure surface. When comparing the two processes, the two-part product dries quicker and offers a higher level of finish, a shinier gloss, color retention, hardness, longevity, chemical and abrasion resistance, and overall compound integrity. Consequently, the two-part process costs more and requires more time and labor.

Gelcoat Painting

A gel coat treatment is resin-based on often used on newly manufactured boats. Once applied, it dries into a hard, shell-like casing. Gel coating is designed to be UV protective and resistant to harsh chemicals. Since yacht hulls are often exposed to chemical vapors, this protection proves invaluable. A gel coat finish is durable and, when properly maintained, can last for decades without major repairs.

Ceramic Coating

Marine-grade ceramic coating is highly resistant to wear, scratching, and hull damage. The ceramic layer of protection protects paint and fiberglass. Ceramic coating protects at the molecular level with a comprehensive seal. Contaminants do not penetrate the surface, and any residue can be removed with a pH-neutral cleaner.

Bottom Painting

The bottom of a vessel, usually submerged in saltwater, is vulnerable to sea organisms, including acorn barnacles, zebra mussels, and microscopic bacteria that can cause hull drag, higher fuel costs and repair costs associated with the hull drag.

The correct yacht bottom painting treatment increases the longevity and performance of the vessel. The key ingredients in antifouling bottom paints include copper, biocides, algaecides, Teflon, vinyl, and proprietary two-part bottom coatings that create a hard, slippery biofilm that prevents organisms from attaching the hull.

One of the best ways to keep your props and other underwater metal in working order is by protecting them. One of the best ways is a professional application of Propspeed.

Propspeed uses a super slick “foul release” film that is safe for marine life. It is meant to last at least a year and keep running gear and any other underwater metals free of marine growth and protected against corrosion.

Vessels that sit in the water for extended periods have the greatest need for this type of protection. Our expert technicians can provide a professional application to protect your underwater metal.

Varnishing & Carpentry

Varnish Restoration

Onyx Yacht Detailing & Maintenance ____________________

Onyx yacht detailing & maintenance.

Much a luxury car, your yacht boat needs regular detailing and maintenance work to keep it sparkling on the seas and humming along the waves. Detailing and maintenance include exterior boat detailing, washing, boat waxing, buffing, polishing, interior detailing, and monthly systems check.

Buffing & Waxing vs Polishing

There is an ongoing debate on buffing and waxing your yacht versus polishing it. Though similar, the processes are different. In the trade, professionals use polishing compounds, manual polishing, and rotary machines to buff out scratches. Most craftsmen use powerful buffing and polishing tools to remove blemishes, scuffs, oxidation, and other imperfections. Waxing usually follows the buffing process. Polishing a vessel restores the “good as new” finish. Using a high-gloss polish delivers a brilliant shine.

Additional Options

Other options include wet sanding and high-speed buffing to give your vessel a showroom look and erase oxidation stains and minor scratches on fiberglass and Gelcoat surfaces. While we are making the vessel’s exterior shine, we also inspect the vessel from top to bottom.

Monthly Packages

Onyx offers three monthly packages, in addition to our one-time services:

STAINLESS CLEANING PACKAGE

This package offers Exterior Cleaning & Detailing services once every two weeks as well as weekly Cabin Cleaning & Detailing services.

DEEP SAPPHIRE CLEANING PACKAGE

This package offers weekly Exterior Cleaning & Detailing services as well as weekly Cabin Cleaning & Detailing services.

ONYX DELUXE PACKAGE

This package offers weekly Exterior Cleaning & Detailing services as well as Cabin Cleaning & Detailing services twice weekly. The interior detailing treats all hard surfaces, including appliances and restroom fixtures, floors, blinds and cabinets.

Systems Check

Our comprehensive Systems Check includes checking the following:

• Alternator

• Navigation Lights

• Interior/Exterior Bulbs

• Bilge Pumps

• Instrument Panels/Electronics

• Solar Panels

• Fluid Levels

• A/C Units

• Wiring • Battery

• Alternator • Fluid Levels

• Solar Panels • A/C Units

• Bilge Pumps • Navigation Lights

• Belts • Interior/Exterior Bulbs

• Heads • Instrument Panels/Electronics

Onyx Yacht Repair ____________________

Onyx yacht repair.

Sometimes, repairs to your yacht go beyond the superficial and fall into the substantiative repair category. These repairs include fiberglass boat repair, gel coat boat repair, marine upholstery, teak repair and renewal.

Our craftsmen are highly skilled in repairing damage to your fiberglass or gel coat surface, whether dinged on a pier or scuffed on the rocks. We can also return your marine upholstery to its original luster and even tackle repair and restoration to teak, a classic favorite in yachting circles. Our corporate skillset includes lift and haul-out, carpentry, hydraulics, air conditioning, electrical and complete interior and/or exterior reconstruction.

Fiberglass & Gelcoat Repair

Marine Upholstery

Teak Repair & Renew

- [email protected]

- Privacy Policy

- Terms of Use

- Predeparture Checklist

The Yacht Rigger

Empowering Your Marine Adventures

Advanced Alternator Regulator

#1 Authorized Rainman Distributor in the USA

We’re committed to offer the lowest Rainman prices in the US!

Marine Solar & Electrical

Marine solar installations on all vessels

DIY Marina Wet Slips & Haul-Out Facilities

Slips can accommodate catamarans up to 55' with beam limitations at 30'

New Youtube Series

Join us as we venture into the world of Marine Professionals! Like Share & Subscribe!

The Yacht Rigger is a marine specialist group dedicated to marine upgrades and maintenance. From rigging, electrical, lithium batteries, solar, custom metal fabrication, air conditioning, deck hardware and much more.

We specialize in all types of yacht rigging, whether your boat is for cruising or racing, our team provides a comprehensive unbiased service tailored around you and your vessel. Please explore our services and products pages to discover what we have to offer.

Meet the crew

Featured Services

Rigging & lines, solar & electrical.

- Sailboat Arches

HVAC & Refrigeration

Quality brands.

High quality brands namely Blue Wave, Selden Furlex, Ewincher, Rainman, Spectra, Mantus, Harken, Waterline Design and more. We are currently expanding the store so keep an eye out.

Quality Services

At The Yacht Rigger we pride ourselves in offering top quality service, installation, and maintenance to a wide range of products and brands. Have a look at our lit of services below.

Marine Solar & Electrical Systems

The Yacht Rigger is proud to be the premier choice in Florida for marine solar installations on all vessels, from sailing catamarans, to cruising mono-hulls, to power cats and small motor trawlers. We’ve got your solar & electrical needs covered. Including new system installation, existing system troubleshooting, parts replacement, new system integration or additions, new battery banks and much more. Let our partnered ABYC certified technicians come out to take a look at your electrical needs and we’ll make sure you have an efficient, well integrated system up and running in no time.

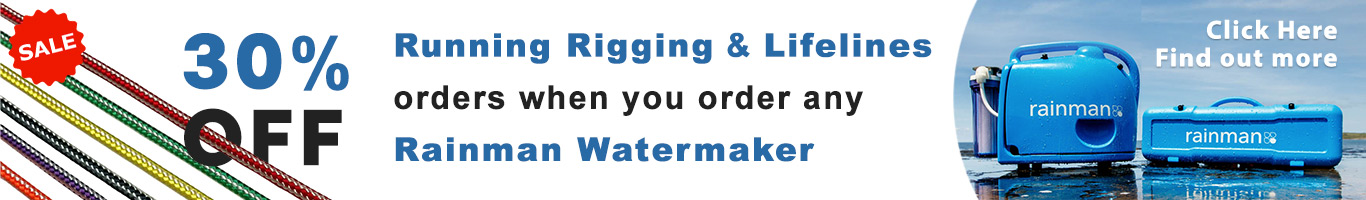

Standing Rigging Production Facility

With our Wireteknik A350 swage machine and a production shop full of swage fittings, spools of KOS Stainless steel wire and wire rope, and brand new chrome bronze turnbuckles by the dozen, we can produce standing rigging from lifeline size – up to 5/8″ (16mm) standing rigging. Competitive pricing and top quality parts mean your new standing rigging will be safe for many years to come.

We have a very large inventory of Blue Wave standing rigging components on hand at all times. See our Blue Wave page for more details on this top quality Danish supplier.

We ship anywhere, so send us your orders for standing rigging and we’re happy to produce your rigging and ship it out to you, or come see us at the boat yard!

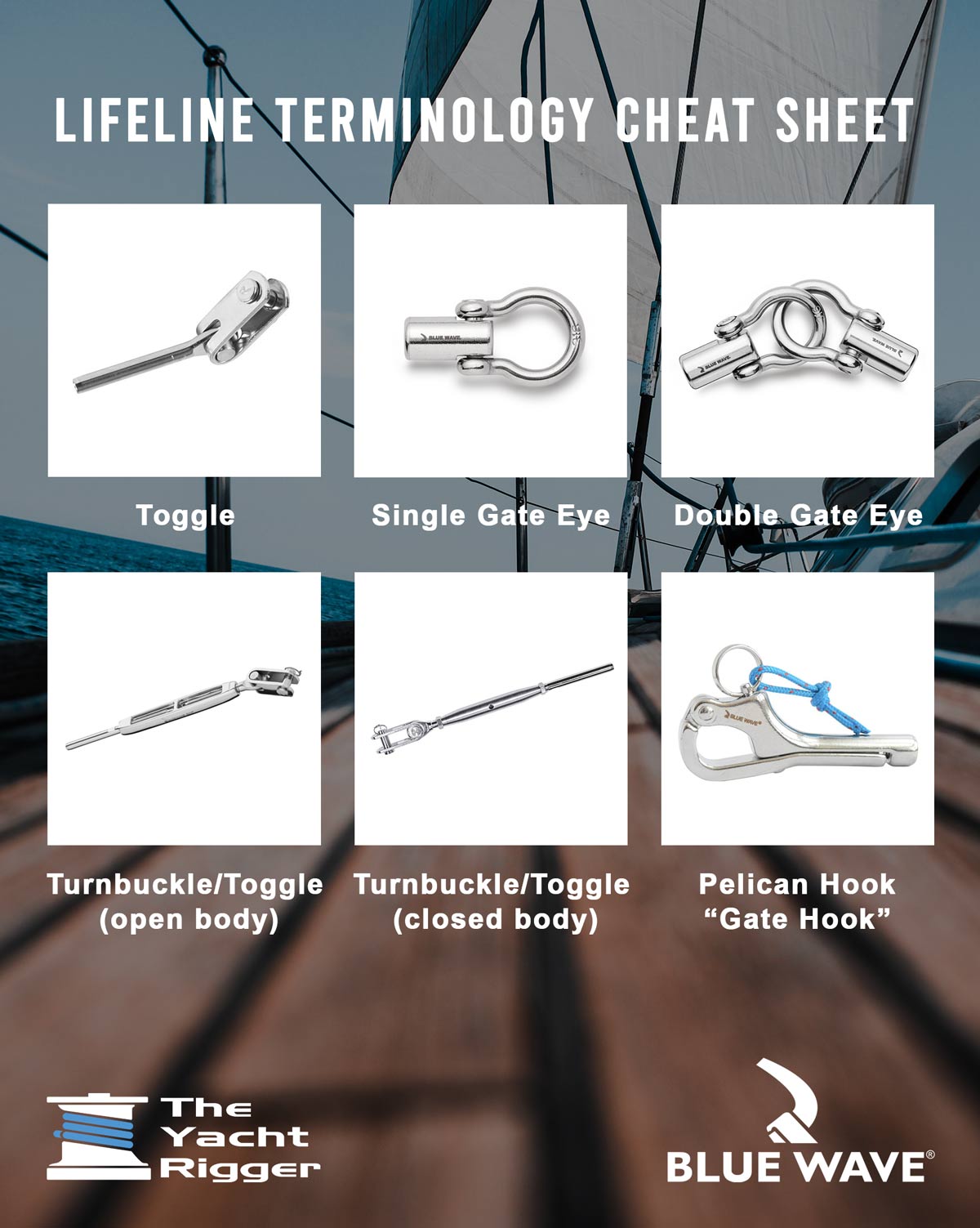

Lifeline Rigging

If you need your Lifeline rigging replaced, look no further. We offer full service Lifeline rigging replacement. We only use top of the line marine grade stainless steel products, and our A350 swaging machine can handle swaging up to 5/8″ (16mm) wire.

Let our team renew your Lifeline rigging and get back out on the water sailing safely.

Marina Wet Slips & Haul Out Facilities

In our wet slips we can accommodate catamarans up to 55′ with beam limitations at 30′. We have a large float bag on site for service work on catamarans such as thru-hull installations, sail drive removal, propeller work, and underwater light installations.

On the hard we are limited to a 16′ beam for haul out and offer full service bottom jobs as well as gelcoat repairs, propeller and shaft replacements, and even re-power projects (and more).

We do offer do it yourself “DIY” yard spaces, as well as DIY wet slip spaces, and all our wet slip spaces allow liveaboard and offer bathrooms with showers and laundry facilities.

Solar Frame & Arch Fabrication

We utilize the latest state of the art solar panels and build custom frames in house out of light weight marine grade bright anodized aluminium. (Stainless steel frame fabrication is also available if requested). Our goal is to maximize your vessel’s solar potential whilst maintaining minimalist concepts to create a beautiful, and highly functional end product.

Custom Frames Arches

Rigging Inspections & Consultations

The Yacht Rigger provides comprehensive rigging inspections on all masts to vessels located within our service area. We inspect all running and standing rigging. All rigging termination points are visually inspected. Sheave pins and sheaves inspected, spreaders, furler or headsail foils, and all gooseneck fittings. Electrical wiring is inspected for chafe/corrosion.

We also check all light fittings, blocks, cars, tracks, clutches, winches and any other hardware. A complete cleaning of all rigging ends, pins, and cars can be added if the mast is going into storage. We provide a detailed report of our findings, including suggestions for any additional parts and work required.

At the Yacht Rigger we also offer a consultation service designed to assist you with both troubleshooting as well as with selection of any new rigging parts, from winches or furling gear, to a new mast, no job is too big or too small. Please visit our Contact Us page and get in touch so that we can assist you!

HVAC (heat, ventilation, air conditioning) systems, helps to control the climate on your boat allowing you and your crew to enjoy the time on board all year long. Not only control the temperature on cold winters or hot summers, they also control the humidity levels, making the living area feel more comfortable and helping to keep the boat dry, increasing the life of electronics, fabrics, headliners, etc. reducing mold growth and other moisture related problems.

Investing in a new installation or upgrade of an existing one will extend your boating season and increase the value of your boat.

Winch Servicing

Servicing your winches regularly not only improves their longevity, but also greatly improves performance. Correctly cleaned and lubricated winches will operate faster, and require less force when grinding.

We can service all of your winches professionally, on site, in a matter of a few hours. We carry parts for most major brands and can source parts for almost any winch out there today.

Our riggers are highly competent splicers, capable of splicing any line in a given application. From basic polyamide docklines, to covered Vectran, we can assist you in selecting the correct line for the correct application. Be it a weight saving halyard for a race boat, or a topping lift for a cruiser, look no further than TYR.

Hardware Installation

At TYR we can supply all hardware relating to your mast and deck, for all brands of masts. Our team of expert riggers will guide you through getting the right equipment for your boat.

We supply many top of the line models of headsail furlers, including Selden Furlex and Harken. TYR can also provide servicing and spare parts for existing systems to ensure efficiency and reliability.

We supply a full range of blocks, clutches, cars and travelers from the leading brands Spinlock, Harken, Selden, and Ronstan. Be it a cruising boat wanting to maximize ease of use for all of running systems, or a high performance dinghy or racing yacht wanting to minimize weight, we will provide a product suited to your needs.

New Sails & Sail Covers

If you’re considering replacing your sails or sail covers, please get in touch with us through our contact portal. Our team has decades of experience in both cruising and racing and we’ve partnered with the most talented and detail oriented sailmakers and canvas specialists in the Tampa Bay area to offer you a comprehensive sail replacement service.

Our sail replacement service includes: Consultation – we’ll help you choose the sail material and cut that best suits your needs.

Measurement – if you fall within our service area we’ll come out to your boat and take precise measurements to make sure that your new sails perform optimally. We’ll also advise you regarding the variety of sail covers, mainsail storage systems, and sail furling systems available.

Installation – when your crisp new sails or sail covers are ready we’ll come out to your vessel and install them, to make sure they fit and perform exactly as needed.

Stern Arch & Davit Systems

If you are looking to store your tender on your stern, we have you covered. From large stern arches to smaller davit systems. We’ve partnered with suppliers from across the US to bring you the most cost effective, aesthetically pleasing, and practical solutions to this complex issue. We can also supply fully integrated solar and wind systems on top of our stern arches that will get you off the grid and ready to go out into the big blue!

Anchoring & Windlass Systems

We supply and install new windlasses, anchors, anchor chain, rode, and all the accessories in between. We can fabricate custom mounting platforms, install all the necessary switches, wiring, fuses, and additional batteries if needed.

Marine Electronics

At The Yacht Rigger we offer a comprehensive marine electronics service that includes new system installation, existing system troubleshooting, parts replacement, new system integration or additions, new battery banks and much more. Let our partnered ABYC certified technicians come out to take a look at your electrical needs and we’ll make sure you have an efficient, well integrated system up and running in no time.

Google Reviews

“ “ Stephen does regular work for me on rigging. He is very knowledgeable and dependable. First rate! ” Robert K

“ “ Steve and his crew listened to what we needed, then stopped by our just purchased 1997 Catalina 38 to look it over. In 10 minutes they diagnosed the issue, proposed a solution, removed the sail, gave me an estimate on money and time and off they went. Came in right on budget, hit the completion date on the mark, sent me photos to see the final product. Thoroughly professional and timely. I'd recommend these guys anytime, an will have them back on our boat as we need them for sure. ” Mike Conroy

“ “ Extremely knowledgeable in repair or upgrades to not just rigging, but all systems of sailboats. Professional and prompt service. These guys have helped my wife and I outfit our boat for live aboard cruising. From rigging replacement to solar panel install and also repair of systems specific to our boat, we couldn't have done it without them. Fair, reasonably priced, and always available for questions. 5 stars plus, nothing more I can say. ” Zach Duncan

“ “ These are the most professional guys I've met in the marine industry in St. Pete. They were very helpful in getting my boat ready for passage on a tight timeline. The job was done in time and on budget, but what really sets them apart is the fantastic communication. Highly recommend! ” Nate Mortensen

“ “ Great service. These guys are very knowledgeable. ” Pat M

Recent Posts / View All Posts

Contact number

We are monthly supporters. click below to donate..

- HVAC & Refrigeration Services

- Marine Solar

- Marine Electrical Systems

- Solar Frame Fabrication

- Standing Rigging & Forms

- Running Rigging & Forms

- Lifeline Rigging & Forms

- Anchor Chain & Rode Form

- DIY Marina Wet Slips

- Haul-Out Facilities

- Stern Arch & Davit Install

- Blue Wave USA

- Cyclops Load Sensors

- Robline Ropes

- Marlow Ropes

- Mantus Marine

- Tides Marine – SailTrack

- Anchor Chain and Rode

- Waterline Design

- Furlex Furling Systems

- Selden GX & CX Furlers

- Selden SMF System

- Bamar Products

- Hood Furling Systems

- RuuviTag Pro

- Victron & Solar Panel Store

- Kilovault Batteries

- Custom Fabricated Frames & Arches

- Mabru Air Conditioners

- Velair Air Conditioners

- RAINMAN WATERMAKERS

- Portable Rainman Watermakers

- Modular Rainman Watermakers

- Gasoline Rainman Watermakers

- Framed Rainman Watermakers

- Rainman Accessories

- Rainman Spare Parts & Consumables

- Spectra Watermakers

- Integrel Solutions

- Manuals/Catalogues

- Account details

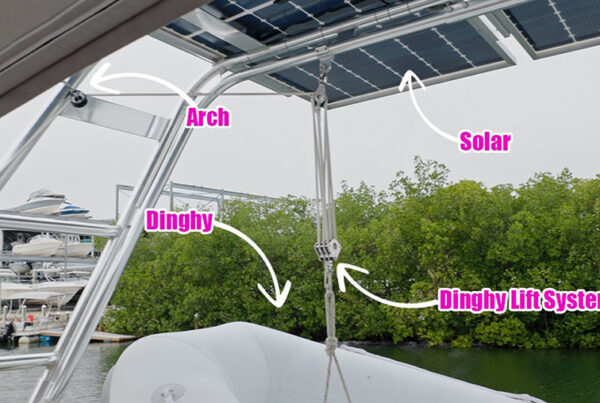

ARCH INSTALLATION TIPS

- Measure where you think The arch feet are going to land on the back of the boat, pick either the front or back leg landing positions and measure the span. Check for backing plate/nut access at these positions.

- Assemble the arch laying on dock and slide the sides into the bridge evenly until the leg span you measured is Approx 5-6” wider than your goal span. Tape the joints at the bridge using masking tape to stop it sliding further in when you are test fitting.

- Measure the “drop” from where you think the forward legs will land and the aft legs will land and trim the forward legs. Accordingly. I usually leave them a couple inches longer than I think they need to be, and do the final trim once I’m at the mocking up stage.

- Assemble the arch feet and install them, using string to secure them to the arch legs using a rolling hitch.

- Use a block and tackle or a truckers hitch to squeeze the legs together to match the span you are aiming for. No more than 6”.

- Hoist arch into position using topping lift or main halyard (and two people) and test fit. At this point you can measure exactly how much you need to trim off the forward legs to make the arch fit level.

- If the arch needs to sit lower, once you have it level, you can trim both legs the same amount. Keep in mind that as the arch gets shorter the span will narrow slightly due to the geometry of the arch.

- Once you like the position, mark the feet in their positions using sharpie and lower the arch back to the dock. Release the block and tackle and drill/bolt the bridge. Drill and epoxy/bolt the feet into position.

- Hoist the arch again and check all landing positions on feet one final time. Mark bolt holes on gelcoat and move arch out of the way for drilling. Try to pick the forward or aft feet and do them in pairs, pick whichever set you think will allow you to bolt it down securely then pivot the arch back or forward to do the other pair after (check orientation of arch feet for pivot ability).

- Through bolt all feet and tighten. If fitting to an uneven surface, back fill the area behind the plate with thickened epoxy.

- Tighten all bolts on foot bases.

Salt Creek Marina and Yard Rules & Regulations (DIY & Storage)

“Common Sense, Compliance with Laws, Consideration Toward Others” (January 1, 2023)

This agreement shall be effective on the date hereunder by and between the undersigned Owner or Agent of the vessel(s) hereinafter (“Vessel Owner”) described below and Salt Creek Marina, Inc. and The Yacht Rigger LLC located at 107 15th Ave SE, St. Petersburg, FL 33701.

8/21/2023 UPDATE – If a hurricane system becomes a named storm and your boat is in one of our wet slips you MUST move it back to its original berth. The boat is not allowed to stay. The owner is responsible for planning with their preferred captain, or The Yacht Rigger has two captains on staff.

1. Fees: The Yacht Rigger and Salt Creek Marina reserves the right to change its rates upon one (1) months’ notice.

- Monohull DIY Dry Storage will be $900 monthly or $225 weekly, with a minimum of 1 week required. After the first 4 weeks, the rate will increase by $50 per week, for the remainder of the boat’s duration.

- Monohull Wet Slip will be $1,100 monthly or $275 weekly, with a minimum fee of $100.

- Catamaran Wet Slip will be $2200 monthly or $550 weekly.

- Haul / Block / Relaunch – One Time Charge $12 per foot

- Emergency Haulout – $25 per foot

- Short Haul – – – Special Haul to be scheduled by The Yacht Rigger or approved contractor only + $175 contractor fee (includes normal haul out rate)

2. Insurance: Vessel owners must provide insurance with Salt Creek listed as additional insurer on their vessel before arrival. Vessels must always be insured.

3. Hurricane & Summer Storm Season: June 1 – November 30 Haul out boats for storage or DIY work on the hard during this time are required to remove all canvas (including but not limited to Bimini, sail covers, dodgers, e.g.) as well as all sails on the boom or furlers. Remove all moveable equipment: canvas, sails, dinghies from davits, cushions, water toys, grills, biminis, roller furling sails, etc. Canvas and sails must be stored below and not on deck. Lash down everything you cannot remove tillers, wheels, booms.