- Building Skerry

- Building a Scamp

- Boatbuilding Links & Resources

- Boatbuilding Tools

Plans for Boats, oars and paddles. Many free plans

As I was looking through my boat plan links I realized that they were scattered here and there. I decided to compile the links all in one page to make it easier to navigate.

Email me if a link is broken. I try to update everything often but the internet is a fast paced place. (and I'm not so quick), I've also included free oar and paddle plans and books with plans in them.

I offer a few plans but most of these boat designs are links. I have not built most of these and cannot endorse them. Some plans are good, others not so much.

Many plans are now available, particularly those that offer hundreds of plans for very cheap, which are reprints from old Popular Mechanics and other magazine. The building methods are somewhat dated and the plans often not very detailed. Of more concern materials such as lead paint are sometimes recommended. Do your homework before building these. Often buying a good set of plans from a recognized designer will save you time and money in the end.

The following plan links may have duplicate because they may fit in different categories. A kayak plan might also be a free stitch and glue plan. Enjoy and go build a boat.

Links to All kinds of boat plans, oars, some free plans

- Miscellaneous Boat Plans many of them free. It's my largest plan page. Whenever I find a new plan I try and add it to this list.

- Motorboats Everything from simple skiffs to elaborate speedboats, classic wooden boats and fishing vessels.

- Dory Boat Plans Various plans some of which are free. Wide range of dory styles, usually characterized by a pointy front, relatively flat sides and toumbstone transom.

- Skiff Plans By skiff I mean a simple shaped pointy boat with a wide transom. Often used as a fishing boat. Capable of planing and carrying a motor.

- Strip Building Plans Often cedar strips are used. Often results in lovely rounded shapes with glorious wood finish. A favourite for canoes and kayaks but often seen in sailboats and multihulls.

- Ultra-Light Boat plans Imagine building a boat that weights less than 30 pounds and even less.

- Canoe and Kayak plans Many free plans included.

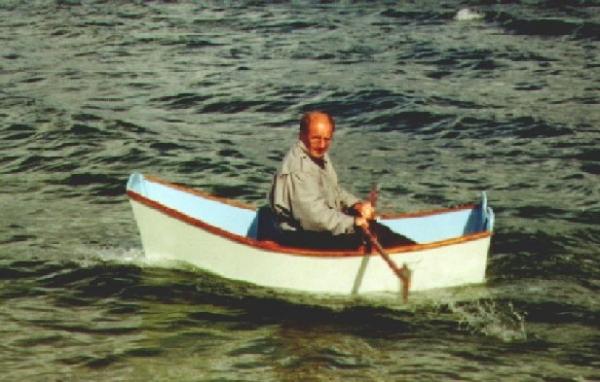

- Tenders Selection of boats suitable as tenders, some free. Many methods of building including stitch and glue, ultralight and strip building.

Free Boat Plans

- Free Skiff Plans Skiffs are fast easily built boats.

- Free Canoe and Kayak Plans There are some nice free designs out there. They vary in amount of detail offered.

- Free Stitch and Glue Plans Also plans that could be built using stitch and glue method.

- Free Rowboat Plans

- One Sheet Plans Boats can be built using only one sheet of plywood. Here are a few.

Free Canoe and Paddle Plans some links some actual plans

- Free Plans for Simple Oars by Spark Geissler Nice easy to build oars.

- Links to many Free Oar, kayak and Canoe Paddles. Some nice designs including traditional kayak paddles.

- Free Paddle Plan From an old boy's book.

Surf Boards and Paddle Boards

- Surf Boards and Paddle Board Plans

Multihulls and Proas

- Multihulls including catamarans, trimarans and proas.

House Boats

I have a few free actual boat plans, some in pdf format.

These are mostly from old sources. Check before building.

- Folding Boat Plan from Boy Mechanic Book Turn of the century design for a folding boat. Link to a video of someone who actually built it. It's quite good. I think the builder had to fiddle the dimensions some before it would fold properly, but it's a fun boat.

- Old Plan for Plywood Tender Actual plans, seems like a nice pram dinghy.

- Old Plan for Punt Actual plans, from old book. Substitute plywood for solid wood.

- Old Plan for Take Apart Skiff Actual plans, in PDF format. Boat is in 3 clip-together sections.

- Old Plan for folding boat in PDF format. Plywood with canvas hinges folding skiff.

- Take apart Jonboat come in 3 sections and has a built in cooler.

- Building a Skerry from plans

- Boatbuilding Links & Resources from my Website

I try to be accurate and check my information, but mistakes happen. ALSO keep in mind that not all free boats are good designs. Some are but others are worth exactly what you pay. Also keep in mind while I'm in a preachy mood, that a good set of plans will save you lots of time and if you've paid for them you can actually often contact the designer and get help.

Free Boat Plans

- BoatBuilders

Free boat plans, sailing stuff and more

Free Boat Plans from old magazines Old Boat plans from Science and Mechanics and Boat Builder Handbooks. Plans for Hydroplanes, Sailboats, Inboards, Runabouts, Canoes, Kayaks and many other boats. This is a FREE, NON-COMERCIAL, user supported site. An online library. To contribute just send an email. ".pdf" files can be viewed and printed with Adobe Reader By acquiring these images you accept all responsibility for thier use. You also agree that I am not responsible for anything that happens as the result of your acquiring these images. If you do not accept responsibility then do not acquire the images from this site.

New sections added - 02/28/09

New section BoatBuilders. In this section I will add links to other boatbuilders websites. Check out the beautiful Plyak. I have also added a link to my Bateau canoe.Make sure you check the Galleries section. If you want me to add the pictures of your boat here, just email me.

The Ultimate Guide on How to Build a Sailboat – Step by Step Instructions and Expert Tips

Alex Morgan

Building a sailboat can be a rewarding and fulfilling project for those with a passion for sailing and craftsmanship. Whether you’re an experienced builder or a novice, constructing your own sailboat allows you to customize it to your specific needs and preferences. This comprehensive guide will take you through the step-by-step process of building a sailboat.

To start, gather the necessary tools and materials required for the construction. The specific tools needed may vary depending on the design and complexity of the sailboat. Basic tools such as measuring tape, saws, drills, and sandpaper are commonly used during the building process. specialized tools like a planer, router, and clamps may be required for more intricate details.

In terms of materials, you’ll need various types of wood for the hull, frames, and deck, as well as epoxy resin, fiberglass cloth, and marine-grade plywood. Other materials like stainless steel screws, bolts, and fittings will be needed for assembling and securing the different components of the sailboat.

Choosing the right sailboat design is a crucial step in the building process. Consider factors such as the intended use, sailing conditions, and your own level of experience. Factors like the boat’s size, stability, and performance characteristics should also be taken into account.

Before diving into the construction, it’s important to prepare a suitable building site. This includes having enough space to work on the boat, a clean and organized area, and proper ventilation. A sturdy workbench or support system is necessary for holding the boat’s components during assembly.

The hull of the sailboat is a fundamental part of the construction process. Follow a step-by-step process for constructing the sailboat hull, which involves shaping and assembling the frames, planking the hull with marine-grade plywood, and applying epoxy resin and fiberglass for added strength and durability.

Once the hull is completed, it’s time to install the sails and rigging. Properly attaching and rigging the sails is essential for optimal performance and maneuverability. This includes setting up the mast, boom, and other rigging components in accordance with the sailboat’s design specifications.

Next, focus on essential systems and finishing touches. Install electrical and plumbing systems as per your requirements, ensuring they are safe and efficient. Applying finishes and sealants to the boat’s exterior not only enhances its appearance but also protects it from the elements.

Before launching your sailboat, conduct safety checks to ensure everything is in proper working order. Inspect the hull, rigging, and other components for any potential issues. Once you have done all the necessary checks, follow tips for a successful sailboat launch, ensuring a smooth transition from construction to the open water.

By following this guide, you’ll be well-equipped to embark on the exciting journey of building your own sailboat. With careful planning, attention to detail, and patience, you’ll soon have a vessel that reflects your skills and passion for sailing.

Key takeaway:

- Building a sailboat maximizes creativity and adventure: Constructing your own sailboat allows you to embark on a unique and fulfilling journey while enabling you to express your creativity and personal style.

- Gathering the right tools and materials is crucial: Having the necessary tools and materials is essential for building a sailboat successfully. Ensure you have the appropriate tools and high-quality materials to construct a sturdy and reliable sailboat.

- Choosing the right sailboat design is vital: Consider various factors such as size, intended use, and sailing conditions when selecting a sailboat design. This will ensure you build a sailboat that meets your specific needs and provides optimal performance.

Gathering the Necessary Tools and Materials

In order to build a sailboat, the first step is to gather the necessary tools and materials.

- Start by researching the specific type of sailboat you want to build to determine the required tools and materials.

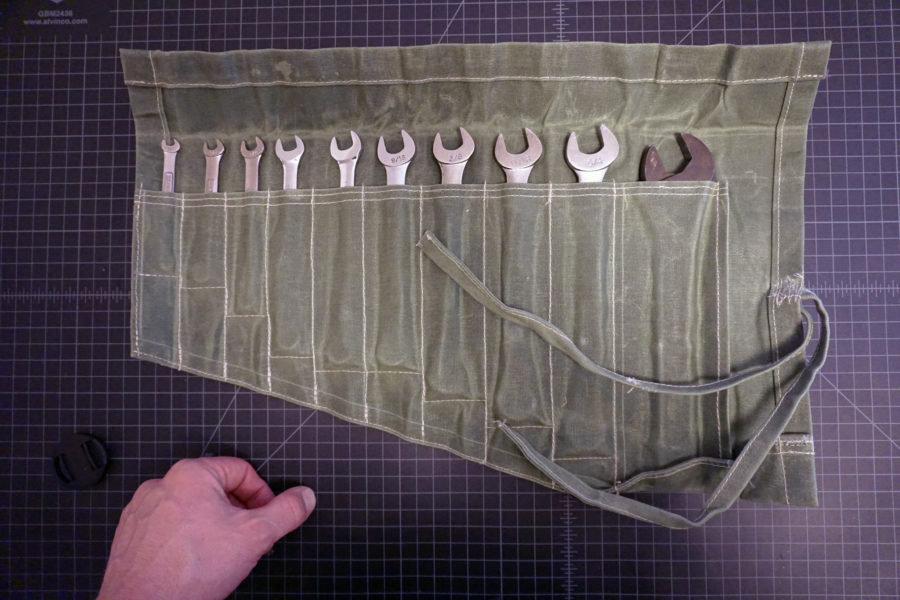

- Make a list of tools in good working condition, including a saw, hammer, drill, measuring tape, and screwdrivers.

- Create a material list that includes plywood, fiberglass, epoxy resin, screws, and nails . Calculate the quantities based on the sailboat plans.

- Find reliable suppliers and compare prices and quality for the materials.

- Set a budget for the project, taking into account the cost of both tools and materials.

- Plan the layout of your workspace for maximum efficiency and keep the tools and materials easily accessible and organized.

Throughout the building process, it is important to prioritize safety by wearing protective gear and following the guidelines for tool usage. If needed, seek assistance from experts or experienced builders. Building a sailboat may pose challenges but it is also a rewarding experience. So, enjoy the process and take satisfaction in creating something with your own hands.

What Tools Do You Need to Build a Sailboat?

To build a sailboat, you need the following tools:

1. Measuring tools: To accurately measure and mark dimensions, use a tape measure, ruler, and carpenter’s square.

2. Cutting tools: For cutting large pieces of wood, use a jigsaw or circular saw, and for intricate cuts, use a coping saw or handsaw.

3. Joinery tools: Assemble and join parts using a hammer, screwdriver, drills, and chisels.

4. Sanding tools: Smooth and shape wood surfaces using sandpaper or a power sander.

5. Clamping tools: Hold pieces together while working using clamps and a vise.

6. Safety equipment: Ensure your safety with gloves, safety glasses, and a dust mask.

In addition to these tools, you’ll need a well-ventilated workspace with a sturdy workbench. This is crucial for building a sailboat. It’s also advisable to have a set of plans or blueprints to guide you through the construction process.

True story:

I always dreamt of building my own sailboat, so I gathered the necessary tools and materials. With dedication and passion, I started constructing the hull, following the step-by-step process. It was challenging but rewarding. Installing the sails and rigging was exciting too. I could already envision the boat sailing on open water. After applying the finishing touches and conducting safety checks, it was time for the sailboat’s launch. With a mix of nerves and anticipation, I set the boat into the water. To my delight, it sailed smoothly, taking me on incredible adventures. Building a sailboat was a labor of love that fulfilled my lifelong dream of being a boat builder.

What Materials Are Required to Build a Sailboat?

Materials Required to Build a Sailboat:

– Marine plywood : Several sheets

– Fiberglass cloth : Sufficient length

– Epoxy resin : Recommended amount

– Hardwood lumber : Various sizes

– Stainless steel screws : Sufficient quantity

– Aluminum mast : Appropriate size

– Sails : Multiple types

– Rigging hardware : Various components

– Navigation lights : Required number

– Steering system : As per design

– Electrical wiring : According to needs

Pro-tip : When choosing materials for building a sailboat, select high-quality marine-grade materials suitable for the intended purpose and capable of withstanding the harsh marine environment.

Choosing the Right Sailboat Design

Choosing the perfect sailboat design sets the course for an unforgettable journey on the sea . Discover the key factors to consider in selecting the ideal sailboat design that suits your needs. Get ready to navigate through a sea of options and explore the world of sailboat aesthetics , performance , and practicality . So, prepare to steer your way into understanding the vital elements that influence the decision-making process when it comes to selecting the ultimate sailboat design .

Factors to Consider When Selecting a Sailboat Design

When selecting a sailboat design, there are several factors to consider. First and foremost is the intended use of the sailboat. You need to determine whether you plan to race , cruise , or day sail . It is important that the design aligns with your activities on the water.

Another crucial factor is the size of the sailboat. Consider your experience and crew when deciding on the sailboat size. Keep in mind that larger sailboats may require more crew members and expertise to handle.

It is essential to evaluate the stability of different sailboat designs. Factors such as keel type and hull shape can significantly impact the stability and seaworthiness of the sailboat.

Performance is another important consideration. Determine the level of performance you desire. Some designs prioritize speed and agility , while others focus on comfort and ease of handling .

Budget is also a significant factor to keep in mind. Take into account the price of owning and maintaining different sailboat designs, as well as ongoing expenses.

The construction material of the sailboat is yet another factor to consider. Options include fiberglass , wood , aluminum , and steel , each with its own advantages and considerations.

It is important to note that sailboats come in various designs, each with unique features catering to different sailing preferences and conditions.

Preparing the Building Site

When preparing the building site for a sailboat, follow these important steps:

1. Clear the area: Remove vegetation, debris, and obstructions to create a clean workspace.

2. Level the ground: Ensure the site is level and stable for a solid foundation.

3. Mark out the dimensions: Use measuring tools to accurately mark the sailboat’s length, width, and height on the ground.

4. Prepare the ground: Dig or fill the ground to create a smooth surface that meets the required dimensions.

5. Install boundary markers: Place stakes or markers around the perimeter of the building site to clearly define the boundaries and prevent encroachment.

6. Establish access points: Create pathways or access points to allow for easy movement of materials and equipment.

7. Ensure safety: Take necessary precautions such as putting up warning signs, setting up barriers, and having appropriate safety equipment on site.

By following these steps, you can effectively prepare the building site for constructing your sailboat.

What Are the Requirements for a Suitable Building Site?

The requirements for a suitable building site for constructing a sailboat include:

- Ample space: The site should have enough room to accommodate the sailboat’s size and allow for easy movement around the boat.

- Flat and level ground: The ground must be stable and even to prevent structural issues during construction.

- Protection from weather: The site should be sheltered from strong winds, rain, and direct sunlight to prevent material damage and ensure optimal working conditions.

- Access to utilities: Electricity and running water are necessary for powering tools, equipment, cleaning, and maintenance.

- Proper drainage: The site needs good drainage to prevent water accumulation, which can damage materials and hinder progress.

- Secure storage: A secure storage area is essential to protect tools, materials, and equipment from theft and damage.

- Accessibility: The site should be easily accessible for material delivery and transportation of the completed sailboat.

- Permits and regulations: Compliance with local building codes, permits, and regulations is necessary for safety and legal compliance throughout the construction process.

Building the Hull of the Sailboat

Building the hull of a sailboat is an exciting journey that requires meticulous attention to detail and precise craftsmanship. In this section, we will embark on a step-by-step process for constructing the sailboat hull, guiding you through the essential stages of this intricate endeavor. From selecting the right materials to shaping the structure, we’ll cover everything you need to know to create a sturdy and seaworthy foundation . So, grab your tools and let’s dive into the art of crafting the perfect sailboat hull.

Step-by-Step Process for Constructing the Sailboat Hull

The sailboat hull can be constructed in a step-by-step process. Here is how you can construct a strong and durable sailboat hull:

Step 1. Create the hull mold : Start by building a robust and long-lasting frame that accurately represents the shape and size of the hull.

Step 2. Prepare the mold surface: Apply a release agent to ensure that the hull does not stick to the mold.

Step 3. Lay fiberglass : Soak fiberglass cloth in epoxy resin and carefully place it on the mold, forming multiple layers to create a sturdy hull.

Step 4. Apply resin and cure: Distribute epoxy resin evenly across the entire surface in order to bond the layers together. Let it cure as per the instructions provided by the manufacturer.

Step 5. Sand and fair: Smooth out any imperfections on the hull, creating a sleek and flawless shape.

Step 6. Paint the hull: Enhance both appearance and protection by applying high-quality marine paint to the hull.

Step 7. Install hardware: Securely attach cleats, hatches, and fittings to prevent any leaks or damages.

By following these step-by-step instructions, you will be able to construct a sailboat hull that is strong, durable, and ready for the next stages of building your sailboat.

Installing the Sails and Rigging

Get ready to take your sailboat to the next level as we dive into the section on installing the sails and rigging! We’ll be revealing the secrets to properly attaching and rigging the sails for optimal performance. With expert insights and practical tips , you’ll soon be harnessing the wind like a pro. So, tighten your ropes and get ready to set sail on this exciting adventure of sailboat building!

How to Properly Attach and Rig the Sails for Optimal Performance

To properly attach and rig the sails for optimal performance on a sailboat, follow these steps:

- Ensure all necessary hardware is securely attached to the sailboat.

- Attach the halyard to the head of the sail and hoist it up the mast to the desired height.

- Secure the tack of the sail to the tack fitting at the bottom of the mast.

- Attach one end of the mainsheet to the boom and the other end to the traveler .

- Connect the jib sheets to the clew of the jib sail.

- Rig any additional sails according to manufacturer’s instructions.

- Check all lines and rigging for proper tension and alignment.

- Test the rigging and sails in different wind conditions for optimal performance.

- Regularly inspect and maintain the rigging and sails.

By following these steps, you can learn how to properly attach and rig the sails for optimal performance on your sailboat.

Essential Systems and Finishing Touches

Make your sailboat dreams a reality with this guide to essential systems and finishing touches. Discover the ins and outs of installing electrical and plumbing systems, ensuring your vessel is equipped with everything you need for a smooth sailing experience . Learn the art of applying finishes and sealants to protect your sailboat from the harsh marine environment. Get ready to set sail with confidence and style !

Installing Electrical and Plumbing Systems

When building a sailboat, it is essential to install electrical and plumbing systems. Here is a step-by-step process to guide you:

1. Plan the electrical and plumbing layout: Determine locations for electrical outlets, switches, and plumbing fixtures like sinks and toilets. Consider placement for batteries, freshwater tanks, and wastewater holding tanks.

2. Install electrical wiring: Start by installing the main electrical panel and run wires to various components and outlets. Use appropriate wiring sizes and ensure secure connections. Include safety features like circuit breakers and grounding.

3. Connect plumbing lines: Begin by installing freshwater supply lines and connecting them to the freshwater tank. Install plumbing fixtures like sinks and toilets, ensuring proper sealing and secure connections. Then, install the wastewater plumbing system, including drain lines and a holding tank.

4. Install electrical and plumbing components: This involves installing electrical outlets, switches, and lighting fixtures. Ensure proper wiring connections and test the electrical system for functionality. For plumbing, install faucets, showerheads, and toilets, ensuring proper water flow and drainage.

5. Test the systems: Once everything is installed, test the electrical and plumbing systems to ensure correct functioning. Check for leaks, proper water pressure, and operational lights and switches.

6. Make necessary adjustments: If any issues are found during testing, make the necessary adjustments and repairs to ensure optimal functioning of the systems.

7. Secure and protect the systems: Once everything is working correctly, secure and protect the electrical and plumbing systems by organizing wires and pipes, using appropriate insulation, and securing any loose components.

By following these steps, you can successfully install the electrical and plumbing systems in your sailboat, ensuring functionality and convenience on your sailing adventures.

Applying Finishes and Sealants for Protection

Applying finishes and sealants is important in building a sailboat to protect the hull and ensure its longevity.

Clean the hull: Make sure the hull is clean and free from debris or contaminants. Use a marine-friendly cleaner and rinse thoroughly.

Sand the hull: Lightly sand the hull using fine-grit sandpaper to create a smooth surface. This will help the finishes adhere better.

Choose the right finish: Select a high-quality marine-grade finish suitable for the hull material, such as varnish, paint, or gelcoat.

Apply the finish: Follow the manufacturer’s instructions. Apply thin, even coats using a brush or roller and allow proper drying time between coats.

Seal the hull: After applying finishes and sealants for protection, use a marine-grade sealant specifically designed for boat hulls to protect it from water penetration.

Apply multiple coats: Depending on the desired level of protection, it may be necessary to apply multiple coats of finish and sealant.

Inspect and maintain: Regularly inspect the finishes and sealants for signs of wear or damage. Touch up or reapply as needed to maintain optimal protection.

In history, boat builders recognized the importance of protecting the hulls from the sea’s harsh elements by applying finishes and sealants for protection. They used natural materials like tar, pitch, or wax to seal the wood and prevent waterlogging. Advancements in technology and materials have led to more durable finishes and sealants. Today, boat builders have access to marine-grade products designed to provide exceptional protection and enhance the longevity of sailboats. By applying finishes and sealants for protection with care and proper maintenance, sailors can ensure their sailboats remain in excellent condition for years of sailing adventures.

Testing and Launching the Sailboat

Before launching your sailboat, there are crucial steps you need to take to ensure a safe and successful voyage. In this section, we will dive into the necessary safety checks to conduct before setting sail. We will also provide valuable tips from seasoned sailors to ensure that your sailboat launch goes smoothly. So, buckle up and get ready to embark on your sailing adventure with confidence !

Conducting Safety Checks Before Launching

Conducting safety checks before launching your sailboat is crucial to ensure a safe voyage. To guarantee a smooth sailing experience, follow these steps:

1. Carefully inspect the hull of the sailboat for any damage or cracks. Be sure to check the seams and joints thoroughly.

2. Take the time to check the rigging , including the mast , shrouds , stays , and halyards , for signs of wear, fraying, or corrosion.

3. Hoist the sails and test them to ensure they are functioning properly. Make sure that all sail controls are in good condition and working as they should.

4. It is important to examine the electrical system of the sailboat. Check the battery and wiring for any signs of damage. Verify that all lights and instruments are functioning correctly.

5. Inspect the plumbing system , testing the freshwater system and searching for any leaks or clogs that may cause issues during your voyage.

6. Take the time to review all the necessary safety equipment . Ensure that everything is on board and in proper working order.

7. Confirm that all navigation aids , such as the compass , GPS , and any other navigation instruments, are functioning correctly.

8. It is crucial to verify the functioning of all communication devices . Take the time to test the radio or any other communication devices that you may have on board.

9. Inspect the fuel and engine carefully. Check the fuel level, oil levels, and overall engine condition. Test the engine to make sure it is running smoothly.

By conducting these necessary safety checks before launching your sailboat, you can minimize the risk of encountering any issues during your sailing experience.

Tips for a Successful Sailboat Launch

Perform a safety check: Before sailing, inspect the boat for damage, ensure rigging is secure, and test essential systems.

Check weather conditions: Choose a day with favorable weather for launching. Avoid high winds or rough seas.

Prepare a launch area: Clear a suitable pathway, remove obstacles, and ensure sufficient depth and space.

Use adequate support : Use sturdy boat trailers or launch ramps for stability during launch.

Properly position the boat: Center and balance the sailboat parallel to the water’s edge using dock lines or ropes.

Release the boat gradually: Release the boat steadily to prevent damage or injuries.

Monitor the boat’s movements: Check for leaks or instability and address issues immediately. Adjust sails and rigging if necessary.

Enjoy your sail: Follow boating safety guidelines and have a great time on the water.

A friend built a sailboat from scratch and successfully launched it by following these tips. The weather was perfect, and everything went smoothly. With the boat securely supported and positioned, they released it into the water, and it floated beautifully. They had a memorable experience sailing without any issues. By following these tips, they ensured a safe and enjoyable journey on their newly built sailboat.

Some Facts About How To Build A Sailboat:

- ✅ Building a sailboat can take approximately 100 hours over 3 months. (Source: Instructables)

- ✅ The cost of building a sailboat can amount to around $1,000. (Source: Instructables)

- ✅ The first step in building a sailboat involves cutting out the parts using boat building plans and plywood. (Source: Instructables)

- ✅ Assembling the hull of a sailboat involves stitching and gluing the panels together. (Source: Instructables)

- ✅ Fiberglassing the hull of a sailboat makes it waterproof and strong. (Source: Sailboat Cruising)

Frequently Asked Questions

Faq 1: what are the different options for building a sailboat.

There are three main options for building a sailboat. The first option is refurbishing an old boat, the second option is purchasing a hull with the deck moulding already fitted, and the third option is to build a boat from scratch.

FAQ 2: How long does it take to build a sailboat?

Building a sailboat takes approximately 100 hours over a span of 3 months.

FAQ 3: Can I learn the necessary skills for building a sailboat along the way?

Yes, you can learn the necessary skills for building a sailboat slowly and avoid making mistakes along the way.

FAQ 4: Should I hire a professional surveyor before refurbishing an old sailboat?

Yes, it is advisable to involve a professional surveyor before taking on the project of refurbishing an old sailboat.

FAQ 5: What materials are needed for building a sailboat?

The materials required for building a sailboat include oak plywood, epoxy resin, epoxy hardener, silica thickener, wood flour thickener, masking tape, Japanese pull-saw, table saw, router, sander, jigsaw, drill, wire cutter, C-clamps, mixing cups, fiberglass cloth, glue, screws, and fasteners.

FAQ 6: How much does it cost to build a sailboat?

The cost of building a sailboat is approximately $1,000, excluding any additional costs for customization or specific features.

About the author

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Latest posts

The history of sailing – from ancient times to modern adventures

History of Sailing Sailing is a time-honored tradition that has evolved over millennia, from its humble beginnings as a means of transportation to a beloved modern-day recreational activity. The history of sailing is a fascinating journey that spans cultures and centuries, rich in innovation and adventure. In this article, we’ll explore the remarkable evolution of…

Sailing Solo: Adventures and Challenges of Single-Handed Sailing

Solo Sailing Sailing has always been a pursuit of freedom, adventure, and self-discovery. While sailing with a crew is a fantastic experience, there’s a unique allure to sailing solo – just you, the wind, and the open sea. Single-handed sailing, as it’s often called, is a journey of self-reliance, resilience, and the ultimate test of…

Sustainable Sailing: Eco-Friendly Practices on the boat

Eco Friendly Sailing Sailing is an exhilarating and timeless way to explore the beauty of the open water, but it’s important to remember that our oceans and environment need our protection. Sustainable sailing, which involves eco-friendly practices and mindful decision-making, allows sailors to enjoy their adventures while minimizing their impact on the environment. In this…

How I Built a Boat Using Plans from 1935

I found plans for a Gentleman's Racer in an old Popular Mechanics book.

My family has owned a Ford dealership since before the first World War, but when I was a kid, I loved boats most. Even after I took over the dealership and spent 40 years in the automotive business, I completed a number of boat restorations and builds. Years ago, my mother-in-law gave me a 1935 book from the Popular Mechanics Press called The Boat Book, Everything of Interest to the Amateur Boatman .

Inside were plans to build what was known in the 1930s as a Gentlemen's Racer—a modified recreation boat in the spirit of old hot rods. I loved the plans, and after a few years of only imagining the build, I laid out a roll of paper on the dealership’s showroom floor and drew the whole boat, full-size and full-scale, with a protractor, square, and compass. No computer whatsoever.

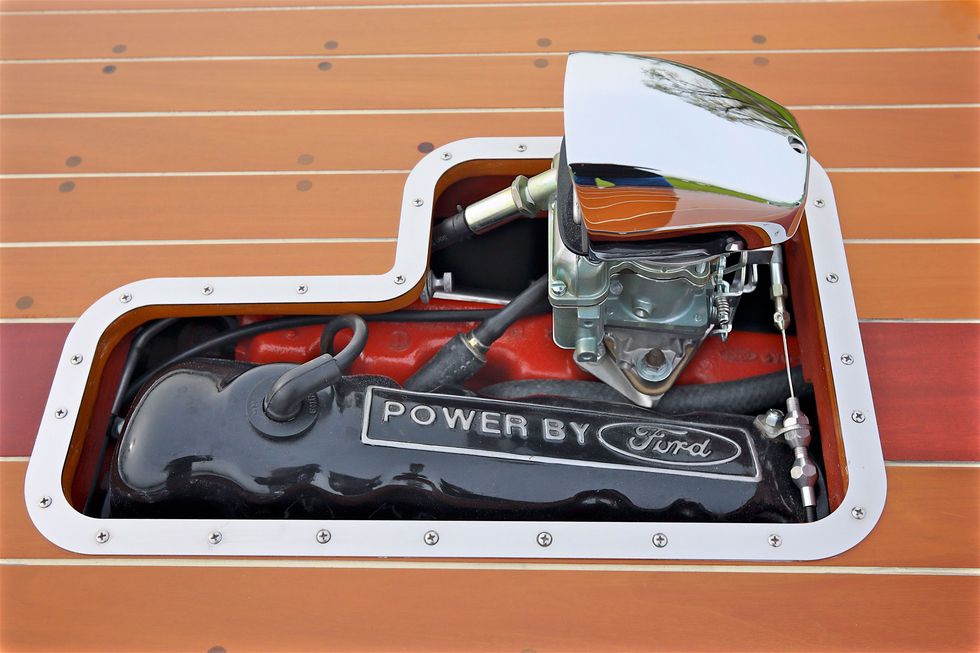

Modernizing the Engine

The original design being from the 1930s, I had to make a few changes. The book outfitted the boat with a Ford Model A engine, but I had my eye on a 250cid straight-six Ford, the same engine you’d find in an early Mustang, Torino, or Granada.

All due respect to my Ford heritage, a Model A motor is heavy, temperamental, and not particularly safe in a boat—the carburetor on the Old A's tended to leak fuel. My inline-six solved those issues and delivered triple the horsepower, 120 horses compared to the Model A’s 40. However, it still fit well within the rpm range in which the boat would be operating, and it struck a nice balance between nostalgia and reliability.

I also modified the original engine installation plans and lengthened the craft by 19 inches to move the engine farther aft. This gave the boat better balance and handling dynamics.

The engine is basically stock, with the exception of a larger carb from a Ford 300cid truck engine. The new engine’s been marinized: It has an open-loop cooling system that pulls water from the lake. There's a pre-cooler for the transmission and a raw-water pump that circulates water through the engine, the water-jacketed exhaust manifold, then out to the lake again.

I also constructed a custom oil pan in order to move the oil sump to the back of the engine—that was necessary with my modifications, which had the engine operating at a 14-degree angle.

A V8 is the typical engine for a custom build, so using the inline-six made things trickier, but the old 250 six matched up perfectly to a Borg Warner Velvet Drive marine transmission. The Velvet Drive is often paired with a 351-Ford engine, which is common in many ski boats.

On the dash, the tachometer, water temp, oil pressure, fuel, and battery gauges are all era-correct Stuart Warners—but I did a few things "incorrect." There's a dead man's switch under the dash and a modern blower system to ventilate the bilge, plus a few other safety items, such as a modern marine fuel tank and a triple-layer epoxy-encapsulated hull for extra strength and durability.

Shaping the Boat

The different engine caused a few ripple effects in how I had to alter the Popular Mechanics design. Because I was extending the length of the boat, it was important to keep the curve of the deck consistent and seamless. I wanted to accentuate the tumblehome — the inward curve of the sides towards the aft—so I called my son and we developed an equation to make sure the geometries worked out.

You can’t just run a straight line from frame to frame, because the side curves more toward the back, and the deck narrows at an ever-increasing rate the more aft you go. I added another frame at the back to support the extra length, so the boat ended up considerably stronger than the original plans.

We used the outside dimensions Popular Mechanics published, but where the original plans called for 1.5-inch white pine frames, I used 2.5-inch oak for additional strength. I had taken down an oak tree from my woods a few years previously. I had the timber aged and dried, and I selected the best planks for the frames.

Once the frames were together, I built the keel and epoxied and bolted the seven main frames and the transom to the keel. Then I ran the battens on the outside of the frames, as called for in the 1935 plans. All the frames are white oak, and the exterior is mahogany.

The toughest build area was the wood forming the bow. You can bend a piece of wood no problem, but where you have a lot of flair (like with the curves on the bow of a boat) you have to roll the plank in two different directions simultaneously. I threw a few pieces of mahogany away, thanks to trial and error.

The proper way to shape the wood would have been to use a steam room. But I ended up soaking the wood in my pond, and made a jig where I could bend the wood little by little until I achieved the shape I wanted. Then, I just let it dry in the sun.

It took me four and a half years of evenings and weekends to frame; build the keel; complete the hull; install the engine, transmission, and driveline; apply a urethane clearcoat; upholster the interior; and install the stainless steel trim. I eventually named it Flash , the same name given to the boat in the old Popular Mechanics book.

Updating a Classic

The book’s materials list was a bit dated. An obvious example: The instructions called for a canvas cover and “plenty of lead paint.” I wanted to stay true to the original design, but not that true. I covered the boat with marine-grade mahogany, with each piece coated in epoxy and screwed to the boat. For the finish, I used a conventional wooden stain, with an automotive-grade urethane clear coat for the top surface.

Popular Mechanics purists from the ‘30s would probably roll over in their graves upon hearing that, but acrylic urethane is harder and superior to varnish. If I had used the organic materials called for in the book, the life expectancy of the boat would have been pretty limited.

The old Gentlemen’s Racer class required two seats: the driver and navigator's seat aft and a "seat" in the forward deck. Many boats had a hatch to cover the forward seat, but even with the covered seat, it was still technically a recreation boat, in the same way a hot-rod is still technically a passenger car.

Some of my dealership connections came in handy for aesthetics and accessories. An upholstery shop in Salina, Ohio sewed the vinyl upholstery for the boat. The plans called for leather, but the ride of this boat produces a lot of spray, so the interior was guaranteed to be wet. The windshield and brackets were made by a speciality shop, and an Amish cabinet shop local to my home in Indiana did some of the complex wood-cutting. Other local Amish companies crafted the stainless steel hardware on the deck and sides, and installed the gold leaf lettering.

With all the modifications, I had to calculate the displacement of the boat to verify balance and water-line height. Water weighs 60 pounds per cubic foot. By calculating the cubic footage of the hull, I was able to establish how deep the boat would sit in the water. When the boat was finally launched, it floated within a half-inch of what my mathematical calculations had predicted.

Testing Its Performance

For the standards of the day, this would have been a really fast boat. It can be dead in the water and reach full plane in just under two seconds. It’ll never be a fast boat by modern standards because of the old-school hydrodynamics and engineering—new boats have designs that lift the boat out of the water at speed, and this one just can’t achieve any of that lift.

With the 18-inch pitch on the propeller—allowing for 15 percent propeller slippage—and the engine turning 3200 rpms, the math says the boat should have a top speed of around 46 mph. But over 40, you would have your hands full. Due to the fresh engine, I haven't pushed it hard to the top end yet.

On this boat, the bow is basically vertical. If you stuff it into a wave, you're going to put water over the deck. This design isn't wrong, but boat builders have learned a thing or two in the past 75 years. The Boat Book describes that exact ride experience as an inherent part of the design. As far as driving and handling, Flash is quite well-mannered. Granted, performance and handling aren't on par with a contemporary sport boat, but a 1930s sedan won't handle or perform comparable to a modern automobile, either.

Cruising at 28 to 30 mph, this boat is as sweet as can be. Flash creates a huge curtain of spray on both sides. When I take the boat out, other boats come alongside and follow us. Cameras come out and people take pictures of it running. Between the gold trim and the finished mahogany, it’s an attention-getter.

I numbered the boat with G-36: G for the Gentlemen's Racer classification, and 36 for the rough vintage. The gold leaf Flash is an exact copy of the script pictured in the book. Finally, I put A.J. Moser—my great-grandfather who founded our family dealership in 1886—on the side, but it’s a nod to my father, too, quite a craftsman himself.

He made things all his life. He told me: “Jim, work with your hands. You can do things if you try, and it’s good for your mind.” I love history, and maybe my great-grandchildren will be able to dig out this column in 85 years and show off the boat to POP readers again.

- As told to Jordan Golson

.css-cuqpxl:before{padding-right:0.3125rem;content:'//';display:inline;} Pop Mech Pro .css-xtujxj:before{padding-left:0.3125rem;content:'//';display:inline;}

The Army Is Clearing Out for Coyote Drone Hunters

Can America’s Aging F-16 Overpower Russia’s Su-35?

Could the Chair You Sit on Have a Soul?

The F-35’s Development Road Is Mercifully Over

This Long-Range Howitzer Has Met Its Achilles Heel

Here’s How We Could Live in Trees

Inside the Development of America's New Nuke

Cooking Pizza in Breeo’s Live-Fire Oven

Ceiling Stains. Now What?

The Engine Driving Our Oceans Could Die by 2100

How Bessie Coleman's Sky-High Ambition Killed Her

DO IT NOW! David Beede GAFF KETCH CHAMELEON For ages 5 to 95... Dream Catcher Pond Skiffs ... I'm no longer building these pond boats,but I'm leaving the page up to inspire home builders. A Celebration of Traditional Sail... 3 Models and many rigs - I have a book in the works with full sized plans! BLUE HERON SHARPIE Projects... Summer Breeze Wins Design Contest! Click the duck! This is an 11'8" skiff from two sheets of plywood inspired by Phil Bolger's Teal. I was gratified to win best overall, and best use of materials Duckworks 2001 contest. All drawing and most current build notes here . Prototype build diary Maiden voyage All the entries were very impressive so I won by a slim margin. Please check them out. Summer Breeze sea trials at the Cedar Key mess about 2002! Steve Bates , of Australia, did a bang-up job on his mini-sharpie - then turned her into a double ender and had a ship wreck! Check it out! Mini Sharpie Here's a one sheet high bowed sharpie skiff of my own design. A Family builds her. She gets a sail rig! Daydream... var options = {}; options.mediaPath = "http://www.simplicityboats.com/Day%20Dream.mp3"; var params = {}; params.allowScriptAccess = "always"; swfobject.embedSWF("http://www.simplicityboats.com/OriginalMusicPlayer.swf", "player-holder", "250", "90", "9.0.0",false, options, {}, {}); A.K.A. Least Cuts Boat This is a 15' Sharpie Skiff made with all straight saw cuts! Rob Smith and 2 nephews build her in 22 hrs in South Africa! Brian Schmittling's Daydream ! A couple of One Sheet boats with capacity for 2 Adults! (click the pic) Wackless Lassie - A double paddle canoe. Cygnet - A One Sheet Skiff designed by Herb McLeod. Featherwind - actually Dave Carnel's $200 sailboat Alternative Methods and Materials for boat building! Yuloh info... - a collection of resources on the oriental sculling oar. $10 Yuloh!! Shantydock! - This is an 8' x 16' swim platform with an arched canopy roof. Dream Catcher Pond Skiffs ... are here! " Coolwater " a shoe string shanty boat! Also.... Shantyboat Dreams - sketches and resources... Model making - this one is a one sheet skiff of my own design superceded by my Mini Sharpie. Local Builders See what the local (North Florida) boys are up to. Old Boat Plans from the 40s, 50s & 60s This is a cheap and quick boat shelter that can be easily broken down and moved. PVC and poly tarp to the rescue again! Alternative Methods and Materials for boat building! Miscellaneous ... Resources - informational and inspirational stuff like Gavin Atkin's Free Design Page - Gav, in addition to starting the Boat Design group on Yahoo, won the Duckworks design contest in 2000 and originated the "Mouse" line of boats, which are being built all over the globe! (Good starting point... less overwhelming than the links page.) Links from my bookmarks for the last year, loosely categorized. A Rant Ravings about boat building, music, and life as spectator sport. [the above email link is NOT clickable - thanks to the spam web bots - please type it in]

The truth about Acorn

ail freesailor line sailing pond skiff model sailboat model boat model sailboat toy sailboat toy boat model sailboat pond sailer model boat sailboat pond sailer pond boat pond boat model yacht miniature yacht toy boat toy boat toy boat pondsailer pond sailer pond boat model pondsailor pond sailor sailboat model sailboat models sail sail sail sail sail toy toy toy boats sailing sailing model sailing model miniature sailboat model sailboat boat kit sailboat kit ship model sailing model scale model scale model scale boat scale boat scale sailing model ship model fun yacht sloop model sloop model yacht sailboat model sailboat radio control model sailboat modelsailboat pond yacht

tion. Boat design addiction may lead to a new 12 step program.

- About Modern Wooden Boats

- Tips & tricks

- What’s inside a boat plan ?

Petrel 33: widen your horizons

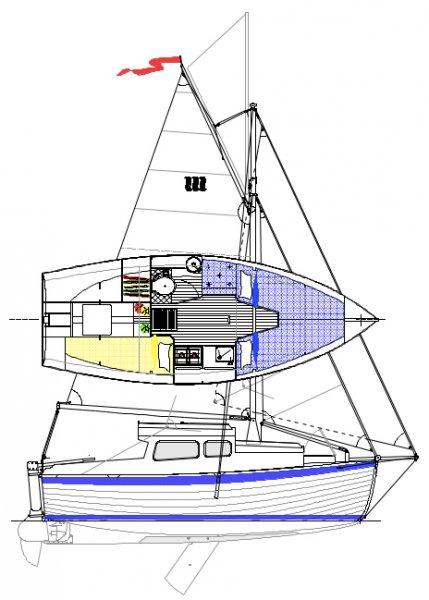

Petrel 33 is the logical evolution of her smaller sister petrel 28 , with the task to expand the horizons of cruising activity for a 4-6 person crew, raising the bar of onboard comfort, keeping the boat size under the critical (for a homebuilder) size of 34 foot – 10 meters of overall length., a “new classic” looking cruiser, sturdy, with no frills and weird solutions, ready to let you sail with a decent speed and a very good comfort level both at anchor and sailing., the starting point is the very good sailing capabilities shown by the petrel 28, so i decided to develope this hull into a enlarged design, keeping a quite narrow hull for actual standard, prolonging the bow lines for a plumb stempost; i expect to have a similar behaviour of the proven 28footer, with a tender weather helm in every situation, a very soft and gentle wave riding attitude in a seaway, and a good acceleration coming out of the tacks, i expect a little bit more speed given the longer water length ; section are moderately full at the bow, maximum beam is around 60% of hull lenght , transom sections keep a moderate vee.

Stability calculations give us good parameters (see stability curve attached) , with a real large positive area stability, a 123° AVS (Angle of Vanishing Stability) with loaded boat, and a minimal negative area in the stability curves.

Rig and sailplan:

Sailplan is based on a 50% area split among mainsail and a furling jib ; we kept the upwind sailing area to a moderate value, avoiding “wannabe racers” temptations; a decent sized gennaker can be hoisted on the fixed bowsprit, an obvious choice given the fact that the new generation furlers are making this sails very easy to manage for cruising crews too, adding the pleasure of sailing downwind in light airs at a decent pace, a weather situation which is quite a pain in normal mainsail + jib configurations ; in roughest situation you can hoist a storm jib on a removable internal stay fitted on a high load chainplate leaning on the forward structural bulkhead ; rig is a classical 2 spreaders mast , spreaders are 15° swept, there is a structural backstay and no structural runners, lower shrouds are doubled., deck gear configuration features classical sturdy and manageable solutions, without too many frills : 4 self tailing winches to pull sheets, halyards and control lines, 2 stoppers array on cabin top panel, 2 tracks for jib cars, so that the jib can keep a decent shape even furled, a small track for the mainsail purchase, all the control lines are led to cockpit to avoid bow walks in “spicy” situations (plans will detail how to make bombproof fitting points for lifelines too);, boat will be powered by a diesel (20-30 hp) or electric (7 kw) inboard engine fitted with a saildrive or shaft-line transmission ; this will allow to keep a decent pace while motoring in zero wind situation, or to add a good booster to sail thrust if needed; i expect to reach a 6.5 knots boat speed at 2000 rpm with a 30 hp diesel engine., rudder and steering system:, rudder is a single blade semi-compensated one with tiller steering system ; there will be two options detailed on plans: spade rudder with ss steel shaft (this solution is depicted in rendered images), and an easier to build transom hung rudder., finkeel is naca profile keel made of welded steel plates, ; ballast is made by lead poured in the keel hollows ; keel is fitted on the hull with a web of bolts on solid hardwood floors, with nuts and high thickness ss steel counterplates under the cabin floorings; keel load is carefully distributed to avoid any local high stress area., interiors and on board living:, this area marks the main differences among this 34 footer and her smaller sister; higher hull topsides and two more meters of boat make a world of difference in terms of interiors and on board comfort; we have 6 regular berths, a comfortable galley and dinette area, a decent volume for on board systems and storage, all that you need to medium-long range sailing given the size of the boat ; both forward and after cabin are closed with a small door to gain a little bit more privacy ; cabin height is around 191 cm , cockpit is quite wide, and it’s designed to be comfortable for a crew of 6 while sailing with the heeled boat too ; transom area is protected by a sturdy wooden hinged structure that can be lowered when moored to be used as a transom platform. low sleek coamings protect the forward area of the cockpit , making the primary winch basement too; toerails and good sized areas among cabin flanks and hull sheerline make going to the bow a very safe operation even when boat is heeled and in rough conditions;, building system:, given the good amount of miles sailed by petrel 28 in every sea state with very good reliability, i keep a similar structure for this project, upgrading the scantlings to cope with higher stresses; so the boat structure is a grid of plywood bulkheads and frames linked by solid wood stringers and a mixed plywood-solid wood structure forming keel backbone and stempost ; hull planking is made by 12 mm plywood, with the radiused area made by two layers of 6 mm plywood panels , all glued to the underlying structural grid , in a reliable , sturdy and easy to build system called “radius chine” ; cabin , cockpit and deck surfaces are made by 10-12 mm plywood panels stiffened by a grid of secondary stringers, solid beams and other structural elements; the hull bottom is further stiffened by a number of solid wood floors , tightly spaced in the centerboat area, where they bear the finkeel loads. all critical areas and structural bondings are strengthened and stiffened by epoxy resin laminated glass fabric and epoxy resin liquid joinery and structural bondings. this building system is definitely suited to be realized by home builders or small boatyards, with a basic level of wood craftmanship , in a decent amount of time given the size of the boat., in my view this will allow a small boatyard to build and offer a highly customized top level sailboat keeping the final prize to a reasonable level, which is basically the main concern when it comes to manage a small boatyard..

Building plans and study plans: project Petrel 33 is is completed : now I’m starting the long and meticulous process of drawing the building plans; complete plans will be available approximately at the end of spring at this link , anyway if someone is so committed to long for an immediate start of construction he can purchase plans starting from now, a first batch of drawings (hull parts , assembly scaffold and hull structures) will be delivered within a week so that he can start building, the rest will follow as scheduled within half of June 2018; study plans and bill of materials will be available approximately within the end of April 2018 and will be downloadable form this page for free, as usual. Stay tuned !!!

Plans price: 900 € for paper sheets, 840€ for pdf format drawings, 350 € for cad engraving files (required if you want to cut all the plywood parts with cnc machinery, includes keel steel plating shapes) ; plans will be made approximately of 27 drawings and a 25 pages booklet with assembly sequence, tips and tricks, plans can be purchased here, a discount will be available for the first buyer ., petrel 33 specifications, hull length: 9,90 m (bowsprit included), overall length: 9,90 m, maximum beam: 3,03 m, prismatic coefficient: 0,53, sink rate: 170kg/cm, canoe body wet surface: 18 m2, draft at design displacement: 1,80 m, vacant ship diplacement: 3400 kg (all gear up, no water and food, no fuel), design displacement: 4050kg (crew of 4 + luggage, 50kg fuel, acqua 150 liters water, 100 kg extra), maximum displacement: 4500 kg (crew of 6 + luggage, full fuel, full water), ballast: 1300 kg: fixed keel, upwind sail area : 47,3 m2 , mainsail 23.2 m2, jib 24 m2, staysail on removable babystay: 6.5 m2, gennaker: 65 m2, mast height on dwl: m 13,3, performance parameters : sa/displ^0.66 = 19.5 , sa/wet surface = 2.6 (canoe body only), engine: diesel inboard with saildrive or shaftline transmission, 20-30 hp, 50 liters fuel tank , electric engine specifications on plans, accommodations: 6 fulls sized (1,90 m or more) berths, 1 v berth at bow, 1 double berth on transom , 2 galley berths, interiors: charting table with main electric panel, vhf radio and chart plotter area, galley with stove, sink and 30 liters fridge, enclosed toilet with wc sink and shower, central table in dinette with foldable wings. 190 cm height in the whole galley area., systems: 12 v and 220 v wiring scheme, fresh water and black water plumbing scheme, 200 or more liter freshwater tanks.; two service batteries and a engine dedicated battery, ce label : possible b6/c10 , data to be required as extra item..

- plans: 900€ for paper version, 840 for PDF version , 350 for CNC cutting files , can be purchased here

By continuing to use the site, you agree to the use of cookies. more information Accept

The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.

- General FAQ

- Privacy Policy

- Copyright Terms

- Testimonials

- How to Pay with CC

- DOWNLOAD HELP

- USB FLASH DRIVE DELIVERY OPTION

- COMPLETE Wood Plan Packages

- Shed Plans - DOWNLOAD

- Gazebo Plans - DOWNLOAD

- Tattoo Flash - DOWNLOAD

- Boat Plans - DOWNLOAD

- Jungle Gym Plans - DOWNLOAD

- Dog House Plans - DOWNLOAD

- Furniture Wood Plans - DOWNLOAD

- Outdoor Wood Plans - DOWNLOAD

- Workshop Wood Plans - DOWNLOAD

- More Wood Plans - DOWNLOAD

- Small Home Project Plans

- Old Time Radio Shows

- Magazines and Books

- Unique Downloads

- Classic Woodworking Books

- DOOMSDAY PREPPING - Downloads

- Hentai Manga Wallpaper

- Educational

- War and Bombing

- Parks and Fairs

- Advertising and TV

- Social Guidance

- Cars and Transportation

- Communications

- Railroad Maps

- Feature Length

- Classic Literary Audio

- Gift Certificates

- Free Articles - How To Guides

- New Products

- Model: DL-ADV-BTS-165

Please Choose:

Download-boats-01, download-boats-02, download-boats-03, download-boats-04, download-boats-05, download-boats-06, download-boats-07, download-boats-08, download-boats-09, download-boats-10, download-boats-11, download-boats-12, download-boats-13, download-boats-14, download-boats-15, download-boats-16, download-boats-17, download-boats-18, download-boats-19, download-boats-20, download-boats-21, download-boats-22, download-boats-23, download-boats-24, download-boats-25, download-boats-26, download-boats-27, download-boats-28, download-boats-29, download-boats-30, download-boats-31, download-boats-32, download-boats-33, download-boats-34, download-boats-35.

Current Reviews: 1

Customers who bought this product also purchased...

Shopping cart - more, reviews - more, articles - how to guides.

Link to us, get 20% off! Sell us your original wood plans, get $$$ paid Free Shed & Wood Plans: Free Gable Shed Plans Part 1 - 2 - 3 Free Garden Storage Shed Plans Part 1 - 2 Free Outdoor Kitchen Pavilion Wood Plans Part 1 - 2 Free Backyard Garden Shed Plans Free Garden Gazebo Plans Part 1 - 2 Free Simple Shed Plans Free Swim Raft Wood Plans Free Wood Cabin Plans Free Picnic Table Plans Free Wood Plans - Building a Wood Table Free Doghouse Plans Free Jungle Gym Tree House Plans Free Tree House Tower Plans Free Wood Swimming Ladder Plans Free Canoe Boat Rack Plans Free BBQ Cart Wood Plans Free Outdoor Shower Wood Plans Free Elegant Poster Bed Plans Free How To Guides: Planning a shed Shed Plans Glossary Understanding Blueprints Laying out a shed Shed Site Evaluation Shed Foundation Options Concrete Slab Foundations Choosing Lumber Ordering Shed Material Nails and Fasteners Building a Wood Shed Part 1 Building a Wood Shed Part 2 Introduction to Framing Structural Loads Free Wood Painting Tips Achieving a smooth finish Veneer and Varnish Short Guides: Storage Shed Plans Wood Sheds Metal Shed Plans Shed Designs Free Shed Plans Finding the Right Shed Our Gazebo Plans Woodworking Plans Shed Plans Guide Garden Shed Plans Intro to Woodworking Social Guidance Films Browse All Articles

March / April Issue No. 297 Preview Now

Plans & Kits

If you’re in the market for a boat to build, this directory of Boat Plans & Kits is a fine place to start. And if your company sells plans or kits, we invite you to list your offerings here. There is no charge for listing, but the featured boats must be built of wood. To refine your search of this directory, use quotation marks. If you search Nutshell Pram Kit, you’ll receive all the listings that include the words Nutshell, Pram, and Kit. To refine your search, enter “Nutshell Pram Kit”; you’ll then see only the results for Nutshell Pram kits.

Post Your Boat Plans & Kits

Post Your Plans/Kits login or register

Search plans & kits.

To refine your search, add quote marks. If you search Nutshell Pram Kit, you will get all the listings which include Nutshell, Pram, and Kit. To refine, search “Nutshell Pram Kit” and you’ll see just Nutshell Pram Kit results.

715 Results

Sailboats - Cruising

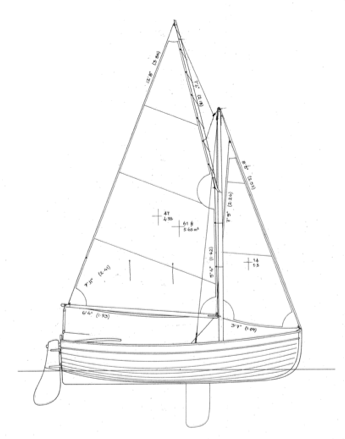

Design no. 165.

A development from our very successful and popular Design No.

Oar / Paddle

A small and very simple tender to fit inside a station wagon or on a roofrack, this little plywood dink will suit some one wanting a tender for their small yacht or motorboat.

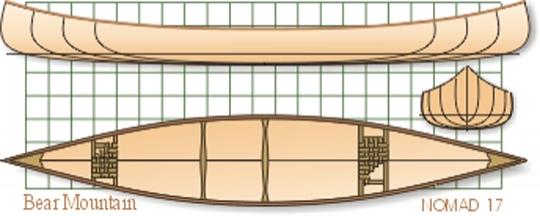

17' 0" Nomad

The Nomad is long, sleek, easy to plank and easier to paddle.

Northeaster Dory

The Northeaster Dory is small enough to be rowed singly, but big enough for tandem rowing with two adults. Even four adults have comfortable seating. Performance rowers may add a sliding seat.

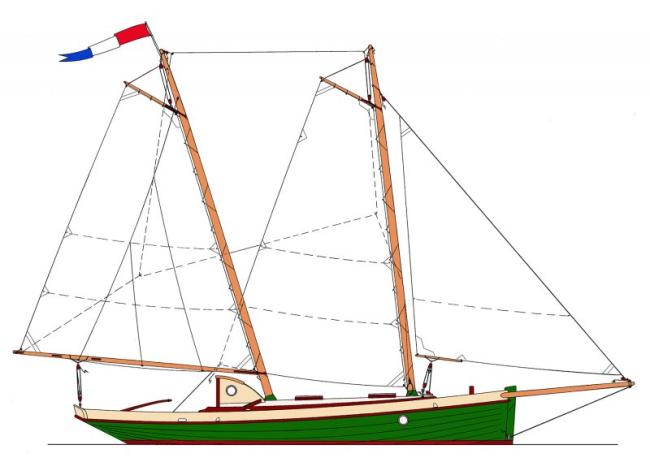

Pilot Schooner 28

Swansea Pilot Schooner, flush-decked cruiser, based on the earliest type (late 18th/early 19th century). This vessel is intended for open ocean cruising.

11' 2" Shellback Dinghy

This beautiful 11′ 2″ dinghy is similar in construction to the Nutshell Pram, although it is slightly larger, with a pointed bow.Construction: Glued-lapstrake plywood.Alternative construction: Traditional lapstrake.No lofting is required.Plans include 5 sheets.

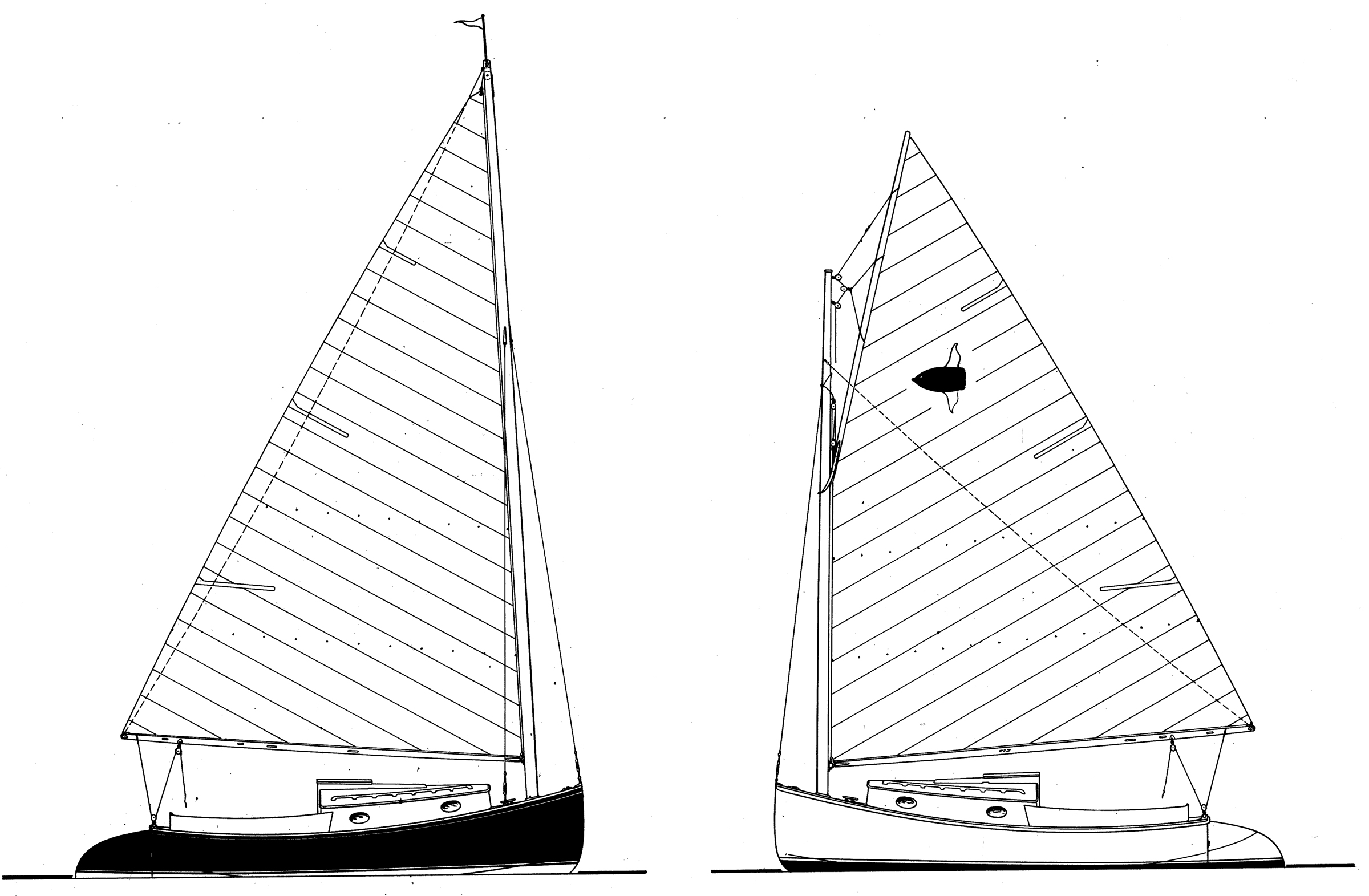

Sailboats - Daysailers

Paper jet 14.

Paper Jet 14 plywood stitch and glue sailing skiff

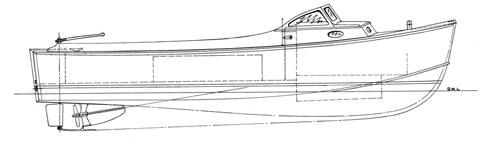

25' Bassboat

Safe, dry, fast, and seaworthy V-bottomed inboard powerboat designed for carvel planking.

Construction: Carvel planked over sawn frames.

Alternative construction: Strip

Lofting is required.

Propulsion: 6 cylinder 350 cubic inboard.

Plans include 6 sheets.

10' 2" OUGHTRED Acorn (Puffin)

Resembling her 8′ cousin more than the sleeker 12′ Acorn, this chunky dinghy will be a good load carrier for her length—and she looks very, very British.Oughtred saves you from guess work by showing precisely how her planking should be lined off.Construction: Glued lapstrake plywood.Alternative c

Sharpie 24 Hampton Flattie

24′ Chesapeake Bay Hampton FlattieL.O.A.: 24′ 2″L.W.L.: 22′ 8″Beam: 7′ 9″ Draft: 2′ ½″/3′ 9″Sail Area: 263 sq ftWeight: 2,500# (approx)Proportionately, this is the largest sharpie type known, and shows the maximum beam ratio successfully used in the sharpie type.

Share your boatbuilding plans or kits today.

Login Sign up

From the Community

1957 Ted Carpentier 47' Ketch with 11' Beam 7' Draft. Hull is strip-planked tongue and grooved. Customer built for CEO of United Airlines

This vessel was built by Naval Architect Ted Carpentier who also worked as an engineer for Hughes

Custom Larson 40

Lowell Type Coast Guard Dory

2020 Tawas dory, a Lowell type Coast Guard dory described and drawn in John Gardner’s THE DOR

17' Whitehall Rowboat - $8,500

17′ Whitehall Rowboat - Traditionally built by Doug Cooper of Falmouth, MA;.Cedar planking on oak

From Online Exclusives

Whiskey Plank

Anchor Windlasses

Varnishing Basics

Thicker Than a Coat of Paint

Two Chesapeake Skiffs

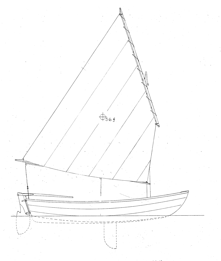

Drawn by Howard I. Chapelle and Reuel Parker Commentary by Mike O'Brien

Chesapeake Bay sailing crab skiffs can, with little alteration, make fast and able daysailers. These skiffs first appeared on the big estuary during the last years of the nineteenth century. The type — perhaps we should say "types" — varied wildly from creek to creek. Depending upon local conditions and prejudices, an observer at the time would have found single- and two-stick rigs, with or without headsails. Deadrise amidships (amount of V to the bottom) ranged from 0 degrees to about 12 degrees. Hulls were double-ended or transom-sterned. In fact, the diversity in skiff design allowed watermen to identify a boat as the product of a particular county, if not a particular builder.

In addition to serving as their name suggests, the skiffs earned their keep in general waterfront transportation and by handling odd jobs. Although these boats went extinct half a century ago (at least as working watercraft), many of their characteristics survive in contemporary Chesapeake outboard-powered skiffs. Cross-planked bottoms, strong sheerlines, and sharp forward sections still can be seen in the working powerboats at public landings along the Bay's convoluted 5,000-mile shoreline.

The 16-foot 8-inch sailing skiff shown here must be one of the most handsome of the old boats. According to Howard Chapelle, who wrote about her in the June 1943 issue of Yachting magazine, this striking deadrise hull was hammered together by a builder named Simmons in 1910 at Cambridge, Maryland. Mr. Chapelle took the lines off the old boat on September 11,1942 in the same town. We're told only that the hull construction was "of the usual Bay deadrise type." This suggests a V-bottom cross-planked in herringbone fashion with little internal framing. Although he might have shaped a "chunk" forefoot from a single timber, Mr. Simmons more likely accomplished the considerable deadrise up forward by staving the forefoot. (That is, he filled the space between the backbone and chines with short, thick planks fashioned to the required twist.)

With its 3%-inchby 3%-inch keelson and 1-inch bottom planking, this is not a light hull. Good, old-fashioned inertia will make the boat steadier to work in the notorious Chesapeake chop and will give it the power to punch through now-ubiquitous powerboat wakes. No matter what miracle goops and goos we might employ in building this skiff today, I'd suggest not taking too much weight out of its structure.

We're told that most of the Cambridge boats shared the springy sheer, considerable deadrise, flared sides, and raking ends seen here. Chapelle suggests that the rough water often found at the mouth of the Choptank River provided ample incentive to build able skiffs. Unlike some flat-bottomed skiffs, these deadrise hulls tend to maintain headway when coming about; they don't pay off excessively before settling in on a new tack. (The habit of falling off before heading up to a new course constitutes a potentially dangerous character flaw in half-decked boats. Unless the sheets are carefully tended, a nearly stationary skiff can be knocked down as the wind fills its tightly strapped sails. Builders sometimes fitted flat-bottomed Bay skiffs with substantial foregripes to lessen the risk.)

This Cambridge skiff's rig is fairly representative of those seen elsewhere on the Bay. Its sprit-boomed leg-o'-mutton sails provide their usual advantages: They are self-vanging (the angled foot of the sail tightens and prevents the boom from lifting). They can live with light booms and simple sheeting arrangements. Draft in the sails can be controlled, to a degree, by adjusting the tension in the snotter (the line that secures

Two Chesapeake Skiffs the boom to the mast). Sail twist can be varied by changing snotter tension and/or by sliding the snotter up or down the mast.

Although the curve drawn into the foot of each sail looks fine, our sailmaker will know to cut the bottoms of the sails dead straight to better handle the tension. While we're at it, let's ask him to cut the mainsail somewhat fuller — and with the point of maximum draft farther forward — than he would for, say, a tautly strung sloop . Because the mizzen often will be sheeted closer than the mainsail, among other reasons, it ought to be sewn relatively flat.

At the size we're discussing, these rigs need no ready-made hardware. Absolutely none. Dumb sheaves (well faired and lined holes worked through the sticks near their heads) will substitute for halyard blocks. The single-part sheets need only a bowline at one end and a figure-of-eight knot at the other. Rope snotters do the work of stainless-steel or bronze gooseneck fittings — and then some.

/h The Sharpie Book (International Marine, Camden, Maine, 1994), Reuel Parker gives us drawings for classic designs that have been adapted for sheet-plywood construction. Here is a fine single-sail skiff, Parker's variation on Figure 115 from Howard Chapelle's American Small Sailing Craft (W.W. Norton & Co., New York, 1951). The old boat is believed to have been built on Hoopers Island about 1906. Chapelle took the lines off her at Crisfield, Maryland, in 1943. This hull's shallow, almost flat-bottomed, forefoot allowed Parker to sheathe its virtually unaltered lines with sheet plywood. (The deeper, sharper forefoot of the Cambridge skiff would, most likely, have demanded some fancy on-the-spot laminating in order to mate with a sheet bottom.)

We might note that this skiff and the Cambridge boat have their centerboards located far forward by yacht standards, and the boards are slightly smaller than expected. This arrangement has obvious advantages in working skiffs, and the added cockpit room will be appreciated in the daysailing derivatives. The happy configuration is made feasible by the forward bias of the sail plans' geometrical centers and by the far-aft lateral plane offered by large skegs and rudders.

Before dropping the rig from the old skiff into the new skiff, Parker lopped about 20 inches off the mast. As indicated by the vertical dashed line drawn on the sail, he added a traditional vertical slab-reefing system that was sometimes used for larger sharpies. Details of this arrangement can be found on page 66 of Chapelle's book, Boatbuilding (W.W. Norton & Co,, New York, 1941).

Casual inspection of the contemporary waterfront suggests that too many raceboats masquerade as day-sailers — their shallow cockpits fouled by nests of lines, and nary a seat in sight. Old skiffs from the Chesapeake offer secure and comfortable alternatives.

Plans for the Simmons Cambridge skiff, as drawn by Howard I. Chapelle, can be obtainedfrom Ship Plans, NMAH 5010/MRC 628, Smithsonian Institution, Washington, DC 20560. Ask for CBCSplan No. 4.

Plans for Reuel Parker's version of the Hoopers Island skiff are available from Parker Marine Enterprises, P.O. Box 4102, Key West, PL 33041. Ask for the 18-foot modified sharpie skiff.

Particulars Cambridge Skiff

LOA 16'8" Beam 4'8" Draft l'l" Sail area 110 sq ft

A sharp forefoot will keep the Cambridge skiff quiet at anchor and help it settle in quickly on a new tack.

Continue reading here: Rowing and Sailing Skiff

Was this article helpful?

Recommended Programs

Myboatplans 518 Boat Plans

Boat Alert Hull ID History Search

3D Boat Design Software Package

Related Posts

- Tortured Plywood Boat Plans

- Designs by Karl Stambaugh and Philip C Bolger Commentary by Mike OBrien

- Designs by Weston Farmer and Howard I Chapelle Commentary by Mike OBrien

- Nesting Dinghies - Boat Designs

- Design by Philip C Bolger Commentary by Mike OBrien

- Commentary by Mike OBrien Bls

Readers' Questions

What is the difference between a sharpie and a skiff?

A Sharpie is a brand of writing instrument, whereas a Skiff is a type of small boat. A Sharpie is used to write or draw, while a Skiff is used for transportation on water.

Who built pvc skiffs on kent island?

The original builder of the popular PVC skiffs on Kent Island was a man named Ed Payne. He started building them in 1970 and continued until his death in 2000.

How to build a hoopers island skiff?

Building a Hoopers Island Skiff is a complex process that requires woodworking skills and access to specific tools and materials. Here is a high-level overview of the process: Gather your materials: You will need marine-grade plywood, epoxy resin, fiberglass cloth, screws, nails, paint, and varnish. Obtain plans or a kit for the Hoopers Island Skiff to guide you through the construction process. Prepare the work area: Set up a clean, well-ventilated workspace large enough to accommodate the skiff's size. Construct the skeleton: Start by building the skeleton of the skiff, known as the frame or ribs. This involves carefully cutting and assembling the ribs according to the plans. Use marine-grade plywood and attach them securely to the keelson and chines. Install the keel and chines: Attach the keel, a long center plank running from bow to stern, and the chines, which run along the bottom edges of the skiff. Use epoxy resin and screws to secure them in place. Build the bottom panels: Cut and shape the bottom panels using marine-grade plywood. Attach them to the keel and chines, ensuring a tight seal with epoxy resin. Fit the side panels: Cut and shape the side panels to match the skiff's hull shape. Attach them to the frame using epoxy resin. Use screws or nails for added strength. Finish the structural work: Install the stem (the forwardmost part of the skiff) and transom (the stern) using plywood. Strengthen the joints with epoxy resin and fiberglass cloth. Fiberglass the hull: Apply multiple layers of fiberglass cloth to the bottom and sides of the skiff. Use epoxy resin to saturate and bond the cloth layers. This provides additional strength and increases the skiff's water resistance. Apply finishes: Sand down the entire skiff to smoothen any rough edges or imperfections. Apply paint or varnish to protect the wood and enhance its appearance. Consider using marine-grade products for added durability. Install hardware: Attach necessary hardware such as cleats, oarlocks, and other fittings according to the skiff's design and intended use. Launch and test: Once the skiff is complete, carefully transport it to the water and launch it. Test the skiff's stability and integrity before using it for boating activities. Remember, this is just a general overview of the building process, and more specific instructions are available in detailed plans or a kit for the Hoopers Island Skiff. It is recommended to seek expert advice or consult experienced boat builders during the construction process to ensure safety and quality.

How to bulid a chesapeake deadrise skiff?

Building a Chesapeake deadrise skiff requires a significant amount of woodworking skills, knowledge of boat building, and access to the necessary tools and materials. Here are some general steps to guide you through the process: Research and gather information: Familiarize yourself with the characteristics, dimensions, and construction techniques of a Chesapeake deadrise skiff. Study boat plans, books, and online resources to understand the design and building process. Acquire the plans: Purchase or download a set of Chesapeake deadrise skiff plans. These plans will guide you through the construction process, providing detailed measurements, instructions, and diagrams. Gather materials and tools: Obtain the necessary materials for the boat construction. This would include plywood for the hull and deck, solid wood for frames, stringers, and other structural components, fiberglass cloth and epoxy for the hull coating, screws, nails, and other fasteners, and marine-grade paint and varnish. You will also need various woodworking tools such as saws, drills, planes, chisels, clamps, and sanding equipment. Lofting and cutting the parts: Transfer the dimensions from the boat plans onto full-size layouts called "lofts." From the lofts, you will create templates, or patterns, of various parts, including the hull panels, frames, and faired battens. Cut the parts according to the templates. Assemble the hull: Begin by constructing the backbone and fitting it into a strongback, a long stable frame used to support the boat during construction. Attach the frames and reinforce them with stringers on top. Fit and fasten the pre-cut plywood panels to form the hull, ensuring proper alignment and fair curves. Use epoxy and fiberglass cloth to seal the seams and reinforce the hull. Building the deck and interior: Construct and fit the deck beams, carlins, and other supporting structures. Install the plywood deck and secure it to the frames and hull. Add cockpit bracing, flotation, and any other necessary structural components. Create and install seats, storage compartments, and other interior features as desired. Finishing touches: Smooth out any imperfections on the hull and deck by filling and fairing with epoxy putty or fairing compound. Sand all surfaces to achieve a smooth finish. Apply suitable marine-grade paint and varnish to protect the wood and provide a polished appearance. Note that these steps provide a general overview of the building process. It is highly recommended to consult and follow the specifics outlined in your chosen set of plans. Additionally, consider enrolling in woodworking or boat building classes or seeking guidance from experienced builders to ensure a successful build.

How to build a crab skiff?

Start by purchasing the materials you’ll need to build a skiff. The materials will depend on the size and design of the skiff. Consider the size and weight of the skiff, and purchase the necessary wood, fiberglass, and epoxy to complete the build. Cut the wood pieces for the skiff according to the design plans. Generally, skiff hulls are made from plywood panels or strips, and will require precise cuts. Use clamps to hold the wood in the precise shape as you cut it. Assemble the plywood pieces to form the hull of the skiff. Secure the pieces with screws and epoxy. Once the frame of the skiff is complete, lay cloth over it and secure with staples or glue. Make sure to protect the edges with tape to prevent them from getting damaged. Saturate the cloth with epoxy, making sure to fill any gaps between the cloth and the wood. Let the epoxy cure overnight. Sand the skiff to remove any rough edges. Attach handles and other hardware to the skiff. Try to position them so that they are not difficult to reach when a person is seated in the boat. Apply paint or a sealer to protect the surfaces of the skiff. Launch your skiff and enjoy! Make sure to inspect the boat regularly and repair any damage as necessary.

Where to get chesapeak deadrise plans?

You can find Chesapeake Deadrise plans through classic boat plans, The WoodenBoat Store, and Chesapeake Marine Design.

How to make a cheasepeake bay skiff?

Start by designing your skiff. Consider the size, materials, and weight you want to use. Make sure that proportions and lines look correct when viewed from the front, side and rear of the boat. Mark and cut the parts for your skiff. Commonly used materials forChesepeake Bay skiffs are marine-grade plywood, cedar strips and fiberglass resin. Assemble your skiff. Use epoxy to join the parts and permanently adhere the pieces together. Shave, sand, and shape the hull. Use power sanders and other tools to make the exterior smooth and appealing. Install the flooring, decks and other components. Use screws and epoxy to attach these components to the bottom of the hull. Finish and seal the hull. Use a quality paint or polyurethane to give the skiff a nice finish. Outfit the skiff. Install any navigation lights, anchors, and other equipment necessary for a successful trip.

How to plank the forefoot portion of a dead rise work boat?