Cold Molded Construction

Cold molded hulls have been built since the technique was used for World War II planes—often using casein or urea-based glues. Today, one would use epoxy almost exclusively, benefiting from its superior bonding, gap-filling, strength and water resistance.

The temporary framework (or jig) will commonly allow for a permanent gunwale to be fitted as well as a keelson, as the diagonal veneers will be permanently attached to these.

Wood for the veneer strips is very critical. It must be cut flat with even thickness, be well seasoned and resistant to cracking. Western red cedar and mahogany are two good choices. Some builders even use thin, high quality plywood.

The pre-cut veneers (2–6 mm thick depending on boat size, bilge radius and stringer spacing) will typically be laid up about 35-45 degrees from the vertical and stapled to the stringers where they cross and also near both edges.

Veneer width will depend on the curvature of the hull, with more curvature requiring narrower strips. Knowing what radius various woods can bend will help decide the strip size and thickness for a particular shape.

This table is from a fine book entitled 'The Gougeon Brothers on Boat Construction' - with their kind permission.

If the staples are arranged in a row and a strip of tough strapping material laid under them, they will be much easier to remove without damaging the wood.

(This sketch also comes from the excellent book 'The Gougeon Brothers on Boat Construction' and shown here with their kind permission)

After the 2nd layer, modern builders are now often enclosing the whole surface with plastic and vacuum-bagging the bond to improve pressure between the surfaces while curing. But this requires that the working surface of the mold be made air-tight and that is impossible with an open frame+stringer arrangement. One interesting method (see URL below for Nexus Marine) is to seal the first layer airtight and then vacuum bag to that. Either way, if it can be done, vacuum-bagging is surprisingly effective and not that difficult either as long as certain precautions are taken (see separate article on this).

Some larger designs call for a 3rd veneer layer—perhaps even laid up fore and aft for appearance. In such a case, this could well be the hardest layer to fit, especially if the hull has a sharp radius in its section. Narrower strips will help in this case but that means more joints to fit. (I'd personally suggest to avoid a lengthwise veneer and plan on painting the exterior.) Once cured, the exterior is typically sanded and at least partly faired before removal. Cold-molding is good when you have a capable partner to work with as you can each work on strips, starting amidships.

Click here for clear photos of the process: www.sixrivermarine.com/Cold%20molding%20QA.htm www.nexusmarine.com/odysy_const.html (with vacuum bagging) www.bruceroberts.com.au/gallery/index.htm (see Roberts 24 and Roberts 25 wood)

Advantages are: If well executed, this system produces a very tough, long-lasting hull that is stiff and resistant to damage and rot. It requires only the minimum of internal stiffening. Still a useful option where labor costs are low or just not counted.

Disadvantages: The system is pretty labor intensive and solid veneers of moisture-resistant wood are also becoming expensive and difficult to obtain in some parts of the world. The system also requires a good, solid mould prior to construction, which has no further use after the hull is lifted off. The surface, both inside and outside, also requires a considerable amount of sanding and the outside will need additional fairing to get a professional finish. As this is more work than other competing systems, this system is now used less and less, except where labor costs are low or discounted. The Constant Camber system was first developed to try and overcome this high labor issue—see separate article.

"New articles, comments and references will be added periodically as new questions are answered and other info comes in relative to this subject, so you're invited to revisit and participate." —webmaster

"See the Copyright Information & Legal Disclaimer page for copyright info and use of ANY part of this text or article"

- Client Galleries

Our Construction Process

The crew, well versed in old-world craftsmanship and building techniques (the skill-set that is at the foundation of Van Dam Custom Boats), also embraces technology and innovative design as an integral part of the future of custom wooden boat building.

Technology, at the hands of a master, will not strip away the intricacies of custom handworkings in wood, but will assist in making it last longer and perform better. A balance is reached between function, performance and beauty. Our processes envelop them all.

Wood Composite Construction

It has been called a master craftsman’s art form. At Van Dam Custom Boats, we use the process of wood composite construction to build all of our one-in-the-world watercraft. This process involves the utilization of epoxy adhesive to laminate many thin layers of wood together – creating the hull and structural elements of our boats. By marrying legacy craftsmanship with sound engineering principles, we are able to construct vessels that are stronger, lighter and more durable than boats built via other methods. Van Dam Custom Boats are built for generational enjoyment and constructed to stand the test of time.

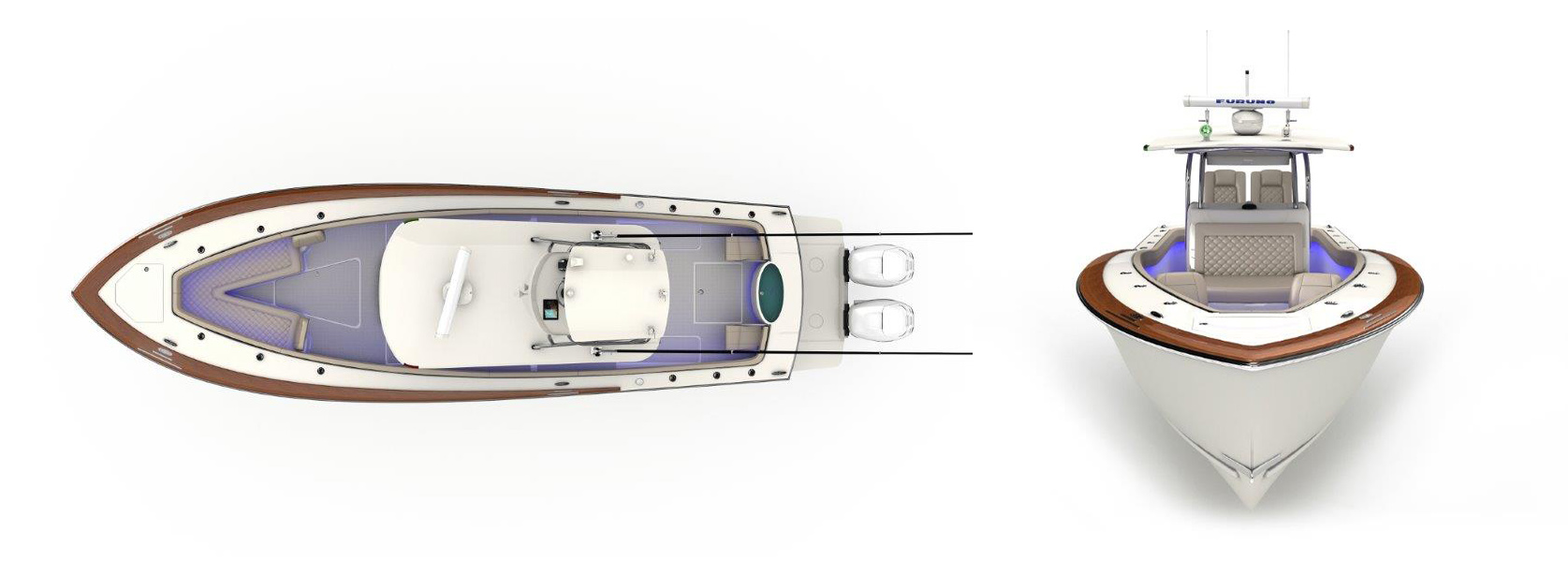

In the design phase we shift from 2D drawings to 3D virtual models, using state-of-the-art 3D computer aided design (CAD) software to detail every inch of your boat. Propulsion, systems and construction details are married with style and concept. There’s still plenty of creative work to be done here as the space evolves and design opportunities present themselves.

Systems Design

Every Van Dam boat requires its own unique systems package to meet the owner’s expectations of performance, function and capability. Whether it’s Garmin, C-Zone, Humphree, Seakeeper, Volvo or future technology, we design, program and thoroughly test each system to ensure they complement one another and operate in unison.

Innovations

At Van Dam, we continuously explore new horizons in recreational boating. Drawing inspiration from the automotive, aviation, and marine sectors, we integrate cutting-edge principles of design, engineering, and construction into our projects. Whether it’s pioneering digital switching systems, wake-adapted rudders, or advanced lighting solutions, we have the expertise to turn innovative ideas into reality.

Hand Cut Lumber

Every board that goes into our custom builds is craftsman selected and carefully sorted by characteristics that will dictate whether it is used for structure, cosmetics, or in some cases both. Each is hand cut and hand bent per design specifications, while attention is given to book matching the grain throughout the construction. Our wood is used as a unidirectional fiber as it is much stronger along the grain than it is across the grain. Engineering takes full advantage of this characteristic and while such precision takes time, it is what separates a Van Dam Custom Boat from others in the industry.

Artistry and functionality carry over to our metalwork, with intricate craftsmanship being a company wide offering. From hand polished cutwaters to custom shaped seating and framing adornments, all metal work is skillfully created on site. Design revisions, or improvements to performance, are made at the hands of our metal craftsmen, utilizing their natural talents and the state-of-the art equipment at their disposal.

Paint & Varnish

Finishing the areas of each boat that will rarely be seen, with the same care and meticulous standards as our mirrored exteriors, is one of many attributes that sets Van Dam Custom Boats apart in the world of custom wooden boat building. It not only guarantees the longevity of quality and function, it affords you peace of mind – your commission is of top-of-range craftsmanship, inside and out. It is not about simply finishing the build and moving on to the next project. It is about you, your expectations and your future enjoyment on the water.

We are no less meticulous in our approach to mechanical and electrical component construction. Power, performance and ease of use are integral aspects of your boating experience and Van Dam Custom Boats recognizes this area as a craft unto itself. Master Certified craftsmen in systems and electronics create and assemble the perfect inner workings, allowing you to control your boat effortlessly, safely and with confidence.

Pay attention to the details.

Do the little things right so the big things work out.

The best place to go with your idea for a dream boat is Van Dam Custom Boats. We were impressed as much with the total experience as we were with the end result. WOW’s on and off the water.”

– Chocolate Chip 3 Owner

HIGHER QUALITY, LOWER COST COLD MOLDED CONSTRUCTION

Todd French of French & Webb Boatbuilders in Belfast, Maine has been thinking about this for years. Dan Miller, of Belfast Boatworks, enthusiastically agreed to provide his workspace and skilled workers. What if there were a way of laying up a WEST-system yacht hull with something approaching the efficiency of laying up a fiberglass hull? They knew that it would require;

- An expensive, completely fair and “closed”, male mold. In fiberglass layup the same tradeoff is made in the industry― you acquire a very high cost but perfectly smooth mold, so that the individual parts that come out of the mold can be constructed quickly… you spend more money upfront in order to spend less money later and attract a bigger market. Alternatively, in the case of cold molded wood construction, this requires a male, not female, mold, and you end up with a hull that is perfectly finished on the inside, but must be faired and painted on the outside. Meaning such hulls will never be built as cheaply as can a fiberglass hull. But on a boat where the inside of the hull is always visible, like the LEVANT 15 daysailer, the tradeoff is that it is easier to fair and paint a convex surface (the outside) than a concave surface.

- A team of highly trained workers. This is not necessary in fiberglass construction- there are no time constraints (you can apply as few or as many layers of cloth as you like in a given day). Todd’s objective was to laminate an entire half of a yacht’s hull in one intense session. He reckoned this could be done with four active workers, plus one in the background to fix problems when they emerged.

- A proper vaccuum-bag pump, process materials, and workers who were trained how to use it under time pressure.

- And a yacht design that would have sufficient appeal to justify the large initial expenditure for a perfectly fair, closed, vacuum-baggable mold. You wouldn’t want to invest in this sort of mold if you were building only one or two boats.

Todd decided to try this approach on his new LEVANT 15 daysailer. It had the advantage of being small enough to potentially laminate four layers of wood veneers in one session. The constraint here is the time available before WEST-system epoxy cures. By keeping the workspace cold (below 50 degrees) and using slow hardener, this meant four hours of working time before the epoxy begins to cure, when the heat is turned up to finalize the cure. But is it possible to apply 240 veneers in four 60-veneer layers, within such a short timeframe? Todd teamed up with his boatbuilder friends at Belmont Boatworks, just up the road, in order to have a large enough team to attempt it. The video below should give you a good idea of the process.

Todd wisely began by building a small test panel, just to make sure there were no unforeseen problems. Using conventional techniques epoxy primer is the last thing to go on, and fiberglass cloth is pressed onto a surface from the outside rather than pulled into the primer by a vacuum. The test panel proved that there were no problems using the vacuum to press the “skin” layers into each other rather than using a serrated roller and paint sprayer as is the usual case.

The mold was waxed, and a layer of epoxy finish primer applied to the mold. This would become the visible layer on the inside of the hull once the finished part was removed. No time pressure here― it could have been done days in advance. A layer of 10-ounce fiberglass cloth was then laminated on in fast-cured epoxy resin. Again, no time constraints, and this was allowed to cure.

Then began many hours of pre-fitting the lightweight cedar veneers. Beginning with the inside layer (inside the boat once it is finished), the 1/10″ thick cedar veneers were stapled into place, and marked and numbered and carefully stacked so that they could later be selected and rapidly re-stapled into place on layup day. Just one single veneer out of place in the stack would precipitate disaster, as you can imagine.

The layup day was choreographed in advance. Four stacks of veneers, four workers who could have at it for potentially four hours without a bathroom break, and somebody gutsy enough to say, “start.” The veneers were put into place and sporadically fastened with plastic staples― easily sanded flush when necessary. After only 2 1/2 hours the four layers were in place, and the vacuum bag going on. Somebody must have been heaving a sigh of relief, and wondering just how much larger a boat could be built with this method?

Is this the future of boatbuilding? Fiberglass has not run its course, surely. But the market for pleasure boats has evolved. Poorly designed sailboats, sold on the basis of their low price, have no future but to fail, You can buy old fiberglass sailboats for nothing on craigslist. You make the decision to own a sailboat for the joy of sailing her. But you are not a fool and you thing “green” and you hope that the effort and resources that go into her will endure until your grandchildren grow old. If so, you will choose a LEVANT 15 built by Todd French, and you will have chosen wisely.

This article is about entrepreneurs, like Todd French and Dan Miller, who try to advance the methods of boatbuilding. But I am a yacht designer. And I design yachts that bring jot to folks who own and sail them. My greatest joy will be when you choose to own a LEVANT 15 , and tell me how much it has enhanced your life.

The Legendary Night Runner

Possibly no other yacht has achieved greater success in the realms of both cruising and racing than Night Runner. Designed by Robert H. Perry for Seattle sailor Doug Fryer, she is a well known “wolf in sheep’s clothing” in Pacific Northwest waters with a classic appearance above the waterline and modern lines below. It is said that she is Perry’s favorite design. Under Fryer, she won just about every notable race in the Pacific Northwest. She is a veteran of 38 Swiftsure International Yacht Races (three times first overall), a singlehanded Transpac, four Victoria to Maui races (including a first in class) and four Van-Isle 360 races (Division II winner in 2009). At the same time, she served her owner as a comfortable and capable cruising platform, extensively exploring Pacific Northwest waters north to Alaska and a dozen circumnavigations of Vancouver Island. As if that is not enough, Night Runner completed a 21,000 mile voyage around South America by way of Cape Horn and the Panama Canal for which Fryer received the Blue Water Medal from the Cruising Club of America in 1998. To say that Night Runner knows her way is an understatement.

Night Runner’s cold molded construction by Cecil Lange and Son of Port Townsend, Washington provides the beautiful interior and exterior aesthetics of a traditional wood boat in a strong and lightweight package that stands the test of time. Night Runner is truly an heirloom boat.

New teak decks – repowered diesel – Balmar alternator – extensive sail inventory – forced air heat – Raymarine electronics

Interior Accommodations

Night Runner’s interior is beautifully finished. In the typical cold molded style, the interior of her hull is bright finished and all her structure is visible, giving a wonderful aesthetic. An offset companionway allows for a roomy aft stateroom and salon layout that feels larger than her 42 feet. Her U-shaped seagoing galley is opposite a stand up nav station. Forward, the centerline drop leaf table is flanked to port and starboard by straight settees with pilot berths outboard. Large skylights provide great light into the salon space. There are gimbaled tables for food and drink that mount on both the salon table and above the engine compartment at the galley. Forward of the salon, a passageway leads to the head with separate shower stall and the fo’c’sle with ample storage in large lockers to starboard, a work bench with vise, and sail storage bins.

Force 10 propane three burner stove and oven

Xintex S2A propane solenoid control

Propane tank

Pressure water – plumbed but not currently in operation

Fresh and raw water foot pumps at galley sink

Top loading refrigerator/freezer (2013)

Jabsco toilet

Espar Airtronic forced air diesel heater

Electronics and Navigation

Raymarine radar/chartplotter with radar antenna on pole (2012)

Icom IC-M120 VHF radio

Kenwood TKM-707 SSB radio

Kenwood MAT100 antenna tuner

Raymarine X30 autopilot computer with linear drive Autohelm Speed and Depth displays and Raymarine ST70 Wind display at cockpit

Autohelm Multi display in salon

Danforth Constellation compass at binnacle

Garmin GPS72 handheld GPS

West Marine VHF 460 handheld VHF (floating and submersible)

Running lights, deck light, anchor light, and LED masthead tricolor

Sony AM/FM/Cassette stereo with two Sony speakers

Electrical Systems

12v DC and 120v AC electrical systems

Weems and Plath AC distribution panel

Marinetics DC distribution panel

DC voltmeter

Heart Link 2000 panel

Magnum inverter/charger with external control panel

(2) Interstate 6v batteries

Pow R Surge 908D battery

Interstate SRM 8DS battery

Mechanical Systems

Westerbeke “55D Four” diesel engine (151 hours)

Engine control panel with tachometer, oil pressure, voltmeter, temperature gauges

HBW 250 direct drive transmission

Packing gland shaft seal

1 ¼” stainless propeller shaft and folding propeller (new 2009)

Balmar 100 amp alternator with ARS 5 external regulator

Racor primary fuel filter

Manual bilge pump below deck

Whale Gusher 10 manual bilge pump at cockpit

Deck and Hull

Night Runner’s was constructed by Cecil M Lange and Son in Port Townsend, Washington. Her hull was built in the cold molded style with four layers of 1 ¼” red cedar set in epoxy with the outer layer of planking laid longitudinally. The hull is stiffened by a laminated cedar keel, laminated frames, and bulkheads bonded to the hull, and a stainless grid that bears the load of her mast and keel. Her ballast is lead fasten with stainless bolts. Her topsides are finished bright with black and white boot stripes. There is a rub rail along her hull sides. A short bulwark and double lifelines surround her deck. Then decks are plywood with teak overlay, replaced in 2014. A large foredeck space with vertical capstan windlass and samson post is well configured for handling ground tackle. The cockpit serves well for both racing and cruising. The mainsheet is sheeted from the end of the boom to a Harken traveler just forward of the large wheel. There is good cockpit seating aft with storage below and lockers below the aft deck.

Simpson Lawrence V2000 anchor windlass

Bruce anchor with chain and rode

Danforth anchor with chain and rode Fortress FX37 folding anchor

Samson post

Green canvas mainsail cover and binnacle cover

Sails and Rigging

Black anodized aluminum mast and boom

Solid rod standing rigging (2009)

Strong Track low friction mainsail track

Storm trysail track

Hydraulic backstay adjuster

Furlex 400s headsail furler (2009)

(2) spinnaker, (2) jib, staysail, (1) mainsail halyard, (1) spinnaker pole topping lift

Removable (adjustable) inner forestay and babystay

Dyneema running backstays

Spinnaker pole and reaching strut

Harken mainsheet traveler

Port and starboard boom preventers

(3) Barient 26 winches on mast

(1) Barient 22 winch on mast

(1) Barient 20 self tailing winch on cabin top

(1) Barinet 23 self tailing winch on cabin top

(1) Lewmar 50 self tailing winch on cabin top

Barient primary and secondary winches

Sail inventory:

Mainsail (tri-radial) – Dacron – Ullman Sails

Mainsail (tri-radial) – Dacron – Lidgard Sails

Mainsail (cross cut) – Dacron – Shattauer

#1 genoa – Carbon – Hodges

#2 genoa – Tape Drive – UK

#3 jib – laminate – Hodges

#4 jib – Dacron

#5 jib – Dacron

(2) .5 oz spinnakers

.65 oz spinnaker

.75 oz spinnaker

1.5 oz spinnaker

1.5 oz reacher spinnaker

2.2 oz spinnaker

Genoa staysail – Dacron

Spinnaker staysail – Dacron

Jib top – Dacron

Drifter (older) – Dacron

Code 0 windseeker

Storm trysail

Miscellaneous and Safety

Lifesling in custom canvas bag

McMurdo 406 EPIRB (battery expired May, 2018)

Avon roll up inflatable dinghy

Charcoal BBQ

Notable recent maintenance and upgrades

August, 2003

New Engine, Regulator and Exhaust – $21,774

North Harbor Diesel

January, 2009

Roller furler – $4,630

Rod Rigging – $5,819

New folding prop and shaft

Canoe Cove Marina – $4,136

Summer, 2012

Radar and chart plotter

January, 2013

New bowsprit, king post and cockpit hatch covers

David’s Custom Installations – $18,652

Refrigeration – New compressor, plates and water pump

Sea Freeze of America – $4,317

September, 2014

New main sail

Ullman Sails – $7,382

October, 2014

New teak deck

Townsend Bay Marine – $ 41,877

Cold Molded

Projects: Building with the cold-moulded method

After an unfortunate motorbike accident, Harry Evans was forced to put his boating career on hold. However, an opportunity to train as a boatbuilder at the Boat Building Academy in Lyme Regis has given him a fresh start. Here, Harry tells us about his work at the college to build a Clinker sailing boat, which he’s called ‘The Last Leg’.

How did the project come about?

Building a boat is a key part of the training here at the Boat Building Academy Lyme Regis. It was such an exciting prospect to get back into the practical side of things after the accident.

The Last Leg was initially intended to be a traditional Clinker. However, to make things more interesting I decided to build it using the cold-moulded method of construction.

Which WEST SYSTEM® epoxy products did you use? How did they help?

I used WEST SYSTEM epoxy products throughout the build, as I believe they’re the most efficient and reliable.

The WEST SYSTEM 30kg C pack plus the corresponding pumps were great. The pack gave me both 105 Epoxy Resin® and 205 Fast Hardener® , while the easy-to-use pump system was quick, accurate and took the guesswork out of time-pressured college tests.

I also used WEST SYSTEM 406 Colloidal Silica – it’s a fantastic thickening agent, very strong and hard.

The WEST SYSTEM 409 Microsphere Blend low density filler was easy to use and shape. Finally, I used WEST SYSTEM 740 Glass Fabric , a 135g/m² plain weave glass cloth which is essential for water-tightness, strength and resistance to abrasion.

What did you learn about the cold-moulded method whilst doing this?

I would definitely recommend giving serious consideration to cold moulding and epoxy as a construction method – it’s fast and very strong. For a start, the cold-moulded method was a lot quicker than the traditional method of Clinker construction; we managed to fully plank the hull and have it watertight in approximately three weeks. What’s more, you can really see how lightweight and strong modern epoxy-wood methods are. Using epoxy enabled us to create a smooth hull with a monocoque structure, eliminating the need for through-hull fastenings and calling for fewer reinforcements. All in all, compared to traditional methods, the cold-moulded method is very satisfying, relatively trouble-free and produces a low maintenance boat that will have a long life in the water.

What was the most rewarding part of the project?

It was incredible to see how fast and strong the cold-moulded wood-epoxy method can be. It was also great to be working as part of a team. We are all looking forward to finishing the boat and seeing it in the water.

What’s your top tip for boatbuilders looking to start a similar project?

Manage your time well and source materials that you can trust – make sure you do your research. Apart from that, just go for it!

Our thanks to Harry Evans for his contribution. You can learn more about the Boat Building Academy at Lyme Regis on their website .

Do you have a project that you’re working on? Email us at [email protected] and we could feature it in a future edition of epoxycraft!

Want to know more about the products mentioned in this article, including the full range of WEST SYSTEM epoxies? Visit the WEST SYSTEM website .

Back to projects

How Can You Repair a Hole in a Fibreglass Boat?

Can Gelcoat and Epoxy Bond?

How Did I Become a Skipper Through Boat Restoration?

- Yachting World

- Digital Edition

LA 28: The modern trailable boat that’s cold-molded from mahogany

- October 8, 2019

The LA 28 is a beautiful, cold-moulded wooden trailer-sailer that was designed to be unique, and has now sold nine boats across Europe. Sam Fortescue steps on board

Appropriately, it’s a long train ride through thick, thick forest before I reach the LA Yachts yard on the banks of Lake Müritz in central Germany. This seems apposite because the boat I’ve come to see is an exquisite example of how wood is just as relevant as ever when it comes to boatbuilding.

In truth, the LA 28 has little in common with the endless rows of fir that fringe the lake; she is cold-moulded from nobler stuff. But it is striking that this young shipyard chose to build in wood. I ask yard owner Lothar Fichtner why.

“It’s lighter than GRP and cheaper than carbon,” he says without blinking. So much for the romance of traditional construction, then. In fact, there’s little about this vessel the boatbuilders of 100 years ago would recognise.

Around 60kg of Sicomin epoxy is used in the lay-up. Photo: Soenke Hucho

For one, cold moulding is a technique that relies heavily on epoxy resin to stick each layer of wood to the last and sheath the whole structure to keep the water out. Then there can be as much or as little carbon in the rig and the finish as you want, while propulsion comes courtesy of a Torqeedo electric motor.

Despite her elegant tumblehome and the plunging curve of her coachroof, this is a thoroughly modern boat. “The best of modern and traditional,” Fichtner says.

The story of the LA 28 begins with the desire of a wealthy man to have a beautiful sailing toy. Lothar Fichtner was that man and, having sold his engineering business, he wanted to enjoy more of life from his second home on Mallorca.

Article continues below…

Revolver: Bruce Ritchie’s gentleman’s racer blends traditional and modern craftsmanship

“I wasn’t expecting this,” said Michael Ritchie when his 83-year-old father Bruce showed him the lines he had drawn up…

European Yacht of the Year 2019: Special yachts

This category assembles a varying mix of interesting craft, many of which we might otherwise not have had the chance…

He approached a boatbuilder in the Muritz region called Andreas Zehle who specialised in the building of the German 20er Jollenkreuzer racing dinghy class, also cold moulded. Then he drafted in designer Martin Menzner from Berckemeyer Yacht Design in Laboe on the Kieler Fjord.

This small design house has worked on everything from dinghies to high-latitude yachts, using a range of construction materials and techniques. Crucially, Berckemeyer is strong in cold-moulded yacht design, or ‘speed strip’ as they call it.

The brief was for a trailerable 8-9m boat, that was “simple to rig, as single-handed as possible and with excellent sailing characteristics,” Fichtner explains. “I am bothered by the current development in boatbuilding. Almost all boats look the same. I wanted something exclusive that is modern in design and traditionally built.”

It takes more than 15 coats of varnish to achieve this degree of shine on the finish. Photo: Soenke Hucho

Menzner is a successful J/80 sailor himself, and the two men quickly saw eye-to-eye. The whole design process took just three months. Fichtner had no clear idea of it at the time, but he wasn’t just buying a boat, he was establishing a yard.

“I founded the shipyard because two boatbuilders were unemployed and I wanted to have a boat for my area in Germany and Mallorca,” he recalls. But one thing led to another, and Fichtner is a naturally ambitious man.

“We had a lot of success at trade fairs and continuous orders. Then I found my way into Germany’s Yacht magazine.” They have now sold nine boats since 2015, when the first garnered rave reviews at Interboat in Friedrichshafen.

Working with wood

Cold moulding requires a rough plug to be made, but no female tooling is needed, making it much cheaper to set-up than in the case of GRP or carbon. The plug around which the hull is formed is simply made from strips of softwood fastened around CNC-milled frames. It’s quick, cheap and relatively easy. The natural flexibility of the 2.5mm strips of wood used in cold moulding the hull iron out any imperfections in the mould.

The first stage of the process is to place a layer of plastic sheeting over the mould. Then the strips are bent into shape and clamped in place to hold their form. Each layer is bagged and vacuum infused with Sicomin epoxy resin, which soaks into the very top layer of the wood and helps to bond each strip edge-to-edge.

Each layer is laid in a different direction to the previous: longitudinal strips of okoume first, then lateral, then diagonal. For the outer layers, Lothar prefers African mahogany (khaya), giving a warm, reddish finish to the hull, which is many times stronger than the equivalent in glassfibre, and lighter too.

The deep curve of the tumblehome is all part of the hull shape, so it isn’t possible to mould the whole hull at the same time. Instead, there are two symmetrical plugs, one for the port side, one for starboard.

When the two halves are finished, they are simply epoxied together in the middle with a sort of low keelson covering the whole length of the joint for extra strength.

Cold moulding leads to a beautiful interior finish. Photo: Soenke Hucho

At this stage, the hull is still just a hollow form, albeit a beautiful one. Extra strength must be added next, which is achieved by ‘backfilling’ frames, ringframes and stringers – all glued into place after the event. These support the stresses of the mast, the shrouds and the keel, and provide structure for the transom, keelbox and so on.

The finish is a matter of personal taste – every owner makes their own decisions on this. Some have opted for carbon detailing; a layer of carbon epoxied around the aluminium mast post, for instance, a carbon keelbox and carbon fibre pads where the line for the retractable bowsprit passes through the companionway bulkhead into the cockpit. The mast and boom are both in carbon, with sails recommended in X-Drive carbon from UK Sailmakers.

Others have requested a white painted interior (a lot more work, observes Fichtner), or different woods used in the construction process to give a slightly different finish. The point is that every boat is unique and can be formed and specified to fit its new owner’s wishes: engine or no engine; spade rudder or transom-mounted kick-up rudder.

LA Yachts uses a very light wooden core for the tiller, then laminates it with carbon fibre. Photo: Soenke Hucho

Below the waterline the usual keel is a 600kg lead bulb, but again you can choose from a number of options. With the fixed keel there is the option of a 1.7m, 1.8m or 1.9m draught – depending on where you sail and how aggressively rigged she is.

But the hydraulic lift is proving a popular option, which reduces draught by 0.9m in the raised position. It’s a handy option for shallow waters, and makes it more feasible to land wherever the fancy takes you – perhaps with a family and a picnic basket.

True to the boat’s thoroughly modern character, Fichtner worked closely with Torqeedo in designing the LA 28 to use one of the company’s 2.5kW electric drives.

This is permanently mounted on a pod under the cockpit, but the throttle lives out of sight on a fold-down panel that pops out of one of the cave lockers. It’s a neat solution to the fact that the Torqeedo control is chunky and modern, and rather at odds with the otherworldly lines of the LA 28.

Controlled growth

The boat is resolutely designed to be simple to handle. “They sail easily and they’re very light. I can come into port by myself, and handle her myself,” Fichtner says. “With a bigger boat you always need a team – you are never alone.”

That said, there is a bigger boat on the horizon. Taking its cues from the look and handling of the LA 28, a larger 35-footer has been designed and will shortly enter the build phase. At 10.8m long, she can still be trailered, thanks to an all-up towing weight of just less than 3.5 tonnes.

“I want to invest in quality,” says Fichtner determinedly. “My dream would be to build just three boats per year.” There seems to be a preponderance of billionaires among the ownership ranks of LA Yachts, so perhaps three a year is more ambitious than it sounds.

Specification

LOA: 8.8m (28ft 11in) LWL: 8.0m (26ft 3in) Beam: 2.5m (8ft 2in) Draught: 1.7-1.9m (5ft 7in-6ft 3in) Keel raised: 0.8-1.0m (2ft 8in-3ft 3in) Displacement: 1.5 tonnes Ballast: 600kg (1,322lb) Engine: Torqeedo Cruise 2.0FP Price: €120,000 (ex. VAT)

Your shopping cart is empty!

Boat Building in "Cold Moulded"

Moulded Ply or Veneer

From full size patterns supplied with the plans , station frames are marked and cut out of scrap timber and plywood. Stringer positions are marked and notched. The frames are erected on a prepared strongback and the stringers, keelson and stem are added.

Very little fairing off is necessary as the stringers go in at the correct angle and allow the plywood or veneer strips to be added glued and nailed to the stringers.

The plywood or veneer strips are applied diagonally and sometimes vertically and fore and aft as shown in the plans.

BUILDING TIP: When installing veneers or other material that requires temporary staples, one of the most onerous jobs is removing the staples. Many methods have been tried but this one successfully used by Russ Stevenson works well....buy some narrow THIN packaging METAL tape and this can be used underneath the staples....easy to remove when the glue has set...simply give a hefty tug on one end of the tape and the staples come out without a whimper...make sure to wear goggles as staples may fly in all directions.

There are no products to list in this category.

- SPECIFICATIONS

The second yacht in the LM46 line of performance cruisers features a 7’7″ keel for top performance on the racecourse and a second head for increased comfort while either cruising or racing. Arcadia was launched in the spring of 2022. The yacht’s owner, an experienced racer, plans to enter the vessel in some of the most famous ocean races, including the 2022 edition of the Bermuda Race.

LM46 Hull No. 2, like every yacht in the LM46 series, is a high-performance, cold-molded sailing yacht that features the comfort and ambience of a wooden boat but delivering 10 knots of speed under both sail and power. The LM46 is a collaboration between Lyman-Morse founder Cabot Lyman, his son and company president Drew Lyman, and top Kiwi designer Kevin Dibley .

Specifications

- displacement 24,250 pounds

- fuel capacity 81 gallons

- water capacity 156 gallons

- type Sail - 1,183 sq. ft.

- designed by Kevin Dibley

- builder Lyman-Morse Boatbuilding Co.

- construction Cold-molded wood composite

- hull material Douglas Fir/Western Red Cedar

- configuration Sloop

- location Thomaston, Maine

- boat engine Yanmar 4JH80

- horsepower 80 hp

Whiskey Plank Installed

Construction is moving along quickly. The crew recently celebrated the installation of the Whiskey Plank in Hull #2 of the LM46. This second hull in the LM46 cold-molded performance sailboat series is scheduled to launch this summer.

Performance

LM46 Hull No. 2 features a powerful cruising rig with swept-back spreaders and 1,183 square feet of sail, including a squaretop main, that gives the LM46 an impressive turn of speed. Rolling out the optional asymmetrical spinnaker steps thing up a notch and lets the yacht hit speeds of 10 knots or more. When conditions are right, this yacht can click off 240 miles per day, while the wooden hull, 43’ waterline length, and comfortable displacement-length ratio of 133 allows for one-handed steering or easy steering by autopilot, no matter the weather. Equipped with a 7’7″ fin keel, LM46 Hull No. 2 will stand up to the most strenuous conditions whether racing offshore or family cruising along the coast.

Like everything else aboard the LM46, sail-handling is kept simple, efficient, and user-friendly: roller furling for the jib, a detachable staysail, and a mainsail furling system that is fast, easy, and effective. Following the French lead, we’re keeping weight out of the bow of the LM46 by using almost all anchor rode instead of chain. Quiet, easy — just like the LM46 itself.

And while LM46 Hull No. 2 will excel under sail, it can also deliver its crew just as swiftly under power, with an 80-horsepower Yanmar diesel powering the yacht at up to 10 knots.

Layout & Design

One word sums up the layout and design of the LM46: Soul. Too many boats built and bought today lack this key element, but by carefully considering every aspect of this new yacht – including the hull material itself – boatbuilders Cabot and Heidi Lyman and yacht designer Kevin Dibley have created a boat that is ingenious in its simplicity, efficiency, and performance.

The spacious cockpit features 6’5″ seats, ideal for accommodating guests or, when the weather is right, a night of sleeping under the stars. Twin helms offer unrivaled visibility, while the drop-down transom affords no-step access to and from the dinghy. All sail-handling is easily managed without ever leaving the cockpit.

Step below and enjoy a seat in the spacious salon and take in the V-groove overhead and combination of painted and bright-finished bulkheads and trim – you’ll instantly find yourself transported from your daily life to somewhere quieter, simpler, more elegant. The wraparound galley, designed using the lessons Cabot and Heidi learned during 16 years of living on their boats around the world, is as appropriate to preparing a three-course dinner as it is for mixing up a batch of evening cocktails. Aft, to port, a second head and wet locker provide easy access for guests or crewmembers coming off watch. The aft full berth to starboard makes for a welcoming guest cabin or, when offshore, the ideal sea berth.

Moving forward, to starboard you’ll find a separate head with vanity and a shower. The huge forepeak aboard LM46 Hull No. 2 includes a vee berth that converts into a centerline queen and storage for a weekend or a month’s worth of clothes and gear. Here, as everywhere aboard the LM46, you’ll be struck as much by what you see as what you don’t – we’ve included everything that you need and nothing that you don’t (watermaker, A/C, excess electronics).

Sails & Rigging

- Fully battened squaretop main

- Asymmetrical spinnaker (optional)

- Staysail (optional)

- Code Zero (optional)

- Mast – Carbon (air clearance of 63’10” allows access under ICW bridges)

Sail handling:

- Primary and secondary sheet winches, easily reached by helmsman and crew with the ability to stand and grind without leaving the cockpit

- Halyard winches – Electric (optional), also used for reefing lines, located on cabinhouse top

- Spinlock jammers/clutches

- 78-gallon custom stainless water tanks (2)

- 81-gallon custom aluminum fuel tank

- Polyethylene Vetus holding tank

- Tecma marine head

- Life preservers (optional, Spinlock vest-type)

- Sailing instruments

- Navionics plotter on GPS-enabled iPad

- Broadband radar -12-mile range

- LED lighting throughout

- Marelon seacocks by Forespar

- 120-amp engine alternator

- Jabsco anchor washdown pump (optional)

- Groco Sea Strainers

- Centek muffler, with stripper for silent charging

- 4″ blower for engine compartment

- Scott vented loops

- Rule and Whale automatic bilge pumps

- Whale manual bilge pump (near helm)

- Seadog deck fills and pumpout deck fitting

- Perko hinges (head door)

- Cushions – mid-density foam with ultrasuede covers on seats, canvas on berths

- Feathering propeller by MaxProp

- Isotemp hot water heater (plumbed to engine)

- Force 10 propane stove, with Trident controls and detector

- Espar heater (optional, for those in higher latitudes)

- Jabsco pressure water pump

- Lewmar low-profile deck hatches

- 640AH Lithium Phosphate batteries (optional) for unlimited cycles

- 44 lbs CQR anchor, equipped with 20’ of 3/8″ chain and 150’of 3/4″ Yale Brait anchor rode

- Lewmar anchor windlass

- Blue Seas electrical panel at navigation station, with 12VDC and 110 AC breakers

- Isotherm refrigerator/freezer, with evaporation plates

- Polar stainless double galley sink

- Scandvik faucets

Construction

The LM46 uses modern design and technology to improve upon the most sustainable building material ever created: Wood. Wooden boats 70 years old or more are still winning offshore and coastal races, sailing over many horizons, and, when necessary, are far easier to bring back to life after years of neglect. The Douglas Fir and Western Red Cedar planks that comprise the LM46’s nearly 1”-thick hull are sustainable, originating from sound growth- and forest-management plans and thousands of years of experience. Using the cold-molded building process results in a hull that delivers a quiet ride underway and is both flexible and incredibly strong. A layer of glass on the topsides increases durability and reduces maintenance. Wisely employing modern building materials and techniques and eliminating excess electronics allows us build a low-maintenance yacht that breaks the cycle of having to travel from boatyard to boatyard to keep a yacht in top condition – an ironic claim for the owner of a service yard to make, we’ll admit!

Lyman-Morse’s intelligent use of its Haas GR712 Computer Numerical Control (CNC) machine to cut planks, bulkheads, and joinery reduces costs for the hull and deck construction, but we have not thrown out the baby with the bathwater in the LM46. The cockpit, deck, and cabinhouse, often the site of water-infiltration in older wooden boats, feature a composite structure that keeps things bone-dry belowdecks. To use anything other than modern materials in these locations would be irresponsible.

Whenever possible, all items for the LM46 are built as modular units outside the boat – the same system used by wooden production boatbuilders half a century ago and somehow forgotten. We use such time-tested processes, combined with expert Maine shipwrights and high-tech tools such as lasers and 3D printers, to create a construction plan that is competitive with production boats but that yields a yacht that is meaningful and carefully constructed – a world apart from the fiberglass cookie-cutter boats that fill marinas and boat shows these days.

LM46: Putting the Real World in Perspective

The LM46 doesn’t deny the “real” world – it puts it in perspective.

More than 170,000 miles of sailing together, including a three-year circumnavigation with their three boys and numerous offshore races and trips to the Caribbean and the South Pacific, has shown Cabot and Heidi Lyman one thing: Boats have become too complicated. As the founders and owners of the world-renowned Lyman-Morse Boatbuilding Company for the past 42 years, they’ve built over 110 vessels, many of them equipped with watermakers and digital screens of all shapes and sizes. For many of us, all that gadgetry just distances us from why we started sailing in the first place: Reconnecting to a simpler way of life. Our day-to-day lives have become consumed with devices, passwords, and updates. Over time, our boats have tried to keep pace instead of providing an escape, a place where you can forget the world and simply enjoy. The LM46 changes that.

Spectacular in its simplicity, powerful in its performance, unparalleled in its quality. Contact us today and make the LM46 a member of your sailing family.

- Name * First Last

- Add me to your mailing list

- Phone This field is for validation purposes and should be left unchanged.

Custom cold-molded wooden boat construction The 34' Odyssey

- $ 0.00 0 items

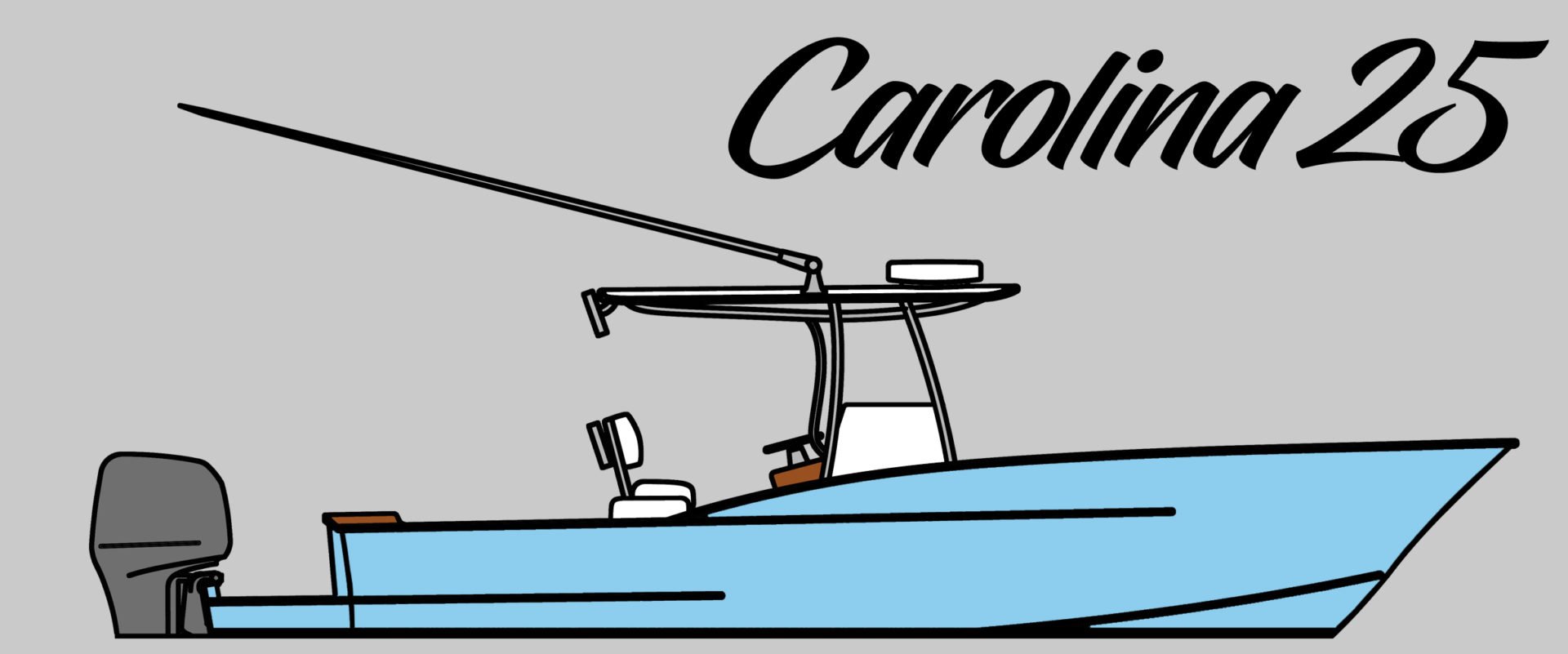

Carolina 25

$ 750.00 – $ 4,750.00

The Carolina 25 is a classic North Carolina sport fishing boat design in a trailer-able center console layout. This design features the famous Carolina flare, broken shear and tumblehome that is sure to turn heads. This boat is built using the cold molded method and best suited for those with boat building or woodworking experience.

Looking for more photos? Want to connect with others who have built this boat? Check out the Salt Boatworks boat builders group, HERE!

Boat Plans include prints detailing assembly of the boat and full size templates to trace and cut all jig parts.

Jig Kit includes prints detailing assembly of the boat, plywood jig parts CNC cut, and HIN assignment.

NOTE: Jig components include stringers, transverse frames, bulkhead, transom, stem, bracket plus temporary structure. We do not include all plywood like the FRS series because hull side and hull bottom are cut to fit during assembly using the cold mold method.

Jig Kits are shipped by motor freight or can be picked up from Morehead City, NC. Shipping will vary by destination and you should contact us for a quote BEFORE placing an order if you plan to have the kit shipped. Some ball park costs from past shipments are ~$600 for South Carolina and ~$800 for southern Florida and Texas.

Orders placed here can only ship within the USA at this time. If you are outside of the USA, please send us a message on our contact page for a shipping quote.

Description

Additional information.

- Reviews (1)

Our Carolina 25 is a classic North Carolina sport fishing boat design in a trailerable center console layout. This design features the famous Carolina flare, broken shear, and tumblehome that is sure to turn heads. The bottom shape is that of a traditional “Carolina” bottom with 18 degrees of dead rise aft and a sharp V at entry for a smooth and efficient ride with stability at rest. There are no interior compromises either, a single level floor all the way forward and a large single fuel tank which allows a step down inside the console makes a spacious and easy to navigate interior. Powered by single or twin engines this boat will take your family to the sand bar or off shore to the fish!

This boat is built using cold molding and is recommended for those with boat building and/or wood working experience. Available as a pre-cut jig or full size patterns, both options include detailed assembly drawings, making it easy to build a boat of your own.

- 28’0″ LOA (including bracket)

- 25’2″ hull length

- 8’6″ beam (trailer-able width)

- 18 degrees dead rise aft

- 17″ hull draft @ 6000 lbs

- 140 gal fuel capacity (single tank)

- 350hp (30″ shaft) or twin 200hp (25″shaft)

- Cruise 30-35mph, single 350hp runs ~40mph and twin 200hp runs ~45mph

- Single level / flat deck full length of the hull

- Can be built as a center console or express with cabin

Material Estimates for Hull:

- Jig Kit: 9 sheets marine grade plywood 1/2”x4’x8′ (stringers, transverse frames, bulkhead)

- Jig Kit: 5 sheets marine grade plywood 3/4”x4’x8′ (transom, stem, bracket)

- Jig Kit: 5 sheets standard plywood 1/2”x4’x8′ (temporary structure)

- Strong back : Pine – 2 boards 2”x6”x16′, 2 boards 2”x6”x14′, 3 boards 2”x6”x10′, 5 boards – 2”x4”x8′, 6 boards – 2″x4″x10′

- Bottom : 12 sheets of marine grade plywood 3/8”x4’x8′

- Sides: 18-20 sheets of marine grade plywood 1/4”x4’x8′

- Floor & Gunnel: 8 sheets of marine grade plywood 1/2”x4’x8′

- Ceiling: (optional) 7 sheets of marine grade plywood 3/16”x4’x8′

- Keel: Fir – 6 boards 2”x4”x8′

- Stringers: Fir – 4 boards 2″x6″x16′ (board)

- Sheer: 200 linear feet of Juniper or Fir 3/4”x1” & 100 linear of Juniper or Fir at 1/2”x1”

- Rib Bands: 180 linear feet of Juniper or Fir 3/4”x1”

- Chine: 250 linear feet of Juniper or Fir 3/4”x3” OR 3/4” marine plywood cut in 3″x8′ strips

- Sheer Bumper: 140 linear feet of Fir or Sapelle 1/2”x1-1/2”

- Spray Rail: 50 linear feet of Fir or Sapelle 3/4”x1-1/2”

- Floor Supports: 200 linear feet of Juniper or Fir 1.5”x1.5”

- Resin: 30 gallons of marine grade epoxy resin (DO NOT USE POLY OR VINYL ESTER RESINS)

- Glass: 250 linear feet of 1708 bi-axial fiberglass 50” wide

- Filler: 5 lbs of fumed silica or similar for fillets

Questions about Boat Building? Check out our FAQ

1 review for carolina 25.

Kyle – October 10, 2019

I am a couple months into this build and can say that the plans are very well thought out and precise. One of the major advantages of these plans is that you will have most of the flooring framework done as well when fully assembled. There is a LOT of cutting for this jig, but it is a 25′ boat with a bracket. You can save about 80 hours of cutting by ordering the pre-cuts. So far I remain impressed and excited to get her done.

You must be logged in to post a review.

Related products

Flats River Skiff 14

Carolina Bay 17

Flats River Skiff 18

Luders 16 by A. E. Luders

The Luders 16 is the smallest of a series of yachts designed by “Bill” Luders, in which beauty was one of the primary design objectives. Created a bit later than many of the designs on this site, she has a definite air of modernity about her, with her steeply angled, shapely ends, relatively high freeboard, distinctive cabin trunk, and rounded transom.

Small and light for this general shape, she has a delicacy of appearance that we find very appealing. Her relatively high freeboard gives her cockpit a little more depth and her cabin a little more headroom than one might expect in a boat of this size. You sit down inside the boat and have a clear passage into the cabin, which gives a great feeling of security. The boats customarily carry a pair of pipe berths in the cabin, over a small bench on either side. Sitting on the benches one has sitting headroom under the side decks, which is very rare in a boat of this size and type, and is a great addition to her comfort and utility.

Deeply V’d sections mean she will have the best possible motion going to windward in a chop, and will not pound. These characteristics will make her faster, drier, and more comfortable sailing to windward in those conditions, compared to many other boats.

The L16 started life as a more conventional plank on frame boat, and was modified into its current form when it became one of the first keel sailboats to be built using “hot molded” plywood construction, differing from cold molded construction only in the use of earlier glues, which required heat to cure. Our version would be cold-molded using epoxy glue, and would (unless otherwise agreed) follow current racing practice in the use of aluminum spars and tasteful modern hardware. The interior of this boat is frameless, and thus very smooth and easy to clean and maintain. Most owners would want the interior to be finished bright, which we think would be a warm and rather stunning look much in keeping with the style of the boat. Maintenance characteristics would be very favorable, and we would predict a very long lifespan for the structure.

L16s are still raced in Northeast Harbor, Maine, and in Chicago.

Fast, pretty, nimble, easy to handle, useful as a small cruising boat, and requiring little strength to sail, an L16 would be a delightful and versatile boat.

- Where We Are Located

- General FAQs

- Using this Website

- Boat Building Methods

- Boatbuilding FAQs

- Builders' Forum

Login to your account

- Forgot your password?

- Forgot your username?

Create an account

The Principles:

- Laminating multiple layers of that core (in this case plywood)

- In alternating directions

- Forming a monocoque structure (key point)

- It is for waterproofing as it encapsulates the core, inside and out.

- It also provides some degree of abrasion / penetration resistance.

HIGHGROUND BOATWORKS 32 CENTER CONSOLE

Handbuilt in stuart, florida, “with years of experience between them in building premiere sportfishing boats, it’s exciting to see the highground boys bring their enthusiasm into starting their own production company. i’m confident their boats will shine through with the same attention to detail they’ve already shown in the sportfishing world, and i’ve thoroughly enjoyed working with them to design a boat we can all be proud of.”, – dusty rybovich, true to the finest marine standards.

From the High Rocky Cliffs of Maine to the Highlands of the West Coast of Scotland Highground Boatworks is proudly located in Stuart Florida and owned by partners John StDenis and Martin Currie. The Highgrounds of our childhood are where we got the name, achieving the high ground in life can be seen as an advantage.

Highground Boatworks is a boatbuilding company in which every process is guided by our passion for fine workmanship and our love for the Sea fairing craft. We are a company that works squarely in the enduring traditions of the world’s best boat builders, innovates with modern technique and uses the finest materials available to produce a beautiful boat—one at a time. We will build your boat with you, not just for you.

Vacuum Infused Composite Hulls and our Cold Molded mahogany planked Hull are only the beginning of Highground Boatworks commitment to the finest in marine craftsmanship. We have spent many years and countless hours at our company in Stuart Florida, researching and manufacturing vessels and parts of varying sizes. At Highground Boatworks we are lucky enough to work alongside some of the best Builders, Riggers, Designers and Architects in the industry today and we truly believe that all aspects of our 32cc will reflect our years of determination and dedication to the boat building industry and our craft.

From hand-lofted boats on a plywood floor to 3D computer modeled hulls with CNC cut parts, we have seen firsthand the developments in boatbuilding and what they can deliver in terms of our structural integrity, weight distribution and product consistency.

Each of HighGround’s vessels is built to John and Martin’s exacting standards, honed over their decades of working side-by-side with some of the finest in the industry. In the HighGround 32 CC, they have created a boat whose style is unforgettable, its quality, is unmatched, and the ride, unrivaled.

Highground Boatworks 32 cc Composite/Kevlar

Our 32 CC is constructed using a vacuum infused resin process that provides us with consistent weight, strength and structural integrity into every part of the boat. We take every step possible to ensure the lamination schedule and structural integrity of each one of our boats meets and exceeds the latest marine standards and requirements. Below the waterline we laminate Kevlar into our hull skin to ensure impact resistance and provide you with the comfort and peace of mind to handle the unexpected.

“Highground Boatworks, high standard of workmanship and attention to detail along with their extensive experience in the construction of sportfishing boats has been a joy to work with and I believe is a great basis for a boatbuilding company of their own. I’m confident they will continue to build their excellent reputation and achieve great success. “

– larry belkov, belkov yacht company.

Fuel: 300 gallons Water: 30 gallon fresh water Length Over All: 32’ Beam Over All: 9’ 11” Draft: 20″ Displacement: 8200 lbs. with twin Suzuki 350’s standard

The Craft of Cold-Molded Hulls

The strength and integrity of the HighGround Boatworks 32 Cold Molded Center Console, springs from its core: the hand-built hull, constructed in the classic cold-molded process with pure mahogany planking, fitted and laminated by hand. That triple-planked mahogany hull has an incredible strength-to-weight ratio providing a core that is impact absorbing, smooth riding, and takes shock loads more efficiently than a traditional foam-cored composite hull.

The cold-molded process begins with every new boat built, new jig up on the shop floor and precise attention to detail at every step. It’s the preferred method of the finest custom boatbuilders. HighGround Boatworks builds each of its vessels with the highest standards of craftsmanship and construction. They know that’s exactly what their clients expect and deserve and that’s what they deliver. That is The HighGround Boatworks pledge.

Classic Style, High Performance

Whether you’ll be fishing hard on a HighGround 32’—in the Bahamas or out to the Northeast Canyons—or cruising your local waterways with family and friends, your Highground will carry you to your destination in comfort and distinctive style.

With sportfishing in its DNA, The Highground 32’ presents striking lines, hybrid bow flare, smooth broken shear transitions, and a tumblehome hull with intermediate side rails. It’s an elegant vessel that means business on blue water.

FLORIDA-BUILT, AMERICAN MADE

Email Address

- About the School

- Mission & History

- Sign up for E-News

- Watch Shop Talk

- Hull Raiser Magazine

- Program List

- Boatbuilding Program

- Marine Systems Program

- Marine Systems Intensives

- School Catalog

- School Calendar

- Accreditation

- Shop Photos

- Submit Inquiry

- Admissions Process

- Tuition & Fees

- Financial Aid

- Scholarships

- Required Tools

- Housing & Community

- Career Services

- School Library

- Library Catalog

- Annual Security Report

- Instructors

- Diversity/Inclusion

- Boat Projects

- Clean Bay Update Fall 2021: Shaping the Future

- Boats for Sale

- Commissions

- Boat Donations

- Contact Information

- Alums Reconnect

- Submit Alumni Job

- Donate Online

- Boat School Store

- More Ways to Support

- Thanks for Giving

Cold Molded Construction

The first cold-moulded hulls commercially produced were derived from wooden aircraft technology developed during World War II. These used phenol-formaldehyde glue and vacuum pressure was employed to hold the veneers together in an autoclave oven. Hulls produced this way have proved extremely durable with a life of over 30 – 40 years. Nowadays no such plant exists and all cold moulded boats are produced on a one-off basis. Glues other than epoxy are still relatively popular but chosen on convenience grounds rather than performance. Urea-formaldehyde types are viewed as being simpler to use and clean off easily using water. However there are noticeable benefits in terms of hull stiffness using epoxy. This is due mainly to epoxy’s good gap filling properties and the resulting continuity of glue line. A contributory reason for the superior stiffness of an epoxy hull is that with other glues moisture is introduced into the veneer during application and by the process of curing.

Source: SP Systems. This article was derived from ‘Wooden Boat Const. Meth.pdf’ which can be downloaded from the SP Systems website.

For more information on this source please visit SP Systems

Sign up for our E-news

Stay up-to-date with what's happening at the Boat School.

Founded in 1981, the school offers a full-time 12 month Associate of Occupational Studies (AOS) degree in Boatbuilding, a 9-month Diploma program in Marine Systems, and 5-day Intensive courses in Marine Systems topics.

Quick Links

- Sign-up for enews

42 N. Water St. Port Hadlock, WA 98339

Phone : (360) 385-4948

Email : [email protected]

The New Cold-Molded Boatbuilding

- Create New Wish List

- Description

by Reuel B. Parker Published by WoodenBoat Books 320 pages, lots of black & white photos and illustrations, soft cover. Copyright 2005, ISBN: 0-937822-89-2 It's generally agreed that cold-molded construction is the best method for the amateur or low-profile professional interested in building a full-size cruising boat. A truly appropriate technology, cold molding combines the beauty of wood with the low-maintenance characteristics of fiberglass. "The New Cold-Molded Boatbuilding" is the complete, soup-to-nuts presentation of this process, with chapters detailing every facet of construction--from choosing a design and setting up through engine installation and wiring to launching and sea trials. In addition, the author has streamlined the cold-molding process considerably, producing boats that are more economical, efficient, and sturdy--boats built from native materials that will last the life of the builder and turn heads in harbors around the world. Note: The Cold Molded process described in this book is similar but not the same as used in our designs. However, there is a lot of other helpful information such as joinery work, keel lamination, turning the hull, electrical, plumbing, finishing and more.

Related Products

Boatbuilding with Plywood

Fiberglass Boatbuilding for Amateurs

Fiberglass Boatbuilding Manual

Stitch & Glue Boatbuilding DVD

Steel Boatbuilding Guide

IMAGES

VIDEO

COMMENTS

Cold Molded Construction. Cold molded hulls have been built since the technique was used for World War II planes—often using casein or urea-based glues. Today, one would use epoxy almost exclusively, benefiting from its superior bonding, gap-filling, strength and water resistance. ... The pre-cut veneers (2-6 mm thick depending on boat size ...

In terms of durability, a cold-molded hull is more like a fiberglass hull than a traditional wooden one, he says, and cold molding has some advantages over fiberglass. It yields a hull that is lighter than same-size fiberglass boats, and it adds wood's noise reduction, better insulating properties and looks.

With a low-maintenance, cold-molded hull that offers the unmatched, comfortable motion and ambiance of a wooden boat with the 10-knot-plus speeds of a modern performance yacht, you and your family will form a bond with the LM46 that will last generations. ... Using the cold-molded building process results in a hull that delivers a quiet ride ...

From the cold moulded structure to the electrical and mechanical integrations, we perfect the build process on each custom wooden boat. ... Van Dam Custom Boats are built for generational enjoyment and constructed to stand the test of time. 3D CAD In the design phase we shift from 2D drawings to 3D virtual models, using state-of-the-art 3D ...

Alternatively, in the case of cold molded wood construction, this requires a male, not female, mold, and you end up with a hull that is perfectly finished on the inside, but must be faired and painted on the outside. ... But on a boat where the inside of the hull is always visible, like the LEVANT 15 daysailer, the tradeoff is that it is easier ...

Night Runner's cold molded construction by Cecil Lange and Son of Port Townsend, Washington provides the beautiful interior and exterior aesthetics of a traditional wood boat in a strong and lightweight package that stands the test of time. Night Runner is truly an heirloom boat. New teak decks - repowered diesel - Balmar alternator ...

All the Vicem Vintage Line yachts - which includes Classic, Flybridge, Cruiser and Bahama Bay lines - are built with the Cold-Molded Process .This operation simply involves applying layers of thin solid-wood veneers, oriented at different angles, to be saturated by epoxy over a computer-designed mold. This marriage of engineered woods with ...

Building with the cold-moulded method. After an unfortunate motorbike accident, Harry Evans was forced to put his boating career on hold. However, an opportunity to train as a boatbuilder at the Boat Building Academy in Lyme Regis has given him a fresh start. Here, Harry tells us about his work at the college to build a Clinker sailing boat ...

Ballast: 600kg (1,322lb) Engine: Torqeedo Cruise 2.0FP. Price: €120,000 (ex. VAT) The LA 28 is a beautiful, cold-moulded wooden trailer-sailer that was designed to be unique, and has now sold ...

Vicem, which recently consolidated all of its operation in Antalya, is practically synonymous with cold-molded construction. It has been utilizing cold-molded construction techniques since its first yacht—a 62-foot (19-meter) sailing ship, launched 20 years ago. The company recently celebrated its 20th anniversary by introducing the Vicem 100.

Boat Building in "Cold Moulded". Moulded Ply or Veneer. This method of construction can be used to build several of our designs, and plans are available based on this technique. From full size patterns supplied with the plans , station frames are marked and cut out of scrap timber and plywood. Stringer positions are marked and notched.

LM46 Hull No. 2, like every yacht in the LM46 series, is a high-performance, cold-molded sailing yacht that features the comfort and ambience of a wooden boat but delivering 10 knots of speed under both sail and power. The LM46 is a collaboration between Lyman-Morse founder Cabot Lyman, his son and company president Drew Lyman, and top Kiwi ...

French & Webb and Belmont Boatworks build the hull of the Paine 15 sailboat, designed by Chuck Paine. Video and narration by Chuck Paine.

This boat, like our other V-bottom hulls, was built using a stringer/frame system. In this system, transverse frames are erected, in this case on 20" centers. Over the frames go longitudinal stringers. The cold-molded planking goes over the stringers. In the photo, the frames are set up and faired, ready for the stringers.

Carolina 25. The Carolina 25 is a classic North Carolina sport fishing boat design in a trailer-able center console layout. This design features the famous Carolina flare, broken shear and tumblehome that is sure to turn heads. This boat is built using the cold molded method and best suited for those with boat building or woodworking experience.

The L16 started life as a more conventional plank on frame boat, and was modified into its current form when it became one of the first keel sailboats to be built using "hot molded" plywood construction, differing from cold molded construction only in the use of earlier glues, which required heat to cure.

The first half of building a cold-molded wooden power yacht here at French & Webb in Belfast, Maine.

Forming a monocoque structure (key point) It is called cold-mold because the binder (glue / resin) is designed to fully cure at room temperature. From Wikipedia: Monocoque, from Greek for single (mono) and French for shell (coque), is a construction technique that supports structural load by using an object's external skin as opposed to using ...

The cold-molded wooden hull is lighter with a more quiet and comfortable ride than its typical fiberglass counterpart. It requires a smaller engine for the same performance. ... Unlike traditional wooden boat construction where the hull planking shrinks and swells each season, a cold-molded boat requires no more annual maintenance than an ...

Sporer Sailboat Boats for Sale Craigslist & Sporer Sailboat Specs & Pictures. Year: 1984. Manufacturer: Bruce Tait & Associates. Price: US$29,000. 1984 Custom cold-molded Sporer 30. Designed to the MORC rule (and sails great in PHRF), this beautiful, the brightly finished boat will turn heads in every harbor and on every race course.

The cold-molded process begins with every new boat built, new jig up on the shop floor and precise attention to detail at every step. It's the preferred method of the finest custom boatbuilders. HighGround Boatworks builds each of its vessels with the highest standards of craftsmanship and construction.

The first cold-moulded hulls commercially produced were derived from wooden aircraft technology developed during World War II. These used phenol-formaldehyde glue and vacuum pressure was employed to hold the veneers together in an autoclave oven. Hulls produced this way have proved extremely durable with a life of over 30 - 40 years. Nowadays no such plant exists and all cold moulded boats ...

The New Cold-Molded Boatbuilding. 320 pages, lots of black & white photos and illustrations, soft cover. It's generally agreed that cold-molded construction is the best method for the amateur or low-profile professional interested in building a full-size cruising boat. A truly appropriate technology, cold molding combines the beauty of wood ...